Global Gantry Cartesian Robot Market

Market Size in USD Billion

CAGR :

%

USD

5.30 Billion

USD

16.10 Billion

2024

2032

USD

5.30 Billion

USD

16.10 Billion

2024

2032

| 2025 –2032 | |

| USD 5.30 Billion | |

| USD 16.10 Billion | |

|

|

|

|

Gantry (Cartesian) Robot Market Size

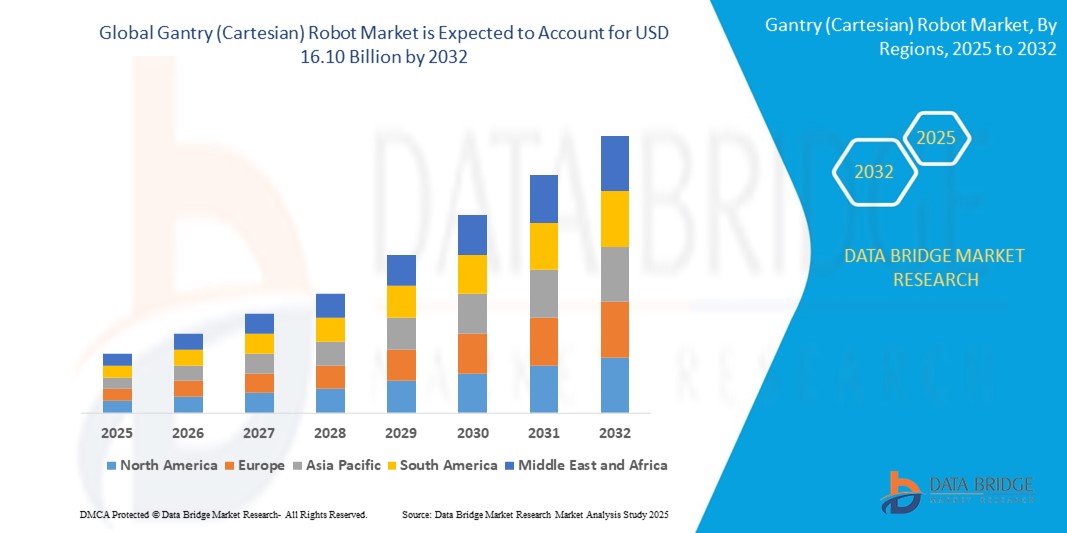

- The global Gantry (Cartesian) Robot market size was valued at USD 5.30 Billion in 2024 and is expected to reach USD 16.10 Billion by 2032, at a CAGR of 14.90% during the forecast period

- The rise in acceptance of gantry and Cartesian systems owing to their enhanced programming and communication interfaces is also anticipated to flourish the growth of the gantry (Cartesian) robot market.

Gantry (Cartesian) Robot Market Analysis

- Gantry robot, also known as Cartesian or linear robots are machinery or devices that provide movements of payload in a horizontal space. These robots offer picking and placement provisions of the payload, but with modernization their applications have extended to other applications as well.

- The rapid urbanization and rise in the increase in deployment of Cartesian systems that can be programmed for collaborative applications are also likely to positively impact the growth of the market. Moreover, the high demand for industrial robots across different regions and applications are also expected create a huge demand for gantry (cartesian) robot as well as lifting the growth of the gantry (cartesian) robot market.

- Asia-Pacific dominates the Gantry (Cartesian) Robot market with the largest revenue share of 48.01% in 2025, The Asia-Pacific gantry (Cartesian) robot market is driven by rapid industrial automation, especially in manufacturing, electronics, and automotive sectors. Rising labor costs, government support for smart factories, and increasing adoption of robotics in China, Japan, and South Korea accelerate demand for precise, efficient gantry robots in production lines.

- North America is expected to be the fastest growing region in the Gantry (Cartesian) Robot market during the forecast period. North America’s gantry robot market grows due to advanced manufacturing technologies, strong automotive and aerospace industries, and increasing automation to enhance productivity and safety. The region benefits from technological innovation, investments in Industry 4.0, and demand for custom, high-precision robotic solutions in warehouses and assembly processes.

- The 1-Axis segment is anticipated to hold the largest market share of 31.9% in the Gantry (Cartesian) Robot Market during the forecast period. The A1-Axis segment in the Gantry (Cartesian) Robot Market is driven by its capability to provide precise linear motion along a single axis, ideal for tasks requiring high accuracy and repeatability. Its simplicity, cost-effectiveness, and ease of integration boost adoption in packaging, material handling, and assembly applications.

Report Scope and Gantry (Cartesian) Robot Market Segmentation

|

Attributes |

Gantry (Cartesian) Robot Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Gantry (Cartesian) Robot Market Trends

“Advancing Automation with Precision and Flexibility”

- One key trend in the Gantry (Cartesian) Robot market is the increasing adoption of multi-axis gantry systems, enabling complex and high-precision tasks in automotive, electronics, and packaging industries. These robots improve throughput and accuracy in assembly and material handling.

- Integration with AI and machine vision systems is enhancing gantry robots’ capabilities for real-time quality inspection, defect detection, and adaptive control, driving smarter manufacturing processes.

- Collaborative gantry robots (cobots) are emerging, designed to safely work alongside humans, increasing flexibility on production floors without extensive safety fencing.

- The shift towards Industry 4.0 and smart factories is pushing demand for gantry robots capable of seamless integration with IoT platforms, enabling data-driven maintenance and operational optimization.

- Lightweight and modular gantry designs facilitate easier installation and scalability, appealing to small and medium enterprises aiming to automate specific production tasks without high upfront costs.

Gantry (Cartesian) Robot Market Dynamics

Driver

“Growing Demand for Automated Material Handling and Assembly Solutions”

- The rising need for automated material handling in warehouses, logistics centers, and manufacturing plants is a major growth driver for gantry robots, which excel in high-speed palletizing, sorting, and pick-and-place operations.

- Expansion of e-commerce and consumer electronics manufacturing significantly fuels demand for gantry robots to improve efficiency and reduce labor dependency.

- Increasing adoption of gantry robots in cleanroom environments, such as semiconductor manufacturing and pharmaceuticals, drives market growth due to their precise and contamination-free operation capabilities.

- Government initiatives promoting automation and smart manufacturing, especially in emerging economies, encourage investment in gantry robotics for enhancing industrial productivity.

Restraint/Challenge

“High Initial Investment and Integration Complexity”

- High capital expenditure and long payback periods associated with advanced gantry robot systems limit adoption among small-scale manufacturers.

- Complex integration requirements with existing manufacturing execution systems (MES) and legacy equipment pose challenges, requiring skilled personnel and increased setup time.

- Maintenance costs and the need for regular calibration to maintain precision can deter companies from fully adopting gantry robots.

- Limited standardization across gantry robot components and software restricts interoperability, complicating system upgrades and expansions.

- Supply chain disruptions impacting key components like linear guides and servo motors create delays in deployment and increase overall project costs.

Gantry (Cartesian) Robot Market Scope

The market is segmented on the axis type, payload, support, application and end user.

|

Segmentation |

Sub-Segmentation |

|

By Axis Type |

|

|

By Payload |

|

|

By Support |

|

|

By Application |

|

|

By End User |

|

Gantry (Cartesian) Robot Market Scope

The market is segmented on the basis axis type, payload, support, application and end user.

- By Axis Type

On the basis of axis type, the Gantry (Cartesian) Robot market is segmented into 1-axis, 2-axis, 3-axis and 4-axis. The 1-axis segment dominates the largest market revenue share of 31.9% in 2025, The 1-axis gantry robot segment is driven by its simplicity, cost-effectiveness, and ease of integration for linear motion tasks. It is widely used in pick-and-place, inspection, and basic material handling applications, especially in industries seeking affordable automation solutions with precise single-axis movement.

The 2-axis segment is anticipated to witness the fastest growth rate of 18.7% from 2025 to 2032, The 2-axis gantry robot segment sees growth due to its enhanced flexibility in handling tasks requiring movement across two dimensions. It supports more complex automation in packaging, assembly, and CNC machining, offering improved accuracy and speed, which boosts productivity in manufacturing and logistics operations.

- By Payload

On the basis of payload the Gantry (Cartesian) Robot market is segmented into less than 50 kg, 51–350 kg and more than 350 kg. The less than 50 kg held the largest market revenue share in 2025. The less than 50 kg payload segment is driven by demand for lightweight, high-speed automation in electronics, pharmaceuticals, and small parts assembly. Its compact design suits precise, repetitive tasks, enabling manufacturers to enhance productivity and reduce labor costs in industries requiring delicate handling and fast cycle times.

The 51–350 kg segment is expected to witness the fastest CAGR from 2025 to 2032, The 51–350 kg payload segment grows due to increasing automation in heavy-duty applications like automotive assembly, metal fabrication, and large component handling. These robots offer robust performance, high accuracy, and scalability, meeting industrial needs for transporting heavier loads with speed and reliability on production lines.

- By Support

On the basis of support, the Gantry (Cartesian) Robot market is segmented into end effector and robot. The Robot held the largest market revenue share in 2025, and it is expected to witness the fastest CAGR from 2025 to 2032. The robot support segment in the Gantry (Cartesian) Robot market is driven by the increasing need for customized installation, maintenance, and integration services that ensure optimal robot performance. As industries adopt more complex gantry systems, demand for expert support in calibration, troubleshooting, and system upgrades rises. Comprehensive support reduces downtime, improves operational efficiency, and extends robot lifespan, making it a crucial factor for manufacturers investing in long-term automation solutions.

- By Application

On the basis of application, the Gantry (Cartesian) Robot market is segmented into handling, welding and soldering, dispensing, processing and others. The handling segment accounted for the largest market revenue share in 2024 and it is expected to witness the fastest CAGR from 2025 to 2032. The handling application segment is a key driver in the Gantry (Cartesian) Robot market due to growing demand for efficient, precise material movement across industries like automotive, electronics, and logistics. Gantry robots excel in repetitive pick-and-place tasks, palletizing, and loading/unloading operations. Their ability to handle large payloads over extended workspaces enhances productivity and reduces human error, making them ideal for streamlining high-volume production and warehouse automation processes.

- By End-User

On the basis of end-user, the Gantry (Cartesian) Robot market is segmented into automotive, electrical and electronics, plastics, rubber, and chemicals, food and beverages, pharmaceuticals and cosmetics, precision engineering and optics, manufacturing, metals and machinery and others. The Automotive segment accounted for the largest market revenue share in 2024 and it is expected to witness the fastest CAGR from 2025 to 2032. The automotive end-user segment significantly drives the Gantry (Cartesian) Robot market due to the industry's increasing reliance on automation for precision assembly, welding, painting, and material handling. Gantry robots offer high-speed, accurate, and repeatable operations essential for vehicle component production. With the rise of electric vehicles (EVs) and smart manufacturing, automakers are investing heavily in flexible robotic systems to improve efficiency, reduce labor costs, and maintain consistent product quality in competitive markets.

Gantry (Cartesian) Robot Market Regional Analysis

- Asia-Pacific dominates the Gantry (Cartesian) Robot market with the largest revenue share of 48.01% in 2024, Asia-Pacific dominates the global Gantry Robot market due to rapid industrialization and the proliferation of electronics and automotive manufacturing. Countries like Japan, South Korea, and India invest heavily in factory automation, fostering demand for high-precision, cost-effective Cartesian robotic solutions.

China Gantry (Cartesian) Robot Market Insight

The China Gantry (Cartesian) Robot market captured the largest revenue share of 71.2% within Asia-Pacific in 2025, driven by rapid digital transformation across industries. China leads the Gantry (Cartesian) Robot market in Asia-Pacific, driven by its dominance in global manufacturing and strong government support through policies like “Made in China 2025.” Massive EV production, expanding battery assembly lines, and demand for cost-effective automation are fueling growth. The rise of smart warehousing, rapid industrial digitalization, and investment in robotic R&D further accelerate gantry robot adoption across multiple high-growth sectors.

Europe Gantry (Cartesian) Robot Market Insight

The Europe Gantry (Cartesian) Robot market is projected to expand at a substantial CAGR throughout the forecast period, Europe’s Gantry Robot market is driven by advanced manufacturing, stringent emission norms, and rapid EV adoption. Investments in automation, Industry 5.0 initiatives, and a strong automotive sector promote demand for high-precision gantry systems across production and assembly lines.

Germany Gantry (Cartesian) Robot Market Insight

The Germany Gantry (Cartesian) Robot market is anticipated to grow at a noteworthy CAGR during the forecast period, Germany plays a pivotal role in Europe’s Gantry Robot market, backed by its world-class automotive and mechanical engineering sectors. The country emphasizes smart factories and robotics integration, resulting in significant investments in high-speed, high-accuracy gantry systems for production optimization.

France Gantry (Cartesian) Robot Market Insight

The France Gantry (Cartesian) Robot market is expected to expand at a considerable CAGR during the forecast period, France is witnessing growing adoption of Gantry Robots across aerospace, automotive, and pharmaceutical sectors. Supportive government policies and an increasing focus on digital transformation encourage manufacturers to deploy Cartesian robots to improve accuracy, scalability, and cost-efficiency in industrial operations.

North America Gantry (Cartesian) Robot Market Insight

The North America Gantry (Cartesian) Robot market is poised to grow at the fastest CAGR of over 25.1% in 2025, The Gantry Robot market in North America is expanding steadily, driven by automation in automotive and aerospace sectors. Technological advancements and high labor costs encourage industries to adopt gantry systems for precision and efficiency, particularly in packaging and assembly lines.

U.S. Gantry (Cartesian) Robot Market Insight

The U.S. Gantry (Cartesian) Robot market is fueled by strong focus on technological innovation and high-quality production. The U.S. Gantry Robot market benefits from robust demand in aerospace, defense, and automotive industries. Rising labor costs and the push for reshoring manufacturing activities drive companies to automate processes using flexible, high-precision Cartesian robots for material handling and assembly.

Canada Gantry (Cartesian) Robot Market Insight

The Canada Gantry (Cartesian) Robot market accounted for the largest market revenue share in Asia Pacific in 2025, Canada’s Gantry Robot market is growing, fueled by increasing adoption in metal fabrication, logistics, and electronics industries. Investments in smart manufacturing and a skilled workforce support the use of Cartesian robots to enhance throughput, safety, and operational efficiency in industrial applications.

Gantry (Cartesian) Robot Market Share

The Gantry (Cartesian) Robot industry is primarily led by well-established companies, including:

- Yamaha Motor Co., Ltd.

- ABB

- Bosch Rexroth Corporation

- STON ROBOT

- Güdel Group AG

- Aerotech Inc.

- DENSO CORPORATION

- Shibaura Machine CO., LTD.

- IAI America, Inc.

- Liebherr-International Deutschland GmbH

- PARKER HANNIFIN CORP

- Bahr Modultechnik GmbH

- PROMOT Automation GmbH

- Cimcorp

- OMRON Corporation

- Nordson Corporation

- Sage Automation Inc.

- FISNAR

- KUKA AG

- Yaskawa Europe GmbH

Latest Developments in Global Gantry (Cartesian) Robot Market

- In July 2024, Rollon introduced the H-Bot, a compact gantry system featuring a unique single-belt drive mechanism powered by two stationary motors on the X-axis. This design reduces moving masses and vibrations, enhancing performance in applications requiring high dynamics and precision.

- In March 2023, KUKA unveiled a new Gantry Industrial Robot optimized for precision in logistics and warehousing applications. The robot features enhanced payload capacity and advanced AI capabilities, enabling adaptability to different operational scenarios, positioning KUKA at the forefront of automation in supply chain management.

- June 2023, ABB entered a strategic partnership with a leading global technology firm to co-develop innovative Gantry Robots for automotive manufacturing. This collaboration focuses on integrating advanced IoT solutions into robotic systems, enhancing their connectivity and data analytics capabilities.

- October 2023, Yaskawa Electric Corporation announced its acquisition of a robotics software company specializing in AI-driven automation solutions. This strategic move aims to enhance Yaskawa's product portfolio and capacity for developing next-generation Gantry Robots equipped with sophisticated analytics.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Gantry Cartesian Robot Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Gantry Cartesian Robot Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Gantry Cartesian Robot Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.