North America Bioplastic Multi Layer Films Market For Compostable Food Service Packaging

市场规模(十亿美元)

CAGR :

%

USD

38.49 Million

USD

68.13 Million

2022

2030

USD

38.49 Million

USD

68.13 Million

2022

2030

| 2023 –2030 | |

| USD 38.49 Million | |

| USD 68.13 Million | |

|

|

|

北美可堆肥食品服务包装生物塑料多层薄膜市场,按材料(淀粉共混物、聚丁二醇对苯二甲酸酯聚乳酸、PBS 等)、最终用途包装(袋装和小袋装、翻盖包装、杯子、托盘等)、最终用户(连锁餐厅、非连锁餐厅、连锁咖啡馆、非连锁咖啡馆、外卖餐饮、独立卖家和售货亭等)划分 - 行业趋势和预测到 2030 年。

北美可堆肥食品服务包装生物塑料多层薄膜市场分析及规模

多层薄膜可用于包装新鲜产品和干货,以经济高效的方式延长保质期。生物塑料是一种坚固的材料,可以替代传统的石油基塑料,用于可持续食品包装。源自可再生资源和可生物降解聚合物的材料是生物塑料,例如 PLA、PHA、PBAT 和淀粉。

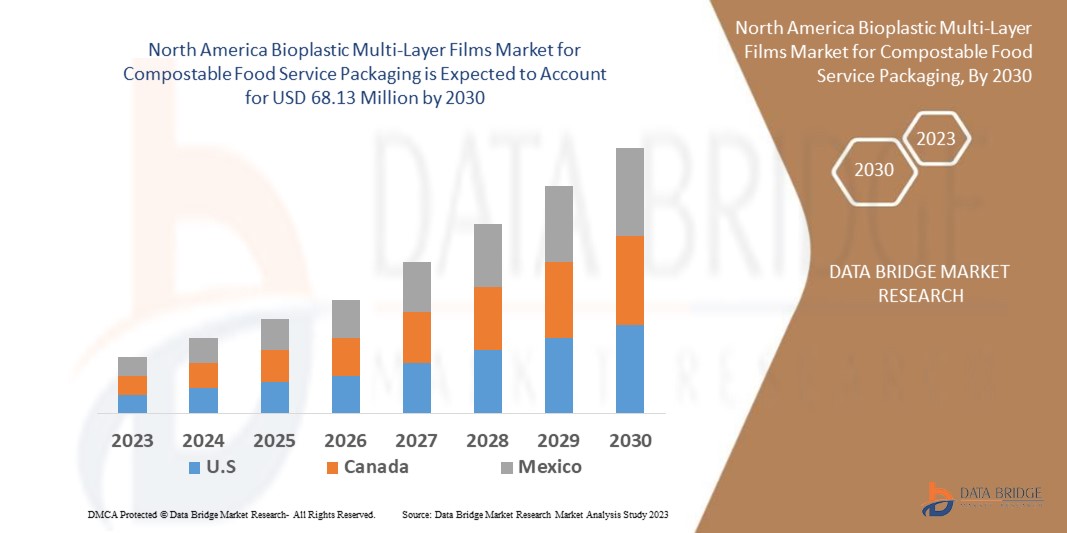

Data Bridge Market Research 分析,北美可堆肥食品服务包装生物塑料多层薄膜市场规模从 2022 年的 3849 万美元,到 2030 年将飙升至 6813 万美元,预计在 2023 年至 2030 年的预测期内复合年增长率为 7.4%。 “淀粉混合物”在北美可堆肥食品服务包装生物塑料多层薄膜市场的材料领域占据主导地位。

除了对市场价值、增长率、细分、地理覆盖范围和主要参与者等市场情景的见解之外,Data Bridge Market Research 策划的市场报告还包括深入的专家分析、按地理位置表示的公司生产和产能、分销商和合作伙伴的网络布局、详细和更新的价格趋势分析以及供应链和需求的赤字分析。

北美可堆肥食品服务包装生物塑料多层薄膜市场范围和细分

|

报告指标 |

细节 |

|

预测期 |

2023 至 2030 年 |

|

基准年 |

2022 |

|

历史岁月 |

2021 (可定制为 2015-2020) |

|

定量单位 |

收入(千美元)、数量(吨)、定价(美元) |

|

涵盖的领域 |

按材料(淀粉共混物、聚己二酸对苯二甲酸丁二醇酯、聚乳酸、PBS 等)、最终用途包装(小袋和小包装袋、翻盖包装、杯子、托盘等)、最终用户(连锁餐厅、非连锁餐厅、连锁咖啡馆、非连锁咖啡馆、外卖餐饮、独立卖家和售货亭等) |

|

覆盖国家 |

美国、加拿大和墨西哥 |

|

涵盖的市场参与者 |

BASF SE(德国)、TIPA LTD(以色列)、Biome Bioplastics(Biome Technologies plc 的子公司)(英国)、BioBag International AS.(挪威)和 Transcontinental Inc.(加拿大)等 |

|

市场机会 |

|

市场定义

生物塑料源自可再生资源,可生物降解,或两者兼而有之。源自可再生资源和可生物降解聚合物的材料是生物塑料,例如淀粉共混物、聚丁二酸对苯二甲酸酯、聚乳酸和 PBS。在多层薄膜技术中,两种或多种具有特定和互补特性的材料结合在一起,从而提高了生物塑料的整体性能。这些材料在软包装和硬包装方面具有竞争力,同时最大限度地减少了传统石油基塑料的负面影响。

在食品服务包装中,可堆肥多层薄膜为新鲜和干燥食品提供出色的保护。采用这种材料制成的最终用途包装产品可以使用传统和数字印刷技术轻松印刷。可堆肥多层薄膜使食品服务提供商能够摆脱传统包装,走在创建循环经济的前沿。

北美可堆肥食品服务包装生物塑料多层薄膜市场动态

驱动程序

- 倾向于消费方便食品

方便食品包括预洗、烹制、大部分包装好的即食食品。由于时间紧迫,西方文化对消费者影响很大。此外,快节奏的生活方式变化增加了人们对健康和保健的兴趣,消费者需求的变化也增加了对熟食的需求。人们希望减少去杂货店的次数,这促使他们批量购买冷冻食品和不同的饮料,并将它们存放在软包装中,以保持食品和饮料产品的保质期。此外,方便食品需要完美的温度来保护食物免受生物污染和物理损坏。因此,这增加了对生物塑料多层薄膜包装产品的需求。

- 软包装解决方案日益普及

包装行业正在采用智能和可持续的解决方案,使产品包装更加消费者友好、品牌友好和环保,从而使包装行业能够开发涉及包装互联网、主动包装和纳米技术的智能包装。由生物塑料薄膜制成的软包装产品重量轻、方便且经济高效,可轻松运输。用于制造软包装的材料可用于包装任何形状、设计和配色方案、尺寸和体积的产品。可堆肥软包装由纤维素或其他植物衍生材料制成。这些生物基塑料或生物塑料是植物基材料,可替代传统的石油基塑料。

- 消费者偏好转向卫生食品包装产品

食品包装有多种用途,它可以保护食品免受污染或变质,使包装看起来美观,并使货物便于运输。包装可以保持产品的新鲜度,防止其受到化学或生物污染。食品包装使用各种材料,如生物塑料、薄膜和铝,保护食品免受不同类型的暴露,包括阳光、气体和湿气。由生物塑料薄膜制成的包装材料可保护食品免受病原体和化学物质的侵害。生物包装材料包括塑料和缓冲材料,可防止食品在包装、运输和货架期间移位和被压碎。

- 消除一次性塑料的趋势日益明显

不可回收塑料的增加已在世界各地形成了大量垃圾填埋场。这种垃圾污染了地球的自然资源,以至于水生生态系统也面临不利影响,此外,其中的化学物质还会带来其他明显的不良影响。多层生物塑料材料广泛用于包装食品,以便将产品从一个地方运送到另一个地方。多层生物塑料材料用于软包装,包括塑料和聚合物,用于制造不同类型的软包装,如袋子、信封、小袋、纤维素和铝箔。各地区人口的增加和对一次性塑料产品的禁令导致对生物塑料材料包装的需求不断增加。

机会

- 电子商务领域的需求不断增长

互联网普及、智能手机用户增加、社交媒体影响力和政府举措等各种因素推动了电子商务行业的发展。电子商务平台的日益普及凸显了在线零售对现代经济的重要性。来自主要在线零售商和其他零售商的运输箱象征着电子商务。它们也是生物塑料多层薄膜包装需求增长的最重要来源之一。为了增强消费者在电子商务平台上的体验,人们越来越倾向于让生物塑料多层薄膜包装更具吸引力和愉悦感。

- 新设计的创新包装解决方案激增

与其他印刷工艺相比,数字印刷包装等创新包装解决方案具有显著的节约潜力,并且设置成本低。制造商可以省去大批量订单,无需大量印刷和库存。与排版等机械工艺相比,先进的包装解决方案为包装商提供了更大的个性化和定制自由。许多顶级产品品牌都探索了个性化包装,并从这种创新的营销投资中获得了可观的回报。因此,采用新的先进印刷技术为消费者提供个性化包装解决方案的趋势正在兴起。这有助于企业提高其在市场上的品牌价值,并增强客户对产品包装的参与度。

限制/挑战

- 可生物降解薄膜成本高昂

制造生物塑料薄膜产品取决于生产所用原材料的数量,因为环保原材料比传统材料更昂贵。此外,包装产品的尺寸和产品特性等因素也会影响食品包装行业所用产品的价格。由于全球优质可生物降解包装数量有限,任何可生物降解包装产品都会比标准包装产品贵一点。生物塑料袋比传统塑料袋更贵,因为原材料更贵、更难获得,而且小批量生产的成本更高。

- 替代产品的可用性

传统塑料是第三大最常用的石油衍生物,可以替代生物塑料材料,被称为化石燃料塑料。由于其成本相对较低、易于制造、用途广泛且不透水,它被用于许多产品中。它已经成为木材、皮革和纸张的良好替代品。另一方面,生物塑料产品是由可再生生物质来源生产的材料,例如植物脂肪和油、玉米淀粉、稻草、木屑和回收的食品垃圾,这些材料比传统产品更昂贵。此外,在低温下,使用不同的硬质化学品会影响生物塑料的生产,从而影响产品的柔韧性。

- 与可生物降解薄膜相关的问题

生物塑料的使用越来越多,用于制造在许多应用中性能优于传统塑料的包装产品。生物塑料通常最终被填埋,由于缺氧,它们会释放温室气体甲烷。如果生物塑料没有得到妥善处理,它们会污染回收的塑料批次并损害回收框架。用于包装产品的不同生物聚合物具有高水蒸气渗透性、氧气渗透性、易碎性、低热阻性、低机械性能、易降解和低可加工性等缺点。这些反过来又降低了对基于生物塑料薄膜的包装产品的需求。此外,与传统塑料薄膜相比,生物塑料薄膜对空气、水和氧气的阻隔性较低,耐热性也较低。

- 生物塑料生产过程和报废选择的不确定性

生物塑料薄膜包装产品的生产单位的特点是产品生命周期短,产品变化多端,对客户需求的响应时间快。这需要对各种生产活动进行有效的规划和安排,因此僵化的计划不再能满足制造过程中的所有约束和变化。此外,由于缺乏技术开发和制造生物塑料薄膜包装产品的资本投资减少,发展中国家对这些产品的需求进一步减少。

这份用于可堆肥食品服务包装的生物塑料多层薄膜市场报告详细介绍了最新发展、贸易法规、进出口分析、生产分析、价值链优化、市场份额、国内和本地市场参与者的影响,分析了新兴收入来源、市场法规变化、战略市场增长分析、市场规模、类别市场增长、应用领域和主导地位、产品批准、产品发布、地域扩展、市场技术创新等方面的机会。如需了解有关用于可堆肥食品服务包装的生物塑料多层薄膜市场的更多信息,请联系 Data Bridge Market Research 获取分析师简报,我们的团队将帮助您做出明智的市场决策,实现市场增长。

最新动态

-

2022 年 6 月,巴斯夫 SE 和澳大利亚食品包装制造商 Confoil 合作开发了一种经过认证的可堆肥和可双烤箱加热的纸质托盘,用于准备即食食品。这些托盘通过有机可回收延长了纸质包装的报废选择。它们可以与垃圾箱中收集的有机废物一起进行商业堆肥。这有助于该公司在澳大利亚市场获得认可。

-

2021 年 11 月,Transcontinental Inc. 收购了 HS Crocker Co., Inc.,这是一家北美领先的食品行业模切盖制造商和制药行业标签制造商。此次收购将增强包装解决方案组合,尤其是在乳制品和咖啡盖以及保质和冷藏甜点市场,并提供重要的交叉销售机会。

北美可堆肥食品服务包装生物塑料多层薄膜市场范围

用于可堆肥食品服务包装的生物塑料多层薄膜市场根据材料、最终用途包装和最终用户进行细分。这些细分市场之间的增长将帮助您分析行业中增长微弱的细分市场,并为用户提供有价值的市场概览和市场洞察,帮助他们做出战略决策,确定核心市场应用。

材料

- 淀粉混合物

- 聚己二酸对苯二甲酸丁二醇酯

- 聚乳酸

- 美国公共广播公司

- 其他的

最终用途包装

- 小袋和小袋

- 翻盖

- 杯子

- 托盘

- 其他的

终端用户

- 连锁餐厅

- 非连锁餐厅

- 鏈接咖啡店

- 非连锁咖啡馆

- 配送餐饮

- 独立卖家和售货亭

- 其他的

可堆肥食品服务包装的生物塑料多层薄膜市场区域分析/见解

对可堆肥食品服务包装的生物塑料多层薄膜市场进行了分析,并按国家、材料、最终用途包装和最终用户提供了市场规模见解和趋势,如上所述。

可堆肥食品服务包装生物塑料多层薄膜市场报告涵盖的国家包括美国、加拿大和墨西哥。

由于不断增长的消费者群体和不断增加的政府举措推动市场增长,美国在可堆肥食品服务包装的生物塑料多层薄膜市场中占据主导地位。

报告的国家部分还提供了影响市场当前和未来趋势的各个市场影响因素和国内监管变化。下游和上游价值链分析、技术趋势和波特五力分析、案例研究等数据点是用于预测各个国家市场情景的一些指标。此外,在提供国家数据的预测分析时,还考虑了全球品牌的存在和可用性以及它们因来自本地和国内品牌的大量或稀缺竞争而面临的挑战、国内关税和贸易路线的影响。

可堆肥食品服务包装的竞争格局和生物塑料多层薄膜市场份额分析

可堆肥食品服务包装用生物塑料多层薄膜市场竞争格局按竞争对手提供详细信息。详细信息包括公司概况、公司财务状况、收入、市场潜力、研发投资、新市场计划、全球影响力、生产基地和设施、生产能力、公司优势和劣势、产品发布、产品宽度和广度、应用主导地位。以上提供的数据点仅与公司对市场的关注有关。

可堆肥食品服务包装生物塑料多层薄膜市场的一些主要参与者包括:

- 巴斯夫公司(德国)

- TIPA LTD(以色列)

- Biome Bioplastics(Biome Technologies plc 的子公司)(英国)

- BioBag International AS.(挪威)

- Transcontinental Inc.(加拿大)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

研究方法

数据收集和基准年分析是使用具有大样本量的数据收集模块完成的。该阶段包括通过各种来源和策略获取市场信息或相关数据。它包括提前检查和规划从过去获得的所有数据。它同样包括检查不同信息源中出现的信息不一致。使用市场统计和连贯模型分析和估计市场数据。此外,市场份额分析和关键趋势分析是市场报告中的主要成功因素。要了解更多信息,请请求分析师致电或下拉您的询问。

DBMR 研究团队使用的关键研究方法是数据三角测量,其中包括数据挖掘、数据变量对市场影响的分析和主要(行业专家)验证。数据模型包括供应商定位网格、市场时间线分析、市场概览和指南、公司定位网格、专利分析、定价分析、公司市场份额分析、测量标准、全球与区域和供应商份额分析。要了解有关研究方法的更多信息,请向我们的行业专家咨询。

可定制

Data Bridge Market Research 是高级形成性研究领域的领导者。我们为向现有和新客户提供符合其目标的数据和分析而感到自豪。报告可定制,包括目标品牌的价格趋势分析、了解其他国家的市场(索取国家列表)、临床试验结果数据、文献综述、翻新市场和产品基础分析。目标竞争对手的市场分析可以从基于技术的分析到市场组合策略进行分析。我们可以按照您所需的格式和数据样式添加您需要的任意数量的竞争对手数据。我们的分析师团队还可以为您提供原始 Excel 文件数据透视表(事实手册)中的数据,或者可以帮助您根据报告中的数据集创建演示文稿。