Global Powder Metallurgy Market

市场规模(十亿美元)

CAGR :

%

USD

2.56 Billion

USD

5.60 Billion

2021

2029

USD

2.56 Billion

USD

5.60 Billion

2021

2029

| 2022 –2029 | |

| USD 2.56 Billion | |

| USD 5.60 Billion | |

|

|

|

|

全球粉末冶金市场,按产品类型(黑色金属、有色金属)、工艺(增材制造、金属注射成型、粉末金属热等静压)、应用(航空航天、汽车、电气和电子、工业机械、医疗、其他)、最终用户(OEM、AM 运营商)划分 - 行业趋势和预测到 2030 年。

粉末冶金市场分析及规模

在过去的几年中,粉末冶金活动的参与人数大幅增长。此外,随着从控制台向移动设备的过渡,粉末冶金的参与人数迅速激增。近几十年来,合法的粉末冶金已成为包括美国在内的各个国家的主要现象。超过 80% 的美国成年人一生中至少下过一次赌注,这一事实使粉末冶金在美国的受欢迎程度可见一斑。因此,预计市场将在 2023-2030 年预测期内快速增长。

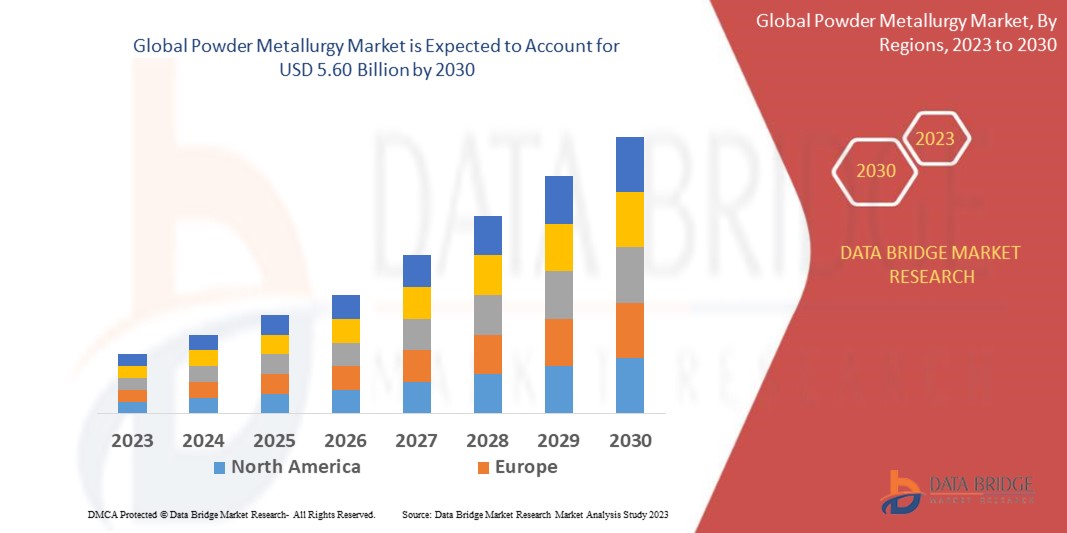

Data Bridge Market Research 分析称,全球粉末冶金市场在 2022 年为 25.6 亿美元,预计到 2030 年将达到 56 亿美元,预计在 2023-2030 年预测期内的复合年增长率为 10.26%。据说“汽车”行业主导着全球粉末冶金市场。这是因为粉末冶金广泛用于制造汽车中的齿轮、轴承和结构件等部件,受益于该行业的大规模生产和对轻质耐用零件的需求。除了对市场价值、增长率、细分、地理覆盖范围和主要参与者等市场情景的见解外,Data Bridge Market Research 策划的市场报告还包括深入的专家分析、按地理表示的公司生产和产能、分销商和合作伙伴的网络布局、详细和更新的价格趋势分析以及供应链和需求的缺口分析。

粉末冶金市场范围和细分

|

报告指标 |

细节 |

|

预测期 |

2023 至 2030 年 |

|

基准年 |

2022 |

|

历史岁月 |

2021 (可定制为 2015-2020) |

|

定量单位 |

收入(单位:十亿美元)、销量(单位:台)、定价(美元) |

|

涵盖的领域 |

产品类型(黑色金属、有色金属)、工艺(增材制造、金属注射成型、粉末金属热等静压)、应用(航空航天、汽车、电气和电子、工业机械、医疗、其他)、最终用户(OEM、AM 运营商) |

|

覆盖国家 |

美国、加拿大、墨西哥、巴西、阿根廷、南美洲其他地区、德国、法国、意大利、英国、比利时、西班牙、俄罗斯、土耳其、荷兰、瑞士、欧洲其他地区、日本、中国、印度、韩国、澳大利亚、新加坡、马来西亚、泰国、印度尼西亚、菲律宾、亚太其他地区、阿联酋、沙特阿拉伯、埃及、南非、以色列、中东和非洲其他地区 |

|

涵盖的市场参与者 |

BASF SE(德国)、Carpenter Corporation(美国)、Comtec Mfg.Inc.(美国)、Fine Sintered Co. Ltd.(日本)、Melrose Industries PLC(英国)、Phoenix Sintered Metals LLC(美国)、Precision Sintered Parts(美国)、Sandvik AB(瑞典)、住友电气工业株式会社(日本)、通用电气(美国)、Miba AG(奥地利)、ExOne(美国)、昭和电工材料株式会社(日本)、PMG Holding GmbH(德国)、西门子(西班牙)、上海电气(中国)、ABB(瑞士)和日立有限公司(日本) |

|

市场机会 |

|

市场定义

粉末冶金是用金属粉末制造或生产部件或材料的工艺。它主要用于制造无法通过熔化或成型制造的独一无二的部件,例如碳化钨。粉末冶金可减少制造产量损失并生产出成本较低的产品。这是一种节省时间、金钱和精力的方法。它将起始材料转化为必要的粉末形式,然后将粉末粘在一起以形成理想的独特产品。粉末冶金还用于生产惰性机器零件,例如转子、齿轮、轴承、衬套和磁铁。

全球粉末冶金市场动态

驱动程序

- 汽车行业的高利用率

粉末冶金是汽车工业中一种流行的技术。粉末冶金在汽车工业中的应用正在稳步增长,因为粉末冶金被广泛认为是机加工或铸造零件的一种经济高效的替代品。一些发展中地区对提高燃油效率的认识日益增强,推动了汽车行业对粉末冶金的需求。对轻型车辆、轻型材料和替代能源的需求增加推动了粉末冶金部件的需求,这些需求通过金属注射成型、金属粉末锻造和温压实现。粉末冶金部件用于制造各种汽车部件,因此市场对汽车行业的需求将加速增长。

- 可支配收入增长

消费者可支配收入的增长进一步推动了对电子设备和小工具的需求,这直接影响了粉末冶金市场。在预测期内,市场将受到增材制造日益广泛的使用推动,以减轻航空航天、国防和医疗保健领域使用的零件或部件的重量。此外,粉末金属在电气和电子设备(如汽车电池和电子产品)中的应用增加也将推动市场价值增长。由于对可控孔隙率、高热容量和高弹性模量的需求增加,粉末冶金正被用于航空航天部件。航空航天工业对热塑性部件的需求不断增长,推动了对粉末冶金的需求。

机会

- 投资与进步

市场参与者正在大量投资研发活动,以进一步增强产品应用,并在预测期内为市场参与者扩大盈利机会。此外,电气和电子元件的进步进一步扩大了全球粉末冶金市场的未来增长。

限制/挑战

- 粉末冶金成本高

全球粉末冶金市场扩张的主要障碍之一是,与铸造和锻造中使用的其他原材料相比,该工艺中使用的金属粉末成本较高。预计这一因素将阻碍 2023-2030 年预测期内的市场增长。

- 加工零件质量低下

这些零件的机械性能不如铸造或机加工零件。此外,由于压缩不均匀,最终产品不同部分的密度在某些情况下可能会有所不同,这对全球粉末冶金市场来说是一个缺点。因此,这将对全球粉末冶金市场的增长率提出挑战。

这份全球粉末冶金市场报告详细介绍了最新发展、贸易法规、进出口分析、生产分析、价值链优化、市场份额、国内和本地市场参与者的影响,分析了新兴收入来源、市场法规变化、战略市场增长分析、市场规模、类别市场增长、应用领域和主导地位、产品批准、产品发布、地域扩展、市场技术创新等方面的机会。如需了解有关全球粉末冶金市场的更多信息,请联系 Data Bridge Market Research 获取分析师简报,我们的团队将帮助您做出明智的市场决策,实现市场增长。

原材料短缺和运输延误的影响和当前市场状况

Data Bridge 市场研究提供高水平的市场分析,并通过考虑原材料短缺和运输延迟的影响和当前市场环境来提供信息。这意味着评估战略可能性、制定有效的行动计划并协助企业做出重要决策。除了标准报告外,我们还提供从预测运输延迟、按地区划分的分销商映射、商品分析、生产分析、价格映射趋势、采购、类别绩效分析、供应链风险管理解决方案、高级基准测试以及其他采购和战略支持服务等方面的采购层面的深入分析。

经济放缓对产品定价和供应的预期影响

当经济活动放缓时,行业开始受到影响。DBMR 提供的市场洞察报告和情报服务考虑了经济衰退对产品定价和可获得性的预测影响。借助这些,我们的客户通常可以领先竞争对手一步,预测他们的销售额和收入,并估算他们的盈亏支出。

近期发展

- 2023 年 7 月,粉末冶金高速钢领域的全球领导者 Erasteel 将推出 BlueTap Max,这是一款用于高性能丝锥的创新解决方案。凭借数十年的经验、客户合作伙伴关系和一支技术精湛的研发团队,Erasteel 始终如一地提供可持续的高性能产品

全球粉末冶金市场范围

全球粉末冶金市场根据产品类型、工艺、最终用户和应用进行细分。这些细分市场之间的增长情况将帮助您分析行业中增长缓慢的细分市场,并为用户提供有价值的市场概览和市场洞察,帮助他们做出战略决策,确定核心市场应用。

产品类型

过程

- 增材制造

- 金属注射成型

- 粉末金属热等静压

应用

- 航天

- 汽车

- 电气和电子

- 工业机械

- 医疗的

- 其他的

最终用户

- OEM

- AM 操作员

全球粉末冶金市场分析/见解

全球粉末冶金市场根据上述国家、产品类型、工艺、最终用户和应用进行细分。

全球粉末冶金市场报告涵盖的国家包括北美洲的美国、加拿大和墨西哥,欧洲的德国、法国、英国、荷兰、瑞士、比利时、俄罗斯、意大利、西班牙、土耳其,欧洲其他地区,亚太地区的中国、日本、印度、韩国、新加坡、马来西亚、澳大利亚、泰国、印度尼西亚、菲律宾,亚太地区的亚太地区其他地区,沙特阿拉伯、阿联酋、以色列、埃及、南非,中东和非洲其他地区,以及南美洲的巴西、阿根廷和南美洲其他地区。

亚太地区在市场份额和市场收入方面占据市场主导地位,并将在预测期内继续保持主导地位。该地区的市场增长归因于快速的城市化、人口增长以及该地区对改善基础设施的需求。

另一方面,由于欧洲医疗、汽车、航空航天和国防工业等各个行业对粉末冶金的需求增加,预计欧洲在预测期内 (2023-2030) 将呈现丰厚的增长。

报告的国家部分还提供了影响单个市场因素和国内市场监管变化,这些因素和变化会影响市场的当前和未来趋势。下游和上游价值链分析、技术趋势和波特五力分析、案例研究等数据点是用于预测单个国家市场情景的一些指标。此外,在提供国家数据的预测分析时,还考虑了全球品牌的存在和可用性以及它们因来自本地和国内品牌的大量或稀缺竞争而面临的挑战、国内关税和贸易路线的影响。

竞争格局和全球粉末冶金市场份额分析

全球粉末冶金市场竞争格局按竞争对手提供详细信息。详细信息包括公司概况、公司财务状况、收入、市场潜力、研发投资、新市场计划、全球影响力、生产基地和设施、生产能力、公司优势和劣势、产品发布、产品宽度和广度、应用主导地位。以上提供的数据点仅与公司对全球粉末冶金市场的关注有关。

全球粉末冶金市场的一些主要参与者包括:

- 巴斯夫公司(德国)

- Carpenter 公司 (美国)

- Comtec Mfg.Inc.(美国)

- Fine Sinter 有限公司 (日本)

- 梅尔罗斯工业公司 (英国)

- 菲尼克斯烧结金属有限责任公司 (美国)

- 精密烧结零件(美国)

- 山特维克公司(瑞典)

- 住友电气工业株式会社(日本)

- 通用电气(美国)

- Miba AG(奥地利)

- ExOne(美国)

- 昭和电工材料有限公司(日本)

- PMG Holding GmbH(德国)

- 西门子(西班牙)

- 上海电气(中国)

- ABB(瑞士)

- 日立有限公司(日本)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

研究方法

数据收集和基准年分析是使用具有大样本量的数据收集模块完成的。该阶段包括通过各种来源和策略获取市场信息或相关数据。它包括提前检查和规划从过去获得的所有数据。它同样包括检查不同信息源中出现的信息不一致。使用市场统计和连贯模型分析和估计市场数据。此外,市场份额分析和关键趋势分析是市场报告中的主要成功因素。要了解更多信息,请请求分析师致电或下拉您的询问。

DBMR 研究团队使用的关键研究方法是数据三角测量,其中包括数据挖掘、数据变量对市场影响的分析和主要(行业专家)验证。数据模型包括供应商定位网格、市场时间线分析、市场概览和指南、公司定位网格、专利分析、定价分析、公司市场份额分析、测量标准、全球与区域和供应商份额分析。要了解有关研究方法的更多信息,请向我们的行业专家咨询。

可定制

Data Bridge Market Research 是高级形成性研究领域的领导者。我们为向现有和新客户提供符合其目标的数据和分析而感到自豪。报告可定制,包括目标品牌的价格趋势分析、了解其他国家的市场(索取国家列表)、临床试验结果数据、文献综述、翻新市场和产品基础分析。目标竞争对手的市场分析可以从基于技术的分析到市场组合策略进行分析。我们可以按照您所需的格式和数据样式添加您需要的任意数量的竞争对手数据。我们的分析师团队还可以为您提供原始 Excel 文件数据透视表(事实手册)中的数据,或者可以帮助您根据报告中的数据集创建演示文稿。