Europe Industrial Valves Market

市场规模(十亿美元)

CAGR :

%

USD

17,074.58 Million

USD

26,604.18 Million

2022

2030

USD

17,074.58 Million

USD

26,604.18 Million

2022

2030

| 2023 –2030 | |

| USD 17,074.58 Million | |

| USD 26,604.18 Million | |

|

|

|

Europe Industrial Valves Market, By Components (Actuators, Valve Body, Others), Type (Gate Valve, Globe Valve, Ball Valve, Butterfly Valve, Diaphragm Valve, Check Valve, Plug Valve, Pinch Valve, Needle Valve, Pressure Relief Valve, Safety Valve, Others), Function (On/Off, Control, Isolation, Regulation Safety Relief Valve, Special Purpose, Non-Return), Material (Iron, Carbon Steel, Alloy, Plastic, Brass, Bronze, Copper, Cryogenic, Aluminium, Others), Accessories (Hydraulic Filter, Power Cable, Mounting Screw and Bolts, Seal Kits, Dust Protection Cover, Others), Size (1 Inch to 6 Inch, 6 Inch to 12 Inch, 12 Inch to 24 Inch, 24 Inch to 48 Inch, Above 48 Inch), Application (Oil and Gas, Building and Construction, Semiconductors, Water and Waste Treatment, Chemical, Energy and Utilities, Food and Beverages, Pharmaceutical, Agriculture, Marine, Automotive, Metals and Mining, Paper and Pulp, Others) – Industry Trends and Forecast to 2030.

Europe Industrial Valves Market Analysis and Size

Industrial valves are mechanical or electromechanical devices used in various industries to regulate the flow of liquids, gases, slurries, and other substances through pipes and tubes. Different types of industrial valves serve a variety of purposes, including pressure control, shut-on/off, and other regulation needs. Industrial valves are also made from metal alloys such as carbon steel, cast iron, stainless steel, and others for high efficiency. Additionally, industrial valves with high levels of automation and control operate more effectively in risky environments such as nuclear power plants, oil and gas fields, and chemical processing. Additionally, the use of automation technologies has helped to lessen the amount of liquid waste that passes through pipes and valves, which lowers costs.

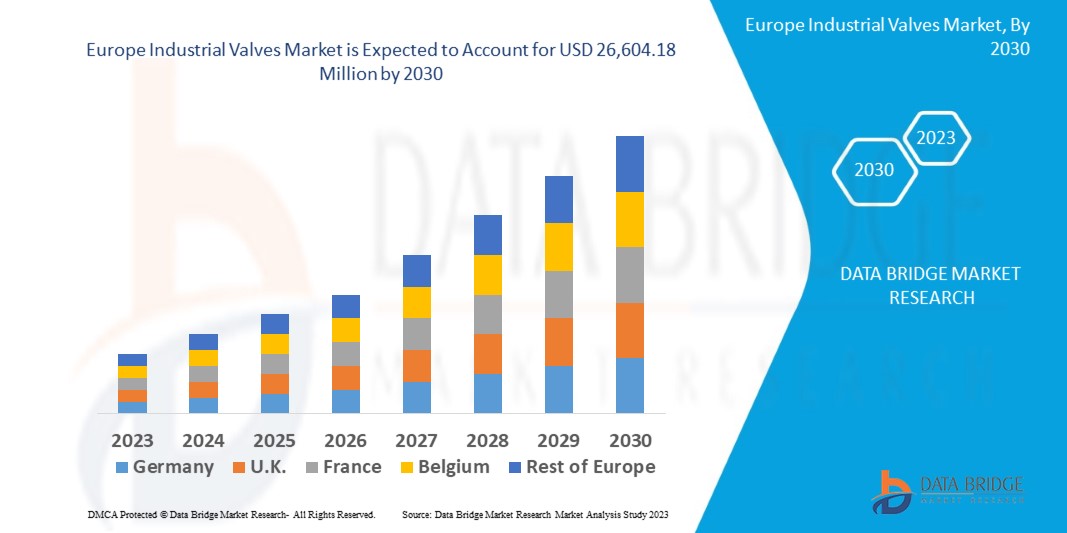

Data Bridge Market Research analyses that the industrial valves market, valued at USD 17,074.58 million in 2022, will reach USD 26,604.18 million by 2030, growing at a CAGR of 5.7% during the forecast period of 2023 to 2030. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand.

Europe Industrial Valves Market Scope and Segmentation

|

Report Metric |

Details |

|

Forecast Period |

2023 to 2030 |

|

Base Year |

2022 |

|

Historic Years |

2021 (Customizable to 2015 - 2020) |

|

Quantitative Units |

Revenue in USD Million, Volumes in Units, Pricing in USD |

|

Segments Covered |

部件(执行器、阀体、其他)、类型(闸阀、截止阀、球阀、蝶阀、隔膜阀、止回阀、旋塞阀、夹管阀、针阀、泄压阀、安全阀、其他)、功能(开/关、控制、隔离、调节安全泄压阀、特殊用途、止回)、材质(铁、碳钢、合金、塑料、黄铜、青铜、铜、低温、铝、其他)、配件(液压过滤器、电源线、安装螺钉和螺栓、密封套件、防尘罩、其他)、尺寸(1 英寸至 6 英寸、6 英寸至 12 英寸、12 英寸至 24 英寸、24 英寸至 48 英寸、48 英寸以上)、应用(石油和天然气、建筑和施工、半导体、水和废物处理、化学、能源和公用事业、食品和饮料、制药、农业、海洋、汽车、金属和采矿、造纸和纸浆、其他) |

|

覆盖国家 |

德国、法国、英国、荷兰、瑞士、比利时、俄罗斯、意大利、西班牙、土耳其、欧洲其他地区 |

|

涵盖的市场参与者 |

艾默生电气公司 (美国)、福斯公司 (美国)、克瑞公司 (美国)、IMI (英国)、Velan Inc. (加拿大)、KITZ Corporation (日本)、纽威阀门 (中国)、AVK Holding A/S (丹麦)、美卓 (芬兰)、Spirax Sarco Limited. (英国)、江森自控 (爱尔兰)、Powell Valves (美国)、Curtiss-Wright. (美国)、Mueller Co. LLC. (美国)、克瑞公司、CRANE ChemPharma & Energy Corp (美国)、The Weir Group PLC (英国)、瓦锡兰 (芬兰)、Bray International (美国)、Dwyer Instruments LTD (美国)、Watts. (美国)、Bonney Forge Corporation (美国)、NIBCO Inc. (美国) |

|

市场机会 |

|

市场定义

工业阀门是工业中用于控制管道系统内液体、气体和浆液等流体流动的机械装置。它们通过打开、关闭或部分阻塞通道来调节流量,还可以调节压力、温度并防止回流或泄漏。阀门有不同的类型和尺寸,例如闸阀、截止阀、球阀和蝶阀。它们是石油和天然气、水处理、发电和制造等行业的重要组成部分,通过控制流体流动和保持系统完整性来确保流程安全高效运行。

欧洲工业阀门市场动态

驱动程序

- 工业增长推动市场

石油和天然气、石化、发电、水和废水处理以及制造等行业的工业增长和扩张推动了对工业阀门的需求。随着这些行业的业务扩展,对阀门的需求也随之增加,以调节流体流量、控制工艺参数并确保高效和安全的运行。阀门是这些行业中必不可少的部件,用于启动、停止和调节流体流动、保持压力和温度水平以及防止回流或泄漏等任务。这些行业内日益增长的工业活动和基础设施发展直接导致对工业阀门的需求不断增长,以支持其不断扩大的业务。

- 技术进步推动市场增长

阀门设计、材料和自动化方面的技术进步对工业阀门的需求产生了重大影响。这些进步引入了新的特性和能力,提高了阀门的性能、可靠性和控制力。改进的设计优化了流体流动,降低了能耗并提高了效率。先进的材料提高了耐用性、耐腐蚀性,并与更广泛的流体兼容。自动化技术可实现远程操作、监控和与控制系统的集成,从而改善过程控制和效率。各行业都希望从这些进步中获益,通过升级现有阀门或投资新阀门来提高整体性能、降低维护成本并优化流程,从而提高生产力和卓越运营。

机会

- 日益增长的环境问题使市场得以扩大

环保意识的增强和对可持续性的重视导致绿色技术对工业阀门的需求增加。这些阀门在优化工艺和最大限度地减少可再生能源发电、废水处理和污染控制等领域的环境影响方面发挥着关键作用。在可再生能源领域,阀门用于调节太阳能热系统、水力发电厂和风力涡轮机冷却系统中的流体流量。在废水处理领域,阀门用于控制流量和处理过程,确保高效且环保的处理。阀门还通过调节排放、防止泄漏和保持工艺效率来协助污染控制,这与人们对环境可持续性的日益关注相一致。

- 全球化和国际贸易推动市场扩张

产业全球化和国际贸易的增长导致供应链的扩张和对工业阀门的需求增加。阀门是物流和航运领域的关键部件,用于货物的运输、储存和加工。阀门能够有效控制管道、储罐和容器中的流体流动,确保各种产品的安全运输。随着全球贸易量的增长,港口、码头、仓库和运输网络对阀门的需求也在增加,以满足处理和管理不同地区货物流动的要求,从而增加了对工业阀门的总体需求。

限制/挑战

- 技术过时限制了市场增长

由于技术进步速度快,技术过时是工业阀门行业的一个制约因素。随着新技术的出现,旧的阀门设计和功能可能会过时,导致效率低下和与现代控制系统的兼容性问题。行业需要及时了解最新进展,以确保其阀门高效、可靠并与不断发展的工业流程兼容。无法适应新技术可能会导致生产力下降、维护成本增加和潜在的系统故障。持续监测技术进步并主动投资升级阀门对于降低技术过时的风险并保持市场竞争力是必不可少的。

- 高成本和定期维护的需要限制了增长

工业阀门的成本以及安装、维护和维修的相关费用可能会对预算有限的项目或行业造成重大制约。工业阀门,尤其是大尺寸或特殊设计的阀门,前期成本可能很高。此外,定期维护和偶尔维修也是确保阀门最佳性能的必要条件。这些活动通常需要停机,这可能会中断生产并影响运营效率,尤其是在具有连续流程的行业中。与阀门维护和维修相关的成本以及由此产生的停机时间,可能会给努力平衡成本效益和不间断运营的行业带来挑战和财务限制。

- 复杂的应用程序限制了增长

复杂的应用对工业阀门行业构成了重大制约。某些工业过程涉及高压或高温环境、腐蚀性流体或磨蚀性介质。满足这些苛刻的条件通常需要使用专门设计用于承受如此恶劣的操作条件的阀门。阀门必须由耐用材料制成,采用先进的密封机制,并经过严格的测试以确保可靠性和使用寿命。

本工业阀门市场报告详细介绍了最新发展、贸易法规、进出口分析、生产分析、价值链优化、市场份额、国内和本地市场参与者的影响,分析了新兴收入领域的机会、市场法规的变化、战略市场增长分析、市场规模、类别市场增长、应用领域和主导地位、产品批准、产品发布、地域扩展、市场技术创新。如需了解有关工业阀门市场的更多信息,请联系 Data Bridge Market Research 获取分析师简报,我们的团队将帮助您做出明智的市场决策,实现市场增长。

原材料短缺和运输延误的影响和当前市场状况

Data Bridge Market Research 提供高水平的市场分析,并通过考虑原材料短缺和运输延误的影响和当前市场环境来提供信息。这意味着评估战略可能性、制定有效的行动计划并协助企业做出重要决策。

除了标准报告外,我们还提供从预测的运输延迟、按区域划分的分销商映射、商品分析、生产分析、价格映射趋势、采购、类别绩效分析、供应链风险管理解决方案、高级基准测试等角度对采购层面的深入分析,以及其他采购和战略支持服务。

经济放缓对产品定价和供应的预期影响

当经济活动放缓时,行业开始受到影响。DBMR 提供的市场洞察报告和情报服务考虑了经济衰退对产品定价和可获得性的预测影响。借助这些,我们的客户通常可以领先竞争对手一步,预测他们的销售额和收入,并估算他们的盈亏支出。

最新动态

- 2022 年,艾默生推出了 Crosby J 系列泄压阀产品线,旨在确保在背压下实现平衡操作,以提高性能并降低拥有成本。它们具有波纹管泄漏检测系统,可以远程检测阀门中的波纹管破裂并降低体积排放量。

- 2022 年,KSB SE & CO. KGaA 推出了一系列采用独特合金材料制成的增材制造/3D 打印隔膜阀。制药行业是新阀门设计的重点。

- 2022 年,总部位于芬兰的科技公司 Flowrox 的阀门和纸浆业务被全球领先的流量控制解决方案提供商 Neles 收购。Neles 希望通过此次收购增加其产品供应并扩大其在采矿和金属领域的影响力。

- 2022 年,航空航天、国防和能源市场的全球领导者 Meggitt PLS 被派克汉尼汾公司成功收购。工业阀门和控制系统是其提供的广泛技术和产品之一。

- 2020 年,美国环境保护署将年度能源之星合作伙伴奖颁发给了 Hayward Industries, Inc.,这是一家生产住宅和商业游泳池设备的公司。根据测试,Hayward 为游泳池提供了最节能的变速泵。该公司将从该奖项中受益,提高品牌价值和全球知名度。

欧洲工业阀门市场范围

工业阀门市场根据组件、类型、功能、材料、配件、尺寸、应用进行细分,这些细分市场之间的增长将帮助您分析行业中的微弱增长细分市场,并为用户提供有价值的市场概览和市场洞察,帮助他们做出确定核心市场应用的战略决策。

成分

- 执行器

- 阀体

- 其他的

- 定位器

- I/P 转换器

类型

- 闸阀

- 截止阀

- 球阀

- 蝶阀

- 隔膜阀

- 止回阀

- 旋塞阀

- 夹管阀

- 针阀

- 压力释放阀

- 安全阀

- 其他的

功能

- 开/关

- 控制

- 隔离

- 规定

- 安全泄压阀

- 特殊目的

- 不归还

材料

- 铁

- 延展性

- 铸铁

- 碳钢

- 合金

- 塑料

- 黄铜

- 青铜

- 铜

- 低温

- 铝

- 其他的

配件

- 液压过滤器

- 电源线

- 安装螺钉和螺栓

- 密封套件

- 防尘罩

- 其他的

尺寸

- 1 英寸至 6 英寸

- 6 英寸至 12 英寸

- 12 英寸至 24 英寸

- 24 英寸至 48 英寸

- 48英寸以上

应用

- 石油和天然气

- 建筑和施工

- 半导体

- 水和废物处理

- 化学

- 能源和公用事业

- 食品和饮料

- 制药

- 农业

- 海洋

- 汽车

- 金属和采矿

- 纸张和纸浆

- 其他的

- 纺织品

- 玻璃

工业阀门市场区域分析/见解

对工业阀门市场进行了分析,并按上述组件、类型、功能、材料、配件、尺寸和应用提供了市场规模的见解和趋势。

工业阀门市场报告涵盖的国家包括欧洲的德国、法国、英国、荷兰、瑞士、比利时、俄罗斯、意大利、西班牙、土耳其和欧洲其他地区

德国占据最大的市场份额,这得益于政府和市政当局正在进行的水和废水处理项目,以及该国在石油和天然气勘探活动上的支出不断增加。

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Competitive Landscape and Industrial Valves Market Share Analysis

The industrial valves market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to industrial valves market.

Some of the major players operating in the industrial valves market are:

- Emerson Electric Co. (U.S.)

- Flowserve Corporation (U.S.)

- Crane Company (U.S.)

- IMI (U.K.)

- Velan Inc. (Canada)

- KITZ Corporation (Japan)

- Neway valve (China)

- AVK Holding A/S (Denmark)

- Metso (Finland)

- Spirax Sarco Limited. (U.K.)

- Johnson Controls (Ireland)

- Powell Valves (U.S.)

- Curtiss-Wright. (U.S.)

- Mueller Co. LLC. (U.S.)

- Crane Co., CRANE ChemPharma & Energy Corp (U.S.)

- The Weir Group PLC (U.K.)

- Wärtsilä Finland)

- Bray International (U.S.)

- Dwyer Instruments LTD (U.S.)

- Watts (U.S.)

- Bonney Forge Corporation (U.S.)

- NIBCO Inc. (U.S.)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

研究方法

数据收集和基准年分析是使用具有大样本量的数据收集模块完成的。该阶段包括通过各种来源和策略获取市场信息或相关数据。它包括提前检查和规划从过去获得的所有数据。它同样包括检查不同信息源中出现的信息不一致。使用市场统计和连贯模型分析和估计市场数据。此外,市场份额分析和关键趋势分析是市场报告中的主要成功因素。要了解更多信息,请请求分析师致电或下拉您的询问。

DBMR 研究团队使用的关键研究方法是数据三角测量,其中包括数据挖掘、数据变量对市场影响的分析和主要(行业专家)验证。数据模型包括供应商定位网格、市场时间线分析、市场概览和指南、公司定位网格、专利分析、定价分析、公司市场份额分析、测量标准、全球与区域和供应商份额分析。要了解有关研究方法的更多信息,请向我们的行业专家咨询。

可定制

Data Bridge Market Research 是高级形成性研究领域的领导者。我们为向现有和新客户提供符合其目标的数据和分析而感到自豪。报告可定制,包括目标品牌的价格趋势分析、了解其他国家的市场(索取国家列表)、临床试验结果数据、文献综述、翻新市场和产品基础分析。目标竞争对手的市场分析可以从基于技术的分析到市场组合策略进行分析。我们可以按照您所需的格式和数据样式添加您需要的任意数量的竞争对手数据。我们的分析师团队还可以为您提供原始 Excel 文件数据透视表(事实手册)中的数据,或者可以帮助您根据报告中的数据集创建演示文稿。