Introduction

In a world characterized by rapid innovation and evolving consumer expectations, pursuing excellence in product design and manufacturing is more paramount than ever. The ability to create vibrant, long-lasting colors is a critical component of this pursuit, transcending industry boundaries and influencing our daily lives. However, traditional dyes, while offering a broad spectrum of varieties, are not without their limitations. Challenges such as poor water solubility, color instability, and environmental concerns have compelled us to seek innovative solutions.

This whitepaper is dedicated to the exploration and introduction of a groundbreaking technological innovation: water-soluble lipophilic dyes. We recognize the significance of addressing the shortcomings of traditional dyes and the transformative potential of these novel dyes across diverse industries.

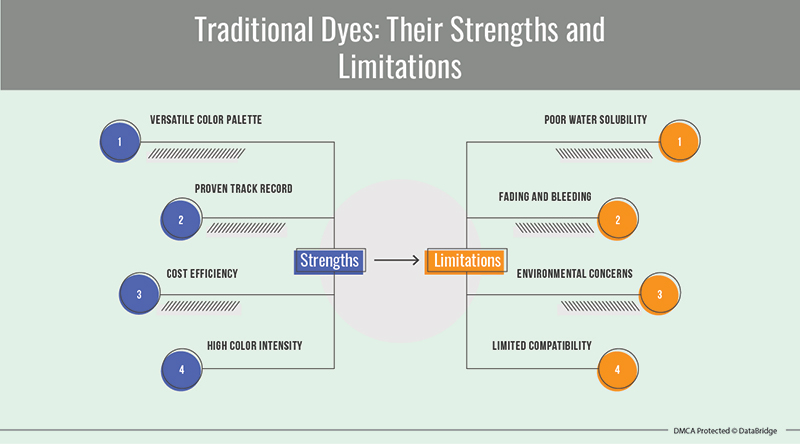

Traditional Dyes: Their Strengths and Limitations

Traditional dyes, deeply entrenched in the history of coloration across various industries, come with distinct advantages and notable limitations. Understanding these aspects is crucial for informed decision-making in coloration processes.

Strengths

- Versatile Color Palette: Traditional dyes offer a vast and diverse spectrum of colors, making them a valuable asset for businesses seeking to differentiate their products. The extensive color options enable manufacturers to create bespoke designs that cater to consumer preferences and market trends.

- Proven Track Record: These dyes have an extensive track record of successful application in numerous industries, including textiles, plastics, and printing. Their established reliability and consistent performance have earned them the trust of manufacturers over the years.

- Cost Efficiency: Traditional dyes are often cost-effective, which can be advantageous for businesses that manage production expenses. The accessibility of these dyes helps keep the overall manufacturing costs in check, particularly for businesses with budget constraints.

- High Color Intensity: Traditional dyes are known for their ability to produce vibrant and intense colors. This feature enhances the aesthetic appeal of products, creating visually striking and eye-catching end results.

Limitations

- Poor Water Solubility: A prominent limitation of traditional dyes is their limited solubility in water. This characteristic can present challenges when these dyes are used in water-based processes, as it may lead to difficulties in achieving even color distribution and can result in reduced process efficiency.

- Fading and Bleeding: Traditional dyes are susceptible to fading when exposed to environmental factors like sunlight or harsh conditions. Additionally, they may bleed or transfer color onto adjacent surfaces or materials, compromising the quality and longevity of colored products.

- Environmental Concerns: The production and disposal of traditional dyes can raise environmental concerns. These dyes often involve the use of chemicals that are potentially hazardous, and the release of pollutants during the production process can have adverse environmental impacts.

- Limited Compatibility: Traditional dyes may not be universally compatible with all materials or manufacturing processes. This limits their versatility in specific industries and applications, requiring businesses to seek alternative solutions for materials where traditional dyes are not suitable.

In light of these strengths and limitations, businesses must conduct a thorough analysis of their unique coloration needs and the specific requirements of their manufacturing processes. This evaluation is essential for making informed decisions and ensuring that the chosen coloration method aligns with the desired color quality, cost-effectiveness, and sustainability goals within their respective industries.

Water-Soluble Lipophilic Dyes: A Game-Changing Innovation

Water-soluble lipophilic dyes represent a revolutionary breakthrough in the field of coloration, offering a unique and innovative solution to the inherent limitations of traditional dyes. This section provides an in-depth exploration of these groundbreaking dyes and why they are considered a game-changing innovation.

- Fundamental Chemistry and Properties: At their core, water-soluble lipophilic dyes are characterized by their ability to simultaneously dissolve in both water and lipids (oils and fats). This property is achieved through their molecular structure, which combines hydrophilic (water-attracting) and lipophilic (fat-attracting) components. This dual solubility is achieved by careful chemical engineering and design, allowing these dyes to thrive in both aqueous and non-aqueous environments.

- Versatility in Application: The unique property of dual solubility makes water-soluble lipophilic dyes incredibly versatile. They can be effectively used in various industries, such as textiles, cosmetics, food, and pharmaceuticals. In textiles, these dyes enable the production of fabrics with vibrant, long-lasting colors. In cosmetics, they enhance the stability and intensity of pigments, ensuring makeup products maintain their visual appeal throughout the day. In the food industry, they add enticing colors to consumable goods without compromising safety or taste.

- Enhanced Color Stability: Water-soluble lipophilic dyes offer significantly improved color stability when compared to traditional dyes. Their resistance to fading, even when exposed to environmental factors like sunlight, moisture, or heat, ensures that products maintain their intended appearance over an extended period. This stability is particularly crucial for industries where colorfastness is paramount.

- Improved Solubility: Overcoming the key limitation of traditional dyes, water-soluble lipophilic dyes exhibit excellent solubility in both water and oil-based solutions. This makes them highly adaptable to a wide range of manufacturing processes, ensuring even color distribution and efficiency, regardless of whether the process is water-based or oil-based.

- Resistance to Bleeding and Washout: These innovative dyes also demonstrate a notable resistance to bleeding and washout, ensuring that colors remain vibrant and do not run or transfer onto other surfaces or materials. This attribute is particularly significant in industries where color quality and durability are essential.

- Sustainability and Environmental Benefits: Water-soluble lipophilic dyes have the potential to offer environmentally friendly solutions. Their chemistry often involves less harmful substances and reduced environmental impact compared to certain traditional dyes. This aligns with the growing global emphasis on sustainability and responsible manufacturing practices.

- Pioneering Technology: Water-soluble lipophilic dyes are at the forefront of innovation, driving the evolution of coloration processes. Their ability to address longstanding challenges and provide a superior alternative to traditional dyes positions them as a pioneering technology, poised to reshape the industry's landscape.

In summary, water-soluble lipophilic dyes represent a game-changing innovation with their unparalleled properties, including dual solubility, color stability, improved solubility, resistance to bleeding, and environmental benefits. These dyes offer a versatile, sustainable, and technologically advanced solution for industries seeking to elevate the quality, longevity, and environmental responsibility of their colored products. Their adoption is expected to continue reshaping the way coloration is approached across various sectors.

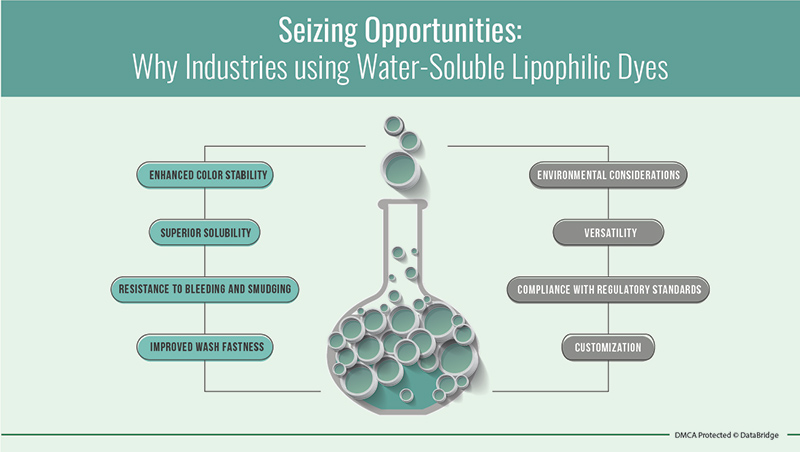

Seizing Opportunities: Why Industries are using Water-Soluble Lipophilic Dyes

Water-soluble lipophilic dyes represent a groundbreaking advancement in the field of coloration, offering several distinct advantages over traditional dyes. Industries prefer water-soluble lipophilic dyes for specific applications because these dyes offer a unique set of properties that make them advantageous. The preference for water-soluble lipophilic dyes can be attributed to the following reasons:

- Enhanced Color Stability: These dyes exhibit remarkable color stability, ensuring that products retain their vibrant hues over time. Whether used in textiles, cosmetics, or food products, the colors do not easily fade or degrade, even when exposed to challenging environmental conditions, thus extending the lifespan of colored items.

- Superior Solubility: The unique feature of water-soluble lipophilic dyes is their dual solubility, allowing them to dissolve effectively in both water and lipophilic substances, such as oils and fats. This characteristic provides versatility, enabling their use in various applications. Businesses can seamlessly integrate these dyes into aqueous and non-aqueous processes, expanding their utility.

- Resistance to Bleeding and Smudging: In applications where precise color boundaries are essential, these dyes shine. They are known for resisting bleeding and smudging, even under challenging conditions. This quality is precious in textiles and cosmetics, where well-defined and long-lasting colors are crucial.

- Improved Wash Fastness: Water-soluble lipophilic dyes have transformed the textile industry by offering wash-fast fabrics. Clothes and textiles colored with these dyes maintain their colors even after multiple wash cycles, enhancing the durability of garments and reducing the environmental impact of premature color fading and disposal.

- Environmental Considerations: These dyes are recognized for their eco-friendliness. They can be formulated with fewer or no hazardous chemicals, making them a more sustainable choice compared to some traditional dyes. As environmental regulations become more stringent and consumers prioritize eco-friendly products, these dyes provide a significant advantage.

- Versatility: The adaptability of these dyes across multiple industries is one of their standout features. From textiles to cosmetics, food, and pharmaceuticals, they consistently perform well in diverse applications, making them a versatile and practical choice for businesses.

- Compliance with Regulatory Standards: Water-soluble lipophilic dyes can be tailored to meet stringent regulatory requirements. This ensures that products colored with these dyes adhere to safety and quality standards in different regions. In industries such as cosmetics and food, where safety and quality are paramount, this advantage is indispensable.

- Customization: These dyes enable a high degree of color customization. Manufacturers can precisely match colors to meet their customers' specific needs and preferences. This flexibility allows businesses to create unique and appealing products.

The advantages of water-soluble lipophilic dyes extend far beyond traditional coloration methods. They enhance color performance and address environmental concerns and regulatory requirements. This innovative technology empowers businesses to produce more visually appealing, longer-lasting products that align with evolving sustainability goals, thus reshaping the landscape of coloration across various industries.

Transforming Sectors: Intriguing Applications of Water-Soluble Lipophilic Dyes

Water-soluble lipophilic dyes find versatile applications across various industries. In the textile sector, they are used to create colorfast fabrics, ensuring that clothing retains its vibrant colors even after multiple washes. The cosmetics industry employs these dyes in products lipsticks and eyeshadows, ensuring makeup retains its color vibrancy throughout the day. In the food industry, they provide long-lasting, vibrant colors to a range of food products, from confectionery to beverages. For pharmaceuticals, they aid in medication identification, ensuring patients and healthcare professionals can differentiate various drugs. These dyes are also instrumental in the automotive industry, providing UV-resistant and durable colors for both vehicle interiors and exteriors and leather and upholstery materials. In the packaging industry, they contribute to branding and packaging design, helping maintain the visual appeal of product packaging and labels. Furthermore, they are vital in 3D printing for achieving colorful and detailed 3D printed objects. Finally, artists and craft enthusiasts find these dyes useful for a wide range of creative projects, benefiting from their vivid colors and long-lasting qualities. These diverse applications highlight the adaptability and potential of water-soluble lipophilic dyes in enhancing the visual appeal, durability, and functionality of products and materials across multiple sectors.

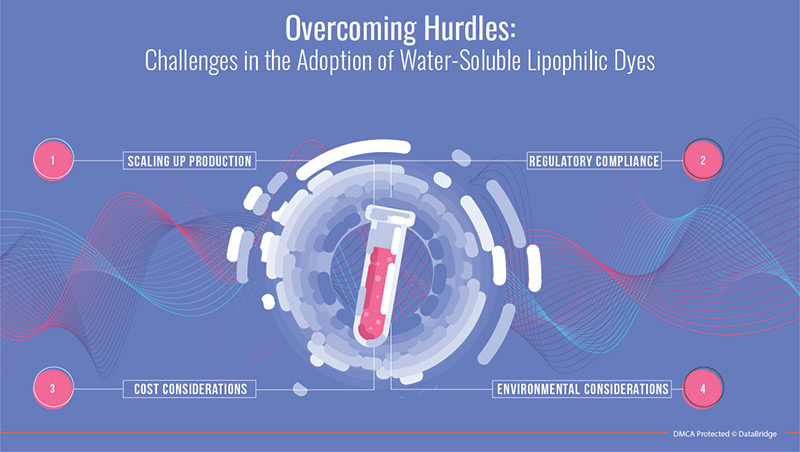

Overcoming Hurdles: Challenges in the Adoption of Water-Soluble Lipophilic Dyes

Water-soluble lipophilic dyes represent a promising innovation in coloration technology, offering numerous advantages as outlined in previous sections. However, like any new technology, their adoption and continued development come with challenges and uncertainties. In this section, we will explore the challenges that researchers and industries face in adopting water-soluble lipophilic dyes and discuss the future prospects and potential advancements in this field.

-

Scaling Up Production: One of the immediate challenges is scaling up the production of water-soluble lipophilic dyes to meet the demands of various industries. Achieving large-scale production while maintaining product quality and consistency is complex, often requiring significant investments in manufacturing infrastructure and processes.

Scaling up production can be complex due to several reasons:

- Quality Assurance: Maintaining product quality and consistency at a larger scale is a paramount concern. Any variations in color or quality can result in rejected batches or customer dissatisfaction

- Equipment and Infrastructure: To produce dyes on a larger scale, manufacturers may need to invest in additional equipment, facilities, and manufacturing processes. This includes scaling up chemical reactors, increasing storage capacity, and enhancing quality control measures

- Supply Chain Management: Expanding production often necessitates reevaluating the entire supply chain, from sourcing raw materials to distribution. Ensuring a consistent and reliable supply of materials is vital for uninterrupted production

- Workforce and Expertise: Scaling up production might require a larger, more specialized workforce. Hiring and training employees, particularly those experienced in handling larger-scale manufacturing, can be challenging

- Cost Management: As production scales up, costs can also rise. Finding ways to balance increased expenses with competitive pricing is a critical concern for manufacturers

Some of the Examples in Industries:

-

Textile Industry: As more textile manufacturers adopt water-soluble lipophilic dyes for coloration, the need for larger quantities increases. Scaling up production is essential to meet the demands of clothing brands, home furnishing companies, and industrial textile manufacturers

To get more insights into the market regarding the market growth, please visit the link mentioned below: https://www.databridgemarketresearch.com/reports/global-textile-dyes-market

As per our market analysis, Global Cosmetic Dyes Market was valued at USD 441.80 million in 2021 and is expected to reach USD 662.76 million by 2029, registering a CAGR of 5.20% during the forecast period of 2022-2029.

To get more insights into this, please visit our below mentioned link: https://www.databridgemarketresearch.com/reports/global-cosmetic-dyes-market

- Food Industry: Bakeries and food producers using these dyes for vibrant food coloring face the challenge of scaling up production to cater to a broader market. It requires them to adapt their manufacturing processes and facilities to accommodate the increased demand

- Pharmaceuticals: Pharmaceutical companies use water-soluble lipophilic dyes for coloring capsules, tablets, and syrups. As they expand their product lines or reach new markets, they must scale up dye production to ensure a consistent supply of colored medications

Overall, scaling up production is a common challenge when a new technology or product gains popularity. It requires careful planning, investment, and management to ensure that product quality and consistency are maintained while meeting the rising demands of various industries.

- Regulatory compliance: The process of ensuring that water-soluble lipophilic dyes adhere to the strict regulations and safety standards set by various authorities and organizations. Compliance is essential to guarantee the safety and quality of products and to prevent any potential harm to consumers and the environment. However, navigating the complex regulatory landscape can be a significant challenge due to the varying requirements in different industries and regions. Different industries and geographic regions often have specific and stringent regulatory standards when it comes to the use of dyes in their products. These standards may encompass factors such as permissible ingredients, safety levels, labeling, and documentation. Regulations can vary widely from one industry to another. For example, the standards for using these dyes in textiles may differ significantly from the regulations for cosmetics, food, or pharmaceuticals. Understanding and adhering to these industry-specific requirements can be a complex and time-consuming task. Regulatory requirements are not static; they can change over time as new scientific evidence emerges or as societal values shift. Keeping up with evolving regulations is a continuous effort for manufacturers. Compliance with textile industry regulations ensures that dyed fabrics are safe and do not pose health risks, such as skin irritation or allergies. Manufacturers must demonstrate that the dyes used meet the textile industry's standards for colorfastness, durability, and safety. In the cosmetics sector, compliance is crucial to ensure that makeup products containing these dyes are safe for use on the skin and around the eyes. This may involve extensive testing to prove that the dyes do not cause skin sensitization or eye irritation.

In conclusion, ensuring regulatory compliance for water-soluble lipophilic dyes is a critical step in their adoption in various industries. Manufacturers must navigate the complexities of different industry and regional regulations, conduct extensive testing, and maintain comprehensive documentation to meet stringent safety and quality standards. This process is vital to assure consumers and regulatory authorities that products containing these dyes are safe and compliant with established standards.

- Cost Considerations: While water-soluble lipophilic dyes offer numerous advantages, such as enhanced color stability and versatility, their production costs can sometimes be higher compared to traditional dyes. Here's a more detailed exploration of this challenge:

- Ingredients and Production Complexity: Water-soluble lipophilic dyes often involve more intricate chemical processes and specialized raw materials, which can increase production costs. Traditional dyes, in some cases, rely on simpler and more readily available compounds

- Research and Development Costs: Developing and perfecting the chemistry of these dyes can require substantial investments in research and development. These costs are typically reflected in the final product price

- Quality Assurance: Maintaining consistent quality and color stability with water-soluble lipophilic dyes may require more stringent quality control measures, which can contribute to higher production costs

- Economies of Scale: Achieving cost competitiveness can be challenging, particularly for smaller manufacturers. Large-scale production can offer economies of scale, driving down production costs, but smaller producers may find it harder to match these cost advantages

- Balancing Cost and Quality: Businesses must strike a balance between the benefits of these dyes and their overall production costs. Decisions about cost-effectiveness often involve trade-offs between quality, performance, and pricing

- Environmental Considerations: While water-soluble lipophilic dyes offer potential environmental benefits, their overall sustainability must be thoroughly assessed. The entire lifecycle, from production to disposal, must be evaluated to determine their eco-friendliness fully. Here's a more comprehensive explanation:

- Raw Material Sourcing: The environmental impact begins with sourcing raw materials for the dyes. Sustainable and responsible sourcing is essential to minimize the ecological footprint

- Production Processes: Assessing the environmental impact of the manufacturing process is critical. This includes evaluating energy consumption, emissions, waste generation, and the use of hazardous chemicals

- Product Use and Disposal: Consideration should also be given to how these dyes perform during the use phase and their eventual disposal. For instance, do they pose any risks when released into the environment or when products containing these dyes reach the end of their lifecycle?

- Eco-Friendly Alternatives: Evaluating whether these dyes are genuinely more eco-friendly than traditional alternatives is essential. It's important to verify that the environmental benefits outweigh any potential drawbacks

- Regulatory Compliance: Complying with environmental regulations and standards is crucial. Businesses must ensure that their dye production and use align with existing environmental protection laws

In conclusion, cost considerations, compatibility with existing processes, and environmental considerations are significant challenges associated with adopting water-soluble lipophilic dyes. Addressing these challenges requires a careful balance of cost-effectiveness, process optimization, and environmental responsibility. Successfully navigating these challenges is essential for businesses looking to harness the benefits of these innovative dyes while ensuring long-term sustainability and competitiveness.

Casting a Vibrant Future: The Evolving Landscape of Water-Soluble Lipophilic Dyes

In a rapidly changing world, the future prospects of water-soluble lipophilic dyes are filled with promise and potential. These innovative dyes have revolutionized coloration in various industries, and their journey is far from over. As we look ahead, one can anticipate a future marked by continuous advancements, widespread adoption, and a heightened focus on sustainability.

- Improved Formulations: The development of advanced dye formulations is expected to continue. This involves enhancing the chemistry of these dyes to address various challenges, such as improving solubility (how easily they dissolve in liquids), stability (how well they retain color over time), and versatility (their ability to work in different applications). Innovations in dye chemistry could lead to even better performance and expanded color options. For instance, dyes might become even more vibrant, stable, and compatible with an even wider range of products.

- Wider Adoption: As industries witness the benefits of water-soluble lipophilic dyes, their adoption is likely to grow. Sectors such as automotive, packaging, and 3D printing could find innovative applications for these dyes. For instance, these dyes could be used in the automotive industry for more durable and fade-resistant car interiors. In packaging, they might enhance the visual appeal of product packaging. The versatility of these dyes opens doors for new and creative uses.

- Sustainability Focus: With increasing environmental concerns, there is a potential for water-soluble lipophilic dyes to become a preferred choice due to their eco-friendly attributes. Businesses and consumers are increasingly looking for sustainable options. These dyes, known for their eco-friendliness, may see greater adoption as companies prioritize sustainability. This could be particularly relevant in industries where sustainability is a significant selling point, such as textiles and cosmetics.

- Customization and Precision: Future developments are likely to enable even more precise color matching and customization. This means that businesses can create colors that perfectly meet specific and niche consumer preferences. For instance, in the cosmetics industry, this could lead to makeup products matching an individual's skin tone or desired color. Such customization enhances the appeal of products and meets diverse consumer needs.

- International Standards: Establishing international standards for producing and applying these dyes may simplify regulatory compliance and promote their global adoption. Having consistent and globally recognized standards can streamline the process for manufacturers and help ensure that these dyes meet the same safety and quality criteria worldwide. This makes it easier for businesses to produce and trade products containing these dyes internationally.

- Research and Development: Ongoing research into novel dye chemistries and improved production methods is expected to result in breakthroughs in coloration technology. These breakthroughs may lead to even more efficient, cost-effective, and versatile dyes. For instance, research might uncover new compounds or processes that reduce production costs while improving performance. This continuous R&D effort drives innovation and stays competitive in the coloration industry.

In summary, the future of water-soluble lipophilic dyes holds great promise with expectations of improved formulations, wider adoption across industries, a growing focus on sustainability, enhanced customization and precision, the establishment of international standards, and ongoing research and development. These developments are likely to shape a dynamic and innovative landscape for coloration technology as businesses and researchers work together to overcome challenges and harness the full potential of these innovative dyes.

Conclusion

In conclusion, water-soluble lipophilic dyes have emerged as a transformative force in coloration. Their remarkable versatility, stability, and sustainability advantages have propelled them to the forefront of diverse industries, from textiles to cosmetics and beyond. While challenges such as scaling up production and ensuring regulatory compliance exist, the future prospects are promising. We anticipate more precise formulations, wider adoption, and a heightened focus on eco-friendly practices. The journey of water-soluble lipophilic dyes is a testament to human ingenuity, addressing the evolving demands of a rapidly changing world and illuminating the path to a more colorful, enduring, and sustainable future for businesses and consumers alike.