Global Maintenance Repair And Operations Mro Market

Размер рынка в млрд долларов США

CAGR :

%

USD

2,138.12 Billion

USD

3,372.54 Billion

2024

2032

USD

2,138.12 Billion

USD

3,372.54 Billion

2024

2032

| 2025 –2032 | |

| USD 2,138.12 Billion | |

| USD 3,372.54 Billion | |

|

|

|

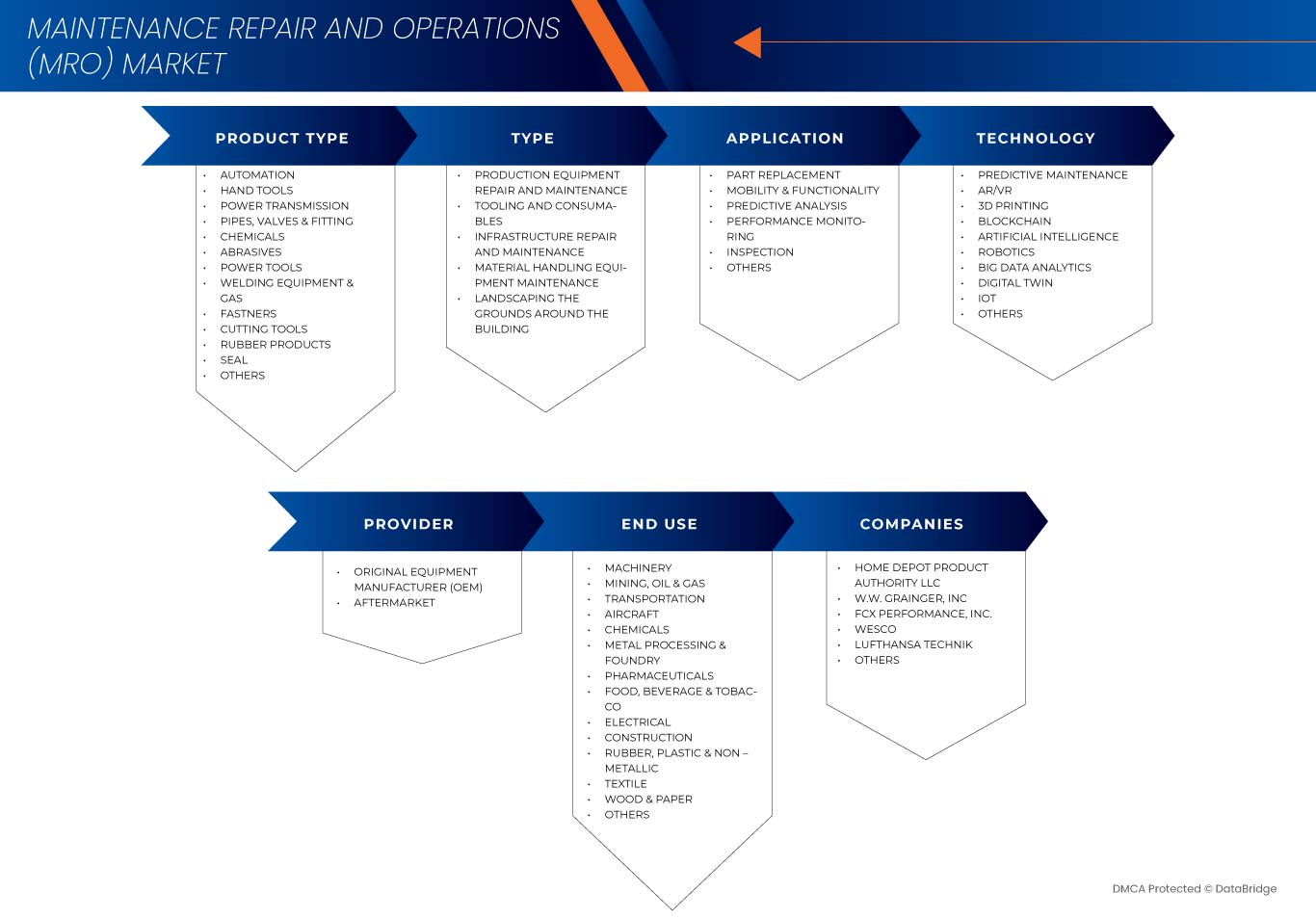

Глобальная сегментация рынка технического обслуживания, ремонта и эксплуатации (MRO) по типу продукта (автоматизация, ручные инструменты, передача энергии, трубы, клапаны и фитинги, химикаты, абразивы, электроинструменты , сварочное оборудование и газ, крепеж, режущие инструменты, резиновые изделия, уплотнения и другие), тип (ремонт и обслуживание производственного оборудования, инструменты и расходные материалы, ремонт и обслуживание инфраструктуры, обслуживание подъемно-транспортного оборудования и благоустройство территории вокруг здания), применение (замена деталей, мобильность и функциональность, предиктивный анализ, мониторинг производительности, инспекция и другие), технология (предиктивное обслуживание, дополненная и виртуальная реальность, 3D-печатьблокчейнискусственный интеллект , робототехника, аналитика больших данных, цифровой двойник, Интернет вещей и другие), поставщики (производитель оригинального оборудования (OEM) и вторичный рынок), конечное использование (машиностроение, горнодобывающая промышленность, нефть и газ, транспорт, самолеты, химикаты, обработка металлов и литейное производство, Фармацевтика, продукты питания, напитки и табак, электротехника, строительство, резина, пластик и неметаллические материалы, текстиль, деревообработка и бумага и другие) – тенденции и прогноз развития отрасли до 2032 года

Анализ рынка технического обслуживания, ремонта и эксплуатации (MRO)

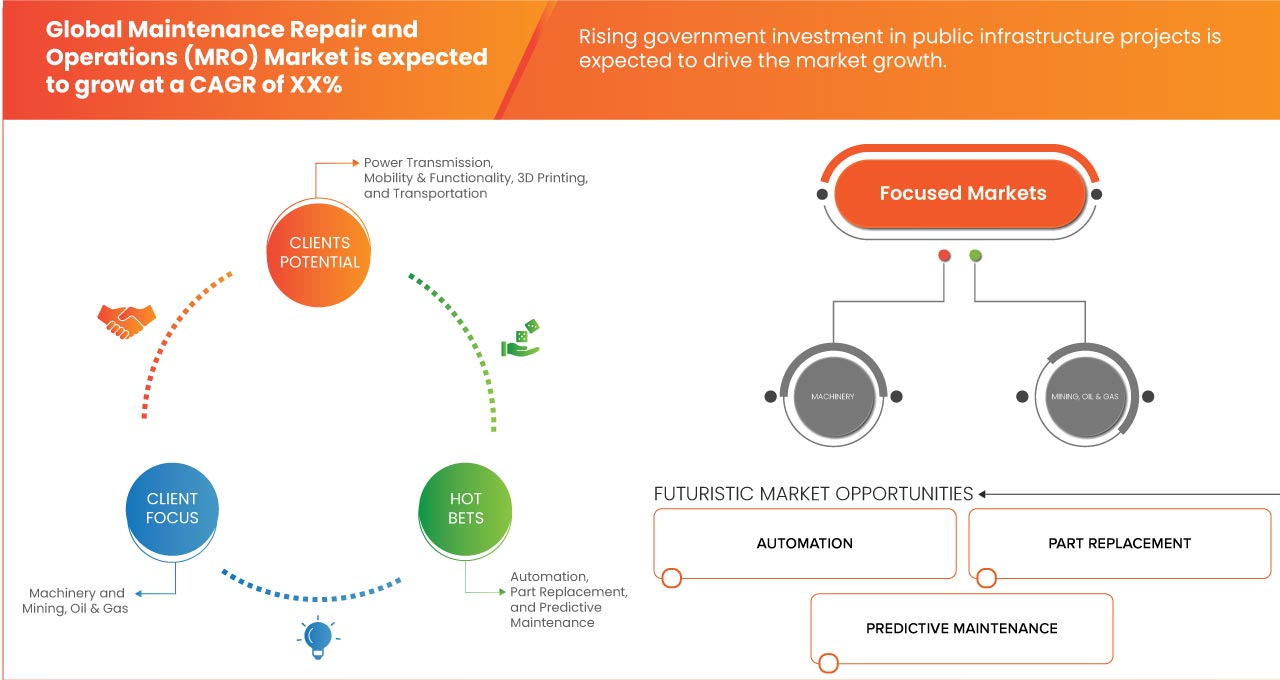

Рынок MRO охватывает услуги и продукты, используемые для обслуживания, ремонта и эксплуатации машин, инфраструктуры и систем в таких отраслях, как производство, аэрокосмическая промышленность, энергетика и строительство. Рост обусловлен ростом промышленной автоматизации, растущей потребностью в безотказной работе оборудования и интеграцией передовых технологий, таких как IoT и предиктивная аналитика для обслуживания. Основные тенденции включают переход к аутсорсингу услуг MRO, принятие цифровых платформ для управления запасами и закупками и акцент на устойчивость в цепочках поставок. Северная Америка и Европа лидируют на рынке, в то время как Азиатско-Тихоокеанский регион быстро растет из-за индустриализации. Проблемы включают колебания цен на сырье и зависимость от квалифицированной рабочей силы для высокоточного ремонта.

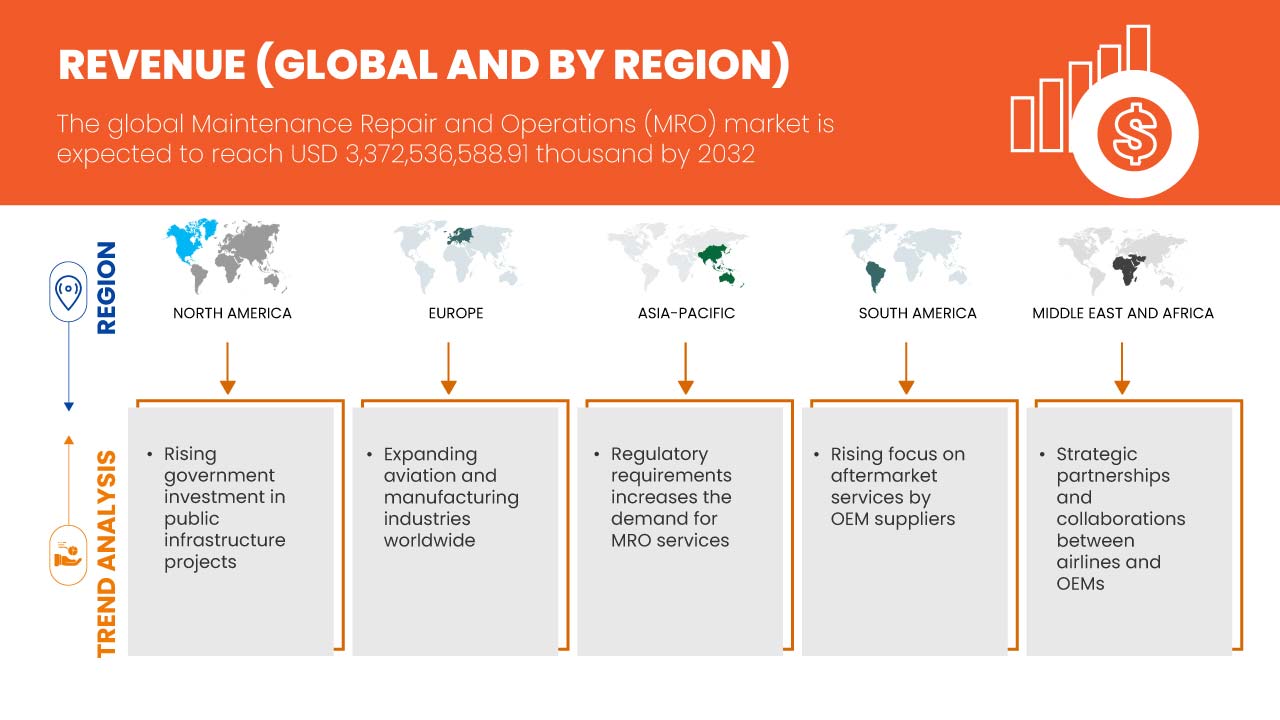

Размер рынка технического обслуживания, ремонта и эксплуатации (MRO)

Ожидается, что глобальный рынок технического обслуживания, ремонта и эксплуатации (MRO) достигнет 3 372,54 млрд долларов США к 2032 году с 2 138,12 млрд долларов США в 2024 году, увеличившись с среднегодовым темпом роста на 6,19% в прогнозируемый период с 2025 по 2032 год. Помимо информации о рыночных сценариях, таких как рыночная стоимость, темпы роста, сегментация, географический охват и основные игроки, рыночные отчеты, подготовленные Data Bridge Market Research, также включают анализ импорта и экспорта, обзор производственных мощностей, анализ потребления продукции, анализ ценовых тенденций, сценарий изменения климата, анализ цепочки поставок, анализ цепочки создания стоимости, обзор сырья/расходных материалов, критерии выбора поставщиков, анализ PESTLE, анализ Портера и нормативную базу.

Тенденции рынка технического обслуживания, ремонта и эксплуатации (MRO)

«Расширение авиационной и производственной отраслей по всему миру»

Расширение авиационной и производственной отраслей во всем мире является ключевой тенденцией для роста рынка MRO. Поскольку спрос на авиаперевозки и промышленное производство продолжает расти, потребность в регулярном техническом обслуживании, ремонте и модернизации самолетов и производственного оборудования становится все более важной. Авиационный сектор, в частности, требует постоянных услуг MRO для обеспечения безопасности, эффективности и долговечности парка воздушных судов. Аналогичным образом, обрабатывающая промышленность полагается на решения MRO для обслуживания и оптимизации машин и оборудования, предотвращая дорогостоящие простои. Поскольку эти отрасли расширяются во всем мире, рынок MRO будет демонстрировать значительный рост, создавая возможности для предприятий по предоставлению основных услуг, технологий и деталей для поддержки этого спроса.

Отчет о сфере применения и сегментации рынка технического обслуживания и ремонта (ТОиР)

|

Атрибуты |

Техническое обслуживание, ремонт и эксплуатация (MRO) Ключевые аспекты рынка |

|

Охваченные сегменты |

|

|

Страны, охваченные |

США, Канада, Мексика, Германия, Великобритания, Франция, Италия, Испания, Россия, Турция, Нидерланды, Норвегия, Финляндия, Дания, Польша, Швейцария, Бельгия, остальная Европа, Китай, Япония, Индия, Южная Корея, Австралия, Индонезия, Таиланд, Малайзия, Сингапур, Филиппины, Новая Зеландия, остальная часть Азиатско-Тихоокеанского региона, Бразилия, Аргентина, остальная часть Южной Америки, ОАЭ, Саудовская Аравия, Южная Африка, Египет, Израиль и остальная часть Ближнего Востока и Африки |

|

Ключевые игроки рынка |

Home Depot Product Authority LLC (США), WW Grainger, Inc. (США), FCX Performance, Inc. (США), Wesco (США), Lufthansa Technik (Дания), ST Engineering (Сингапур), Airgas, Inc. (США), Textron Aviation Inc. (США), GKN AEROSPACE (Великобритания), Iberia (Испания), Sonepar (Франция), AAR (США), Wajax Limited (США), Sepang Aircraft Engineering Sdn Bhd. (Малайзия), SR Technics (Швейцария), Hisco – TestEquity LLC (США), MJETS (Таиланд), TAP (Португалия) и United Airlines, Inc. (США) и другие |

|

Возможности рынка |

|

|

Информационные наборы данных с добавленной стоимостью |

Помимо информации о рыночных сценариях, таких как рыночная стоимость, темпы роста, сегментация, географический охват и основные игроки, рыночные отчеты, подготовленные Data Bridge Market Research, также включают анализ импорта и экспорта, обзор производственных мощностей, анализ потребления продукции, анализ ценовых тенденций, сценарий изменения климата, анализ цепочки поставок, анализ цепочки создания стоимости, обзор сырья/расходных материалов, критерии выбора поставщиков, анализ PESTLE, анализ Портера и нормативную базу. |

Определение рынка технического обслуживания, ремонта и эксплуатации (MRO)

Техническое обслуживание, ремонт и эксплуатация (MRO) относится к видам деятельности, процессам и ресурсам, необходимым для обеспечения функциональности, безопасности и эффективности оборудования, машин и инфраструктуры. MRO охватывает широкий спектр услуг, включая плановое техническое обслуживание, ремонт оборудования, замену запасных частей и эксплуатационную поддержку, направленную на минимизацию простоев и продление срока службы активов. Он широко используется в различных отраслях, таких как производство, авиация, автомобилестроение, энергетика, здравоохранение и управление объектами. Гарантируя надежную работу оборудования и систем, MRO играет важную роль в поддержании производительности, безопасности и соответствия нормативным требованиям.

Динамика рынка технического обслуживания, ремонта и эксплуатации (MRO)

Драйверы

- Рост государственных инвестиций в проекты общественной инфраструктуры

Рост государственных инвестиций в проекты общественной инфраструктуры существенно стимулирует рынок технического обслуживания, ремонта и эксплуатации (MRO), создавая повышенный спрос на содержание, ремонт и оптимизацию необходимой инфраструктуры. Инвестиции в дороги, мосты, аэропорты, электростанции и водные объекты требуют надежных решений MRO для обеспечения эксплуатационной эффективности, сокращения простоев и продления срока службы активов. Эта тенденция особенно ярко выражена в развивающихся экономиках, где развитие инфраструктуры ускоряется, наряду с развитыми странами, сосредоточенными на модернизации устаревших объектов. Поскольку правительства отдают приоритет устойчивой и устойчивой инфраструктуре, роль передовых технологий и услуг MRO становится ключевой в достижении долгосрочных целей проекта.

Например,

Согласно блогу, опубликованному Советом по международным отношениям, в сентябре 2023 года государственные инвестиции в проекты общественной инфраструктуры по всей территории США достигли значительных уровней, составив миллиарды долларов по ключевым секторам. Дороги и мосты лидируют по объему инвестиций в размере 110 миллиардов долларов США, за ними следуют железнодорожные системы (66 миллиардов долларов США), по 65 миллиардов долларов США на модернизацию электросетей и расширение широкополосного интернета и 55 миллиардов долларов США на улучшение систем питьевой воды. Дополнительные ассигнования включают 50 миллиардов долларов США на меры по повышению устойчивости, 39 миллиардов долларов США на общественный транспорт, 25 миллиардов долларов США на улучшение аэропортов, 21 миллиард долларов США на инициативы по сокращению загрязнения, 17 миллиардов долларов США на порты и водные пути и 8 миллиардов долларов США на инфраструктуру зарядки электромобилей. Эти существенные инвестиции стимулируют рынок технического обслуживания, ремонта и эксплуатации (MRO), создавая повышенный спрос на специализированные услуги и решения по техническому обслуживанию для обеспечения эффективности, безопасности и долговечности этих критически важных инфраструктурных проектов.

- Растущее внимание к послепродажному обслуживанию со стороны поставщиков OEM

Растущее внимание к послепродажному обслуживанию со стороны поставщиков OEM является ключевым фактором для рынка технического обслуживания, ремонта и эксплуатации (MRO). Поскольку производители OEM все больше осознают долгосрочную ценность предложения комплексных послепродажных решений, включая техническое обслуживание, ремонт и запасные части, они расширяют свои предложения услуг, чтобы гарантировать клиентам постоянную поддержку на протяжении всего жизненного цикла продукта. Этот сдвиг в сторону послепродажного обслуживания не только укрепляет лояльность клиентов, но и создает устойчивый спрос на услуги MRO, обеспечивая постоянный поток доходов как для производителей OEM, так и для поставщиков MRO, обеспечивая при этом оптимальную производительность и долговечность оборудования и машин.

Например,

В ноябре 2022 года, согласно блогу, опубликованному Informa PLC, OEM-производители были признаны критически важными для поддержки послепродажного обслуживания усовершенствованной воздушной мобильности (AAM). По мере того, как технологии AAM, такие как eVTOL, набирают обороты, OEM-производители будут играть ключевую роль в техническом обслуживании и поддержке на ранних этапах. Ожидается, что eVTOL будут иметь более низкие затраты на техническое обслуживание по сравнению с традиционными самолетами благодаря передовой конструкции и технологиям. OEM-производители, скорее всего, будут доминировать на послепродажном рынке благодаря своей технической экспертизе и контролю над интеллектуальной собственностью, что делает партнерство с OEM-производителями AAM необходимым для поставщиков услуг MRO

Возможности

- Стратегическое партнерство и сотрудничество между авиакомпаниями и OEMS

Стратегическое партнерство и сотрудничество между авиакомпаниями и OEM-производителями представляют значительные возможности на рынке MRO, способствуя укреплению отношений и повышению операционной эффективности. Работая вместе, авиакомпании и OEM-производители могут оптимизировать процессы технического обслуживания, сократить время простоя и улучшить общее управление жизненным циклом воздушных судов. Такое сотрудничество также может привести к разработке новых технологий и решений по техническому обслуживанию, адаптированных к конкретным потребностям авиакомпаний. Кроме того, общие знания и ресурсы позволяют применять экономически эффективные и инновационные подходы к техническому обслуживанию, что может повысить надежность и производительность парка. Авиакомпании получают выгоду от индивидуальной поддержки, в то время как OEM-производители получают более глубокое понимание эксплуатационных проблем, с которыми сталкиваются их клиенты. Такая синергия помогает укрепить долгосрочную устойчивость обеих сторон. В конечном итоге, такое сотрудничество способствует росту более эффективной и устойчивой экосистемы MRO.

Например,

В феврале 2024 года Safran подписала трехлетнее эксклюзивное соглашение о техническом обслуживании с Malaysia Airlines Berhad (MAB) на авиасалоне в Сингапуре. Контракт охватывает ремонт и техническое обслуживание электропроводки на более чем 40 самолетах Boeing 737 компании MAB, оснащенных двигателями CFM56-7B. Это соглашение повысит операционную эффективность и конкурентоспособность MAB за счет предоставления услуг по ремонту OEM, сокращения сроков выполнения работ, расширенного гарантийного покрытия и поддержки обмена. Постоянная поддержка Safran через региональных представителей в Сингапуре подчеркивает их приверженность инновациям и долгосрочному улучшению обслуживания. Это партнерство будет способствовать повышению надежности и производительности парка MAB, обеспечивая безопасность и удовлетворенность пассажиров и экипажа.

- Интеграция передовых технологий, а именно искусственного интеллекта и Интернета вещей, для повышения общей эффективности

Интеграция передовых технологий, таких как искусственный интеллект (ИИ) и Интернет вещей (IoT), открывает значительные возможности для рынка технического обслуживания, ремонта и эксплуатации (MRO). Используя ИИ для предиктивной аналитики и IoT для мониторинга в реальном времени, поставщики MRO могут повысить эффективность работы, сократить время простоя и оптимизировать графики обслуживания. Эти технологии позволяют принимать более разумные решения, улучшать управление активами и оптимизировать процессы обслуживания, что приводит к снижению затрат и повышению надежности работы. По мере того, как отрасли внедряют эти инновации, рынок MRO готов извлечь выгоду из возросшего спроса на технологически продвинутые решения по обслуживанию.

Например,

В мае 2024 года, согласно статье, опубликованной NDTV, HCL Technologies внедрила возможности генеративного ИИ в свое решение iMRO/4 для повышения эффективности использования активов предприятия. Интеграция ИИ направлена на оптимизацию процессов обслуживания и повышение общей эффективности. Используя ИИ, HCL Tech обеспечивает более разумный подход к управлению активами, позволяя проводить предиктивное обслуживание, сокращая время простоя и повышая эксплуатационные показатели. Этот шаг создает значительные возможности для рынка технического обслуживания, ремонта и эксплуатации (MRO), поскольку компании все чаще ищут решения на основе ИИ для повышения эффективности и использования активов.

Ограничения/Проблемы

- Нарушение цепочки поставок и сложность оборудования

Нарушение цепочки поставок и растущая сложность оборудования создают существенные проблемы для рынка MRO. Перерывы в цепочке поставок, такие как задержки в закупке деталей и логистике, могут привести к длительному простою и более высоким эксплуатационным расходам. Кроме того, по мере того, как оборудование становится более технологически продвинутым, растет потребность в специализированных навыках и инструментах для обслуживания, что еще больше усложняет процессы обслуживания и ремонта. Эти факторы создают нагрузку на поставщиков услуг MRO, которые должны быстро адаптироваться, чтобы поддерживать эффективность, управляя при этом более высокими расходами и сложностью новых систем.

Например,

В мае 2024 года Центр стратегических и международных исследований сообщил, что мировые экономические тенденции, включая колебания темпов инфляции, замедление роста в США и неравномерное восстановление Китая, выявили сохраняющиеся проблемы в цепочках поставок. Возросший импорт Китаем высокотехнологичного оборудования для поддержки ИИ и производства указал на давление на цепочки поставок, в то время как медленное восстановление потребительских расходов показало нестабильные экономические условия. Эти сбои и экономические сложности создали проблемы для рынка технического обслуживания, ремонта и эксплуатации (MRO), усложнив закупки и усложнив эффективное управление современным техническим обслуживанием оборудования.

- Обучение персонала для новых цифровых систем MRO

Обучение рабочей силы для новых цифровых систем MRO представляет собой значительную проблему для рынка, поскольку требует изменения набора навыков и адаптации к передовым технологиям. Многим сотрудникам необходимо обширное повышение квалификации для эффективной работы с инструментами на основе ИИ, системами на основе IoT и платформами предиктивного обслуживания. Переход требует значительных инвестиций в программы обучения, времени и ресурсов, что может напрягать организации, особенно малые и средние предприятия. Сопротивление изменениям среди рабочей силы и отсутствие знакомства с цифровыми системами могут замедлить процесс внедрения. Кроме того, преодоление разрыва между традиционными практиками и современными цифровыми решениями требует надежных стратегий управления изменениями. Обеспечение последовательного и всестороннего обучения имеет решающее значение для полного использования потенциала цифровых систем MRO. Организации должны уделять первоочередное внимание развитию рабочей силы, чтобы преодолеть эту проблему и оставаться конкурентоспособными.

Например,

В марте 2024 года, согласно статье, опубликованной WorldRef Pte Ltd, сохраняющаяся проблема нехватки квалифицированной рабочей силы в тяжелой промышленности усугубляется старением рабочей силы и быстрым технологическим прогрессом. Многие опытные работники приближаются к выходу на пенсию, что создает пробел в наличии квалифицированных рабочих, необходимых для современных задач MRO. С ростом цифровых систем MRO отрасли сталкиваются с проблемой обучения рабочих эффективному использованию новых технологий. Нехватка квалифицированной рабочей силы создает трудности в поиске и удержании сотрудников, способных выполнять сложные задачи по техническому обслуживанию и ремонту. Компании могут выиграть, сосредоточившись на обучении рабочей силы, чтобы сократить этот разрыв и обеспечить более плавный переход к передовым цифровым системам MRO.

В этом отчете о рынке содержатся сведения о последних новых разработках, правилах торговли, анализе импорта-экспорта, анализе производства, оптимизации цепочки создания стоимости, доле рынка, влиянии внутренних и локальных игроков рынка, анализируются возможности с точки зрения новых источников дохода, изменений в правилах рынка, анализ стратегического роста рынка, размер рынка, рост рынка категорий, ниши приложений и доминирование, одобрения продуктов, запуски продуктов, географические расширения, технологические инновации на рынке. Чтобы получить больше информации о рынке, свяжитесь с Data Bridge Market Research для получения аналитического обзора, наша команда поможет вам принять обоснованное рыночное решение для достижения роста рынка.

Влияние и текущий рыночный сценарий нехватки сырья и задержек поставок

Data Bridge Market Research предлагает высокоуровневый анализ рынка и предоставляет информацию, учитывая влияние и текущую рыночную среду нехватки сырья и задержек поставок. Это приводит к оценке стратегических возможностей, созданию эффективных планов действий и оказанию помощи предприятиям в принятии важных решений.

Помимо стандартного отчета, мы также предлагаем углубленный анализ уровня закупок на основе прогнозируемых задержек поставок, картирования дистрибьюторов по регионам, анализа товаров, анализа производства, тенденций ценового картирования, поиска поставщиков, анализа эффективности категорий, решений по управлению рисками в цепочке поставок, расширенного сравнительного анализа и других услуг по закупкам и стратегической поддержке.

Ожидаемое влияние экономического спада на ценообразование и доступность продукции

Когда экономическая активность замедляется, отрасли начинают страдать. Прогнозируемое влияние экономического спада на ценообразование и доступность продуктов учитывается в отчетах по анализу рынка и услугах по разведке, предоставляемых DBMR. Благодаря этому наши клиенты обычно могут быть на шаг впереди своих конкурентов, прогнозировать свои продажи и доходы, а также оценивать свои расходы на прибыль и убытки.

Объем рынка технического обслуживания, ремонта и эксплуатации (MRO)

Рынок сегментирован на основе типа продукта, типа, приложений, технологии, поставщика и конечного использования. Рост среди этих сегментов поможет вам проанализировать сегменты с незначительным ростом в отраслях и предоставить пользователям ценный обзор рынка и рыночные идеи, которые помогут им принимать стратегические решения для определения основных рыночных приложений.

Тип продукта

- Автоматизация

- Ручной инструмент

- Передача мощности

- Гидравлика

- Электрика

- Пневматика

- Трубы, клапаны и фитинги

- Химикаты

- Абразивы

- Электроинструменты

- Сварочное оборудование и газ

- Крепежные элементы

- Режущие инструменты

- Резиновые изделия

- Тюлень

- Другие

Тип

- Ремонт и обслуживание производственного оборудования

- Инструменты и расходные материалы

- Ручной электроинструмент (дрели, шуруповерты, циркулярные пилы, лобзики)

- Ручной инструмент (гаечные ключи, наборы торцевых головок, отвертки, молотки, плоскогубцы)

- Режущие биты

- Зажимы и соединительные инструменты

- Другие

- Ремонт и обслуживание инфраструктуры

- Крыша

- Двери

- Окна

- Погрузочные доки

- Другие

- Техническое обслуживание оборудования для обработки материалов

- Благоустройство территории вокруг здания

- Парковки и гаражи

- Уборка снега

- Другие

Приложения

- Замена детали

- Мобильность и функциональность

- Прогностический анализ

- Мониторинг производительности

- Инспекция

- Другие

Технологии

- Прогностическое обслуживание

- AR/VR

- 3D-печать

- Блокчейн

- Искусственный интеллект

- Робототехника

- Аналитика больших данных

- Цифровой близнец

- Интернет вещей

- Другие

Провайдер

- Производитель оригинального оборудования (OEM)

- Вторичный рынок

Конечное использование

- Машины

- Искусственный интеллект

- Интернет вещей

- Аналитика больших данных

- Робототехника

- Прогностическое обслуживание

- Цифровой близнец

- AR/VR

- Блокчейн

- 3D-печать

- Другие

- Горнодобывающая промышленность, нефть и газ

- Искусственный интеллект

- Интернет вещей

- Аналитика больших данных

- Робототехника

- Прогностическое обслуживание

- Цифровой близнец

- AR/VR

- Блокчейн

- 3D-печать

- Другие

- Транспорт

- Искусственный интеллект

- Интернет вещей

- Аналитика больших данных

- Робототехника

- Прогностическое обслуживание

- Цифровой близнец

- AR/VR

- Блокчейн

- 3D-печать

- Другие

- Самолеты

- Искусственный интеллект

- Интернет вещей

- Аналитика больших данных

- Робототехника

- Прогностическое обслуживание

- Цифровой близнец

- AR/VR

- Блокчейн

- 3D-печать

- Другие

- Химикаты

- Искусственный интеллект

- Интернет вещей

- Аналитика больших данных

- Робототехника

- Прогностическое обслуживание

- Цифровой близнец

- AR/VR

- Блокчейн

- 3D-печать

- Другие

- Обработка металла и литье

- Искусственный интеллект

- Интернет вещей

- Аналитика больших данных

- Робототехника

- Прогностическое обслуживание

- Цифровой близнец

- AR/VR

- Блокчейн

- 3D-печать

- Другие

- Фармацевтика

- Искусственный интеллект

- Интернет вещей

- Аналитика больших данных

- Робототехника

- Прогностическое обслуживание

- Цифровой близнец

- AR/VR

- Блокчейн

- 3D-печать

- Другие

- Продукты питания, напитки и табак

- Искусственный интеллект

- Интернет вещей

- Аналитика больших данных

- Робототехника

- Прогностическое обслуживание

- Цифровой близнец

- AR/VR

- Блокчейн

- 3D-печать

- Другие

- Электрические

- Искусственный интеллект

- Интернет вещей

- Аналитика больших данных

- Робототехника

- Прогностическое обслуживание

- Цифровой близнец

- AR/VR

- Блокчейн

- 3D-печать

- Другие

- Строительство

- Искусственный интеллект

- Интернет вещей

- Аналитика больших данных

- Робототехника

- Прогностическое обслуживание

- Цифровой близнец

- AR/VR

- Блокчейн

- 3D-печать

- Другие

- Резина Пластик и неметалл

- Искусственный интеллект

- Интернет вещей

- Аналитика больших данных

- Робототехника

- Прогностическое обслуживание

- Цифровой близнец

- AR/VR

- Блокчейн

- 3D-печать

- Другие

- Текстиль

- Искусственный интеллект

- Интернет вещей

- Аналитика больших данных

- Робототехника

- Прогностическое обслуживание

- Цифровой близнец

- AR/VR

- Блокчейн

- 3D-печать

- Другие

- Дерево и бумага

- Искусственный интеллект

- Интернет вещей

- Аналитика больших данных

- Робототехника

- Прогностическое обслуживание

- Цифровой близнец

- AR/VR

- Блокчейн

- 3D-печать

- Другие

- Другие

- Искусственный интеллект

- Интернет вещей

- Аналитика больших данных

- Робототехника

- Прогностическое обслуживание

- Цифровой близнец

- AR/VR

- Блокчейн

- 3D-печать

- Другие

Региональный анализ рынка технического обслуживания, ремонта и эксплуатации (MRO)

Проводится анализ рынка и предоставляются сведения о его размерах и тенденциях по типу продукта, типу, области применения, технологии и конечному использованию, как указано выше.

Страны, охваченные рынком: США, Канада, Мексика, Германия, Великобритания, Франция, Италия, Испания, Россия, Турция, Нидерланды, Норвегия, Финляндия, Дания, Польша, Швейцария, Бельгия, остальные страны Европы, Китай, Япония, Индия, Южная Корея, Австралия, Индонезия, Таиланд, Малайзия, Сингапур, Филиппины, Новая Зеландия, остальные страны Азиатско-Тихоокеанского региона, Бразилия, Аргентина, остальные страны Южной Америки, ОАЭ, Саудовская Аравия, Южная Африка, Египет, Израиль, а также остальные страны Ближнего Востока и Африки.

Северная Америка в настоящее время доминирует на мировом рынке технического обслуживания, ремонта и эксплуатации (MRO), движимая своей прочной промышленной базой, передовыми производственными технологиями и ранним внедрением цифровых решений, таких как предиктивная аналитика и IoT в процессах технического обслуживания. Сосредоточение региона на профилактическом обслуживании и устойчивом развитии, наряду со значительными инвестициями в инфраструктуру и промышленную автоматизацию, еще больше укрепляет его лидирующие позиции на рынке.

Азиатско-Тихоокеанский регион является самым быстрорастущим регионом для глобального рынка технического обслуживания, ремонта и эксплуатации (MRO), подпитываемого быстрой индустриализацией, урбанизацией и ростом инвестиций в инфраструктуру и производственные секторы. Такие страны, как Китай, Индия и страны Юго-Восточной Азии, являются ключевыми участниками, движимыми расширяющимися отраслями, такими как автомобилестроение, электроника и строительство.

Раздел отчета по странам также содержит отдельные факторы, влияющие на рынок, и изменения в регулировании на внутреннем рынке, которые влияют на текущие и будущие тенденции рынка. Такие данные, как анализ цепочки создания стоимости вверх и вниз по течению, технические тенденции и анализ пяти сил Портера, тематические исследования — вот некоторые из указателей, используемых для прогнозирования рыночного сценария для отдельных стран. Кроме того, при предоставлении прогнозного анализа данных по странам учитываются наличие и доступность глобальных брендов и их проблемы, связанные с большой или малой конкуренцией со стороны местных и отечественных брендов, влияние внутренних тарифов и торговых путей.

Доля рынка технического обслуживания, ремонта и эксплуатации (MRO)

Конкурентная среда рынка содержит сведения о конкурентах. Включены сведения о компании, ее финансах, полученном доходе, рыночном потенциале, инвестициях в исследования и разработки, новых рыночных инициативах, глобальном присутствии, производственных площадках и объектах, производственных мощностях, сильных и слабых сторонах компании, запуске продукта, широте и широте продукта, доминировании приложений. Приведенные выше данные касаются только фокуса компаний на рынке.

Лидерами рынка технического обслуживания, ремонта и эксплуатации (MRO) являются:

- Home Depot Product Authority LLC (США)

- WW Grainger, Inc. (США)

- FCX Performance, Inc. (США)

- Веско (США)

- Lufthansa Technik (Дания)

- ST Engineering (Сингапур)

- Airgas, Inc. (США)

- Textron Aviation Inc. (США)

- GKN AEROSPACE (Великобритания)

- Иберия (Испания)

- Сонепар (Франция)

- ААР (США)

- Wajax Limited (США)

- Sepang Aircraft Engineering Sdn Bhd. (Малайзия)

- SR Technics (Швейцария)

- Hisco – TestEquity LLC (США)

- MJETS (Таиланд)

- ТАП (Португалия)

- United Airlines, Inc. (США)

Последние разработки на рынке технического обслуживания, ремонта и эксплуатации (MRO)

- В октябре 2024 года Wesco International объявила о приобретении Ascent, поставщика услуг по управлению объектами ЦОД, с объемом продаж 115 млн долларов США. Приобретение расширило портфель решений Wesco для ЦОД, включая передовые системы охлаждения и поддержку жизненного цикла, что улучшило услуги на рынке ЦОД

- В апреле 2024 года Wesco International объявила о завершении продажи бизнеса Wesco Integrated Supply (WIS) компании Vallen Distribution за 350 миллионов долларов США. Продажа включала бизнес Wesco по промышленному обслуживанию, ремонту и эксплуатации (MRO) в Северной Америке и Европе с чистыми продажами в 2023 году в размере 784 миллионов долларов США. Wesco планировала использовать вырученные средства для сокращения задолженности и выкупа акций

- В январе 2025 года Avianca объединилась с Lufthansa Technik для внедрения своей экосистемы Digital Tech Ops, став первой авиакомпанией в Америке, которая использует этот пакет. Целью сотрудничества является оптимизация управления парком самолетов, сокращение расходов и повышение операционной эффективности с помощью таких цифровых решений, как AMOS, AVIATAR и flydocs.

- В сентябре 2024 года Lufthansa Group продлила свое соглашение об аренде с обслуживанием с airBaltic еще на три года, начиная с лета 2025 года. Это партнерство предоставит до 21 самолета Airbus A220-300 летом и пять — зимой, что повысит гибкость сети и поддержит сезонные пики спроса.

- В августе 2024 года легенда НБА Дирк Новицки сотрудничает с Lufthansa для запуска кампании Allegris, представляющей новый опыт дальних перелетов авиакомпании. Новицки появляется в рекламе, демонстрирующей роскошный бизнес-класс Allegris с его инновационными вариантами сидений, включая функции контроля температуры

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Интерактивная панель анализа данных

- Панель анализа компании для возможностей с высоким потенциалом роста

- Доступ аналитика-исследователя для настройки и запросов

- Анализ конкурентов с помощью интерактивной панели

- Последние новости, обновления и анализ тенденций

- Используйте возможности сравнительного анализа для комплексного отслеживания конкурентов

Содержание

1 INTRODUCTION

1.1 OBJECTIVES OF THE STUDY

1.2 MARKET DEFINITION

1.3 OVERVIEW OF GLOBAL MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET

1.4 CURRENCY AND PRICING

1.5 LIMITATIONS

1.6 MARKETS COVERED

2 MARKET SEGMENTATION

2.1 MARKETS COVERED

2.2 GEOGRAPHICAL SCOPE

2.3 YEARS CONSIDERED FOR THE STUDY

2.4 DBMR TRIPOD DATA VALIDATION MODEL

2.5 PRIMARY INTERVIEWS WITH KEY OPINION LEADERS

2.6 DBMR MARKET POSITION GRID

2.7 VENDOR SHARE ANALYSIS

2.8 MULTIVARIATE MODELING

2.9 PRODUCT TYPE TIMELINE CURVE

2.1 MARKET APPLICATION COVERAGE GRID

2.11 SECONDARY SOURCES

2.12 ASSUMPTIONS

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

4.1 PORTER’S FIVE FORCES

4.2 VENDOR SELECTION CRITERIA

4.2.1 QUALITY OF PRODUCTS AND SERVICES

4.2.2 COST COMPETITIVENESS

4.2.3 DELIVERY AND LEAD TIMES

4.2.4 TECHNICAL EXPERTISE AND INNOVATION

4.2.5 COMPLIANCE AND REGULATORY ADHERENCE

4.2.6 CUSTOMER SUPPORT AND SERVICE

4.2.7 FLEXIBILITY AND SCALABILITY

4.2.8 VENDOR STABILITY AND REPUTATION

4.2.9 GEOGRAPHICAL COVERAGE

4.2.10 1SUSTAINABILITY AND ENVIRONMENTAL CONSIDERATIONS

4.3 CASE STUDIES

4.4 INDUSTRY ANALYSIS & FUTURISTIC SCENARIO

4.4.1 INDUSTRY ANALYSIS

4.4.2 FUTURISTIC SCENARIO

4.5 END USER SEGMENT DEFINITIONS

4.5.1 MACHINERY

4.5.2 MINING, OIL & GAS

4.5.3 TRANSPORTATION

4.5.4 AIRCRAFT

4.5.5 CHEMICALS

4.5.6 METAL PROCESSING & FOUNDRY

4.5.7 PHARMACEUTICALS

4.5.8 FOOD, BEVERAGE & TOBACCO:

4.5.9 ELECTRICAL

4.5.10 CONSTRUCTION:

4.5.11 RUBBER, PLASTIC & NON-METALLIC

4.5.12 TEXTILE

4.5.13 WOOD & PAPER

4.5.14 OTHERS

4.6 TECHNOLOGICAL TRENDS

4.6.1 PREDICTIVE MAINTENANCE AND IOT INTEGRATION:

4.6.2 ARTIFICIAL INTELLIGENCE (AI) AND MACHINE LEARNING (ML):

4.6.3 DRONES AND ROBOTICS:

5 MARKET OVERVIEW

5.1 DRIVERS

5.1.1 RISING GOVERNMENT INVESTMENT IN PUBLIC INFRASTRUCTURE PROJECTS

5.1.2 EXPANDING AVIATION AND MANUFACTURING INDUSTRIES WORLDWIDE

5.1.3 REGULATORY REQUIREMENTS INCREASE THE DEMAND FOR MRO SERVICES

5.1.4 RISING FOCUS ON AFTERMARKET SERVICES BY OEM SUPPLIERS

5.2 RESTRAINTS

5.2.1 HIGH COSTS OF ADVANCED MRO TOOLS AND SYSTEMS

5.2.2 FLUCTUATING RAW MATERIAL PRICES AFFECTING COSTS

5.3 OPPORTUNITIES

5.3.1 STRATEGIC PARTNERSHIPS AND COLLABORATIONS BETWEEN AIRLINES AND OEMS

5.3.2 INTEGRATING ADVANCED TECHNOLOGIES NAMELY AI AND IOT TO ENHANCE OVERALL EFFICIENCY

5.4 CHALLENGES

5.4.1 DISRUPTION IN SUPPLY CHAIN & EQUIPMENT COMPLEXITY

5.4.2 TRAINING WORKFORCE FOR NEW DIGITAL MRO SYSTEMS

6 GLOBAL MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PRODUCT TYPE

6.1 OVERVIEW

6.2 AUTOMATION

6.3 HAND TOOLS

6.4 POWER TRANSMISSION

6.5 PIPES, VALVES & FITTING

6.6 CHEMICALS

6.7 ABRASIVES

6.8 POWER TOOLS

6.9 WELDING EQUIPMENT & GAS

6.1 FASTNERS

6.11 CUTTING TOOLS

6.12 RUBBER PRODUCTS

6.13 SEAL

6.14 OTHERS

7 GLOBAL MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE

7.1 OVERVIEW

7.2 PRODUCTION EQUIPMENT REPAIR AND MAINTENANCE

7.3 TOOLING AND CONSUMABLES

7.4 INFRASTRUCTURE REPAIR AND MAINTENANCE

7.5 MATERIAL HANDLING EQUIPMENT MAINTENANCE

7.6 LANDSCAPING THE GROUNDS AROUND THE BUILDING

8 GLOBAL MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY APPLICATION

8.1 OVERVIEW

8.2 PART REPLACEMENT

8.3 MOBILITY & FUNCTIONALITY

8.4 PREDICTIVE ANALYSIS

8.5 PERFORMANCE MONITORING

8.6 INSPECTION

8.7 OTHERS

9 GLOBAL MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY

9.1 OVERVIEW

9.2 PREDICTIVE MAINTENANCE

9.3 AR/VR

9.4 3D PRINTING

9.5 BLOCKCHAIN

9.6 ARTIFICIAL INTELLIGENCE

9.7 ROBOTICS

9.8 BIG DATA ANALYTICS

9.9 DIGITAL TWIN

9.1 IOT

9.11 OTHERS

10 GLOBAL MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY END USE

10.1 OVERVIEW

10.2 MACHINERY

10.3 MINING, OIL & GAS

10.4 TRANSPORTATION

10.5 AIRCRAFT

10.6 CHEMICALS

10.7 METAL PROCESSING & FOUNDRY

10.8 PHARMACEUTICALS

10.9 FOOD, BEVERAGE & TOBACCO

10.1 ELECTRICAL

10.11 CONSTRUCTION

10.12 RUBBER, PLASTIC & NON – METALLIC

10.13 TEXTILE

10.14 WOOD & PAPER

10.15 OTHERS

11 GLOBAL MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PROVIDER

11.1 OVERVIEW

11.2 ORIGINAL EQUIPMENT MANUFACTURER (OEM)

11.3 AFTERMARKET

12 GLOBAL MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET BY REGIONS

12.1 NORTH AMERICA

12.1.1 U.S.

12.1.2 CANADA

12.1.3 MEXICO

12.2 EUROPE

12.2.1 GERMANY

12.2.2 FRANCE

12.2.3 SPAIN

12.2.4 U.K.

12.2.5 ITALY

12.2.6 NETHERLANDS

12.2.7 RUSSIA

12.2.8 SWITZERLAND

12.2.9 BELGIUM

12.2.10 TURKEY

12.2.11 NORWAY

12.2.12 FINLAND

12.2.13 DENMARK

12.2.14 POLAND

12.2.15 REST OF EUROPE

12.3 ASIA-PACIFIC

12.3.1 CHINA

12.3.2 JAPAN

12.3.3 INDIA

12.3.4 SOUTH KOREA

12.3.5 AUSTRALIA

12.3.6 SINGAPORE

12.3.7 INDONESIA

12.3.8 THAILAND

12.3.9 MALAYSIA

12.3.10 PHILIPPINES

12.3.11 NEW ZEALAND

12.3.12 REST OF ASIA-PACIFIC

12.4 MIDDLE EAST AND AFRICA

12.4.1 SAUDI ARABIA

12.4.2 U.A.E

12.4.3 SOUTH AFRICA

12.4.4 EGYPT

12.4.5 ISRAEL

12.4.6 REST OF MIDDLE EAST AND AFRICA

12.5 SOUTH AMERICA

12.5.1 BRAZIL

12.5.2 ARGENTINA

12.5.3 REST OF SOUTH AMERICA

13 GLOBAL MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, COMPANY LANDSCAPE

13.1 COMPANY SHARE ANALYSIS: GLOBAL

13.2 COMPANY SHARE ANALYSIS: NORTH AMERICA

13.3 COMPANY SHARE ANALYSIS: EUROPE

13.4 COMPANY SHARE ANALYSIS: ASIA-PACIFIC

14 SWOT ANALYSIS

15 COMPANY PROFILE

15.1 THE HOME DEPOT

15.1.1 COMPANY SNAPSHOT

15.1.2 REVENUE ANALYSIS

15.1.3 COMPANY SHARE ANALYSIS

15.1.4 PRODUCT PORTFOLIO

15.1.5 RECENT DEVELOPMENT

15.2 W.W. GRAINGER, IN.

15.2.1 COMPANY SNAPSHOT

15.2.2 REVENUE ANALYSIS

15.2.3 COMPANY SHARE ANALYSIS

15.2.4 PRODUCT PORTFOLIO

15.2.5 RECENT DEVELOPMENT

15.3 FCX PERFORMANCE, INC.

15.3.1 COMPANY SNAPSHOT

15.3.2 COMPANY SHARE ANALYSIS

15.3.3 PRODUCT PORTFOLIO

15.3.4 RECENT DEVELOPMENT

15.4 WESCO

15.4.1 COMPANY SNAPSHOT

15.4.2 REVENUE ANALYSIS

15.4.3 COMPANY SHARE ANALYSIS

15.4.4 PRODUCT PORTFOLIO

15.4.5 RECENT DEVELOPMENT

15.5 LUFTHANSA TECHNIK

15.5.1 COMPANY SNAPSHOT

15.5.2 REVENUE ANALYSIS

15.5.3 COMPANY SHARE ANALYSIS

15.5.4 PRODUCT PORTFOLIO

15.5.5 RECENT DEVELOPMENT

15.6 AAR

15.6.1 COMPANY SNAPSHOT

15.6.2 REVENUE ANALYSIS

15.6.3 PRODUCT PORTFOLIO

15.6.4 RECENT DEVELOPMENT

15.7 AIRGAS, INC.

15.7.1 COMPANY SNAPSHOT

15.7.2 REVENUE ANALYSIS

15.7.3 PRODUCT PORTFOLIO

15.7.4 RECENT DEVELOPMENT

15.8 FOKKER TECHNOLOGIES

15.8.1 COMPANY SNAPSHOT

15.8.2 PRODUCT PORTFOLIO

15.8.3 RECENT DEVELOPMENT

15.9 HISCO

15.9.1 COMPANY SNAPSHOT

15.9.2 PRODUCT PORTFOLIO

15.9.3 RECENT DEVELOPMENT

15.1 IBERIA

15.10.1 COMPANY SNAPSHOT

15.10.2 PRODUCT PORTFOLIO

15.10.3 RECENT DEVELOPMENT

15.11 MJETS

15.11.1 COMPANY SNAPSHOT

15.11.2 PRODUCT PORTFOLIO

15.11.3 RECENT DEVELOPMENT

15.12 SEPANG AIRCRAFT ENGINEERING SDN BHD.

15.12.1 COMPANY SNAPSHOT

15.12.2 PRODUCT PORTFOLIO

15.12.3 RECENT DEVELOPMENT

15.13 SONEPAR

15.13.1 BRAND SNAPSHOT

15.13.2 BRAND PORTFOLIO

15.13.3 RECENT DEVELOPMENT

15.14 SR TECHNICS

15.14.1 COMPANY SNAPSHOT

15.14.2 PRODUCT PORTFOLIO

15.14.3 RECENT DEVELOPMENT

15.15 ST ENGINEERING

15.15.1 COMPANY SNAPSHOT

15.15.2 REVENUE ANALYSIS

15.15.3 PRODUCT PORTFOLIO

15.15.4 RECENT DEVELOPMENT

15.16 TAP

15.16.1 COMPANY SNAPSHOT

15.16.2 PRODUCT PORTFOLIO

15.16.3 RECENT DEVELOPMENT

15.17 TEXTRON AVIATION INC.

15.17.1 COMPANY SNAPSHOT

15.17.2 REVENUE ANALYSIS

15.17.3 PRODUCT PORTFOLIO

15.17.4 RECENT DEVELOPMENT

15.18 UNITED TECHNOLOGIES CORPORATION

15.18.1 COMPANY SNAPSHOT

15.18.2 REVENUE ANALYSIS

15.18.3 PRODUCT PORTFOLIO

15.18.4 RECENT DEVELOPMENT

15.19 WAJAX LIMITED

15.19.1 COMPANY SNAPSHOT

15.19.2 REVENUE ANALYSIS

15.19.3 PRODUCT PORTFOLIO

15.19.4 RECENT DEVELOPMENT

16 QUESTIONNAIRE

17 RELATED REPORTS

Список таблиц

TABLE 1 HIGH PRICE OF MRO (MAINTENANCE REPAIR OPERATIONS) PRODUCTS

TABLE 2 GLOBAL MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PRODUCT TYPE, 2018-2032 (USD THOUSAND)

TABLE 3 GLOBAL AUTOMATION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 4 GLOBAL HAND TOOLS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 5 GLOBAL POWER TRANSMISSION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 6 GLOBAL POWER TRANSMISSION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PRODUCT TYPE, 2018-2032 (USD THOUSAND)

TABLE 7 GLOBAL PIPES, VALVES & FITTING IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 8 GLOBAL CHEMICALS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 9 GLOBAL ABRASIVES IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 10 GLOBAL POWER TOOLS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 11 GLOBAL WELDING EQUIPMENT & GAS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 12 GLOBAL FASTNERS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 13 GLOBAL CUTTING TOOLS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 14 GLOBAL RUBBER PRODUCTS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 15 GLOBAL SEAL IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 16 GLOBAL OTHERS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 17 GLOBAL MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 18 GLOBAL PRODUCTION EQUIPMENT REPAIR AND MAINTENANCE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 19 GLOBAL TOOLING AND CONSUMABLES IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 20 GLOBAL TOOLING AND CONSUMABLES IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 21 GLOBAL INFRASTRUCTURE REPAIR AND MAINTENANCE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 22 GLOBAL INFRASTRUCTURE REPAIR AND MAINTENANCE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 23 GLOBAL MATERIAL HANDLING EQUIPMENT MAINTENANCE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 24 GLOBAL LANDSCAPING THE GROUNDS AROUND THE BUILDING IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 25 GLOBAL LANDSCAPING THE GROUNDS AROUND THE BUILDING IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 26 GLOBAL MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 27 GLOBAL PART REPLACEMENT IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 28 GLOBAL MOBILITY & FUNCTIONALITY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 29 GLOBAL PREDICTIVE ANALYSIS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 30 GLOBAL PERFORMANCE MONITORING IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 31 GLOBAL INSPECTION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 32 GLOBAL OTHERS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 33 GLOBAL MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 34 GLOBAL PREDICTIVE MAINTENANCE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 35 GLOBAL AR/VR IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 36 GLOBAL 3D PRINTING IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 37 GLOBAL BLOCKCHAIN IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 38 GLOBAL ARTIFICIAL INTELLIGENCE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 39 GLOBAL ROBOTICS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 40 GLOBAL BIG DATA ANALYTICS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 41 GLOBAL DIGITAL TWIN IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 42 GLOBAL IOT IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 43 GLOBAL OTHERS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 44 GLOBAL MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET: BY END USE, 2018-2032 (USD THOUSAND)

TABLE 45 GLOBAL MACHINERY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 46 GLOBAL MACHINERY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 47 GLOBAL MINING, OIL & GAS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 48 GLOBAL MINING, OIL & GAS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 49 GLOBAL TRANSPORTATION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 50 GLOBAL TRANSPORTATION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 51 GLOBAL AIRCRAFT IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 52 GLOBAL AIRCRAFT IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 53 GLOBAL CHEMICALS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 54 GLOBAL CHEMICALS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 55 GLOBAL METAL PROCESSING & FOUNDRY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 56 GLOBAL METAL PROCESSING & FOUNDRY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 57 GLOBAL PHARMACEUTICALS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 58 GLOBAL PHARMACEUTICALS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 59 GLOBAL FOOD, BEVERAGE & TOBACCO IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 60 GLOBAL FOOD, BEVERAGE & TOBACCO IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 61 GLOBAL ELECTRICAL IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 62 GLOBAL ELECTRICAL IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 63 GLOBAL CONSTRUCTION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 64 GLOBAL CONSTRUCTION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 65 GLOBAL RUBBER, PLASTIC & NON – METALLIC IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 66 GLOBAL RUBBER, PLASTIC & NON – METALLIC IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 67 GLOBAL TEXTILE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 68 GLOBAL TEXTILE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 69 GLOBAL WOOD & PAPER IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 70 GLOBAL WOOD & PAPER IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 71 GLOBAL OTHERS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 72 GLOBAL OTHERS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 73 GLOBAL MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PROVIDER, 2018-2032 (USD THOUSAND)

TABLE 74 GLOBAL ORIGINAL EQUIPMENT MANUFACTURER (OEM) IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 75 GLOBAL AFTERMARKET IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 76 GLOBAL MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 77 NORTH AMERICA MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY COUNTRY, 2018-2032 (USD THOUSAND)

TABLE 78 NORTH AMERICA MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PRODUCT TYPE, 2018-2032 (USD THOUSAND)

TABLE 79 NORTH AMERICA POWER TRANSMISSION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PRODUCT TYPE, 2018-2032 (USD THOUSAND)

TABLE 80 NORTH AMERICA MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 81 NORTH AMERICA TOOLING AND CONSUMABLES IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 82 NORTH AMERICA INFRASTRUCTURE REPAIR AND MAINTENANCE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 83 NORTH AMERICA LANDSCAPING THE GROUNDS AROUND THE BUILDING IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 84 NORTH AMERICA MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 85 NORTH AMERICA MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 86 NORTH AMERICA MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PROVIDER, 2018-2032 (USD THOUSAND)

TABLE 87 NORTH AMERICA MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY END USE, 2018-2032 (USD THOUSAND)

TABLE 88 NORTH AMERICA MACHINERY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 89 NORTH AMERICA MINING, OIL & GAS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 90 NORTH AMERICA TRANSPORTATION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 91 NORTH AMERICA AIRCRAFT IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 92 NORTH AMERICA CHEMICALS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 93 NORTH AMERICA METAL PROCESSING & FOUNDRY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 94 NORTH AMERICA PHARMACEUTICALS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 95 NORTH AMERICA FOOD, BEVERAGE & TOBACCO IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 96 NORTH AMERICA ELECTRICAL IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 97 NORTH AMERICA CONSTRUCTION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 98 NORTH AMERICA RUBBER, PLASTIC & NON – METALLIC IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 99 NORTH AMERICA TEXTILE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 100 NORTH AMERICA WOOD & PAPER IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 101 NORTH AMERICA OTHERS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 102 U.S. MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PRODUCT TYPE, 2018-2032 (USD THOUSAND)

TABLE 103 U.S. POWER TRANSMISSION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PRODUCT TYPE, 2018-2032 (USD THOUSAND)

TABLE 104 U.S. MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 105 U.S. TOOLING AND CONSUMABLES IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 106 U.S. INFRASTRUCTURE REPAIR AND MAINTENANCE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 107 U.S. LANDSCAPING THE GROUNDS AROUND THE BUILDING IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 108 U.S. MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 109 U.S. MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 110 U.S. MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PROVIDER, 2018-2032 (USD THOUSAND)

TABLE 111 U.S. MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY END USE, 2018-2032 (USD THOUSAND)

TABLE 112 U.S. MACHINERY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 113 U.S. MINING, OIL & GAS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 114 U.S. TRANSPORTATION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 115 U.S. AIRCRAFT IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 116 U.S. CHEMICALS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 117 U.S. METAL PROCESSING & FOUNDRY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 118 U.S. PHARMACEUTICALS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 119 U.S. FOOD, BEVERAGE & TOBACCO IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 120 U.S. ELECTRICAL IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 121 U.S. CONSTRUCTION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 122 U.S. RUBBER, PLASTIC & NON – METALLIC IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 123 U.S. TEXTILE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 124 U.S. WOOD & PAPER IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 125 U.S. OTHERS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 126 CANADA MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PRODUCT TYPE, 2018-2032 (USD THOUSAND)

TABLE 127 CANADA POWER TRANSMISSION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PRODUCT TYPE, 2018-2032 (USD THOUSAND)

TABLE 128 CANADA MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 129 CANADA TOOLING AND CONSUMABLES IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 130 CANADA INFRASTRUCTURE REPAIR AND MAINTENANCE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 131 CANADA LANDSCAPING THE GROUNDS AROUND THE BUILDING IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 132 CANADA MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 133 CANADA MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 134 CANADA MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PROVIDER, 2018-2032 (USD THOUSAND)

TABLE 135 CANADA MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY END USE, 2018-2032 (USD THOUSAND)

TABLE 136 CANADA MACHINERY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 137 CANADA MINING, OIL & GAS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 138 CANADA TRANSPORTATION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 139 CANADA AIRCRAFT IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 140 CANADA CHEMICALS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 141 CANADA METAL PROCESSING & FOUNDRY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 142 CANADA PHARMACEUTICALS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 143 CANADA FOOD, BEVERAGE & TOBACCO IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 144 CANADA ELECTRICAL IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 145 CANADA CONSTRUCTION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 146 CANADA RUBBER, PLASTIC & NON – METALLIC IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 147 CANADA TEXTILE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 148 CANADA WOOD & PAPER IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 149 CANADA OTHERS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 150 MEXICO MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PRODUCT TYPE, 2018-2032 (USD THOUSAND)

TABLE 151 MEXICO POWER TRANSMISSION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PRODUCT TYPE, 2018-2032 (USD THOUSAND)

TABLE 152 MEXICO MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 153 MEXICO TOOLING AND CONSUMABLES IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 154 MEXICO INFRASTRUCTURE REPAIR AND MAINTENANCE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 155 MEXICO LANDSCAPING THE GROUNDS AROUND THE BUILDING IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 156 MEXICO MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 157 MEXICO MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 158 MEXICO MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PROVIDER, 2018-2032 (USD THOUSAND)

TABLE 159 MEXICO MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY END USE, 2018-2032 (USD THOUSAND)

TABLE 160 MEXICO MACHINERY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 161 MEXICO MINING, OIL & GAS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 162 MEXICO TRANSPORTATION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 163 MEXICO AIRCRAFT IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 164 MEXICO CHEMICALS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 165 MEXICO METAL PROCESSING & FOUNDRY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 166 MEXICO PHARMACEUTICALS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 167 MEXICO FOOD, BEVERAGE & TOBACCO IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 168 MEXICO ELECTRICAL IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 169 MEXICO CONSTRUCTION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 170 MEXICO RUBBER, PLASTIC & NON – METALLIC IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 171 MEXICO TEXTILE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 172 MEXICO WOOD & PAPER IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 173 MEXICO OTHERS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 174 EUROPE MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY COUNTRY, 2018-2032 (USD THOUSAND)

TABLE 175 EUROPE MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PRODUCT TYPE, 2018-2032 (USD THOUSAND)

TABLE 176 EUROPE POWER TRANSMISSION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PRODUCT TYPE, 2018-2032 (USD THOUSAND)

TABLE 177 EUROPE MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 178 EUROPE TOOLING AND CONSUMABLES IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 179 EUROPE INFRASTRUCTURE REPAIR AND MAINTENANCE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 180 EUROPE LANDSCAPING THE GROUNDS AROUND THE BUILDING IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 181 EUROPE MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 182 EUROPE MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 183 EUROPE MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PROVIDER, 2018-2032 (USD THOUSAND)

TABLE 184 EUROPE MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY END USE, 2018-2032 (USD THOUSAND)

TABLE 185 EUROPE MACHINERY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 186 EUROPE MINING, OIL & GAS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 187 EUROPE TRANSPORTATION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 188 EUROPE AIRCRAFT IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 189 EUROPE CHEMICALS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 190 EUROPE METAL PROCESSING & FOUNDRY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 191 EUROPE PHARMACEUTICALS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 192 EUROPE FOOD, BEVERAGE & TOBACCO IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 193 EUROPE ELECTRICAL IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 194 EUROPE CONSTRUCTION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 195 EUROPE RUBBER, PLASTIC & NON – METALLIC IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 196 EUROPE TEXTILE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 197 EUROPE WOOD & PAPER IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 198 EUROPE OTHERS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 199 GERMANY MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PRODUCT TYPE, 2018-2032 (USD THOUSAND)

TABLE 200 GERMANY POWER TRANSMISSION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PRODUCT TYPE, 2018-2032 (USD THOUSAND)

TABLE 201 GERMANY MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 202 GERMANY TOOLING AND CONSUMABLES IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 203 GERMANY INFRASTRUCTURE REPAIR AND MAINTENANCE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 204 GERMANY LANDSCAPING THE GROUNDS AROUND THE BUILDING IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 205 GERMANY MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 206 GERMANY MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 207 GERMANY MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PROVIDER, 2018-2032 (USD THOUSAND)

TABLE 208 GERMANY MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY END USE, 2018-2032 (USD THOUSAND)

TABLE 209 GERMANY MACHINERY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 210 GERMANY MINING, OIL & GAS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 211 GERMANY TRANSPORTATION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 212 GERMANY AIRCRAFT IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 213 GERMANY CHEMICALS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 214 GERMANY METAL PROCESSING & FOUNDRY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 215 GERMANY PHARMACEUTICALS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 216 GERMANY FOOD, BEVERAGE & TOBACCO IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 217 GERMANY ELECTRICAL IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 218 GERMANY CONSTRUCTION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 219 GERMANY RUBBER, PLASTIC & NON – METALLIC IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 220 GERMANY TEXTILE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 221 GERMANY WOOD & PAPER IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 222 GERMANY OTHERS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 223 FRANCE MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PRODUCT TYPE, 2018-2032 (USD THOUSAND)

TABLE 224 FRANCE POWER TRANSMISSION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PRODUCT TYPE, 2018-2032 (USD THOUSAND)

TABLE 225 FRANCE MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 226 FRANCE TOOLING AND CONSUMABLES IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 227 FRANCE INFRASTRUCTURE REPAIR AND MAINTENANCE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 228 FRANCE LANDSCAPING THE GROUNDS AROUND THE BUILDING IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 229 FRANCE MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 230 FRANCE MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 231 FRANCE MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PROVIDER, 2018-2032 (USD THOUSAND)

TABLE 232 FRANCE MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY END USE, 2018-2032 (USD THOUSAND)

TABLE 233 FRANCE MACHINERY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 234 FRANCE MINING, OIL & GAS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 235 FRANCE TRANSPORTATION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 236 FRANCE AIRCRAFT IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 237 FRANCE CHEMICALS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 238 FRANCE METAL PROCESSING & FOUNDRY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 239 FRANCE PHARMACEUTICALS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 240 FRANCE FOOD, BEVERAGE & TOBACCO IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 241 FRANCE ELECTRICAL IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 242 FRANCE CONSTRUCTION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 243 FRANCE RUBBER, PLASTIC & NON – METALLIC IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 244 FRANCE TEXTILE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 245 FRANCE WOOD & PAPER IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 246 FRANCE OTHERS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 247 SPAIN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PRODUCT TYPE, 2018-2032 (USD THOUSAND)

TABLE 248 SPAIN POWER TRANSMISSION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PRODUCT TYPE, 2018-2032 (USD THOUSAND)

TABLE 249 SPAIN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 250 SPAIN TOOLING AND CONSUMABLES IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 251 SPAIN INFRASTRUCTURE REPAIR AND MAINTENANCE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 252 SPAIN LANDSCAPING THE GROUNDS AROUND THE BUILDING IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 253 SPAIN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 254 SPAIN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 255 SPAIN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PROVIDER, 2018-2032 (USD THOUSAND)

TABLE 256 SPAIN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY END USE, 2018-2032 (USD THOUSAND)

TABLE 257 SPAIN MACHINERY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 258 SPAIN MINING, OIL & GAS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 259 SPAIN TRANSPORTATION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 260 SPAIN AIRCRAFT IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 261 SPAIN CHEMICALS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 262 SPAIN METAL PROCESSING & FOUNDRY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 263 SPAIN PHARMACEUTICALS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 264 SPAIN FOOD, BEVERAGE & TOBACCO IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 265 SPAIN ELECTRICAL IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 266 SPAIN CONSTRUCTION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 267 SPAIN RUBBER, PLASTIC & NON – METALLIC IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 268 SPAIN TEXTILE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 269 SPAIN WOOD & PAPER IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 270 SPAIN OTHERS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 271 U.K. MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PRODUCT TYPE, 2018-2032 (USD THOUSAND)

TABLE 272 U.K. POWER TRANSMISSION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PRODUCT TYPE, 2018-2032 (USD THOUSAND)

TABLE 273 U.K. MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 274 U.K. TOOLING AND CONSUMABLES IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 275 U.K. INFRASTRUCTURE REPAIR AND MAINTENANCE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 276 U.K. LANDSCAPING THE GROUNDS AROUND THE BUILDING IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 277 U.K. MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 278 U.K. MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 279 U.K. MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PROVIDER, 2018-2032 (USD THOUSAND)

TABLE 280 U.K. MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY END USE, 2018-2032 (USD THOUSAND)

TABLE 281 U.K. MACHINERY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 282 U.K. MINING, OIL & GAS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 283 U.K. TRANSPORTATION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 284 U.K. AIRCRAFT IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 285 U.K. CHEMICALS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 286 U.K. METAL PROCESSING & FOUNDRY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 287 U.K. PHARMACEUTICALS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 288 U.K. FOOD, BEVERAGE & TOBACCO IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 289 U.K. ELECTRICAL IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 290 U.K. CONSTRUCTION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 291 U.K. RUBBER, PLASTIC & NON – METALLIC IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 292 U.K. TEXTILE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 293 U.K. WOOD & PAPER IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 294 U.K. OTHERS IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 295 ITALY MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PRODUCT TYPE, 2018-2032 (USD THOUSAND)

TABLE 296 ITALY POWER TRANSMISSION IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PRODUCT TYPE, 2018-2032 (USD THOUSAND)

TABLE 297 ITALY MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 298 ITALY TOOLING AND CONSUMABLES IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 299 ITALY INFRASTRUCTURE REPAIR AND MAINTENANCE IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 300 ITALY LANDSCAPING THE GROUNDS AROUND THE BUILDING IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 301 ITALY MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 302 ITALY MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)

TABLE 303 ITALY MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY PROVIDER, 2018-2032 (USD THOUSAND)

TABLE 304 ITALY MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY END USE, 2018-2032 (USD THOUSAND)

TABLE 305 ITALY MACHINERY IN MAINTENANCE REPAIR AND OPERATIONS (MRO) MARKET, BY TECHNOLOGY, 2018-2032 (USD THOUSAND)