Global Industrial Tube Market

Размер рынка в млрд долларов США

CAGR :

%

USD

574.15 Billion

USD

936.03 Billion

2021

2029

USD

574.15 Billion

USD

936.03 Billion

2021

2029

| 2022 –2029 | |

| USD 574.15 Billion | |

| USD 936.03 Billion | |

|

|

|

|

Global Industrial Tube Market, By Type (Process Pipes, Heat Exchanger, Mechanical, Structural, Others), Material (Steel, Non-Steel), Manufacturing (Seamless, Welded), End-Use (Oil & Gas and Petrochemical, Automotive, Chemical, Others) – Industry Trends and Forecast to 2029.

Industrial Tube Market Analysis and Size

The rising demand of energy & power is also driving the demand for industrial tubes. The “steel” is the fastest growing material segment due to their different and extensive range of properties such as high durability, high strength, excellent corrosion and chemical resistance, formability, and weldability over the forecast period. Moreover, industrial tubes are anticipated to gain prominence traction due to their high ability to provide protection against fouling and advanced resilience to high-temperature applications during the forecast period.

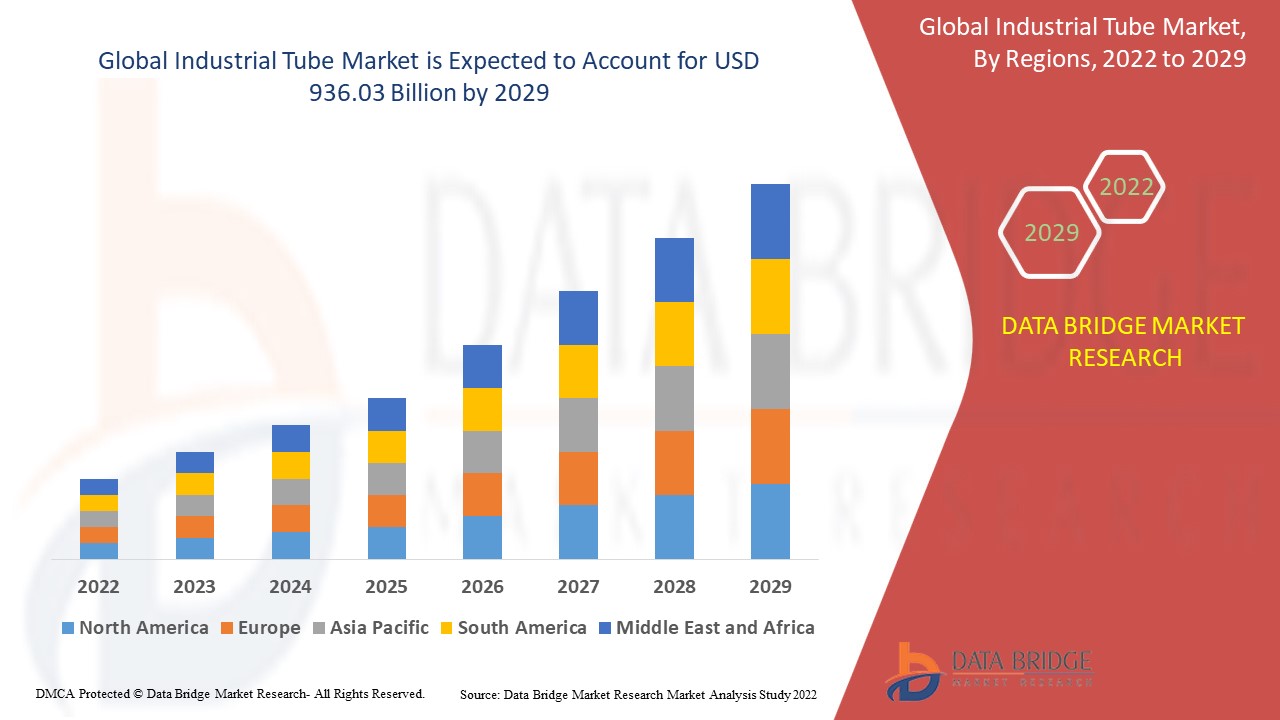

Data Bridge Market Research analyses that the industrial tube market was valued at USD 574.15 billion in 2021 and is expected to reach USD 936.03 billion by 2029, registering a CAGR of 6.30% during the forecast period of 2022 to 2029. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand.

Industrial Tube Market Scope and Segmentation

|

Report Metric |

Details |

|

Forecast Period |

2022 to 2029 |

|

Base Year |

2021 |

|

Historic Years |

2020 (Customizable to 2014 - 2019) |

|

Quantitative Units |

Revenue in USD Billion, Volumes in Units, Pricing in USD |

|

Segments Covered |

Type (Process Pipes, Heat Exchanger, Mechanical, Structural, Others), Material (Steel, Non-Steel), Manufacturing (Seamless, Welded), End-Use (Oil & Gas and Petrochemical, Automotive, Chemical, Others) |

|

Countries Covered |

U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America |

|

Market Players Covered |

Tata BlueScope Steel (Australia), Nippon Steel Corporation (Japan), VALLOUREC (France), Sandvik AB (publ) (Sweden), Tenaris (Luxembourg), United States Steel Corporation (U.S.), Benteler (Germany), Aperam (Luxembourg), Cleveland-Cliffs Inc. (U.S.), Acciai Speciali Terni (Italy), KME GERMANY GMBH (Germany), Wieland (Germany), Hutmen LLC (Poland), Atlas Copco UK Holdings (Sweden), Hindustan Dorr-Oliver Ltd (India), Modine Manufacturing Company (U.S.), GEA Group Aktiengesellschaft (U.S.), Kelvion Holdings GmbH (Germany) |

|

Market Opportunities |

|

Market Definition

Industrial tubes are hollow, long tubes used for several purposes. They are formed by two different methods, resulting in a seamless or welded pipe. Industrial tubes have numerous advantages such as a wide range of sizes, ease of joining and installation, variety of applications, corrosion resistance and versatility.

Global Industrial Tube Market Dynamics

Drivers

- Rising demand of seamless tube in oil and gas industry

The seamless tube is widely used in the oil and gas industry. All seamless tubes and pipes are used for several oil & gas applications such as in OCTG, subsea flowlines, topside process pipes, riser pipes and, instrumentation tubes or heat exchanger tubes, among others. The increasing demand of seamless tube in oil and gas industry are anticipated to drive the growth rate of the industrial tube market.

- Rising demand of industrial tube in several industries

Industrial tubes are used in several industries, mainly automotive, chemical, oil & gas, and petrochemical. The demand for the industrial tube increases due to their wide range of properties such as excellent chemical and corrosion resistance, high strength, high durability, formability, and weldability all over the globe which is expected to act as a major driving factor for the growth of the industrial tube market.

Furthermore, increasing energy & power production is the major factor for boosting the market growth. Also, the effective properties of industrial tubes such as low-temperature properties, excellent strength and productive characteristics offered by steel tubes are the major factors among others which is anticipated to drive market growth rate.

Opportunities

- High usage of industrial tube due to wide range of applications

Industrial tubes are majorly used for several applications such as structural tubes, heat exchanger tubes, mechanical tubes, and hydraulic & instrumentation tubes. Furthermore, industrial tubes are used to manufacture capillary, precision, and boiler tubes. Shell and tube heat exchanger includes several tubes which has installed inside a cylindrical shell. So, the high demand of industrial tube in several applications will create immense opportunities for the market and boost the market growth rate,

Furthermore, the rapid growth of the chemical and pharmaceutical industry and increasing investment in the exploration of oil fields provide lucrative opportunities to the growth of the industrial tubes market.

Restraints/ Challenges

- High cost associated with industrial tube

The unstable prices of raw materials used for industrial tube production is one of the major factors that restrain the demand of industrial tube and obstructs the market growth rate.

Moreover, stringent government rules and regulations and low demand of industrial tube from the saturated market are other factors acting as restraints and will further challenge the market growth rate.

This industrial tube market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the industrial tube market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Impact and Current Market Scenario of Raw Material Shortage and Shipping Delays

Data Bridge Market Research offers a high-level analysis of the market and delivers information by keeping in account the impact and current market environment of raw material shortage and shipping delays. This translates into assessing strategic possibilities, creating effective action plans, and assisting businesses in making important decisions.

Apart from the standard report, we also offer in-depth analysis of the procurement level from forecasted shipping delays, distributor mapping by region, commodity analysis, production analysis, price mapping trends, sourcing, category performance analysis, supply chain risk management solutions, advanced benchmarking, and other services for procurement and strategic support.

Expected Impact of Economic Slowdown on the Pricing and Availability of Products

When economic activity slows, industries begin to suffer. The forecasted effects of the economic downturn on the pricing and accessibility of the products are taken into account in the market insight reports and intelligence services provided by DBMR. With this, our clients can typically keep one step ahead of their competitors, project their sales and revenue, and estimate their profit and loss expenditures.

Global Industrial Tube Market Scope

The industrial tube market is segmented on the basis of type, material, manufacturing and end-use. The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Type

- Process Pipes

- Heat Exchanger

- Mechanical

- Structural

- Others

- Capillary Tubes

- Boiler Tubes

- Precision Tubes

Material

- Steel

- Non-Steel

Manufacturing

- Seamless

- Welded

End-Use

- Oil & Gas and Petrochemical

- Automotive

- Chemical

- Others

- Sanitary Systems

- Water Treatment

- Medical Tubes

- Pharmaceutical

- Food & Beverage

- Aerospace

- Marine

Industrial Tube Market Regional Analysis/Insights

The industrial tube market is analysed and market size insights and trends are provided by country, type, material, manufacturing and end-use as referenced above.

The countries covered in the industrial tube market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

Asia-Pacific dominates the industrial tube market in terms of revenue and market share. This is due to increased automotive production and increasing investment in oil & gas exploration in this region.

North America is anticipated to be the fastest developing region during the forecast period of 2022-2029 due to the growing automotive production, growth in the chemical and petrochemical industry, and development in tnumber of commercial infrastructure projects in this region.

The country section of the report also provides individual market impacting factors and changes in market regulation that impact the current and future trends of the market. Data points like down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Competitive Landscape and Industrial Tube Market Share Analysis

The industrial tube market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to industrial tube market.

Some of the major players operating in the industrial tube market are:

- Tata BlueScope Steel (Australia)

- Nippon Steel Corporation (Japan)

- VALLOUREC (France)

- Sandvik AB; (publ) (Sweden)

- Tenaris (Luxembourg)

- United States Steel Corporation (U.S.)

- Benteler (Germany)

- Aperam (Luxembourg)

- Cleveland-Cliffs Inc. (U.S.)

- Acciai Speciali Terni (Italy)

- KME GERMANY GMBH (Germany)

- Wieland (Germany)

- Hutmen LLC (Poland)

- Atlas Copco UK Holdings (Sweden)

- Hindustan Dorr-Oliver Ltd (India)

- Modine Manufacturing Company (U.S.)

- GEA Group Aktiengesellschaft (U.S.)

- Kelvion Holdings GmbH (Germany)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Интерактивная панель анализа данных

- Панель анализа компании для возможностей с высоким потенциалом роста

- Доступ аналитика-исследователя для настройки и запросов

- Анализ конкурентов с помощью интерактивной панели

- Последние новости, обновления и анализ тенденций

- Используйте возможности сравнительного анализа для комплексного отслеживания конкурентов

Методология исследования

Сбор данных и анализ базового года выполняются с использованием модулей сбора данных с большими размерами выборки. Этап включает получение рыночной информации или связанных данных из различных источников и стратегий. Он включает изучение и планирование всех данных, полученных из прошлого заранее. Он также охватывает изучение несоответствий информации, наблюдаемых в различных источниках информации. Рыночные данные анализируются и оцениваются с использованием статистических и последовательных моделей рынка. Кроме того, анализ доли рынка и анализ ключевых тенденций являются основными факторами успеха в отчете о рынке. Чтобы узнать больше, пожалуйста, запросите звонок аналитика или оставьте свой запрос.

Ключевой методологией исследования, используемой исследовательской группой DBMR, является триангуляция данных, которая включает в себя интеллектуальный анализ данных, анализ влияния переменных данных на рынок и первичную (отраслевую экспертную) проверку. Модели данных включают сетку позиционирования поставщиков, анализ временной линии рынка, обзор рынка и руководство, сетку позиционирования компании, патентный анализ, анализ цен, анализ доли рынка компании, стандарты измерения, глобальный и региональный анализ и анализ доли поставщика. Чтобы узнать больше о методологии исследования, отправьте запрос, чтобы поговорить с нашими отраслевыми экспертами.

Доступна настройка

Data Bridge Market Research является лидером в области передовых формативных исследований. Мы гордимся тем, что предоставляем нашим существующим и новым клиентам данные и анализ, которые соответствуют и подходят их целям. Отчет можно настроить, включив в него анализ ценовых тенденций целевых брендов, понимание рынка для дополнительных стран (запросите список стран), данные о результатах клинических испытаний, обзор литературы, обновленный анализ рынка и продуктовой базы. Анализ рынка целевых конкурентов можно проанализировать от анализа на основе технологий до стратегий портфеля рынка. Мы можем добавить столько конкурентов, о которых вам нужны данные в нужном вам формате и стиле данных. Наша команда аналитиков также может предоставить вам данные в сырых файлах Excel, сводных таблицах (книга фактов) или помочь вам в создании презентаций из наборов данных, доступных в отчете.