Global Electrically Conductive Epoxy Adhesive Market

Размер рынка в млрд долларов США

CAGR :

%

USD

829.38 Million

USD

1,435.72 Million

2024

2032

USD

829.38 Million

USD

1,435.72 Million

2024

2032

| 2025 –2032 | |

| USD 829.38 Million | |

| USD 1,435.72 Million | |

|

|

|

|

Глобальный рынок электропроводящих эпоксидных клеев, тип химического состава (силикон, полиуретан, акрил, другие химические соединения), материал наполнителя (серебряные наполнители, медные наполнители, углеродные наполнители и другие), тип (изотропный, анизотропный), применение (солнечные элементы, автомобилестроение, светодиодное освещение, печатные платы, бионауки, бытовая электроника, аэрокосмическая промышленность и другие) – тенденции отрасли и прогноз до 2032 года

Объем рынка электропроводящего эпоксидного клея

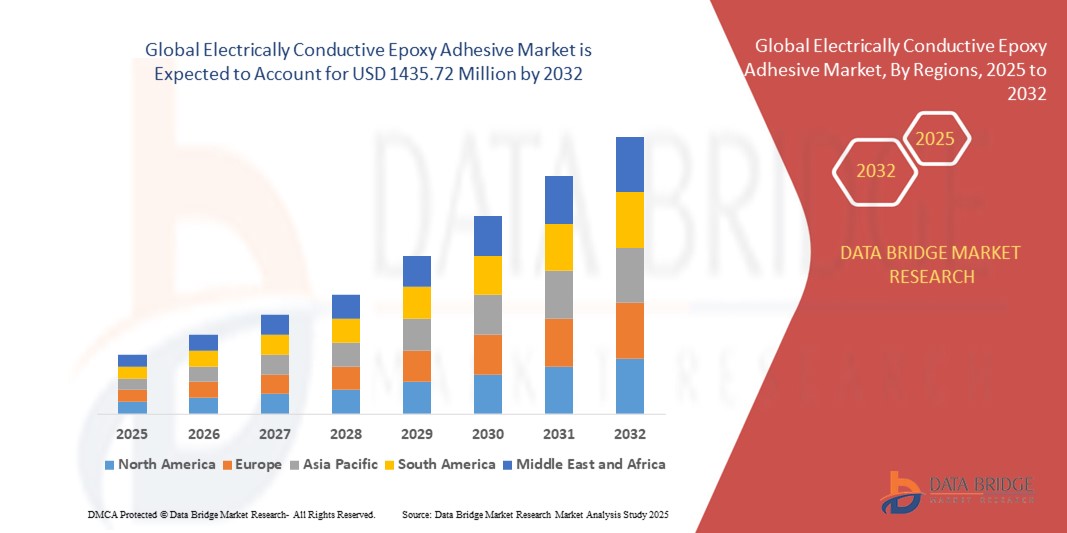

- Объем мирового рынка электропроводящих эпоксидных клеев в 2024 году оценивался в 829,38 млн долларов США и, как ожидается, достигнет 1435,72 млн долларов США к 2032 году при среднегодовом темпе роста 7,10% в течение прогнозируемого периода .

- Рост рынка обусловлен увеличением спроса на легкие, высокоэффективные клеи в секторах электроники, автомобилестроения и возобновляемой энергетики, а также растущим внедрением современных проводящих материалов для улучшения связи и долговечности.

- Растущая осведомленность о преимуществах электропроводящих клеев, таких как улучшенное терморегулирование и надежность в миниатюрных электронных устройствах, еще больше стимулирует рыночный спрос в каналах OEM и вторичного рынка.

Анализ рынка электропроводящих эпоксидных клеев

- Рынок электропроводящих эпоксидных клеев переживает бурный рост из-за растущей потребности в надежных и высокопроизводительных решениях для склеивания в современных электронных и автомобильных приложениях.

- Спрос со стороны солнечной энергетики, светодиодного освещения и производства печатных плат (ПП) побуждает производителей внедрять инновации, предлагая высокопроводящие, долговечные и термостойкие клеевые решения.

- Азиатско-Тихоокеанский регион доминировал на рынке электропроводящих эпоксидных клеев с наибольшей долей выручки в 31,2% в 2024 году, что обусловлено бурным развитием электронной промышленности, крупномасштабным производством и растущим внедрением решений в области возобновляемой энергии в таких странах, как Китай, Япония и Южная Корея.

- Ожидается, что Северная Америка станет регионом с самыми высокими темпами роста в течение прогнозируемого периода, чему будут способствовать стремительные разработки в области автомобильной электроники, рост инвестиций в возобновляемые источники энергии и повышение спроса на высокоэффективные клеи в США и Канаде.

- Сегмент полиуретанов занял наибольшую долю рынка, составив 34% в 2024 году, благодаря своей превосходной адгезионной прочности, механической прочности и превосходной электропроводности. Эпоксидные клеи широко используются в таких отраслях, как бытовая электроника, автомобилестроение и аэрокосмическая промышленность, благодаря своей способности обеспечивать прочное склеивание и надежные электрические соединения в высокопроизводительных системах.

Область применения отчета и сегментация рынка электропроводящих эпоксидных клеев

|

Атрибуты |

Ключевые данные о рынке электропроводящего эпоксидного клея |

|

Охваченные сегменты |

|

|

Страны действия |

Северная Америка

Европа

Азиатско-Тихоокеанский регион

Ближний Восток и Африка

Южная Америка

|

|

Ключевые игроки рынка |

|

|

Рыночные возможности |

|

|

Информационные наборы данных с добавленной стоимостью |

Помимо информации о рыночных сценариях, таких как рыночная стоимость, темпы роста, сегментация, географический охват и основные игроки, рыночные отчеты, подготовленные Data Bridge Market Research, также включают анализ импорта и экспорта, обзор производственных мощностей, анализ потребления продукции, анализ ценовых тенденций, сценарий изменения климата, анализ цепочки поставок, анализ цепочки создания стоимости, обзор сырья/расходных материалов, критерии выбора поставщиков, анализ PESTLE, анализ Портера и нормативную базу. |

Тенденции рынка электропроводящих эпоксидных клеев

Растущая интеграция нанотехнологий и экологически чистых формул

- На мировом рынке электропроводящих эпоксидных клеев наблюдается заметная тенденция к интеграции нанотехнологий и экологически чистых рецептур.

- Нанотехнологии повышают эффективность токопроводящих клеев, улучшая электропроводность, термостабильность и механическую прочность за счет использования наноразмерных наполнителей, таких как серебро, углеродные нанотрубки или графен.

- Эти достижения позволяют повысить эффективность соединения миниатюрных электронных компонентов, что критически важно для применения в потребительской электронике, автомобилестроении и аэрокосмической промышленности.

- Например, компании разрабатывают эпоксидные клеи с наноэффектом, которые обеспечивают превосходную проводимость для печатных плат высокой плотности и гибкой электроники, позволяя создавать компактные и легкие конструкции.

- Кроме того, переход к экологически безопасным составам, обусловленный строгими экологическими нормами, такими как директива ЕС RoHS, способствует разработке клеев с низким содержанием летучих органических соединений и без свинца, что делает их более экологичными и привлекательными для производителей, заботящихся об окружающей среде.

- Эти тенденции повышают функциональность и рыночную привлекательность электропроводящих эпоксидных клеев, особенно в регионах с высоким ростом, таких как Азиатско-Тихоокеанский регион.

Динамика рынка электропроводящих эпоксидных клеев

Водитель

Растущий спрос на миниатюрную электронику и электромобили

- Растущий спрос на миниатюрные электронные устройства, такие как смартфоны, носимые устройства и гаджеты с поддержкой Интернета вещей, является ключевым фактором для мирового рынка электропроводящих эпоксидных клеев.

- Эти клеи обеспечивают надежное электрическое соединение и прочное соединение компактных компонентов в таких приложениях, как солнечные элементы, автомобильная электроника, светодиодное освещение и печатные платы.

- Стремительный рост числа электромобилей (ЭМ) и гибридных электромобилей (ГЭМ) еще больше увеличивает спрос, поскольку электропроводящие эпоксидные клеи необходимы для склеивания аккумуляторных систем, датчиков и силовой электроники, обеспечивая легкость и эффективность конструкций.

- Правительственные инициативы, направленные на развитие возобновляемой энергетики, особенно в Азиатско-Тихоокеанском регионе, стимулируют использование этих клеев в производстве солнечных элементов, причем такие страны, как Китай и Индия, лидируют в инвестициях в солнечную энергетику.

- Достижения в области технологий 5G и Интернета вещей обеспечивают более быструю передачу данных и более сложные приложения, что еще больше расширяет применение электропроводящих эпоксидных клеев в электронике следующего поколения.

- Производители все чаще используют эти клеи в качестве стандартных решений, чтобы удовлетворить ожидания потребителей в отношении высокопроизводительных, компактных и экологичных продуктов.

Сдержанность/Вызов

Высокие производственные затраты и проблемы соблюдения нормативных требований

- Высокие производственные затраты, связанные с электропроводящими эпоксидными клеями, включая стоимость сырья, такого как серебряные наполнители, и сложные производственные процессы, создают значительное препятствие для их широкого внедрения, особенно на чувствительных к стоимости развивающихся рынках.

- Интеграция этих клеев в существующие производственные процессы может быть технически сложной и дорогостоящей, требующей специального оборудования и опыта.

- Безопасность данных и соблюдение экологических норм создают дополнительные проблемы, поскольку эти клеи должны соответствовать строгим нормам, таким как директивы ЕС REACH и RoHS, которые предписывают использование составов с низким содержанием летучих органических соединений и без опасных веществ.

- Разрозненность нормативно-правовой базы в разных регионах, особенно в отношении экологических стандартов и стандартов безопасности, усложняет деятельность мировых производителей и увеличивает затраты на соблюдение требований.

- Эти факторы могут сдерживать внедрение в регионах с высокой чувствительностью к затратам или жесткой нормативной базой, что потенциально ограничивает рост рынка, несмотря на высокий спрос в таких областях, как автомобилестроение и солнечные батареи.

Рынок электропроводящих эпоксидных клеев

Рынок сегментирован по типу химического вещества, типу наполнителя и области применения.

- По типу химии

По химическому составу мировой рынок электропроводящих эпоксидных клеев сегментируется на силиконовые, полиуретановые, акриловые и другие виды клея. В 2024 году полиуретановый сегмент занял наибольшую долю рынка, составившую 34%, благодаря своей превосходной адгезионной прочности, механической прочности и отличной электропроводности. Клеи на основе эпоксидной смолы широко используются в таких отраслях, как бытовая электроника, автомобилестроение и аэрокосмическая промышленность, благодаря своей способности обеспечивать прочное соединение и надежные электрические соединения в высокопроизводительных приложениях. Совместимость с различными поверхностями и устойчивость к термическим и механическим нагрузкам еще больше укрепляют их лидирующие позиции на рынке.

Ожидается, что сегмент силиконовых материалов будет демонстрировать самые высокие темпы роста в период с 2025 по 2032 год, поскольку отрасли всё больше внимания уделяют гибкости и термостойкости в суровых условиях. Электропроводящие клеи на основе силикона обладают эластичностью, влагостойкостью и стабильностью характеристик в широком диапазоне температур, что делает их идеальными для гибкой электроники и высокотемпературных применений, таких как светодиодное освещение и солнечные элементы. Растущий спрос на экологичные и гибкие клеевые решения ещё больше ускоряет внедрение силиконовых составов.

- По материалу наполнителя

В зависимости от типа наполнителя мировой рынок электропроводящих эпоксидных клеев подразделяется на серебряные, медные, углеродные и другие наполнители. Сегмент серебряных наполнителей обеспечил наибольшую долю выручки в 2024 году благодаря их исключительной электропроводности и низкому удельному сопротивлению, что обеспечивает эффективность электрических соединений. Клеи с серебряным наполнителем широко используются в микроэлектронике, автомобильных датчиках и аэрокосмической промышленности благодаря своей надежности и способности сохранять эксплуатационные характеристики в сложных условиях. Высокая электропроводность и совместимость с передовыми производственными процессами делают их предпочтительным выбором для высокопроизводительных приложений.

Ожидается, что сегмент углеродных наполнителей будет расти самыми быстрыми темпами в год в период с 2025 по 2032 год, что обусловлено растущим спросом на экономичные и экологичные альтернативы. Углеродные наполнители, такие как углеродные нанотрубки и технический углерод, обеспечивают необходимую электропроводность для таких применений, как печатные платы и бытовая электроника, предлагая при этом преимущества в плане снижения веса и экологичности. Растущее внимание к экологически безопасному производству и растущее внедрение углеродных материалов в возобновляемых источниках энергии, таких как солнечные батареи, дополнительно стимулируют рост этого сегмента.

- По типу

В зависимости от типа, мировой рынок электропроводящих эпоксидных клеев сегментируется на изотропные и анизотропные проводящие клеи. Сегмент изотропных проводящих клеев обеспечил наибольшую долю выручки в 2024 году благодаря их способности равномерно проводить электричество во всех направлениях. Это делает их незаменимыми в областях, требующих стабильного электрического соединения, таких как автомобильная электроника, солнечные элементы и печатные платы. Их универсальность и простота использования в крупносерийном производстве способствуют их широкому распространению.

Прогнозируется, что сегмент анизотропных токопроводящих клеев будет расти самыми быстрыми темпами в период с 2025 по 2032 год, что обусловлено растущим спросом на точность в миниатюрной электронике. Анизотропные клеи проводят электричество в определённом направлении, что делает их идеальными для микросхем с малым шагом выводов в потребительской электронике, такой как смартфоны, носимые устройства и ЖК-дисплеи. Тенденция к миниатюризации устройств и потребность в надёжном и высокоточном соединении в современной электронике стимулируют быстрый рост этого сегмента.

- По применению

По сфере применения мировой рынок электропроводящих эпоксидных клеев сегментируется на следующие сегменты: солнечные элементы, автомобильная промышленность, светодиодное освещение, печатные платы, биотехнологии, бытовая электроника, аэрокосмическая промышленность и другие. Сегмент бытовой электроники обеспечил наибольшую долю выручки в 2024 году благодаря экспоненциальному росту числа смартфонов, планшетов, носимых устройств и других подключенных устройств. Электропроводящие эпоксидные клеи критически важны для склеивания компонентов, снижения электромагнитных помех и обеспечения надежного электрического соединения в компактных высокопроизводительных устройствах. Стремление к бесшовной интеграции и повышению долговечности устройств еще больше увеличивает спрос в этом сегменте.

Прогнозируется, что сегмент солнечных элементов будет расти самыми быстрыми темпами в период с 2025 по 2032 год, чему будет способствовать глобальный переход на возобновляемые источники энергии и всё более широкое внедрение солнечных фотоэлектрических систем. Электропроводящие эпоксидные клеи используются в качестве материалов для соединения ячеек в солнечных панелях, предлагая преимущества по сравнению с традиционной пайкой за счёт снижения температуры обработки и повышения долговечности. Поддержка со стороны государства, такая как инвестиции в солнечную инфраструктуру, и растущий спрос на решения в области устойчивой энергетики являются ключевыми факторами быстрого роста этого сегмента.

Региональный анализ рынка электропроводящего эпоксидного клея

- Азиатско-Тихоокеанский регион доминировал на рынке электропроводящих эпоксидных клеев с наибольшей долей выручки в 31,2% в 2024 году, что обусловлено бурным развитием электронной промышленности, крупномасштабным производством и растущим внедрением решений в области возобновляемой энергии в таких странах, как Китай, Япония и Южная Корея.

- Потребители отдают предпочтение электропроводящим эпоксидным клеям из-за их превосходной электропроводности, механической прочности и термостойкости, особенно в регионах с высоким уровнем внедрения технологий и крупными производственными центрами.

- Росту способствуют достижения в области клеевых технологий, включая высокоэффективные эпоксидные составы и проводящие наполнители, такие как серебро и медь, а также растущее внедрение в сегментах OEM и вторичного рынка для таких применений, как солнечные элементы, автомобильная электроника, светодиодное освещение и печатные платы.

Обзор рынка электропроводящих эпоксидных клеев в Японии

Ожидается, что рынок электропроводящих эпоксидных клеев в Японии будет демонстрировать быстрый рост благодаря высокому потребительскому спросу на высококачественные, технологичные клеи, повышающие надежность цепей и терморегулирование. Присутствие крупных производителей электроники и автомобилей, а также внедрение токопроводящих клеев в производство автомобилей OEM ускоряют проникновение на рынок. Растущий интерес к вторичному рынку потребительской электроники также способствует росту рынка .

Обзор рынка электропроводящих эпоксидных клеев в Китае

Китай занимает наибольшую долю на рынке электропроводящих эпоксидных клеев Азиатско-Тихоокеанского региона, чему способствуют быстрая урбанизация, рост числа автомобилей и растущий спрос на передовые решения для склеивания солнечных элементов и автомобильной электроники. Растущий средний класс страны и ориентация на интеллектуальную мобильность способствуют внедрению высокоэффективных эпоксидных клеев. Мощные внутренние производственные мощности и конкурентоспособные цены повышают доступность рынка.

Обзор рынка электропроводящих эпоксидных клеев в США

Ожидается, что рынок электропроводящих эпоксидных клеев в США продемонстрирует значительный рост, обусловленный высоким спросом на рынке автомобильной электроники и запчастей для потребительской электроники. Растущее понимание преимуществ токопроводящих клеев, таких как надежные электрические соединения и теплоотвод, стимулирует расширение рынка. Тенденция к миниатюризации электронных компонентов и ужесточение правил, поощряющих использование бессвинцовых решений, дополнительно стимулируют рост рынка. Интеграция токопроводящих клеев автопроизводителями в электромобили (ЭМ) дополняет продажи на вторичном рынке, создавая разнообразную продуктовую экосистему.

Обзор европейского рынка электропроводящих эпоксидных клеев

Ожидается, что европейский рынок электропроводящих эпоксидных клеев продемонстрирует значительный рост, чему будет способствовать регулирующее регулирование, ориентированное на экологически чистые и бессвинцовые клеевые решения. Потребители ищут клеи, обеспечивающие надежную электропроводность при сохранении механической прочности. Рост заметен как в сфере OEM-установок, так и в проектах модернизации, при этом такие страны, как Германия и Франция, демонстрируют значительное потребление благодаря растущему спросу в автомобильной и аэрокосмической промышленности, а также экологическим проблемам.

Обзор рынка электропроводящих эпоксидных клеев в Великобритании

Ожидается, что рынок электропроводящих эпоксидных клеев в Великобритании будет демонстрировать быстрый рост, обусловленный спросом на современные электронные и автомобильные решения в городских и пригородных условиях. Повышенный интерес к высокоэффективным клеям для экранирования электромагнитных помех и сборки схем стимулирует их внедрение. Меняющиеся экологические нормы и акцент на устойчивом развитии влияют на выбор потребителей, обеспечивая баланс между электропроводностью и соответствием требованиям.

Обзор рынка электропроводящих эпоксидных клеев в Германии

Ожидается, что в Германии будет наблюдаться быстрый рост рынка электропроводящих эпоксидных клеев, что обусловлено развитыми секторами автомобилестроения и производства электроники, а также высоким вниманием потребителей к энергоэффективности. Немецкие потребители предпочитают технологически продвинутые клеи, которые улучшают электрические характеристики и способствуют снижению энергопотребления электромобилей и умной электроники. Интеграция этих клеев в премиальные автомобили и решения для вторичного рынка способствует устойчивому росту рынка.

Доля рынка электропроводящего эпоксидного клея

Лидерами отрасли по производству электропроводящих эпоксидных клеев являются, в первую очередь, хорошо зарекомендовавшие себя компании, среди которых:

- Master Bond Inc. (США)

- Панакол-Элосол ГмбХ (Германия)

- Aremco Products Inc. (США)

- DuPont (США)

- SOLVAY (Бельгия)

- Доу (США)

- Henkel AG & Co. KgaA (Германия)

- 3M (США)

- Бостик (Франция)

- Sika AG (Швейцария)

- Х. Б. Фуллер (США)

- BASF SE (Германия)

- DAP Global Inc.(США)

- Оуэнс Корнинг (США)

- Компания Chemours (США)

- Paroc Group (Финляндия)

- Kingspan Group (Ирландия)

Каковы последние тенденции на мировом рынке электропроводящих эпоксидных клеев?

- В мае 2024 года компания Azelis выпустила ARALDITE® GY 40100 – усовершенствованную электропроводящую эпоксидную смолу, разработанную корпорацией Huntsman. Этот инновационный продукт содержит низкоконцентрированный (2 мас.%) токопроводящий наполнитель MIRALON®, обеспечивающий высокую электропроводность при сохранении механических свойств и минимизации влияния вязкости. В отличие от традиционных наполнителей, нанотрубки MIRALON® тонко диспергированы, что упрощает обработку смолы и повышает безопасность её использования, исключая попадание наноматериалов в воздух. ARALDITE® GY 40100 совместим с широким спектром добавок и отвердителей, обеспечивая повышенную гибкость рецептур для клеев, используемых в электронике, аэрокосмической промышленности и других отраслях промышленности.

- В июне 2023 года компании Polytec PT и Bostik объединили усилия, чтобы представить новую линейку теплопроводящих клеев (ТКА), специально разработанных для аккумуляторов электромобилей (ЭМ). Это партнерство ориентировано на растущий сектор электромобильности и предлагает передовые решения в области терморегулирования, необходимые для поддержания оптимальной производительности и безопасности аккумуляторов. ТКА, включая XPU TCA 202 на основе полиуретана, сочетают высокую теплопроводность с механической прочностью и гибкостью. Разработанные для простоты обработки и соответствия строгим стандартам безопасности, эти клеи обеспечивают быструю зарядку и эффективное рассеивание тепла — ключевые факторы современных аккумуляторных систем электромобилей.

- В мае 2023 года компания Henkel расширила свой ассортимент продукции для аккумуляторных систем электромобилей, выпустив Loctite® TLB 9300 APSi – инновационный инжекционный теплопроводящий клей. Этот двухкомпонентный полиуретановый клей обеспечивает как структурное склеивание, так и теплопроводность, что делает его идеальным для соединения аккумуляторных элементов с модулями или системами охлаждения. Благодаря теплопроводности 3 Вт/м·К, умеренной вязкости и самовыравнивающимся свойствам он обеспечивает эффективное рассеивание тепла и прочную адгезию к различным поверхностям. Клей отверждается при комнатной температуре, отвечает требованиям устойчивого развития и повышает безопасность, устраняя необходимость в дополнительных энергозатратах во время обработки.

- В январе 2023 года компания Parker Hannifin расширила свой ассортимент продукции для производителей электромобилей (ЭМ), представив новые теплопроводящие (ТП) клеи и однокомпонентные (1К) низкоплотные заполнительные компаунды. Эти продукты дополняют существующую линейку терморегулирующих компаундов, клеев и заполнительных компаундов Parker CoolTherm™. Разработанные с учетом меняющихся потребностей аккумуляторных систем электромобилей, новые ТП клеи обеспечивают прочную адгезию, высокую теплопроводность и низкую диэлектрическую проницаемость, идеально подходящую для прямого приклеивания аккумуляторных элементов к охлаждающим пластинам или шасси. 1К заполнительные компаунды упрощают производство благодаря отличным текучим свойствам и экологичности, способствуя эффективному и масштабируемому производству электромобилей.

- В ноябре 2022 года компания Henkel представила Loctite® Ablestik ICP 2120 – электропроводящий клей, разработанный для сложных условий применения компактных модулей камер (CCM) в мобильных устройствах. Этот инновационный материал отличается низким модулем упругости и быстрым низкотемпературным профилем отверждения, что позволяет производить продукцию большими партиями, защищая хрупкие, термочувствительные компоненты. Его химическая реакция отверждения под воздействием влаги исключает необходимость высокотемпературной обработки, снижая энергопотребление и повышая выход годных изделий. Благодаря отличным характеристикам заземления и высокой теплопроводности (7,0 Вт/м·К) он обеспечивает надежную работу и эффективное рассеивание тепла во все более миниатюрных и многофункциональных системах камер.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Интерактивная панель анализа данных

- Панель анализа компании для возможностей с высоким потенциалом роста

- Доступ аналитика-исследователя для настройки и запросов

- Анализ конкурентов с помощью интерактивной панели

- Последние новости, обновления и анализ тенденций

- Используйте возможности сравнительного анализа для комплексного отслеживания конкурентов

Методология исследования

Сбор данных и анализ базового года выполняются с использованием модулей сбора данных с большими размерами выборки. Этап включает получение рыночной информации или связанных данных из различных источников и стратегий. Он включает изучение и планирование всех данных, полученных из прошлого заранее. Он также охватывает изучение несоответствий информации, наблюдаемых в различных источниках информации. Рыночные данные анализируются и оцениваются с использованием статистических и последовательных моделей рынка. Кроме того, анализ доли рынка и анализ ключевых тенденций являются основными факторами успеха в отчете о рынке. Чтобы узнать больше, пожалуйста, запросите звонок аналитика или оставьте свой запрос.

Ключевой методологией исследования, используемой исследовательской группой DBMR, является триангуляция данных, которая включает в себя интеллектуальный анализ данных, анализ влияния переменных данных на рынок и первичную (отраслевую экспертную) проверку. Модели данных включают сетку позиционирования поставщиков, анализ временной линии рынка, обзор рынка и руководство, сетку позиционирования компании, патентный анализ, анализ цен, анализ доли рынка компании, стандарты измерения, глобальный и региональный анализ и анализ доли поставщика. Чтобы узнать больше о методологии исследования, отправьте запрос, чтобы поговорить с нашими отраслевыми экспертами.

Доступна настройка

Data Bridge Market Research является лидером в области передовых формативных исследований. Мы гордимся тем, что предоставляем нашим существующим и новым клиентам данные и анализ, которые соответствуют и подходят их целям. Отчет можно настроить, включив в него анализ ценовых тенденций целевых брендов, понимание рынка для дополнительных стран (запросите список стран), данные о результатах клинических испытаний, обзор литературы, обновленный анализ рынка и продуктовой базы. Анализ рынка целевых конкурентов можно проанализировать от анализа на основе технологий до стратегий портфеля рынка. Мы можем добавить столько конкурентов, о которых вам нужны данные в нужном вам формате и стиле данных. Наша команда аналитиков также может предоставить вам данные в сырых файлах Excel, сводных таблицах (книга фактов) или помочь вам в создании презентаций из наборов данных, доступных в отчете.