Ротационная формовка или ротационное формование — это производственный процесс, используемый для создания полых бесшовных пластиковых изделий посредством многоэтапного процесса формования. Он включает в себя помещение порошкообразного полимера в форму, которая затем нагревается и вращается в двухосном направлении в печи. При вращении формы тепло расплавляет полимер, который равномерно покрывает внутренние поверхности формы, создавая однородный слой. После достижения желаемой толщины форма охлаждается, а затвердевший продукт извлекается. Ротационная формовка очень универсальна, позволяя создавать сложные формы и прочные детали без швов и стыков.

Продукция, полученная методом ротационного формования, охватывает широкий спектр применения, включая резервуары, контейнеры, игрушки, автомобильные компоненты, морские буи, игровое оборудование и конструкции, разработанные по индивидуальному заказу. Они известны своей прочностью, экономичностью, легкостью и коррозионной стойкостью, что делает их пригодными для таких отраслей, как сельское хозяйство, здравоохранение, строительство и транспорт. Этот процесс обеспечивает стабильное производство с минимальными отходами материала.

Доступ к полному отчету по адресу https://www.databridgemarketresearch.com/reports/latin-america-rotomolding-market

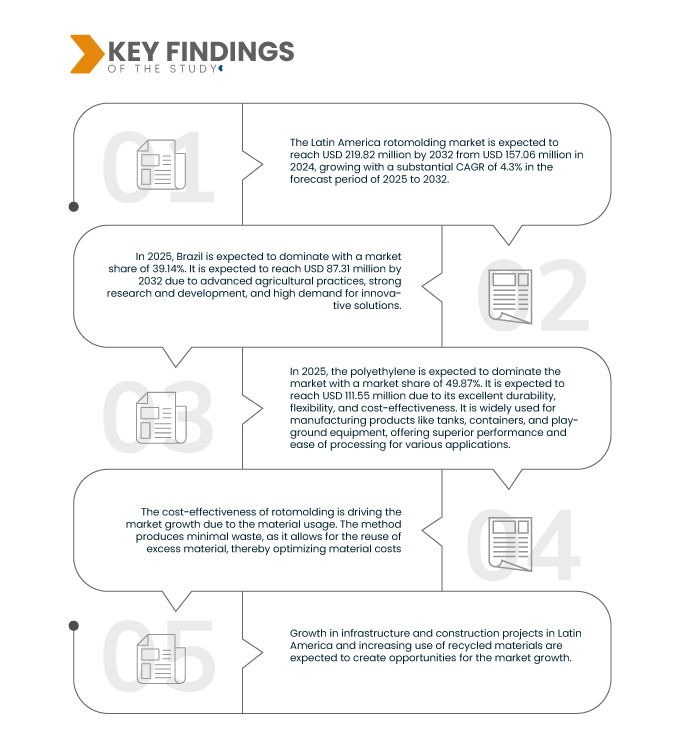

По данным исследования рынка Data Bridge, ожидается, что объем рынка центробежного формования в Латинской Америке к 2032 году достигнет 219,82 млн долларов США по сравнению с 157,06 млн долларов США в 2024 году, при этом среднегодовой темп роста составит 4,3% в прогнозируемый период с 2025 по 2032 год.

Основные выводы исследования

Экономически эффективный производственный процесс

Ротационное формование предлагает экономически эффективный метод производства по сравнению с литьем под давлением и выдувным формованием, что делает его очень выгодным для чувствительных к затратам рынков, таких как развивающиеся экономики Латинской Америки. Процесс включает нагревание порошка пластиковой смолы внутри формы, которая вращается по двум осям, обеспечивая равномерное покрытие и устраняя необходимость в системах высокого давления или сложном оборудовании, что снижает капитальные и эксплуатационные расходы. Ротационное формование минимизирует отходы материала, позволяя повторно использовать излишки материала, и эффективно производит большие, сложные, полые изделия за один цикл без швов или стыков. Это снижает производственные затраты и расходы на оснастку, поскольку формы обычно изготавливаются из доступного алюминия или стали. Процесс также обеспечивает значительную гибкость конструкции, что делает его привлекательным для малых и средних предприятий (МСП) в Латинской Америке, которые ищут высококачественную, разнообразную продукцию, такую как автомобильные компоненты и сельскохозяйственные резервуары. В целом, низкие капитальные требования, минимизация отходов и универсальные производственные возможности ротационного формования обуславливают его экономическую эффективность и широкое внедрение.

Область отчета и сегментация рынка

Отчет Метрика

|

Подробности

|

Прогнозируемый период

|

2025-2032

|

Базовый год

|

2024

|

Исторические годы

|

2023 (Можно настроить на 2013-2017)

|

Количественные единицы

|

Доход в млн. долл. США

|

Охваченные сегменты

|

Материал (полиэтилен, полипропилен , поликарбонат , ПВХ, полиуретан , нейлон, эластомеры и другие), форма (порошок и жидкость), полезность (нагрев, охлаждение и другие), тип машины (двухосная машина, карусельная машина, челночная машина, рок-н-ролльная машина, грейферная машина, машина с поворотным рычагом, вертикальная колесная машина, машина с открытым пламенем и другие), применение (без бака и бак)

|

Страна покрытия

|

Бразилия, Мексика, Аргентина, Колумбия, Перу, Венесуэла, Чили, Боливия и остальные страны Латинской Америки

|

Охваченные участники рынка

|

Группа компаний Tecma (США), ROTOMAQ (Мексика), Rotomold Mexico (Мексика), Krompac (Мексика) и Brecher Manufacturing (Мексика)

|

Данные, отраженные в отчете

|

Помимо аналитических данных о рыночных сценариях, таких как рыночная стоимость, темпы роста, сегментация, географический охват и основные игроки, рыночные отчеты, подготовленные Data Bridge Market Research, также включают в себя углубленный экспертный анализ, географически представленные данные о производстве и мощностях компаний, схемы сетей дистрибьюторов и партнеров, подробный и обновленный анализ ценовых тенденций и анализ дефицита цепочки поставок и спроса.

|

Анализ сегмента

Рынок ротационного формования в Латинской Америке подразделяется на пять основных сегментов в зависимости от материала, формы, функциональности, типа машины и области применения.

- По материалу рынок сегментируется на полиэтилен, полипропилен, поликарбонат, ПВХ, полиуретан, нейлон, эластомеры и др.

Ожидается, что в 2025 году сегмент полиэтилена будет доминировать на рынке с долей рынка 49,87%.

Ожидается, что в 2025 году сегмент полиэтилена будет доминировать на рынке с долей рынка 49,87% благодаря своей превосходной прочности, гибкости и экономической эффективности. Он широко используется для производства таких продуктов, как резервуары, контейнеры и игровое оборудование, предлагая превосходные характеристики и простоту обработки для различных применений.

- По форме рынок сегментируется на порошкообразные и жидкие.

Ожидается, что в 2025 году порошок будет доминировать на рынке с долей рынка 51,78%.

Ожидается, что в 2025 году порошок будет доминировать на рынке с долей рынка 51,78% благодаря своей способности обеспечивать равномерную толщину стенок, превосходную отделку поверхности и сокращение отходов. Порошковые материалы легче обрабатывать, плавить и равномерно распределять, что делает их идеальными для высококачественного крупномасштабного производства.

- По принципу полезности рынок сегментируется на отопление, охлаждение и др. Ожидается, что в 2025 году сегмент отопления будет доминировать на рынке с долей рынка 44,41%.

- На основе типа машины рынок сегментирован на двухосные машины, карусельные машины, челночные машины, рок-н-ролльные машины, грейферные машины, машины с поворотным рычагом, вертикальные колесные машины, машины с открытым пламенем и другие. Ожидается, что в 2025 году сегмент двухосных машин будет доминировать на рынке с долей рынка 26,47%.

- На основе применения рынок сегментируется на non-tank и tank. В 2025 году сегмент non-tank, как ожидается, будет доминировать на рынке с долей рынка 65,50%

Основные игроки

Компания Data Bridge Market Research анализирует Tecma Group of Companies (США), ROTOMAQ (Мексика), Rotomold Mexico (Мексика), Krompac (Мексика) и Brecher Manufacturing (Мексика) как основных игроков рынка.

Региональный анализ

По страновому признаку рынок сегментирован на Бразилию, Мексику, Аргентину, Колумбию, Перу, Венесуэлу, Чили, Боливию и остальные страны Латинской Америки.

Ожидается, что Бразилия станет доминирующей и самой быстрорастущей страной на рынке ротационного формования в Латинской Америке.

Ожидается, что в 2025 году Бразилия будет доминировать на рынке ротационного формования в Латинской Америке благодаря своей крупной промышленной базе, значительному спросу на прочные и легкие изделия из пластика, а также мощному сельскохозяйственному и автомобильному секторам, которые в значительной степени зависят от решений, полученных ротационным формованием, таких как резервуары, контейнеры и автомобильные компоненты.

Согласно анализу Data Bridge Market Research :

Более подробную информацию об отчете о рынке ротационного формования в Латинской Америке можно получить здесь – https://www.databridgemarketresearch.com/reports/latin-america-rotomolding-market