Global Industrial Maintenance Services In Operational Improvement And Operational Maintenance Market

Tamanho do mercado em biliões de dólares

CAGR :

%

USD

51.77 Billion

USD

80.36 Billion

2022

2030

USD

51.77 Billion

USD

80.36 Billion

2022

2030

| 2023 –2030 | |

| USD 51.77 Billion | |

| USD 80.36 Billion | |

|

|

|

|

Serviços globais de manutenção industrial no mercado de melhoria operacional e manutenção operacional, por tipo de serviço (manutenção operacional industrial, melhoria operacional industrial), aplicação (controle de supervisão e aquisição de dados (SCADA), motores e acionamentos elétricos, válvulas e atuadores, sistema de controle distribuído (DCS), interface homem-máquina (HMI), sistema de execução de fabricação (MES), sistema de segurança, outros), indústria (automotiva, metais e mineração, alimentos e bebidas, aeroespacial e defesa, petróleo e gás, água e esgoto, energia e energia, química , farmacêutica, outros) – Tendências da indústria e previsão para 2030.

Análise e tamanho do mercado de serviços de manutenção industrial em melhoria operacional e manutenção operacional

Os processos de fabricação se enquadram na categoria de processos altamente complexos que utilizam diversos tipos de máquinas. O tamanho das instalações aumentou consideravelmente e existe uma variedade de máquinas disponíveis. Além disso, as indústrias estão sempre operando no limite de sua capacidade devido à crescente demanda do usuário final. Esses fatores também tornam extremamente difícil a manutenção e a inspeção das instalações. Além disso, a complexidade das máquinas frequentemente exige profissionais altamente qualificados, o que frequentemente falta na equipe da empresa. Consequentemente, há uma necessidade de empresas que forneçam serviços de manutenção industrial. Somente candidatos experientes e altamente qualificados, que tenham recebido treinamento específico em manutenção, são contratados pela empresa.

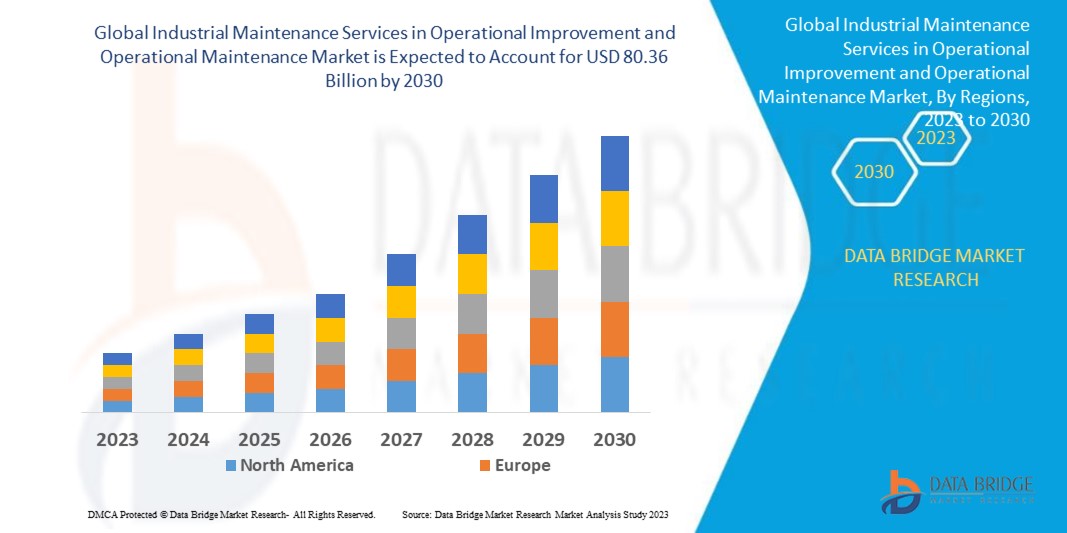

A Data Bridge Market Research analisa que os serviços de manutenção industrial no mercado de melhoria operacional e manutenção operacional, avaliados em US$ 51,77 bilhões em 2022, atingirão US$ 80,36 bilhões até 2030, crescendo a um CAGR de 5,65% durante o período previsto de 2023 a 2030. Além dos insights sobre cenários de mercado, como valor de mercado, taxa de crescimento, segmentação, cobertura geográfica e principais participantes, os relatórios de mercado selecionados pela Data Bridge Market Research também incluem análises aprofundadas de especialistas, produção e capacidade geograficamente representadas por empresas, layouts de rede de distribuidores e parceiros, análise detalhada e atualizada de tendências de preços e análise de déficit da cadeia de suprimentos e demanda.

Serviços de Manutenção Industrial em Melhoria Operacional e Escopo e Segmentação do Mercado de Manutenção Operacional

|

Métrica de Relatório |

Detalhes |

|

Período de previsão |

2023 a 2030 |

|

Ano base |

2022 |

|

Anos Históricos |

2021 (personalizável para 2015 - 2020) |

|

Unidades quantitativas |

Receita em bilhões de dólares americanos, volumes em unidades, preços em dólares americanos |

|

Segmentos abrangidos |

Tipo de serviço (Manutenção operacional industrial, Melhoria operacional industrial), Aplicação (Controle de supervisão e aquisição de dados (SCADA), Motores e acionamentos elétricos, Válvulas e atuadores, Sistema de controle distribuído (DCS), Interface homem-máquina (HMI), Sistema de execução de manufatura (MES), Sistema de segurança, Outros), Indústria (Automotiva, Metais e mineração, Alimentos e bebidas, Aeroespacial e defesa, Petróleo e gás, Água e esgoto, Energia e eletricidade, Química, Farmacêutica, Outros) |

|

Países abrangidos |

EUA, Canadá e México na América do Norte, Alemanha, França, Reino Unido, Holanda, Suíça, Bélgica, Rússia, Itália, Espanha, Turquia, Resto da Europa na Europa, China, Japão, Índia, Coreia do Sul, Cingapura, Malásia, Austrália, Tailândia, Indonésia, Filipinas, Resto da Ásia-Pacífico (APAC) na Ásia-Pacífico (APAC), Arábia Saudita, Emirados Árabes Unidos, África do Sul, Egito, Israel, Resto do Oriente Médio e África (MEA) como parte do Oriente Médio e África (MEA), Brasil, Argentina e Resto da América do Sul como parte da América do Sul |

|

Participantes do mercado cobertos |

ABB (Suíça), Siemens (Alemanha), Schneider Electric (França), Honeywell International Inc. (EUA), General Electric (EUA), Emerson Electric Co. (EUA), Rockwell Automation (EUA), Johnson Controls. (Irlanda), SKF (Suécia), Mitsubishi Electric Corporation (Japão), Yokogawa Electric Corporation (Japão), Danaher (EUA), AECOM (EUA), KBR, Inc. (EUA), Veolia Environnement SA (França), Tetra Tech, Inc. (EUA), John Wood Group PLC (Reino Unido), SNC-Lavalin Group. (Canadá), Fluor Corporation (EUA), Jacobs (EUA), Worley (Austrália), Bechtel Corporation (EUA), Black & Veatch Holding Company (EUA), CBRE (EUA) |

|

Oportunidades de mercado |

|

Definição de Mercado

Manutenção operacional e melhoria operacional são os dois principais componentes dos serviços de manutenção industrial. A melhoria operacional visa aumentar a eficácia e a produtividade geral por meio da otimização de processos, automação e atualização de equipamentos. Ela busca aumentar a produtividade, diminuir o tempo de inatividade, cortar custos e impulsionar a eficiência operacional. Por outro lado, a manutenção operacional envolve procedimentos de manutenção de rotina e preventiva para garantir a operação eficiente dos equipamentos, identificar potenciais problemas e aumentar a vida útil dos ativos. Os serviços de manutenção industrial ajudam as empresas a atingir as metas de produção, aumentar a confiabilidade dos equipamentos, reduzir o tempo de inatividade e maximizar o uso de recursos para aumentar a eficácia operacional e a economia de custos.

Serviços de Manutenção Industrial em Melhoria Operacional e Dinâmica de Mercado de Manutenção Operacional

Motoristas

- A estabilidade ambiental impulsiona o crescimento do mercado

A sustentabilidade ambiental é um fator-chave para os serviços de manutenção industrial em melhorias operacionais e manutenção operacional. Ao otimizar o consumo de energia, os serviços de manutenção ajudam as organizações a reduzir sua pegada de carbono e mitigar o impacto ambiental. Eles identificam oportunidades para minimizar a geração de resíduos, promover práticas de reciclagem e descarte responsável e implementar soluções ecologicamente corretas. Isso se alinha à crescente ênfase em sustentabilidade ambiental e responsabilidade social corporativa, à medida que as organizações se esforçam para operar de forma mais sustentável. Ao integrar práticas sustentáveis às operações de manutenção, as organizações podem contribuir para um futuro mais verde, atender aos requisitos regulatórios, fortalecer sua reputação e atrair stakeholders com consciência ambiental.

- A segurança aprimorada impulsiona o mercado

A melhoria da segurança é um fator crucial para os serviços de manutenção industrial em melhorias operacionais e manutenção operacional. Ao realizar inspeções regulares e manutenção preventiva, esses serviços ajudam a identificar e corrigir potenciais riscos à segurança em equipamentos e sistemas. Abordar problemas como fiação defeituosa, mecanismos de segurança com defeito ou componentes desgastados reduz o risco de acidentes e lesões no local de trabalho. Os serviços de manutenção também garantem a conformidade com as normas de segurança e os padrões do setor, criando um ambiente de trabalho mais seguro para os funcionários. Ao priorizar a segurança, as organizações podem proteger sua força de trabalho, minimizar o tempo de inatividade devido a acidentes e construir uma cultura de conscientização sobre segurança, promovendo o bem-estar e a produtividade dos funcionários.

Oportunidades

- Aumento do avanço tecnológico na expansão do mercado

Os avanços tecnológicos criam oportunidades para serviços de manutenção industrial em melhorias operacionais e manutenção operacional. Esses serviços utilizam ferramentas e técnicas avançadas, como análise de dados, Internet das Coisas (IoT) e software de manutenção preditiva, para aumentar sua eficácia. Ao coletar e analisar dados de sensores de equipamentos, os serviços de manutenção podem identificar padrões, prever falhas e programar atividades de manutenção proativamente. Isso permite que as organizações tomem decisões informadas, otimizem a alocação de recursos e reduzam o tempo de inatividade não planejado. A adoção dessas tecnologias aumenta a eficiência, reduz custos e melhora o desempenho geral dos ativos, permitindo que as organizações alcancem maior produtividade e confiabilidade, maximizando a vida útil de seus ativos industriais.

- Aumento da capacidade de identificação impulsiona oportunidades de mercado

O aumento da confiabilidade gera expansão nos serviços de manutenção industrial em melhorias operacionais e manutenção operacional. Esses serviços se concentram em garantir que os ativos e equipamentos industriais operem de forma confiável, minimizando paradas inesperadas e paradas não planejadas. Por meio de inspeções regulares, medidas de manutenção preventiva e reparos oportunos, os serviços de manutenção abordam proativamente possíveis problemas e mantêm os sistemas críticos em condições ideais. Ao manter a confiabilidade dos equipamentos, as organizações podem reduzir o risco de interrupções dispendiosas nas operações, maximizar a produtividade e atingir as metas de produção. A confiabilidade aprimorada também aumenta a satisfação do cliente, garantindo a qualidade consistente dos produtos e a entrega pontual, fortalecendo assim a reputação e a competitividade da organização.

Restrições/Desafios

- O custo pode atuar como uma restrição ao mercado

O custo é uma grande restrição nos serviços de manutenção industrial para melhoria operacional e manutenção. A implementação de medidas de melhoria e a realização de atividades regulares de manutenção frequentemente exigem investimentos substanciais em atualizações de equipamentos, sistemas de automação e mão de obra qualificada. Essas despesas podem sobrecarregar os orçamentos das organizações, limitando a capacidade de execução desses serviços. Restrições orçamentárias podem forçar as organizações a priorizar atividades de manutenção ou adiar certas iniciativas de melhoria, impactando potencialmente a eficácia e a eficiência geral de suas operações. Equilibrar a necessidade de soluções econômicas e, ao mesmo tempo, garantir a confiabilidade e o desempenho dos ativos industriais é um desafio crucial nos serviços de manutenção industrial.

- A falta de competências e conhecimentos especializados pode impedir o crescimento do mercado

Habilidade e expertise são restrições significativas em serviços de manutenção industrial para melhoria operacional e manutenção. A execução bem-sucedida de iniciativas de melhoria e tarefas complexas de manutenção frequentemente exige conhecimento e habilidades especializadas. No entanto, o acesso a pessoal qualificado ou serviços de terceirização pode ser desafiador, especialmente em locais remotos ou setores com escassez de técnicos qualificados. A disponibilidade limitada de profissionais qualificados pode resultar em atrasos, problemas de qualidade e aumento de custos. Isso exige que as organizações invistam em programas de treinamento, atraiam e retenham talentos ou explorem soluções alternativas, como terceirização ou parcerias, para superar essas restrições relacionadas a habilidades e garantir a implementação eficaz das atividades de melhoria e manutenção.

Este relatório sobre serviços de manutenção industrial no mercado de melhoria operacional e manutenção operacional fornece detalhes sobre novos desenvolvimentos, regulamentações comerciais, análise de importação e exportação, análise de produção, otimização da cadeia de valor, participação de mercado, impacto de participantes do mercado doméstico e local, análise de oportunidades em termos de bolsões de receita emergentes, mudanças nas regulamentações de mercado, análise estratégica de crescimento de mercado, tamanho de mercado, crescimento de categorias de mercado, nichos de aplicação e dominância, aprovações de produtos, lançamentos de produtos, expansões geográficas e inovações tecnológicas no mercado. Para obter mais informações sobre o mercado de serviços de manutenção industrial no mercado de melhoria operacional e manutenção operacional, entre em contato com a Data Bridge Market Research para obter um resumo analítico. Nossa equipe ajudará você a tomar uma decisão de mercado informada para alcançar o crescimento do mercado.

Impacto e cenário atual do mercado de escassez de matéria-prima e atrasos no embarque

A Data Bridge Market Research oferece uma análise de mercado de alto nível e fornece informações considerando o impacto e o ambiente de mercado atual da escassez de matéria-prima e atrasos nas entregas. Isso se traduz na avaliação de possibilidades estratégicas, na criação de planos de ação eficazes e no auxílio às empresas na tomada de decisões importantes.

Além do relatório padrão, também oferecemos análises aprofundadas do nível de aquisição, desde atrasos previstos de remessa, mapeamento de distribuidores por região, análise de commodities, análise de produção, tendências de mapeamento de preços, fornecimento, análise de desempenho de categoria, soluções de gerenciamento de risco da cadeia de suprimentos, benchmarking avançado e outros serviços de aquisição e suporte estratégico.

Impacto esperado da desaceleração econômica nos preços e na disponibilidade de produtos

Quando a atividade econômica desacelera, os setores começam a sofrer. Os efeitos previstos da crise econômica sobre os preços e a acessibilidade dos produtos são levados em consideração nos relatórios de mercado e serviços de inteligência fornecidos pela DBMR. Com isso, nossos clientes podem, normalmente, se manter um passo à frente de seus concorrentes, projetar suas vendas e receitas e estimar suas despesas com lucros e perdas.

Desenvolvimentos recentes

- Em 2020, a Emerson Electric Co. lançou o serviço baseado em tecnologia de realidade aumentada (RA), com suporte ao cliente aprimorado. O novo recurso de Assistência Remota auxilia na solução de problemas com válvulas industriais. Como resultado, a empresa aprimorou seu portfólio de produtos para o mercado de manutenção industrial.

- Em 2019, a Siemens desenvolveu o aplicativo Mindsphere para aprimorar o serviço preditivo para sistemas de acionamento. O novo aplicativo oferece serviços e manutenção eficazes para motores Simotics de baixa tensão e sistemas de acionamento Sinamics. A empresa busca aumentar sua base de clientes e gerar mais receita por meio de soluções de manutenção eficazes.

Serviços globais de manutenção industrial em melhoria operacional e escopo de mercado de manutenção operacional

O mercado de serviços de manutenção industrial no segmento de melhoria operacional e manutenção operacional é segmentado com base no tipo de serviço, aplicação e setor. O crescimento entre esses segmentos ajudará você a analisar os segmentos com baixo crescimento nos setores e fornecerá aos usuários uma visão geral e insights valiosos do mercado para ajudá-los a tomar decisões estratégicas para identificar as principais aplicações do mercado.

Tipo de serviço

- Manutenção Operacional Industrial

- Melhoria Operacional Industrial

Aplicativo

- Controle de Supervisão e Aquisição de Dados (SCADA)

- Motores e acionamentos elétricos

- Válvulas e Atuadores

- Sistema de Controle Distribuído (DCS)

- Interface Homem-Máquina (IHM)

- Sistema de Execução de Fabricação (MES)

- Sistema de segurança

- Outros

Indústria

- Automotivo

- Metais e Mineração

- Alimentos e Bebidas

- Aeroespacial e Defesa

- Petróleo e Gás

- Água e esgoto

- Energia e Poder

- Químico

- Produtos farmacêuticos

- Outros

Serviços de Manutenção Industrial em Melhoria Operacional e Análise/Insights Regionais de Mercado de Manutenção Operacional

Os serviços de manutenção industrial no mercado de melhoria operacional e manutenção operacional são analisados e insights e tendências sobre o tamanho do mercado são fornecidos por tipo de serviço, aplicação e setor, conforme referenciado acima.

Os países abrangidos pelo relatório de mercado de serviços de manutenção industrial em melhoria operacional e manutenção operacional são EUA, Canadá e México na América do Norte, Alemanha, França, Reino Unido, Holanda, Suíça, Bélgica, Rússia, Itália, Espanha, Turquia, Resto da Europa na Europa, China, Japão, Índia, Coreia do Sul, Cingapura, Malásia, Austrália, Tailândia, Indonésia, Filipinas, Resto da Ásia-Pacífico (APAC) na Ásia-Pacífico (APAC), Arábia Saudita, Emirados Árabes Unidos, África do Sul, Egito, Israel, Resto do Oriente Médio e África (MEA) como parte do Oriente Médio e África (MEA), Brasil, Argentina e Resto da América do Sul como parte da América do Sul

A China deteve a maior fatia de mercado em serviços de manutenção industrial no segmento de soluções de melhoria operacional e manutenção operacional, sendo um polo de manufatura e unidades de produção em crescimento para apoiar a industrialização. A Alemanha deteve a maior fatia de mercado devido à demanda por serviços de manutenção preventiva para atingir as metas de produção com eficiência. No entanto, os EUA detiveram a maior fatia de mercado para essa solução devido à crescente automação industrial e à falta de recursos qualificados.

A seção sobre países do relatório também apresenta fatores individuais que impactam o mercado e mudanças na regulamentação do mercado doméstico, que impactam as tendências atuais e futuras do mercado. Pontos de dados como análise da cadeia de valor a montante e a jusante, tendências técnicas, análise das cinco forças de Porter e estudos de caso são alguns dos indicadores utilizados para prever o cenário de mercado para cada país. Além disso, a presença e a disponibilidade de marcas globais e seus desafios enfrentados devido à concorrência forte ou escassa de marcas locais e nacionais, o impacto de tarifas domésticas e rotas comerciais são considerados na análise de previsão dos dados do país.

Análise do Cenário Competitivo e da Participação de Mercado em Serviços de Manutenção Industrial e Melhoria Operacional

O cenário competitivo do mercado de serviços de manutenção industrial em melhoria operacional e manutenção operacional fornece detalhes por concorrente. Os detalhes incluem visão geral da empresa, finanças, receita gerada, potencial de mercado, investimento em pesquisa e desenvolvimento, novas iniciativas de mercado, presença global, locais e instalações de produção, capacidades de produção, pontos fortes e fracos da empresa, lançamento de produto, abrangência e amplitude do produto e domínio da aplicação. Os dados acima fornecidos referem-se apenas ao foco das empresas em serviços de manutenção industrial em melhoria operacional e manutenção operacional.

Alguns dos principais players que atuam no mercado de serviços de manutenção industrial em melhoria operacional e manutenção operacional são:

- ABB (Suíça)

- Siemens (Alemanha)

- Schneider Electric (França)

- Honeywell International Inc. (EUA)

- General Electric (EUA)

- Emerson Electric Co. (EUA)

- Rockwell Automation (EUA)

- Johnson Controls. (Irlanda)

- SKF (Suécia)

- Mitsubishi Electric Corporation (Japão)

- Yokogawa Electric Corporation (Japão)

- Danaher (EUA)

- AECOM (EUA)

- KBR, Inc. (EUA)

- Veolia Environnement SA (França)

- Tetra Tech, Inc. (EUA)

- John Wood Group PLC (Reino Unido)

- Grupo SNC-Lavalin (Canadá)

- Fluor Corporation (EUA)

- Jacobs (EUA)

- Worley (Austrália)

- Bechtel Corporation (EUA)

- Black & Veatch Holding Company (EUA)

- CBRE (EUA)

SKU-

Obtenha acesso online ao relatório sobre a primeira nuvem de inteligência de mercado do mundo

- Painel interativo de análise de dados

- Painel de análise da empresa para oportunidades de elevado potencial de crescimento

- Acesso de analista de pesquisa para personalização e customização. consultas

- Análise da concorrência com painel interativo

- Últimas notícias, atualizações e atualizações Análise de tendências

- Aproveite o poder da análise de benchmark para um rastreio abrangente da concorrência

Índice

1 INTRODUCTION

1.1 OBJECTIVES OF THE STUDY

1.2 MARKET DEFINITION

1.3 OVERVIEW OF GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET

1.4 CURRENCY AND PRICING

1.5 LIMITATION

1.6 MARKETS COVERED

2 MARKET SEGMENTATION

2.1 KEY TAKEAWAYS

2.2 ARRIVING AT THE GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET

2.2.1 VENDOR POSITIONING GRID

2.2.2 TECHNOLOGY LIFE LINE CURVE

2.2.3 MARKET GUIDE

2.2.4 COMPANY POSITIONING GRID

2.2.5 COMAPANY MARKET SHARE ANALYSIS

2.2.6 MULTIVARIATE MODELLING

2.2.7 TOP TO BOTTOM ANALYSIS

2.2.8 STANDARDS OF MEASUREMENT

2.2.9 VENDOR SHARE ANALYSIS

2.2.10 DATA POINTS FROM KEY PRIMARY INTERVIEWS

2.2.11 DATA POINTS FROM KEY SECONDARY DATABASES

2.3 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET : RESEARCH SNAPSHOT

2.4 ASSUMPTIONS

3 MARKET OVERVIEW

3.1 DRIVERS

3.2 RESTRAINTS

3.3 OPPORTUNITIES

3.4 CHALLENGES

4 EXECUTIVE SUMMARY

5 PREMIUM INSIGHTS

5.1 PORTER’S FIVE FORCES

5.2 REGULATORY STANDARDS

5.3 TECHNOLOGICAL TRENDS

5.4 VALUE CHAIN ANALYSIS

5.5 COMPANY COMPARITIVE ANALYSIS

5.6 CASE STUDY

6 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET , BY SERVICES TYPE

6.1 OVERVIEW

6.2 INDUSTRIAL OPERATIONAL MAINTENANCE

6.2.1 PREDICTIVE MAINTENANCE

6.2.2 SCHEDULED MAINTENANCE

6.2.3 MECHANICAL

6.2.3.1. GENERAL LUBRICATION MAINTENANCE

6.2.3.2. PRODUCT RECTIFICATION MAINTENANCE

6.2.3.3. OTHERS

6.3 INDUSTRIAL OPERATIONAL IMPROVEMENT

6.3.1 COMPLAINCES

6.3.2 SYSTEM CONFIGURATION

6.3.3 RETROFIT & REPAIR

6.3.4 INFRASTRUCTURE AUDIT

6.3.5 INSTALLATION AND CONSULTING

7 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET, BY APPLICATION

7.1 OVERVIEW

7.2 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

7.3 ELECTRIC MOTORS & DRIVES

7.4 MOTIONS CONTROLS

7.5 VALVES & ACTUATORS

7.6 DISTRIBUTED CONTROL SYSTEM (DCS)

7.7 HUMAN-MACHINE INTERFACE (HMI)

7.8 MANUFACTURING EXECUTION SYSTEM (MES)

7.9 SAFETY SYSTEM

7.9.1 EMERGENCY SHUTDOWN SYSTEM (ESD)

7.9.2 HIGH-INTEGRITY PRESSURE PROTECTION SYSTEMS (HIPPS)

7.9.3 FIRE & GAS MONITORING & CONTROL

7.9.4 TURBOMACHINERY CONTROL (TMC)

7.1 INDUSTRIAL ROBOTS

7.11 OTHERS

8 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET, BY INDUSTRY

8.1 OVERVIEW

8.2 INTRALOGISTICS

8.2.1 BY SERVICES

8.2.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.2.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.3 AUTOMOTIVE

8.3.1 BY SERVICES

8.3.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.3.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.4 METALS & MINING

8.4.1 BY SERVICES

8.4.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.4.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.5 FOOD & BEVERAGES

8.5.1 BY SERVICES

8.5.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.5.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.6 AEROSPACE & DEFENSE

8.6.1 BY SERVICES

8.6.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.6.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.7 OIL & GAS

8.7.1 BY SERVICES

8.7.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.7.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.8 WATER AND WASTEWATER

8.8.1 BY SERVICES

8.8.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.8.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.9 ENERGY & POWER

8.9.1 BY SERVICES

8.9.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.9.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.1 CHEMICAL

8.10.1 BY SERVICES

8.10.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.10.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.11 PHARMACEUTICALS

8.11.1 BY SERVICES

8.11.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.11.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.12 OTHERS

9 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET, BY GEOGRAPHY

9.1 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET, (ALL SEGMENTATION PROVIDED ABOVE IS REPRESENTED IN THIS CHAPTER BY COUNTRY)

9.1.1 NORTH AMERICA

9.1.1.1. U.S.

9.1.1.2. CANADA

9.1.1.3. MEXICO

9.1.2 EUROPE

9.1.2.1. GERMANY

9.1.2.2. FRANCE

9.1.2.3. U.K.

9.1.2.4. ITALY

9.1.2.5. SPAIN

9.1.2.6. RUSSIA

9.1.2.7. TURKEY

9.1.2.8. BELGIUM

9.1.2.9. NETHERLANDS

9.1.2.10. SWITZERLAND

9.1.2.11. SWEDEN

9.1.2.12. DENMARK

9.1.2.13. POLAND

9.1.2.14. NORWAY

9.1.2.15. FINLAND

9.1.2.16. CZECH REPUBLIC

9.1.2.17. REST OF EUROPE

9.1.3 ASIA PACIFIC

9.1.3.1. JAPAN

9.1.3.2. CHINA

9.1.3.3. SOUTH KOREA

9.1.3.4. INDIA

9.1.3.5. AUSTRALIA AND NEW ZELAND

9.1.3.6. SINGAPORE

9.1.3.7. THAILAND

9.1.3.8. MALAYSIA

9.1.3.9. INDONESIA

9.1.3.10. PHILIPPINES

9.1.3.11. TAIWAN

9.1.3.12. VIETNAM

9.1.3.13. REST OF ASIA PACIFIC

9.1.4 SOUTH AMERICA

9.1.4.1. BRAZIL

9.1.4.2. ARGENTINA

9.1.4.3. REST OF SOUTH AMERICA

9.1.5 MIDDLE EAST AND AFRICA

9.1.5.1. SOUTH AFRICA

9.1.5.2. EGYPT

9.1.5.3. SAUDI ARABIA

9.1.5.4. U.A.E

9.1.5.5. ISRAEL

9.1.5.6. KUWAIT

9.1.5.7. QATAR

9.1.5.8. REST OF MIDDLE EAST AND AFRICA

9.1.6 KEY PRIMARY INSIGHTS: BY MAJOR COUNTRIES

10 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET,COMPANY LANDSCAPE

10.1 COMPANY SHARE ANALYSIS: GLOBAL

10.2 COMPANY SHARE ANALYSIS: NORTH AMERICA

10.3 COMPANY SHARE ANALYSIS: EUROPE

10.4 COMPANY SHARE ANALYSIS: ASIA PACIFIC

10.5 MERGERS & ACQUISITIONS

10.6 NEW PRODUCT DEVELOPMENT AND APPROVALS

10.7 EXPANSIONS

10.8 REGULATORY CHANGES

10.9 PARTNERSHIP AND OTHER STRATEGIC DEVELOPMENTS

11 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET, SWOT & DBMR ANALYSIS

12 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET, COMPANY PROFILE

12.1 SCHNEIDER ELECTRIC

12.1.1 COMPANY SNAPSHOT

12.1.2 REVENUE ANALYSIS

12.1.3 PRODUCT PORTFOLIO

12.1.4 RECENT DEVELOPMENTS

12.2 EMERSON ELECTRIC CO.

12.2.1 COMPANY SNAPSHOT

12.2.2 REVENUE ANALYSIS

12.2.3 PRODUCT PORTFOLIO

12.2.4 RECENT DEVELOPMENTS

12.3 ROCKWELL AUTOMATION, INC.

12.3.1 COMPANY SNAPSHOT

12.3.2 REVENUE ANALYSIS

12.3.3 PRODUCT PORTFOLIO

12.3.4 RECENT DEVELOPMENTS

12.4 SKF GROUP

12.4.1 COMPANY SNAPSHOT

12.4.2 REVENUE ANALYSIS

12.4.3 PRODUCT PORTFOLIO

12.4.4 RECENT DEVELOPMENTS

12.5 SIEMENS

12.5.1 COMPANY SNAPSHOT

12.5.2 REVENUE ANALYSIS

12.5.3 PRODUCT PORTFOLIO

12.5.4 RECENT DEVELOPMENTS

12.6 ADVANCED TECHNOLOGY SERVICES INC.

12.6.1 COMPANY SNAPSHOT

12.6.2 REVENUE ANALYSIS

12.6.3 PRODUCT PORTFOLIO

12.6.4 RECENT DEVELOPMENTS

12.7 SGS SA

12.7.1 COMPANY SNAPSHOT

12.7.2 REVENUE ANALYSIS

12.7.3 PRODUCT PORTFOLIO

12.7.4 RECENT DEVELOPMENTS

12.8 QUANT AB

12.8.1 COMPANY SNAPSHOT

12.8.2 REVENUE ANALYSIS

12.8.3 PRODUCT PORTFOLIO

12.8.4 RECENT DEVELOPMENTS

12.9 METSO

12.9.1 COMPANY SNAPSHOT

12.9.2 REVENUE ANALYSIS

12.9.3 PRODUCT PORTFOLIO

12.9.4 RECENT DEVELOPMENTS

12.1 ICONICS, INC.

12.10.1 COMPANY SNAPSHOT

12.10.2 REVENUE ANALYSIS

12.10.3 PRODUCT PORTFOLIO

12.10.4 RECENT DEVELOPMENTS

12.11 GENERAL ELECTRIC

12.11.1 COMPANY SNAPSHOT

12.11.2 REVENUE ANALYSIS

12.11.3 PRODUCT PORTFOLIO

12.11.4 RECENT DEVELOPMENTS

12.12 INTECH PROCESS AUTOMATION INC.

12.12.1 COMPANY SNAPSHOT

12.12.2 REVENUE ANALYSIS

12.12.3 PRODUCT PORTFOLIO

12.12.4 RECENT DEVELOPMENTS

12.13 DYNAMYSK AUTOMATION LTD.

12.13.1 COMPANY SNAPSHOT

12.13.2 REVENUE ANALYSIS

12.13.3 PRODUCT PORTFOLIO

12.13.4 RECENT DEVELOPMENTS

12.14 ABB

12.14.1 COMPANY SNAPSHOT

12.14.2 REVENUE ANALYSIS

12.14.3 PRODUCT PORTFOLIO

12.14.4 RECENT DEVELOPMENTS

12.15 ENDRESS +HAUSER GROUP SERVICES AG

12.15.1 COMPANY SNAPSHOT

12.15.2 REVENUE ANALYSIS

12.15.3 PRODUCT PORTFOLIO

12.15.4 RECENT DEVELOPMENTS

12.16 HONEYWELL INTERNATIONAL INC

12.16.1 COMPANY SNAPSHOT

12.16.2 REVENUE ANALYSIS

12.16.3 PRODUCT PORTFOLIO

12.16.4 RECENT DEVELOPMENTS

12.17 YASKAWA AMERICA, INC.

12.17.1 COMPANY SNAPSHOT

12.17.2 REVENUE ANALYSIS

12.17.3 PRODUCT PORTFOLIO

12.17.4 RECENT DEVELOPMENTS

12.18 ROHRER BETEILIGUNGS-UND VERWALTUNGS GMBH

12.18.1 COMPANY SNAPSHOT

12.18.2 REVENUE ANALYSIS

12.18.3 PRODUCT PORTFOLIO

12.18.4 RECENT DEVELOPMENTS

12.19 TIETOEVRY

12.19.1 COMPANY SNAPSHOT

12.19.2 REVENUE ANALYSIS

12.19.3 PRODUCT PORTFOLIO

12.19.4 RECENT DEVELOPMENTS

12.2 WUNDERLICH-MALEC ENGINEERING INC.

12.20.1 COMPANY SNAPSHOT

12.20.2 REVENUE ANALYSIS

12.20.3 PRODUCT PORTFOLIO

12.20.4 RECENT DEVELOPMENTS

NOTE: THE COMPANIES PROFILED IS NOT EXHAUSTIVE LIST AND IS AS PER OUR PREVIOUS CLIENT REQUIREMENT. WE PROFILE MORE THAN 100 COMPANIES IN OUR STUDY AND HENCE THE LIST OF COMPANIES CAN BE MODIFIED OR REPLACED ON REQUEST

13 CONCLUSION

14 RELATED REPORTS

15 ABOUT DATA BRIDGE MARKET RESEARCH

Metodologia de Investigação

A recolha de dados e a análise do ano base são feitas através de módulos de recolha de dados com amostras grandes. A etapa inclui a obtenção de informações de mercado ou dados relacionados através de diversas fontes e estratégias. Inclui examinar e planear antecipadamente todos os dados adquiridos no passado. Da mesma forma, envolve o exame de inconsistências de informação observadas em diferentes fontes de informação. Os dados de mercado são analisados e estimados utilizando modelos estatísticos e coerentes de mercado. Além disso, a análise da quota de mercado e a análise das principais tendências são os principais fatores de sucesso no relatório de mercado. Para saber mais, solicite uma chamada de analista ou abra a sua consulta.

A principal metodologia de investigação utilizada pela equipa de investigação do DBMR é a triangulação de dados que envolve a mineração de dados, a análise do impacto das variáveis de dados no mercado e a validação primária (especialista do setor). Os modelos de dados incluem grelha de posicionamento de fornecedores, análise da linha de tempo do mercado, visão geral e guia de mercado, grelha de posicionamento da empresa, análise de patentes, análise de preços, análise da quota de mercado da empresa, normas de medição, análise global versus regional e de participação dos fornecedores. Para saber mais sobre a metodologia de investigação, faça uma consulta para falar com os nossos especialistas do setor.

Personalização disponível

A Data Bridge Market Research é líder em investigação formativa avançada. Orgulhamo-nos de servir os nossos clientes novos e existentes com dados e análises que correspondem e atendem aos seus objetivos. O relatório pode ser personalizado para incluir análise de tendências de preços de marcas-alvo, compreensão do mercado para países adicionais (solicite a lista de países), dados de resultados de ensaios clínicos, revisão de literatura, mercado remodelado e análise de base de produtos . A análise de mercado dos concorrentes-alvo pode ser analisada desde análises baseadas em tecnologia até estratégias de carteira de mercado. Podemos adicionar quantos concorrentes necessitar de dados no formato e estilo de dados que procura. A nossa equipa de analistas também pode fornecer dados em tabelas dinâmicas de ficheiros Excel em bruto (livro de factos) ou pode ajudá-lo a criar apresentações a partir dos conjuntos de dados disponíveis no relatório.