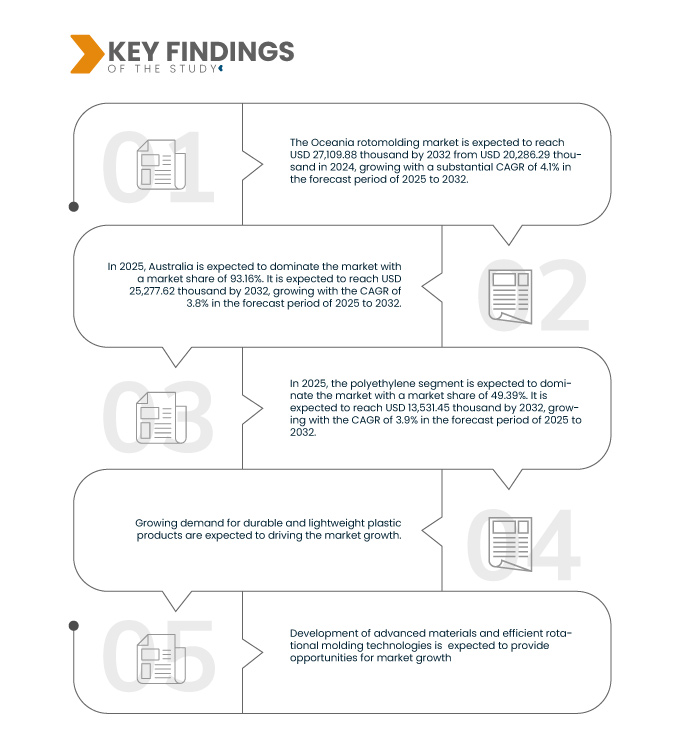

A procura por produtos plásticos duráveis e leves é um dos principais impulsionadores do crescimento do mercado de rotomoldagem da Oceânia. À medida que vários setores da região, incluindo o automóvel, a agricultura, a construção, os bens de consumo e os transportes, continuam a procurar produtos que ofereçam resistência, longevidade e facilidade de utilização, as características únicas da rotomoldagem tornaram-se um processo de fabrico valioso. A rotomoldagem é amplamente reconhecida pela sua capacidade de produzir produtos altamente duráveis. O processo envolve a rotação de um molde aquecido, o que permite que a resina plástica cubra o interior de forma uniforme, criando um produto com uma espessura de parede e integridade estrutural consistentes. A espessura uniforme é um fator essencial para garantir a resistência do produto ao desgaste. Isto torna os produtos rotomoldados ideais para aplicações onde a durabilidade é crucial, como tanques de armazenamento, contentores industriais e mobiliário para exteriores.

Aceda ao relatório completo em https://www.databridgemarketresearch.com/reports/oceania-rotomolding-market

A pesquisa de mercado da Data Bridge analisa que o mercado de rotomoldagem da Oceânia deverá atingir os 27,10 milhões de dólares até 2032, face aos 20,28 milhões de dólares em 2024, crescendo com um CAGR substancial de 4,1% no período previsto de 2025 a 2032.

Principais conclusões do estudo

Inclinação para materiais sustentáveis e recicláveis

A crescente ênfase na sustentabilidade e a crescente procura global de materiais recicláveis são importantes impulsionadores do crescimento do mercado de rotomoldagem na Oceânia. À medida que as preocupações ambientais continuam a ser o centro das atenções, tanto os consumidores como as indústrias da região estão a pressionar por soluções amigas do ambiente. O processo de rotomoldagem, conhecido pela sua capacidade de utilizar materiais sustentáveis e produzir produtos plásticos recicláveis, está numa posição única para satisfazer esta procura, contribuindo para a sua crescente popularidade. Uma das principais vantagens da rotomoldagem é a utilização de materiais recicláveis, como o polietileno (PE), que é um dos plásticos mais utilizados no processo. O polietileno é amplamente aceite nos fluxos de reciclagem e pode ser reutilizado no final do ciclo de vida de um produto. Isto está em linha com a crescente procura por práticas de economia circular, onde os produtos são concebidos para serem reutilizados, renovados e reciclados. Em regiões como a Austrália e a Nova Zelândia, que se estão a concentrar na redução de resíduos plásticos e no aumento das taxas de reciclagem, a capacidade de fabricar produtos utilizando materiais recicláveis ajuda as empresas a satisfazer a procura dos consumidores e os requisitos regulamentares.

Âmbito do Relatório e Segmentação de Mercado

Métrica de Reporte

|

Detalhes

|

Período de previsão

|

2025 a 2032

|

Ano base

|

2024

|

Anos Históricos

|

2023 (personalizável para 2013-2017)

|

Unidades quantitativas

|

Receita em milhões de dólares americanos

|

Segmentos abrangidos

|

Material (polietileno, polipropileno , policarbonato , PVC, poliuretano , nylon , elastómeros e outros), forma (pó e líquido), utilidade (aquecimento, arrefecimento e outros), tipo de máquina (máquina biaxial, máquina carrossel, máquina lançadeira, máquina rock and roll, máquina clamshell, máquina de braço oscilante, máquina de roda vertical, máquina de chama aberta e outros), aplicação (não tanque e tanque)

|

País coberto

|

Austrália, Nova Zelândia e outros

|

Participantes do mercado abrangidos

|

Melbourne Rotomould (Austrália), APR Tanks (Austrália), Rota Moulding (Austrália), Rotamould Pty. Ltd. (Austrália), Superior Group (Austrália), Global Tanks (Austrália), AgBoss Australia Pty Ltd (Austrália) e entre outros.

|

Pontos de dados abordados no relatório

|

Para além dos insights sobre os cenários de mercado, tais como o valor de mercado, a taxa de crescimento, a segmentação, a cobertura geográfica e os principais participantes, os relatórios de mercado selecionados pela Data Bridge Market Research incluem também análises aprofundadas de especialistas, produção e capacidade das empresas representadas geograficamente, layouts de rede de distribuidores e parceiros, análises detalhadas e atualizadas das tendências de preços e análises de défice da cadeia de abastecimento e da procura.

|

Análise de Segmentos

O mercado de rotomoldagem da Oceânia está segmentado em cinco segmentos notáveis baseados no material, forma, utilidade, tipo de máquina e aplicação.

- Com base no material, o mercado está segmentado em polietileno, polipropileno, policarbonato, PVC, poliuretano, nylon, elastómeros e outros

Em 2025, o segmento do polietileno deverá dominar o mercado com uma quota de mercado de 49,39%

Em 2025, prevê-se que o segmento do polietileno domine o mercado com uma quota de mercado de 49,39% devido à sua excelente durabilidade, flexibilidade e relação custo-benefício. É amplamente utilizado no fabrico de produtos como tanques, contentores e equipamentos de recreio, oferecendo um desempenho superior e facilidade de processamento para diversas aplicações.

- Com base na forma, o mercado está segmentado em pó e líquido

Em 2025, prevê-se que o pó domine o mercado com uma quota de mercado de 51,52%

Em 2025, prevê-se que o pó domine o mercado com uma quota de mercado de 51,52% devido à sua capacidade de proporcionar uma espessura de parede uniforme, acabamento superficial superior e desperdício reduzido. Os materiais em pó são mais fáceis de manusear, derreter e distribuir uniformemente, sendo ideais para produção em grande escala e de alta qualidade.

- Com base na utilidade, o mercado está segmentado em aquecimento, arrefecimento e outros. Em 2025, prevê-se que o segmento do aquecimento domine o mercado com uma quota de mercado de 43,91%

- Com base no tipo de máquina, o mercado está segmentado em máquina biaxial, máquina carrossel, máquina lançadeira, máquina rock and roll, máquina clamshell, máquina de braço oscilante, máquina de roda vertical, máquina de chama aberta e outras. Em 2025, prevê-se que o segmento das máquinas biaxiais domine o mercado com uma quota de mercado de 25,64%

- Com base na aplicação, o mercado está segmentado em tanque e não tanque. Em 2025, prevê-se que o segmento não-cisterna domine o mercado com uma quota de mercado de 67,59%

Principais jogadores

A Data Bridge Market Research analisa a Melbourne Rotomould (Austrália), a APR Tanks (Austrália), a Rota Moulding (Austrália), a Rotamould Pty. Lda. (Austrália) e a Superior Group (Austrália) como os principais participantes do mercado.

Análise Regional

Geograficamente, os países abrangidos pelo relatório de mercado são a Austrália, a Nova Zelândia e outros.

Espera-se que a Austrália domine o mercado no período previsto de 2025 a 2032

Espera-se que a Austrália domine o mercado porque a rotomoldagem permite elevados níveis de personalização e flexibilidade no design do produto.

De acordo com a análise de estudos de mercado da Data Bridge :

Para obter informações mais detalhadas sobre o relatório de mercado de rotomoldagem da Oceânia, clique aqui – https://www.databridgemarketresearch.com/reports/oceania-rotomolding-market