O mercado global de raios X industriais é uma indústria automotiva significativa e dinâmica. Ensaio Não Destrutivo (NDT) é uma técnica de teste e análise usada pela indústria para avaliar as propriedades de um material, componente, estrutura ou sistema quanto a diferenças características ou defeitos de soldagem e descontinuidades sem causar danos à peça original. Os sistemas de inspeção por raios X são um componente crucial dos END, pois fornecem detecção precisa e confiável de defeitos e contaminantes que podem comprometer a qualidade e a segurança do produto. Testes não destrutivos modernos são usados na fabricação, fabricação e inspeções em serviço para garantir a integridade e confiabilidade do produto, controlar processos de fabricação, reduzir custos de produção e manter um nível de qualidade uniforme.

Acesse o relatório completo @https://www.databridgemarketresearch.com/reports/global-industrial-x-ray-market

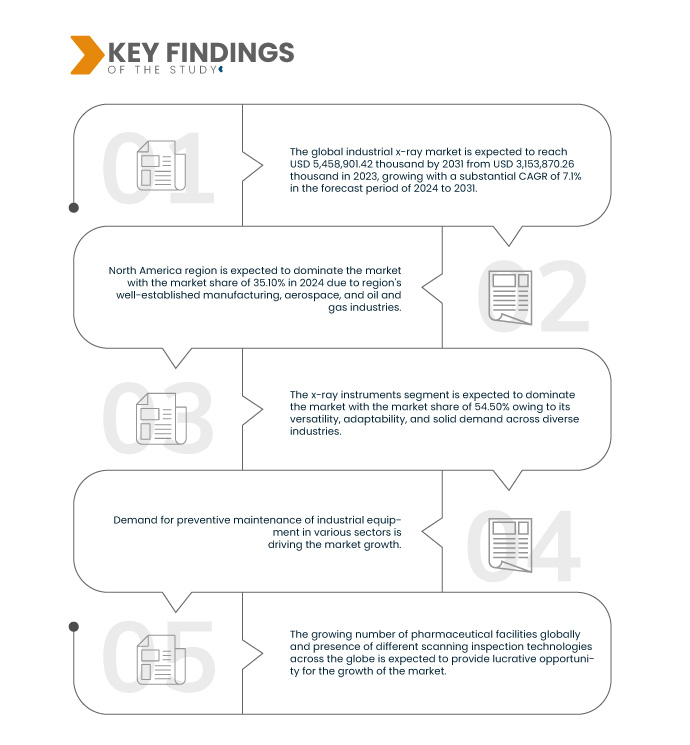

A Data Bridge Market Research analisa que o Mercado global de raios X industriais deverá atingir US$ 5.458.901,42 mil até 2031, contra US$ 3.153.870,26 mil em 2023, crescendo com um CAGR de 7,1% no período de previsão de 2024 a 2031.

Principais conclusões do estudo

Desenvolvimento de Sistemas de Inspeção Portáteis e Móveis

Os sistemas de inspeção por raios X portáteis e móveis oferecem diversas vantagens, como serem compactos, leves e fáceis de transportar, tornando-os ideais para uso em locais remotos ou de difícil acesso. Assim, os sistemas de inspeção por raios X portáteis e móveis podem realizar END em locais remotos ou de difícil acesso e podem configurar e desmontar o sistema conforme necessário rapidamente. A procura por estes sistemas está a aumentar em vários setores, incluindo petróleo e gás, automóvel, aeroespacial e construção, onde o END é fundamental para garantir a segurança e a fiabilidade dos produtos. O sistema de inspeção por raios X portátil e móvel foi projetado para uso em diversas aplicações industriais, como inspeção de dutos, aeroespacial e petroquímica. As empresas estão reagindo à crescente demanda por sistemas portáteis e móveis expandindo suas ofertas de produtos e sistemas. Espera-se que isso aumente a adoção de sistemas de inspeção por raios X portáteis e móveis em vários setores. Assim, o desenvolvimento de novos sistemas de inspeção por raios X portáteis e móveis está impulsionando o crescimento do mercado.

Escopo do relatório e segmentação de mercado

|

Métrica de relatório

|

Detalhes

|

|

Período de previsão

|

2024 a 2031

|

|

Ano base

|

2023

|

|

Anos históricos

|

2022 (personalizável para 2016–2021)

|

|

Unidades Quantitativas

|

Receita em mil dólares

|

|

Segmentos cobertos

|

Técnica de imagem (radiografia digital e radiografia baseada em filme), aplicação (indústrias aeroespaciais, defesa e militar, indústria de geração de energia, indústria automotiva, indústria de transformação, indústria de alimentos e bebidas e outras), modalidade (2D, 3D e híbrida), Alcance (Raio X Micro Focus, Raio X de Alta Energia e Outros), Fonte (Cobalto-59, Iridium-192 e Outros), Canal de Distribuição (Canal Indireto e Canal Direto), Tipo de Produto (Consumíveis de Raio X, instrumentos de raios X e serviços de raios X)

|

|

Países abrangidos

|

EUA, Canadá, México, Alemanha, Reino Unido, Itália, França, Espanha, Suíça, Holanda, Bélgica, Rússia, Turquia, Noruega, Finlândia, Dinamarca, Suécia, Polónia, Resto da Europa, Japão, China, Coreia do Sul, Índia, Austrália e Nova Zelândia, Cingapura, Tailândia, Indonésia, Malásia, Taiwan, Vietnã, Filipinas, Resto da Ásia-Pacífico, Brasil, Argentina, Resto da América do Sul, África do Sul, Emirados Árabes Unidos, Arábia Saudita, Kuwait, Egito, Catar, Bahrein, Israel , Omã e Resto do Oriente Médio e África

|

|

Participantes do mercado cobertos

|

(Canadá), Hamamatsu Photonics KK (Japão), GENERAL ELECTRIC (EUA), Comet Group (Suíça), Varex Imaging (EUA), Carestream Health (EUA), Carl Zeiss Group (Alemanha), Eastman Kodak Company (EUA), North Star Imaging Inc. (EUA), Ixar (Índia), VJ X-Ray (EUA), Rigaku Corporation (Japão), Minebea Intec GmbH (Alemanha), Lohmann X-Ray GmbH (Alemanha), PROTEC GmbH & Co. KG (Alemanha), OR Technology (Alemanha), FUJIFILM Corporation (Japão), Shimadzu Corporation (Japão), Krystalvision Image Systems Pvt. (Índia), Lucky Healthcare Co., Ltd. (China), Canon Electron Tubes & Devices Co., Ltd. (Japão), Applus+ (Espanha), Hitachi High-Tech Analytical Science (Japão), Avonix Imaging (EUA). ) e Nordson Corporation (EUA), entre outros

|

|

Pontos de dados abordados no relatório

|

Além dos insights de mercado, como valor de mercado, taxa de crescimento, segmentos de mercado, cobertura geográfica, participantes do mercado e cenário de mercado, o relatório de mercado com curadoria da equipe de pesquisa de mercado da Data Bridge inclui análise especializada aprofundada, análise de importação/exportação, análise de preços, análise de consumo de produção e análise de pilão

|

Análise de Segmento

O mercado global de raios X industriais é segmentado em sete segmentos notáveis que se baseiam no tipo de produto, técnica de imagem, modalidade, alcance, fonte, aplicação e canal de distribuição.

- Com base no tipo de produto, o mercado global de raios X industriais é segmentado em instrumentos de raios X, consumíveis de raios X e serviços de raios X

Em 2024, espera-se que o segmento de instrumentos de raios X domine o mercado global de raios X industriais

Em 2024, espera-se que o segmento de instrumentos de raios X domine o mercado com uma participação de mercado de 54,50% devido à sua versatilidade, relação custo-benefício e capacidade de realizar missões críticas com risco reduzido para vidas humanas.

- Com base na técnica de imagem, o mercado global de raios X industriais é segmentado em radiografia digital e radiografia baseada em filme

Em 2024, espera-se que o segmento de radiografia digital domine o mercado global de raios X industriais

Em 2024, espera-se que o segmento de radiografia digital domine o mercado com uma participação de mercado de 66,00% devido às suas aplicações em uma ampla gama de indústrias, incluindo segurança, vigilância, industrial, médica, automotiva e aeroespacial.

- Com base na modalidade, o mercado global de raios X industriais é segmentado em 2D, 3D e híbrido. Em 2024, espera-se que o segmento 2D domine o mercado com uma participação de mercado de 59,58%

- Com base no alcance, o mercado global de raios X industriais é segmentado em raios X de micro foco, raios X de alta energia e outros. Em 2024, espera-se que o segmento de raios X micro foco domine o mercado com uma participação de mercado de 65,39%

- Com base na fonte, o mercado global de raios X industriais é segmentado em cobalto-59, irídio-192, entre outros. Em 2024, espera-se que o segmento cobalto-59 domine o mercado com uma participação de mercado de 3,60%

- Com base na aplicação, o mercado global de raios X industriais é segmentado em indústrias aeroespaciais, defesa e militar, indústria de geração de energia, indústria automotiva, indústria manufatureira, indústria de alimentos e bebidas, entre outras. Em 2024, espera-se que o segmento das indústrias aeroespaciais domine o mercado com uma participação de mercado de 33,21%

- Com base no canal de distribuição, o mercado global de raios X industriais é segmentado em canal indireto e canal direto. Em 2024, espera-se que o segmento de canal indireto domine o mercado com uma participação de mercado de 66,09%

Jogadores principais

A Data Bridge Market Research analisa Teledyne Digital Imaging Inc. (Canadá), Hamamatsu Photonics KK (Japão), Carl Zeiss Group (Alemanha), Comet Group (Suíça), Applus+ (Espanha) como principais players do mercado global de raios X industriais .

Desenvolvimento de mercado

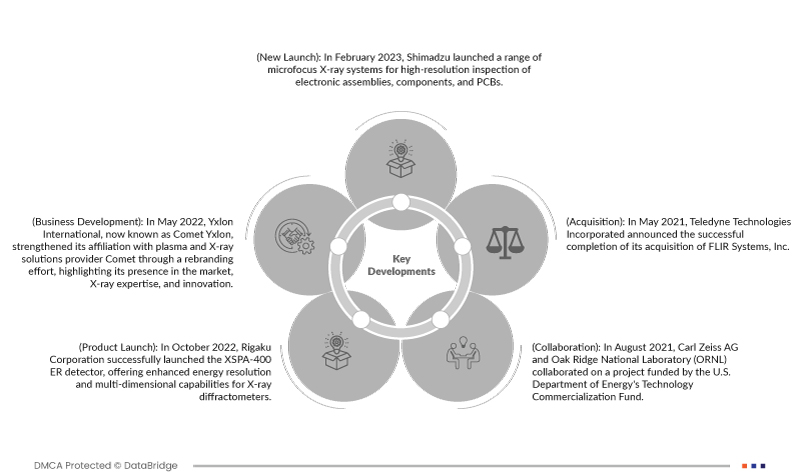

- Em outubro de 2022, a Rigaku Corporation lançou com sucesso o detector XSPA-400 ER, oferecendo resolução de energia aprimorada e recursos multidimensionais para difratômetros de raios X. Esta inovação atendeu setores exigentes como baterias, aço e cerâmica, permitindo medições precisas de amostras contendo metais de transição, promovendo aplicações expandidas e reforçando a posição da Rigaku em soluções avançadas de XRD

- Em agosto de 2021, Carl Zeiss AG e Oak Ridge National Laboratory (ORNL) colaboraram em um projeto financiado pelo Fundo de Comercialização de Tecnologia do Departamento de Energia dos EUA. O projeto teve como objetivo alavancar inteligência artificial(AI) e tecnologia de tomografia computadorizada de raios X para permitir a caracterização não destrutiva confiável de peças fabricadas aditivamente (AM). A Manufatura Aditiva (AM) é um método de fabricação que cria uma forma 3D por meio do acúmulo de materiais. A parceria desenvolverá uma metodologia abrangente de caracterização de pó em peça para fabricação aditiva, melhorando a qualidade e a precisão das medições e potencialmente mudando os testes não destrutivos e a metrologia além da indústria de manufatura aditiva (AM).

- Em fevereiro de 2023, a Shimadzu lançou uma linha de sistemas de raios X microfoco para inspeção de alta resolução de conjuntos eletrônicos, componentes e PCBs. Sua linha inclui o Xslicer SMX-1010/1020, com qualidade de imagem e fluxo de trabalho aprimorados, e o Xslicer SMX-6010, que fornece imagens de alta precisão com ampla faixa dinâmica para observação detalhada de estruturas e defeitos internos.

- Em maio de 2022, a Yxlon International, agora conhecida como Comet Yxlon, reforçou a sua afiliação com o fornecedor de soluções de plasma e raios X Comet através de um esforço de rebranding, destacando a sua presença no mercado, experiência em raios X e inovação. A empresa oferece soluções de sistemas de raios X e CT de ponta para ambientes industriais, apoiadas por serviços integrados que utilizam inteligência artificial e análise de dados sob a égide do Comet Group. A mudança de marca da Yxlon International para Comet Yxlon fortalece a afiliação com a empresa controladora, Comet Group. Reforça a posição do grupo como fornecedor de soluções de plasma e raios X

- Em maio de 2021, a Teledyne Technologies Incorporated anunciou a conclusão bem-sucedida de sua aquisição da FLIR Systems, Inc. A aquisição levou à formação da Teledyne FLIR, uma entidade combinada que oferece uma gama completa de tecnologias e produtos de imagem, ampliando sua gama de sistemas não tripulados e carga útil de imagem. Este movimento estratégico visa melhorar a posição da Teledyne na indústria, fornecendo soluções inovadoras em múltiplos domínios

Análise Regional

Geograficamente, os países cobertos no relatório global do mercado de raios X industriais são EUA, Canadá, México, Alemanha, Reino Unido, Itália, França, Espanha, Suíça, Holanda, Bélgica, Rússia, Turquia, Noruega, Finlândia, Dinamarca, Suécia, Polônia , Resto da Europa, Japão, China, Coreia do Sul, Índia, Austrália e Nova Zelândia, Singapura, Tailândia, Indonésia, Malásia, Taiwan, Vietname, Filipinas, Resto da Ásia-Pacífico, Brasil, Argentina, Resto da América do Sul, África do Sul , Emirados Árabes Unidos, Arábia Saudita, Kuwait, Egito, Catar, Bahrein, Israel, Omã e Resto do Oriente Médio e África.

De acordo com a análise da pesquisa de mercado da Data Bridge:

A América do Norte é a dominante e crescimento mais rápido região no mercado global de raios X industriais

Espera-se que a região da América do Norte domine o mercado com uma forte liderança tecnológica, orçamentos de defesa substanciais, uma indústria de defesa robusta e condições regulatórias favoráveis. Estes factores contribuem colectivamente para a posição da América do Norte como um actor dominante nesta indústria. Espera-se que a América do Norte seja a região que mais cresce, pois há uma grande demanda por produtos de raios X e várias empresas também estão lançando novos produtos. Além disso, fez avanços significativos em tecnologia e inovação, concentrando-se no desenvolvimento e na adoção de tecnologias avançadas de raios X.

Para obter informações mais detalhadas sobre o relatório global do mercado de raios X industriais, clique aqui –https://www.databridgemarketresearch.com/reports/global-industrial-x-ray-market