North America Protective Films Market

시장 규모 (USD 10억)

연평균 성장률 :

%

USD

644.13 million

USD

791.93 million

2022

2030

USD

644.13 million

USD

791.93 million

2022

2030

| 2023 –2030 | |

| USD 644.13 million | |

| USD 791.93 million | |

|

|

|

북미 보호 필름 시장, 종류별(접착제 코팅, 자체 접착), 소재( 폴리에틸렌 , 폴리프로필렌, 폴리에틸렌 테레프탈레이트, 폴리염화비닐, 폴리우레탄, 폴리아미드, 폴리에스테르, 종이, 기타), 두께(0~2mm, 2~4mm, 4~6mm, 6~8mm, 8~10mm, 기타), 표면(금속, 유리, 직물, 목재, 대리석, 성형 플라스틱, 기타), 질감(불투명, 투명, 광택, 무광택, 기타), 최종 사용자(건축 및 건설, 자동차, 전자, 생명 과학, 항공우주, 포장, 산업, 해양, 기타) - 업계 동향 및 2030년까지의 예측.

북미 보호 필름 시장 분석 및 규모

보호 필름은 형광 스크린, 금속, 목재, 유리 등과 같은 고품질 표면을 긁힘, 자국, 먼지 입자, 습기 및 기타 물질로부터 보호하는 데 사용됩니다. 보호 필름은 건설, 자동차, 전자 제품, 포장 및 기타 산업에서 널리 사용됩니다.

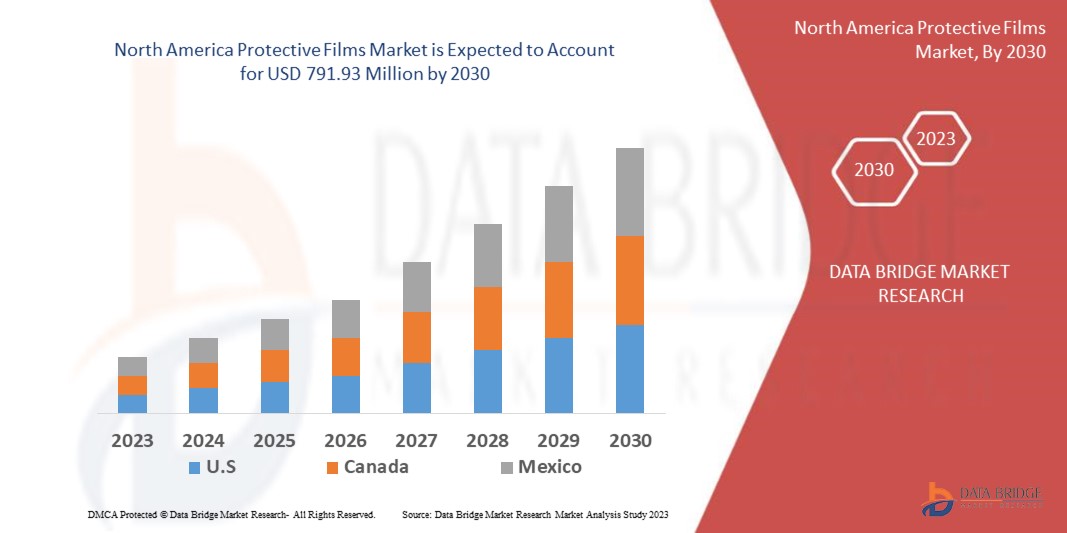

Data Bridge Market Research에 따르면, 2022년에 6억 4,413만 달러였던 북미 보호 필름 시장은 2030년까지 7억 9,193만 달러로 성장할 것으로 예상되며, 2023년부터 2030년까지의 예측 기간 동안 연평균 성장률 5.3%를 기록할 것으로 예상됩니다.

보호 필름에는 여러 가지 이점이 있으며, 자동차 산업에서 차량 표면을 긁힘, 자국, 먼지 및 기타 입자로부터 보호하기 위한 보호 필름에 대한 수요가 증가하고 있으며, 이것이 시장 성장의 원동력입니다. 시장 가치, 성장률, 세분화, 지리적 범위 및 주요 업체와 같은 시장 시나리오에 대한 통찰력 외에도 Data Bridge Market Research에서 큐레이팅한 시장 보고서에는 심층적인 전문가 분석, 지리적으로 표현된 회사별 생산 및 용량, 유통업체 및 파트너의 네트워크 레이아웃, 자세하고 업데이트된 가격 추세 분석 및 공급망 및 수요의 적자 분석이 포함됩니다.

북미 보호 필름 시장 범위 및 세분화

|

보고서 메트릭 |

세부 |

|

예측 기간 |

2023년부터 2030년까지 |

|

기준 연도 |

2022 |

|

역사적 연도 |

2021 (2015-2020까지 사용자 정의 가능) |

|

양적 단위 |

매출(백만 달러), 볼륨(톤) |

|

다루는 세그먼트 |

종류(접착제 코팅, 자체 접착), 재료(폴리에틸렌, 폴리프로필렌 , 폴리에틸렌 테레프탈레이트, 폴리염화비닐, 폴리우레탄, 폴리아미드, 폴리에스테르, 종이, 기타), 두께(0~2mm, 2~4mm, 4~6mm, 6~8mm, 8~10mm, 기타), 표면(금속, 유리, 섬유, 목재, 대리석, 성형 플라스틱, 기타), 질감(불투명, 투명, 광택, 무광, 기타), 최종 사용자(건축 및 건설, 자동차, 전자, 생명 과학, 항공우주, 포장, 산업, 해양, 기타) |

|

적용 국가 |

미국, 캐나다, 멕시코 |

|

시장 참여자 포함 |

Lamin-x(미국), Tee Group Films(미국), Mactac(LINTEC Corporation의 자회사)(미국), DuPont(미국), Arkema(프랑스), Hitachi Chemical Co., Ltd.(일본), Saint-Gobain(프랑스) 및 3M(미국) |

|

시장 기회 |

|

시장 정의

보호 필름은 형광 스크린, 금속, 목재, 유리 등과 같은 고품질 표면을 긁힘, 자국, 먼지 입자, 습기 및 기타 물질로부터 보호하는 데 사용됩니다. 보호 필름은 건설, 자동차, 전자 제품, 포장 및 기타 산업에서 널리 사용됩니다.

이러한 필름은 폴리에틸렌(HDPE), 저밀도 폴리에틸렌(LDPE), 선형 저밀도 폴리에틸렌(LLPE), 폴리프로필렌, 폴리에틸렌 테레 프탈레이트, 폴리염화비닐 , 폴리우레탄, 폴리아미드, 폴리에스테르, 종이 등과 같은 고품질 플라스틱 기반 원료로 만들어집니다.

북미 보호 필름 시장 동향

운전자

- 전자상거래 산업에서 포장 필름의 높은 채택률

오늘날 포장은 한 장소에서 다른 장소로 안전하게 운송하기 위해 다양한 제품이나 상품을 준비하는 조정된 시스템입니다. 포장은 전체 공급망 관리에서 중요한 역할을 합니다. 포장은 제품을 손상, 갑작스러운 움직임, 균열, 긁힘 등으로부터 보호합니다. 사실, 다양한 제조업체가 효과적인 브랜드 아이덴티티를 만들기 위해 새롭고 혁신적인 포장 기술을 채택하고 있습니다.

2020년 National Retail Federation의 조사에 따르면, 쇼핑을 위한 소비자 행동에 있어서 가장 선호하는 매개변수는 품질(32%)과 가격(30%)이며, 편의성이 중요하다고 답한 사람은 13%에 불과합니다. 그러나 이는 전반적인 쇼핑 습관을 반영하지 않는데, 100명 중 97명의 소비자가 단점 때문에 구매하지 않았다고 답했기 때문입니다.

- 보호 필름의 비용이 경쟁업체에 비해 저렴함

보호 필름은 플라스틱을 원료로 하여 만든 필름입니다. 보호 필름의 생산은 필름의 최상층은 견고해야 하고 필름에 사용된 코팅 물질은 두께가 얇은 고무 또는 아크릴 코팅의 얇은 층을 가져야 하며, 제품 표면에 흔적이나 다른 표시가 생기지 않고 층을 쉽게 제거해야 하기 때문에 매우 복잡합니다. 제품의 두께, 반사 및 형성 접착층, 아크릴 및 실리콘 층을 엄격히 모니터링하여 제품을 쉽게 측정하면 제품 낭비를 줄여 필름의 전반적인 품질을 향상시킬 수 있습니다.

보호 필름은 투명, 불투명, 무광 등 다양한 색상, 크기, 모양으로 제공됩니다. 보호 필름의 가격은 페인트와 보호용 투명 코팅보다 저렴합니다. 이러한 필름의 설치 과정은 매우 복잡하며 최적의 결과를 얻으려면 숙련된 인력이 필요합니다. 설치 시 작거나 사소한 실수가 최종 결과에 변화를 일으킬 수 있습니다.

- 건설 및 운송 산업에서 보호 필름에 대한 높은 수요

건설 산업은 제한된 공간 내에서 자재와 중장비를 이동시키는 것으로 잘 알려져 있으며, 이는 높은 수준의 안전 위험을 초래합니다. 카펫, 조리대, 가전제품, 창문, 문 등 모든 것을 외부의 긁힘, 즉 긁힘으로부터 보호해야 합니다. 접착제로 코팅된 필름은 표면에 부착되어 보호하여 값비싼 제품의 수리를 방지합니다. 보호 필름은 표면을 손상 및 기타 대기 활동으로부터 보호하는 데 사용됩니다.

맞춤형 보호 필름은 페인팅에서 리모델링, 장식 또는 페인팅 프로젝트와 같이 다양한 건설 프로젝트와 같이 수행되는 작업의 종류에 따라 건설 산업에서 큰 수요가 있습니다. 보호 필름은 폴리에틸렌 및 프로필렌과 같은 플라스틱을 원료로 하여 만들어지며 일반적으로 보호 필름 제조에 원료로 사용됩니다. 이러한 플라스틱 시트는 높은 내열성으로 인해 건설 산업에서 널리 사용됩니다. 사용되는 다른 플라스틱으로는 TPU, 폴리염화비닐 및 폴리에틸렌 테레프탈레이트가 있습니다. TPU 필름은 높은 내열성으로 인해 건물 및 건설 부문에서 널리 사용되고 있으며 이러한 필름은 창유리 및 패널에 널리 사용됩니다.

기회

- 전자 산업 분야에서 보호 필름의 높은 적응성

전자 산업은 차세대 전자 기기를 형성하겠다고 약속했으며, 대부분의 전자 기기는 광범위한 응용 분야에서 사용되는 다양한 응용 분야에서 전 세계적으로 널리 사용되고 있습니다. TV, AC, 냉장고, 전화기와 같은 전자 기기는 더 넓은 범위에서 소비자의 일상적인 요구의 일부가 되고 있습니다.

표면 보호 테이프 또는 보호 필름은 전자 산업에서 형광등 화면, TV 화면 및 기타 전자 장비를 긁힘, 자국, 먼지 및 기타 불순물로부터 보호하는 데 널리 사용됩니다.

전자 시장에는 저항기, 절연체, 형광 스크린, 모터, 커패시터, 포토레지스트, 플렉서블 인쇄 회로, 평판 디스플레이(FPD), 솔라 스크린, 태양 전지 등이 포함됩니다. 많은 전자 제품이 표면을 보호하기 위해 BOPET 필름에 널리 사용됩니다. 태양 전지 및 태양 전지 기기에서 폴리에스터 필름은 후면 유리에 사용됩니다.

-

최소한의 환경 영향으로 지속 가능한 제품을 제공하기 위한 기술 발전

보호 필름은 플라스틱을 원료로 하여 만든 필름입니다. 보호 필름의 생산은 필름의 최상층은 견고해야 하고 필름에 사용된 코팅 물질은 두께가 낮은 고무 또는 아크릴 코팅의 얇은 층을 가져야 하며, 제품 표면에 흔적이나 다른 표시를 남기지 않고 층을 쉽게 제거해야 하기 때문에 매우 복잡합니다.

제품의 간편한 측정, 두께, 반사율, 접착층 형성, 아크릴 및 실리콘 층을 면밀히 모니터링하면 제품 낭비를 줄여 필름의 전반적인 품질을 향상시킬 수 있습니다.

보호 포장 필름 기술의 제작은 널리 상당한 추진력을 얻었습니다. 상품의 유통기한을 늘리고 취급 및 운송을 용이하게 하기 위해 보호 필름에 대한 소비자 선호도가 높아지면서 보호 필름에 대한 수요가 증가합니다.

제약/도전

원자재 가격 변동

보호 필름은 오염, 먼지, 긁힘 및 표면의 전반적인 모양을 저하시키는 기타 요소와 같은 외부 손상으로부터 고품질 표면을 보호해야 하는 모든 곳에 사용됩니다.

보호 필름은 폴리에틸렌(HDPE), 저밀도 폴리에틸렌(LDPE), 선형 저밀도 폴리에틸렌(LLPE), 폴리프로필렌, 폴리에틸렌 테레프탈레이트, 폴리염화비닐, 폴리우레탄, 폴리아미드 , 폴리에스터, 종이와 같은 플라스틱 원료로 널리 제조됩니다. 보호 필름의 가공은 대부분 소비자가 최적의 결과를 위해 얇은 보호 시트를 요구하기 때문에 매우 복잡합니다.

원자재 가격은 플라스틱 가격이 석유 가격과 기타 시장 변동에 크게 좌우되기 때문에 매우 변동성이 큽니다. 원유는 탄화수소 의 혼합물이며 , 다른 온도에서 다른 제품이 분리됩니다. 예를 들어, 휘발유, 등유, 나프타 디젤 등이 있습니다.

Business Standard가 2018년 7월에 발표한 보고서에 따르면, 전 세계의 팬데믹 상황으로 인해 원유 가격의 변동 가격이 상승하고 수출 중심의 플라스틱 제조업체에서 소비가 활발해지면서 다양한 플라스틱 원료의 가격이 약 13% 급등했습니다. 폴리머 가격은 원유 가격의 급격한 상승으로 인해 상승했습니다.

엄격한 환경 및 정부 규정

포장과 소비자 보호 사이에는 강력한 연관성이 있습니다. 포장은 안전을 위한 수단이며 소비자에게 안전하고 건강하며 영양가 있는 음식을 제공하는 것을 목표로 합니다. 포장 규칙과 법률은 고객과 커뮤니티 전체의 요구를 보호하기 위해 국가에서 채택되었습니다. 대부분 국가의 정부는 이러한 플라스틱 제품이 더 넓은 범위에서 환경을 오염시키기 때문에 다양한 플라스틱 제품의 사용을 금지합니다.

예를 들어,

- 2018년 6월, 인도 총리는 인도가 2022년까지 일회용 플라스틱 사용을 중단하겠다고 발표했습니다. 반면, 캐나다와 유럽 연합은 2021년까지 일회용 플라스틱 사용을 중단할 예정입니다.

최근 개발 사항

- 2022년 5월, Saint-Gobain SA는 프랑스의 ISOVER 공장에 새로운 유리 울 생산 라인에 투자하여 프랑스 시장의 지붕 공간 단열 솔루션 수요 증가에 대응했습니다.

- 2021년 12월, Saint-Gobain SA는 Alghamin Group과 100% 자회사인 Rockwool India Pvt Ltd를 인수하기 위한 계약을 체결했습니다. Rockwool India Pvt Ltd는 열, 음향 및 화재 안전 응용 분야를 위한 다양한 단열 제품을 생산하는 인도의 주요 암면 제조업체입니다.

북미 보호 필름 시장 범위

북미 보호 필름 시장은 제품 유형, 소재 유형, 온도 및 응용 분야를 기준으로 세분화됩니다. 이러한 세그먼트 간의 성장은 산업의 빈약한 성장 세그먼트를 분석하고 사용자에게 귀중한 시장 개요와 시장 통찰력을 제공하여 핵심 시장 응용 분야를 식별하기 위한 전략적 결정을 내리는 데 도움이 됩니다.

수업

- 접착제 코팅

- 아크릴

- 고무

- 자체 접착

재료

- 폴리에틸렌

- 폴리프로필렌

- 폴리에틸렌 테레프탈레이트

- 폴리염화비닐

- 폴리우레탄

- 폴리아미드

- 폴리에스터

- 종이

- 기타

두께

- 0- 2mm

- 2 - 4mm

- 4 - 6mm

- 6 - 8mm

- 8 - 10mm

- 기타

표면

조직

- 불투명체

- 투명한

- 광택있는

- 매트

- 기타

최종 사용자

- 건물 및 건설

- 자동차

- 전자제품

- 생명과학

- 항공우주

- 포장

- 산업

- 선박

- 기타

북미 보호 필름 시장 지역 분석/통찰력

북미 보호 필름 시장을 분석하고, 위에 언급된 대로 종류, 소재, 두께, 표면, 질감 및 최종 사용자별로 시장 규모에 대한 통찰력과 추세를 파악했습니다.

북미 보호 필름 시장 보고서에서 다루는 국가는 미국, 캐나다, 멕시코입니다.

미국은 이 지역의 전자상거래 포장 시장에 대한 대규모 고객 기반을 갖추고 있어 북미 보호 필름 시장을 지배할 것으로 예상됩니다.

보고서의 국가 섹션은 또한 개별 시장 영향 요인과 국내 시장의 현재 및 미래 트렌드에 영향을 미치는 규제 변화를 제공합니다. 다운스트림 및 업스트림 가치 사슬 분석, 기술 트렌드, 포터의 5가지 힘 분석, 사례 연구와 같은 데이터 포인트는 개별 국가의 시장 시나리오를 예측하는 데 사용되는 몇 가지 포인터입니다. 또한 글로벌 브랜드의 존재 및 가용성과 지역 및 국내 브랜드와의 대규모 또는 희소한 경쟁으로 인해 직면한 과제, 국내 관세의 영향 및 무역 경로가 국가 데이터에 대한 예측 분석을 제공하는 동안 고려됩니다.

경쟁 환경 및 북미 보호 필름 시장 점유율 분석

The North America Protective Films Market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width, and breadth, application dominance. The above data points provided are only related to the company’s focus related to North America Protective Films Market.

Some of the major players operating in the North America Protective Films Market are:

- Lamin-x (U.S.)

- Tee Group Films (U.S.)

- Mactac (a subsidiary of LINTEC Corporation) (U.S.)

- DuPont (U.S.)

- Arkema (France)

- Hitachi Chemical Co., Ltd., (Japan)

- Saint-Gobain (France

- 3M (U.S.)

SKU-

세계 최초의 시장 정보 클라우드 보고서에 온라인으로 접속하세요

- 대화형 데이터 분석 대시보드

- 높은 성장 잠재력 기회를 위한 회사 분석 대시보드

- 사용자 정의 및 질의를 위한 리서치 분석가 액세스

- 대화형 대시보드를 통한 경쟁자 분석

- 최신 뉴스, 업데이트 및 추세 분석

- 포괄적인 경쟁자 추적을 위한 벤치마크 분석의 힘 활용

연구 방법론

데이터 수집 및 기준 연도 분석은 대규모 샘플 크기의 데이터 수집 모듈을 사용하여 수행됩니다. 이 단계에는 다양한 소스와 전략을 통해 시장 정보 또는 관련 데이터를 얻는 것이 포함됩니다. 여기에는 과거에 수집한 모든 데이터를 미리 검토하고 계획하는 것이 포함됩니다. 또한 다양한 정보 소스에서 발견되는 정보 불일치를 검토하는 것도 포함됩니다. 시장 데이터는 시장 통계 및 일관된 모델을 사용하여 분석하고 추정합니다. 또한 시장 점유율 분석 및 주요 추세 분석은 시장 보고서의 주요 성공 요인입니다. 자세한 내용은 분석가에게 전화를 요청하거나 문의 사항을 드롭하세요.

DBMR 연구팀에서 사용하는 주요 연구 방법론은 데이터 마이닝, 시장에 대한 데이터 변수의 영향 분석 및 주요(산업 전문가) 검증을 포함하는 데이터 삼각 측량입니다. 데이터 모델에는 공급업체 포지셔닝 그리드, 시장 타임라인 분석, 시장 개요 및 가이드, 회사 포지셔닝 그리드, 특허 분석, 가격 분석, 회사 시장 점유율 분석, 측정 기준, 글로벌 대 지역 및 공급업체 점유율 분석이 포함됩니다. 연구 방법론에 대해 자세히 알아보려면 문의를 통해 업계 전문가에게 문의하세요.

사용자 정의 가능

Data Bridge Market Research는 고급 형성 연구 분야의 선두 주자입니다. 저희는 기존 및 신규 고객에게 목표에 맞는 데이터와 분석을 제공하는 데 자부심을 느낍니다. 보고서는 추가 국가에 대한 시장 이해(국가 목록 요청), 임상 시험 결과 데이터, 문헌 검토, 재생 시장 및 제품 기반 분석을 포함하도록 사용자 정의할 수 있습니다. 기술 기반 분석에서 시장 포트폴리오 전략에 이르기까지 타겟 경쟁업체의 시장 분석을 분석할 수 있습니다. 귀하가 원하는 형식과 데이터 스타일로 필요한 만큼 많은 경쟁자를 추가할 수 있습니다. 저희 분석가 팀은 또한 원시 엑셀 파일 피벗 테이블(팩트북)로 데이터를 제공하거나 보고서에서 사용 가능한 데이터 세트에서 프레젠테이션을 만드는 데 도움을 줄 수 있습니다.