Global Foundry Binders Market

시장 규모 (USD 10억)

연평균 성장률 :

%

USD

3.10 Billion

USD

4.31 Billion

2024

2032

USD

3.10 Billion

USD

4.31 Billion

2024

2032

| 2025 –2032 | |

| USD 3.10 Billion | |

| USD 4.31 Billion | |

|

|

|

Global Foundry Binders Market Segmentation, By Product Type (Cold Box Binders, Hot Box Binders, No-Bake Binders, and Resin Bonded Binders), Material Type (Phenolic Resin, Polymeric MDI, Sodium Silicate, and Urethane), End-Use Industry (Aerospace, Automotive, Construction, and Energy and Power), Application (Cold Box Casting, Foundry Core Making, Metal Casting, and Mold Coating), Technology (Catalyst-Cured Binders, Gas-Cured Binders, and Thermal-Cured Binders), Binder Content (High-Binder Content, Low-Binder Content, and Medium-Binder Content), Chemical Composition (Inorganic Binders and Organic Binders), Processing Method (Automated Processing and Manual Processing), Curing Process (Microwave Curing, Oven Curing, and Room Temperature Curing) - Industry Trends and Forecast to 2032

Foundry Binders Market Analysis

The foundry binders market has seen significant growth driven by advancements in materials and technology. One of the latest methods in binder development is the use of water-based binders instead of traditional chemical binders. These binders provide improved sustainability, reducing the environmental impact of foundry processes. Water-based systems also contribute to better mold strength, reduced toxicity, and enhanced casting quality. In addition, nanotechnology is being integrated into binder formulations to improve the performance of foundry molds, offering enhanced durability and precision in metal casting.

Another significant technology advancement is the use of 3D printing in mold creation, which requires high-performance binders to create more complex and intricate molds with faster production times. These innovations contribute to a reduction in waste and better energy efficiency in the foundry industry.

The market is also benefiting from growing demand in industries such as automotive, aerospace, and construction, where high-quality casting products are in demand. The use of sustainable binders and advanced formulations is expected to propel market growth as manufacturers seek more efficient, eco-friendly solutions.

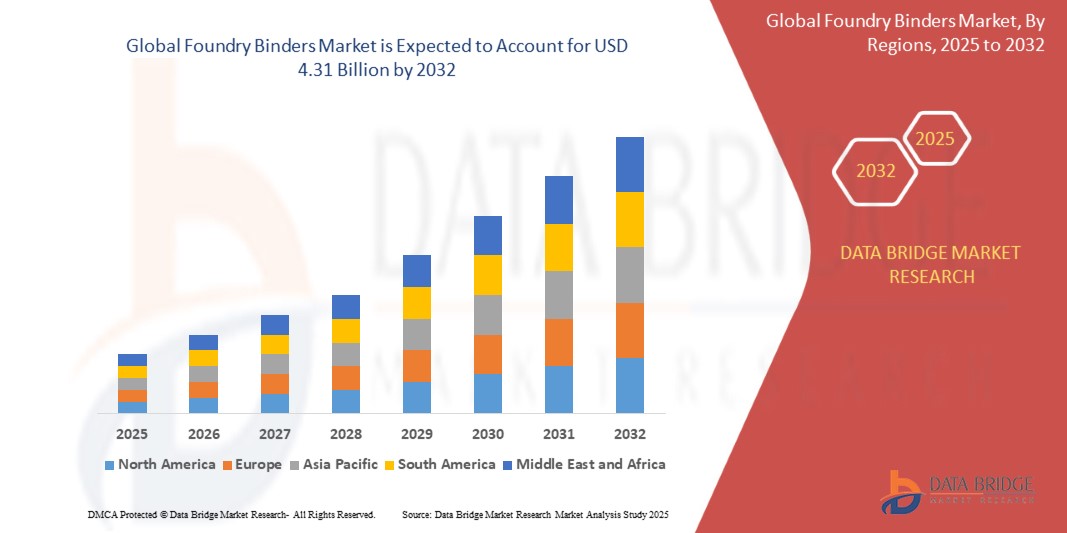

Foundry Binders Market Size

The global foundry binders market size was valued at USD 3.10 billion in 2024 and is projected to reach USD 4.31 billion by 2032, with a CAGR of 4.20% during the forecast period of 2025 to 2032. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework.

Foundry Binders Market Trends

“Increasing Demand for Environmentally Friendly Foundry Binders”

A significant trend driving growth in the foundry binders market is the increasing demand for eco-friendly, sustainable binder solutions. Traditional foundry binders often contain harmful chemicals, contributing to environmental pollution. As industries focus more on sustainability and environmental regulations become stricter, there is a shift towards bio-based and water-soluble binders. For instance, the introduction of starch-based and polymer binders has helped reduce harmful emissions during the casting process. Companies such as Foseco have pioneered green binder technologies, aligning with the industry’s sustainability goals. This trend is not only improving the environmental footprint of foundries but also enhancing operational efficiency, making it a crucial driver for market growth.

Report Scope and Foundry Binders Market Segmentation

|

Attributes |

Foundry Binders Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America |

|

Key Market Players |

Mitsubishi Chemical Corporation (Japan), 3M (U.S.), Wacker Chemie AG (Germany), Huntsman International LLC (U.S.), Henkel AG & Co. KGaA (Germany), Evonik Industries AG (Germany), KYOCERA Corporation (Japan), Dow (U.S.), Asahi Kasei Corporation (Japan), DIC CORPORATION (Japan), The Chemours Company (U.S.), Solvay (Belgium), BASF SE (Germany), Kao Corporation (Japan), KURARAY CO., LTD. (Japan), Imerys (France), United Erie (U.S.), Vesuvius plc (U.K.), IVP Limited (U.K.), Mancuso Chemicals Limited (U.S.), Eurotek Foundry Products Ltd (U.K.), and CARBO Ceramics Inc. (U.S.) |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Foundry Binders Market Definition

Foundry binders are materials used in the casting process to hold sand particles together, forming molds and cores for metal casting. These binders ensure the mold maintains its shape during the pouring and cooling of molten metal. Common types include clay-based, chemical, and organic binders, each with unique properties suited to specific applications. Chemical binders such as furan resins or phenolic resins are popular for their high strength and thermal resistance. Organic binders are often used in environmentally friendly processes due to their low toxicity and better sustainability. The choice of binder affects the quality, durability, and efficiency of the casting process.

Foundry Binders Market Dynamics

Drivers

- Rising Demand for Casting Products

The rising demand for casting products is a major driver of the foundry binders market. Industries such as automotive, aerospace, and construction are experiencing significant growth, increasing the need for high-quality, durable cast metal parts. Foundry binders play a critical role in creating molds that ensure precision and efficiency in casting complex metal components. For instance, the automotive sector requires intricate engine blocks and transmission parts, which demand advanced binders for accurate mold formation. Similarly, in aerospace, precision casting is crucial for producing lightweight, high-strength components. As these industries expand, the demand for reliable foundry binders to meet casting requirements continues to rise, directly driving the market forward.

- Rising Demand for Green Technologies

The rising demand for green technologies is significantly driving the foundry binders market as industries strive to meet environmental standards. Increasing preference for sustainable solutions, such as water-based binders and low-emission alternatives, is reshaping the industry. For instance, Shell Core Technology, which uses water-based binders, offers improved environmental benefits by reducing volatile organic compound (VOC) emissions compared to traditional binders. This transition is especially important in response to strict environmental regulations in regions such as Europe and North America. Manufacturers are also adopting eco-friendly, recyclable binders to minimize waste and environmental impact, further fueling the demand for sustainable foundry solutions in sectors such as automotive, aerospace, and heavy machinery.

Opportunities

- Rising Demand for Lightweight Alloys

The increasing use of lightweight alloys in sectors such as automotive, aerospace, and electronics is creating significant opportunities in the foundry binders market. Lightweight alloys, including aluminum and magnesium alloys, are favored for their strength-to-weight ratios, making them ideal for applications requiring reduced weight without compromising durability. To cast these alloys efficiently, advanced foundry binders are essential, as they support precise mold formation and minimize defects. For instance, the automotive industry’s shift toward lightweight components to improve fuel efficiency is driving the demand for high-performance foundry binders capable of molding complex alloy parts, thereby boosting market growth and fostering technological innovation.

- Growth of the Construction Sector

The rapid expansion of the global construction sector presents significant opportunities for the foundry binders market. As construction projects demand durable and high-quality cast parts such as structural components, fittings, and reinforcements, the need for efficient and effective foundry binders increases. For instance, the rise in urbanization and infrastructure development in emerging markets such as India and China is spurring demand for high-strength cast parts for buildings, bridges, and transportation infrastructure. These projects require advanced binding solutions to ensure precision and durability. As construction projects grow in complexity, the demand for innovative, sustainable, and cost-effective foundry binders is set to rise, driving market growth.

Restraints/Challenges

- High Raw Material Costs

Raw material costs are a significant restraint in the foundry binders market. The prices of essential raw materials, such as resins, additives, and chemicals, can experience considerable fluctuations due to factors such as supply chain disruptions, geopolitical events, and changes in demand. These price variations can directly impact the production costs for foundry binder manufacturers, making it challenging to maintain consistent pricing structures. As a result, manufacturers may face squeezed profit margins, which can hinder their ability to invest in research and development or expand operations. The volatility of raw material costs remains a persistent challenge, adding unpredictability to the market and limiting growth potential.

- Competition from Alternative Technologies

Competition from alternative casting technologies, such as 3D printing and green sand molding, significantly hinders the traditional foundry binder market. These emerging technologies offer advantages such as reduced material waste, faster production times, and the ability to produce complex geometries without the need for conventional binders. As industries adopt more advanced methods, the demand for traditional foundry binders declines, forcing manufacturers to face the challenge of maintaining relevance in a changing market. Furthermore, the growing preference for environmentally friendly alternatives also shifts demand away from conventional binder materials. This trend places significant pressure on the foundry binder market, reducing its growth potential and market share.

This market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Impact and Current Market Scenario of Raw Material Shortage and Shipping Delays

Data Bridge Market Research offers a high-level analysis of the market and delivers information by keeping in account the impact and current market environment of raw material shortage and shipping delays. This translates into assessing strategic possibilities, creating effective action plans, and assisting businesses in making important decisions. Apart from the standard report, we also offer in-depth analysis of the procurement level from forecasted shipping delays, distributor mapping by region, commodity analysis, production analysis, price mapping trends, sourcing, category performance analysis, supply chain risk management solutions, advanced benchmarking, and other services for procurement and strategic support.

Expected Impact of Economic Slowdown on the Pricing and Availability of Products

When economic activity slows, industries begin to suffer. The forecasted effects of the economic downturn on the pricing and accessibility of the products are taken into account in the market insight reports and intelligence services provided by DBMR. With this, our clients can typically keep one step ahead of their competitors, project their sales and revenue, and estimate their profit and loss expenditures.

Foundry Binders Market Scope

The market is segmented on the basis of product type, material type, end-use industry, application, technology, binder content, chemical composition, processing method, and curing process. The growth amongst these segments will help you analyse meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Product Type

- Cold Box Binders

- Hot Box Binders

- No-Bake Binders

- Resin Bonded Binders

Material Type

- Phenolic Resin

- Monomer Phenolic

- Polymer Phenolic

- Polymeric MDI

- Sodium Silicate

- Urethane

End-Use Industry

- Aerospace

- Commercial Aviation

- Military Aviation

- Automotive

- Aftermarket

- OEMs

- Construction

- Commercial

- Residential

- Energy and Power

- Oil and Gas

- Renewable Energy

Application

- Cold Box Casting

- Foundry Core Making

- Metal Casting

- Ferrous Casting

- Non-Ferrous Casting

- Mold Coating

- Chemical Coating

- Thermal Coating

Technology

- Catalyst-Cured Binders

- Gas-Cured Binders

- Thermal-Cured Binders

Binder Content

- High-Binder Content

- Low-Binder Content

- Medium-Binder Content

Chemical Composition

- Inorganic Binders

- Organic Binders

Processing Method

- Automated Processing

- Manual Processing

Curing Process

- Microwave Curing

- High-Frequency Microwave

- Low-Frequency Microwave

- Oven Curing

- Room Temperature Curing

Foundry Binders Market Regional Analysis

The market is analysed and market size insights and trends are provided by product type, material type, end-use industry, application, technology, binder content, chemical composition, processing method, and curing process as referenced above.

The countries covered in the market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

Asia-Pacific is expected to dominate the foundry binder market due to its strong presence in industries such as automotive, aerospace, and machinery manufacturing. The region’s rapid industrialization, growing population, and infrastructure investments boost demand for metal castings. In addition, cost-effective production, technological advancements, and supportive government policies further strengthen the market's growth.

North America is expected to show significant growth in the foundry binder market, driven by a strong manufacturing sector in aerospace, defense, and automotive. The demand for high-performance and eco-friendly binders, technological advancements, and research and development investments, along with supportive government regulations and industry players, are fueling market expansion in the region.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Foundry Binders Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

Foundry Binders Market Leaders Operating in the Market Are:

- Mitsubishi Chemical Corporation (Japan)

- 3M (U.S.)

- Wacker Chemie AG (Germany)

- Huntsman International LLC (U.S.)

- Henkel AG & Co. KGaA (Germany)

- Evonik Industries AG (Germany)

- KYOCERA Corporation (Japan)

- Dow (U.S.)

- Asahi Kasei Corporation (Japan)

- DIC CORPORATION (Japan)

- The Chemours Company (U.S.)

- Solvay (Belgium)

- BASF SE (Germany)

- Kao Corporation (Japan)

- KURARAY CO., LTD. (Japan)

- Imerys (France)

- United Erie (U.S.)

- Vesuvius plc (U.K.)

- IVP Limited (U.K.)

- Mancuso Chemicals Limited (U.S.)

- Eurotek Foundry Products Ltd (U.K.)

- CARBO Ceramics Inc. (U.S.)

Latest Developments in Foundry Binders Market

- In November 2023, BASF, a global leader in battery materials, and SK On, a major electric vehicle battery cell manufacturer, have entered into a partnership to explore collaboration opportunities in the lithium-ion battery market, with a focus on North America and Asia-Pacific. Their combined expertise aims to develop advanced battery materials for the growing market

- In August 2023, Kao Corporation, a prominent Japanese beauty company, announced its acquisition of Bondi Sands, an Australian sun and body care brand, for approximately 450 million Australian dollars. This strategic move strengthens Kao’s position in the sun care market, enhancing its portfolio and expanding its footprint in the global beauty and personal care sector

- In May 2023, Imerys, a global leader in mineral-based specialty solutions, has partnered with TotalEnergies to install a large-scale solar power system with integrated battery energy storage at its Lompoc facility in Santa Barbara County, California. This initiative supports Imerys’ commitment to sustainability by reducing CO2 emissions by approximately 7,000 metric tons annually

SKU-

세계 최초의 시장 정보 클라우드 보고서에 온라인으로 접속하세요

- 대화형 데이터 분석 대시보드

- 높은 성장 잠재력 기회를 위한 회사 분석 대시보드

- 사용자 정의 및 질의를 위한 리서치 분석가 액세스

- 대화형 대시보드를 통한 경쟁자 분석

- 최신 뉴스, 업데이트 및 추세 분석

- 포괄적인 경쟁자 추적을 위한 벤치마크 분석의 힘 활용

연구 방법론

데이터 수집 및 기준 연도 분석은 대규모 샘플 크기의 데이터 수집 모듈을 사용하여 수행됩니다. 이 단계에는 다양한 소스와 전략을 통해 시장 정보 또는 관련 데이터를 얻는 것이 포함됩니다. 여기에는 과거에 수집한 모든 데이터를 미리 검토하고 계획하는 것이 포함됩니다. 또한 다양한 정보 소스에서 발견되는 정보 불일치를 검토하는 것도 포함됩니다. 시장 데이터는 시장 통계 및 일관된 모델을 사용하여 분석하고 추정합니다. 또한 시장 점유율 분석 및 주요 추세 분석은 시장 보고서의 주요 성공 요인입니다. 자세한 내용은 분석가에게 전화를 요청하거나 문의 사항을 드롭하세요.

DBMR 연구팀에서 사용하는 주요 연구 방법론은 데이터 마이닝, 시장에 대한 데이터 변수의 영향 분석 및 주요(산업 전문가) 검증을 포함하는 데이터 삼각 측량입니다. 데이터 모델에는 공급업체 포지셔닝 그리드, 시장 타임라인 분석, 시장 개요 및 가이드, 회사 포지셔닝 그리드, 특허 분석, 가격 분석, 회사 시장 점유율 분석, 측정 기준, 글로벌 대 지역 및 공급업체 점유율 분석이 포함됩니다. 연구 방법론에 대해 자세히 알아보려면 문의를 통해 업계 전문가에게 문의하세요.

사용자 정의 가능

Data Bridge Market Research는 고급 형성 연구 분야의 선두 주자입니다. 저희는 기존 및 신규 고객에게 목표에 맞는 데이터와 분석을 제공하는 데 자부심을 느낍니다. 보고서는 추가 국가에 대한 시장 이해(국가 목록 요청), 임상 시험 결과 데이터, 문헌 검토, 재생 시장 및 제품 기반 분석을 포함하도록 사용자 정의할 수 있습니다. 기술 기반 분석에서 시장 포트폴리오 전략에 이르기까지 타겟 경쟁업체의 시장 분석을 분석할 수 있습니다. 귀하가 원하는 형식과 데이터 스타일로 필요한 만큼 많은 경쟁자를 추가할 수 있습니다. 저희 분석가 팀은 또한 원시 엑셀 파일 피벗 테이블(팩트북)로 데이터를 제공하거나 보고서에서 사용 가능한 데이터 세트에서 프레젠테이션을 만드는 데 도움을 줄 수 있습니다.