世界の産業用コントローラー市場の規模、シェア、トレンド分析レポート

Market Size in USD Billion

CAGR :

%

USD

152.66 Billion

USD

262.27 Billion

2024

2032

USD

152.66 Billion

USD

262.27 Billion

2024

2032

| 2025 –2032 | |

| USD 152.66 Billion | |

| USD 262.27 Billion | |

|

|

|

|

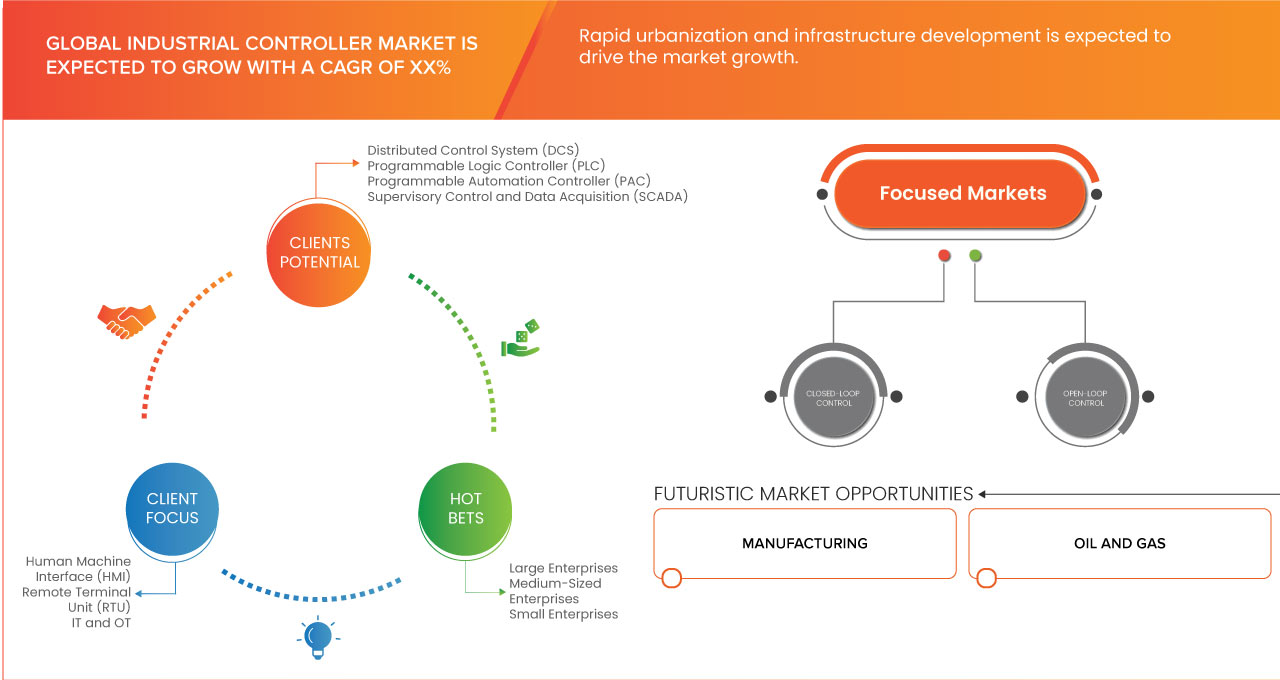

世界の産業用コントローラ市場のセグメンテーション、タイプ別(分散制御システム(DCS)、プログラマブルロジックコントローラ(PLC)、プログラマブルオートメーションコントローラ(PAC)、監視制御およびデータ収集(SCADA))、コンポーネント別(ヒューマンマシンインターフェース(HMI)、リモートターミナルユニット(RTU)、ITおよびOT、プログラマブルオートメーションコントローラ、制御ループ、その他)、制御(閉ループ制御、開ループ制御、オンオフ制御、フィードフォワード制御)、ネットワークタイプ別(制御自動化技術用イーサネット(ETHERCAT)、Modbus、共通産業プロトコル(CIP)、プロセスフィールドバス(Profibus)、オープンプラットフォーム通信(OPC)、分散ネットワークプロトコル(DNP3)、ビルディングオートメーションおよび制御ネットワーク(BACNET))、企業規模別(大企業、中規模企業、小企業)、アプリケーション別(製造、石油・ガス、エネルギー・公益事業、自動車、食品加工・飲料、上下水道、航空宇宙・航空、その他 - 2032年までの業界動向と予測

世界の産業用コントローラー市場分析

世界の産業用コントローラ市場は、自動化、IoT統合、インダストリー4.0の導入の進展に牽引され、大きな成長を遂げています。これらのコントローラは、自動車、エネルギー、食品・飲料、医薬品など、様々な業界において製造プロセスの最適化、精度、効率性、リアルタイム監視の確保において重要な役割を果たしています。スマートファクトリーへの需要の高まりに加え、コスト削減、運用安全性、予知保全のニーズも市場拡大を後押ししています。さらに、AIを活用した自動化、エッジコンピューティング、サイバーセキュリティソリューションの台頭は、シームレスなデータ処理と接続性を実現し、産業用コントローラの未来を形作っています。産業界がデジタルトランスフォーメーションを推進し続ける中、市場は拡張性、相互運用性、持続可能性を重視し、持続的な成長が見込まれています。

世界の産業用コントローラ市場規模

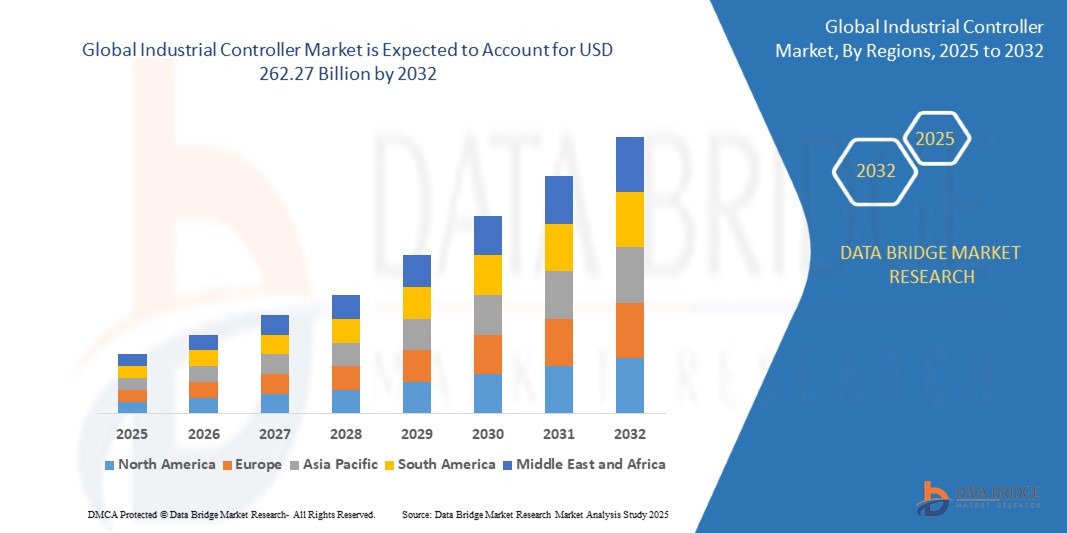

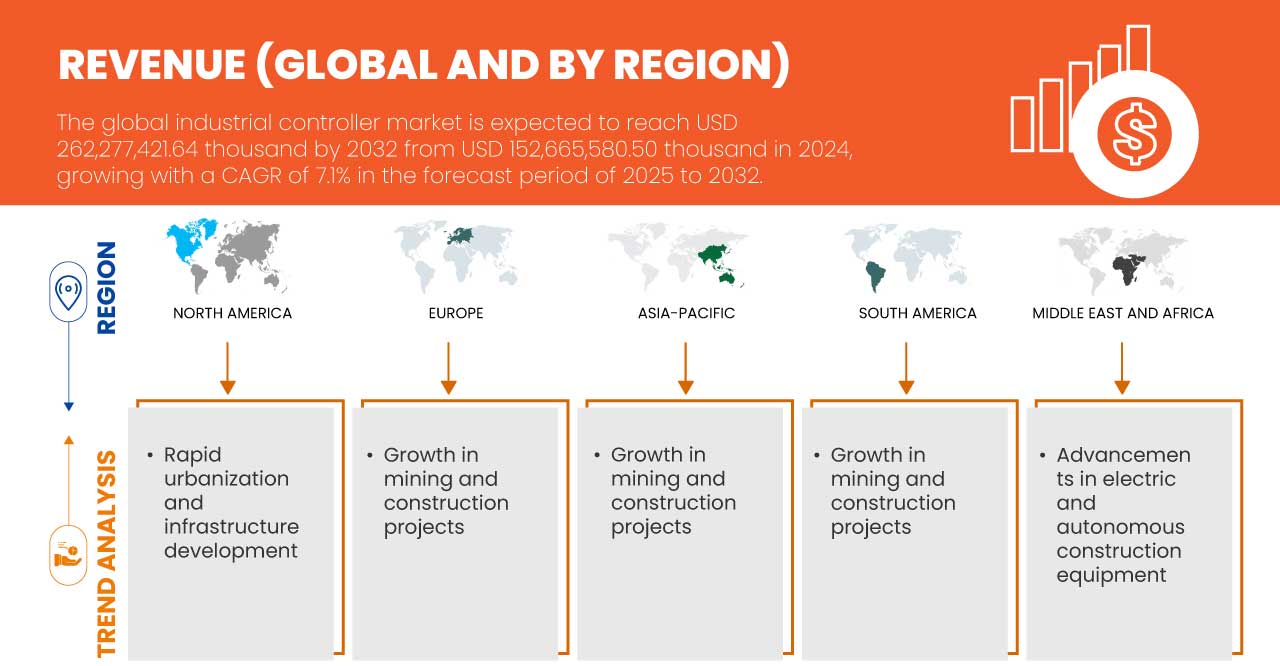

Data Bridge Market Researchは、世界の産業用コントローラー市場は、2025年から2032年の予測期間に7.1%のCAGRで成長し、2024年の1,526.6億米ドルから2032年には2,622.7億米ドルに達すると予測しています。市場価値、成長率、市場セグメント、地理的範囲、市場プレーヤー、市場シナリオなどの市場洞察に加えて、Data Bridge Market Researchチームがまとめた市場レポートには、専門家による詳細な分析、輸入/輸出分析、価格分析、生産消費分析、PESTLE分析が含まれています。

世界の産業用コントローラ市場の動向

「エッジコンピューティングが産業用コントローラのデータ処理速度を向上」

エッジコンピューティングは、集中型のクラウドサーバーからデータ生成ポイントに近いネットワークエッジへと計算処理を移行することで、産業用コントローラーのデータ処理に革命をもたらします。この近接性によりレイテンシが大幅に短縮され、時間的制約が厳しい産業オペレーションに不可欠なリアルタイム分析が可能になります。ローカル処理は迅速な意思決定を可能にし、運用効率を最適化し、コストのかかるダウンタイムを最小限に抑えます。エッジコンピューティングはデータをオンサイトで処理することでネットワークの輻輳を緩和し、外部システムへのデータ転送を削減することでサイバーセキュリティを強化します。このローカルアプローチは高度な予知保全をサポートし、潜在的な機器障害をプロアクティブに特定して解決することを可能にします。産業界が自動化とIoTを導入するにつれ、エッジコンピューティングはパフォーマンスの最適化、応答性の確保、そしてシステム全体の信頼性向上に不可欠なものとなっています。

レポートの範囲と世界の産業用コントローラ市場のセグメンテーション

|

レポートメトリック |

世界の産業用コントローラー市場の洞察 |

|

対象セグメント |

|

|

対象国 |

米国、カナダ、メキシコ、ドイツ、英国、フランス、イタリア、スペイン、ロシア、トルコ、オランダ、ノルウェー、フィンランド、デンマーク、スウェーデン、ポーランド、スイス、ベルギー、その他のヨーロッパ諸国、中国、日本、インド、韓国、オーストラリア、インドネシア、タイ、マレーシア、シンガポール、フィリピン、その他のアジア太平洋諸国、ブラジル、アルゼンチン、その他の南米諸国、UAE、サウジアラビア、南アフリカ、エジプト、イスラエル、その他の中東およびアフリカ諸国 |

|

主要な市場プレーヤー |

ABB(スイス)、シーメンス(ドイツ)、日立産機システム(日本)、ハネウェル・インターナショナル(米国)、シュナイダーエレクトリック(フランス)、三菱電機(日本)、GEグリッドソリューションズ(米国)、エマソンエレクトリック(米国)、オムロン(日本)、川崎重工業(日本)、ジェイテクトエレクトロニクスインディア(東京)、ロックウェルオートメーション(米国)、横河電機(日本)、デルタエレクトロニクス(台湾)、オーデュボンカンパニーズ(米国)、アスロックインダストリアル(台湾)、IDEC(日本)、レッドライオン(米国)、アスコン・テクノロジー(イタリア)、WEINTEK USA。 (米国)、ANAHEIM AUTOMATION, INC.(米国)、South Shore Controls, Inc(米国)、NATIONAL INSTRUMENTS CORP.(米国)、META THERM FURNACE PVT LTD(インド) |

|

市場機会 |

|

|

付加価値データ |

データブリッジ市場調査チームがまとめた市場レポートには、市場価値、成長率、市場セグメント、地理的範囲、市場プレーヤー、市場シナリオなどの市場洞察に加えて、専門家による詳細な分析、輸入/輸出分析、価格分析、生産消費分析、PESTLE分析が含まれています。 |

世界の産業用コントローラー市場の定義

産業用コントローラは、製造、エネルギー、輸送などの産業における産業プロセスや機械の監視、制御、最適化に使用される特殊な自動化デバイスです。リアルタイムデータを処理し、プログラムされた命令を実行することで、精度、効率、信頼性を確保します。産業用コントローラには、プログラマブルロジックコントローラ(PLC)、分散制御システム(DCS)、監視制御データ収集システム(SCADA)などがあり、それぞれ特定の自動化タスク向けに設計されています。これらのコントローラは、センサー、アクチュエータ、通信ネットワークと統合することで、シームレスな産業運用、安全性の向上、ダウンタイムの削減、IoTおよびインダストリー4.0テクノロジーによるデジタルトランスフォーメーションの実現に貢献します。

世界の産業用コントローラー市場の動向

ドライバー

- 急速な都市化とインフラ整備

世界中で製造施設の拡大が進むにつれ、自動化、効率性、そしてプロセス制御を強化する産業用コントローラシステムの需要が高まっています。スマートマニュファクチャリングやインダストリー4.0テクノロジーの導入が進むにつれ、プログラマブルロジックコントローラ(PLC)、分散制御システム(DCS)、監視制御・データ収集システム(SCADA)のニーズが高まっています。これらのコントローラは、運用の最適化、ダウンタイムの削減、生産性の向上を実現するため、現代の製造環境に不可欠な存在となっています。さらに、IoTを活用した自動化とリアルタイム監視の普及により、市場の成長がさらに加速しています。産業界は、生産の効率化と運用の信頼性確保のために高度な制御ソリューションを求めています。

例えば、

- 2024年9月、Fictivが公開したブログによると、製造業市場における企業数は2029年までに614万社に増加し、年平均成長率(CAGR)は2.15%になると予測されています。2024年から2029年にかけて、素材製品と医療機器が最も高い成長率(それぞれ16.7%増)を示し、次いで消費財と工業製品(それぞれ10.8%増)が見込まれ、自動車製品は7.1%の成長が見込まれています。2024年から2029年にかけての全体成長率は11.2%で、2018年から2024年の5.1%増の2倍以上となり、製造業の急速な拡大を浮き彫りにしています。こうした企業数の急増は、成長する産業を支えるために自動化、効率性、プロセス制御を強化しようとするメーカーの動きを反映し、産業用コントローラシステムの需要拡大を促すでしょう。

リアルタイム監視のニーズの高まりがスマート制御システムの導入を促進

産業オペレーションにおけるリアルタイム監視の需要の高まりは、スマート制御システムの導入を促進し、効率性の向上、予知保全、プロセス最適化を実現しています。製造業では、PLC、DCS、SCADAシステムをIoTやAIと統合することで、瞬時のデータ分析、遠隔監視、自動意思決定を実現しています。こうした変化は、ダウンタイムの削減、安全性の向上、そして厳格な運用基準への準拠の確保につながります。製造業やインフラセクターがデータ駆動型制御ソリューションを優先するにつれ、世界の産業用コントローラ市場は、コネクティビティ、エッジコンピューティング、スマートオートメーション技術の進歩に支えられ、大幅な成長を遂げています。

例えば、

- 2024年2月、Endeavor Business Media, LLCが公開したブログによると、PLCとカメラシステムの統合により、産業環境におけるリアルタイム監視のニーズを背景に、品質管理の自動化が強化されています。高度な画像比較アルゴリズム、パターン認識技術、バーコードまたはQRコードリーダーがPLCプログラミングに組み込まれ、より迅速かつ正確な検査を実現しています。Bosch RexrothのctrlX OSは、産業オートメーションへのアプリベースのアプローチを提供することで、この変化をさらにサポートし、モーションコントロール、PLC、IoTアプリケーション、AI駆動型ビジョンシステムのシームレスな統合を可能にします。

機会

- クラウドベースの分析により、リアルタイムの産業用コントローラの洞察を最適化

クラウドコンピューティングを活用することで、企業は産業用コントローラから膨大な量のデータを処理し、最小限のレイテンシで実用的な洞察を得ることができます。これにより、意思決定の改善、ダウンタイムの削減、そしてスケーラブルな運用が可能になります。産業界におけるIoTやAIを活用した自動化の導入が進む中、クラウドベースの分析はシームレスなデータ統合、リモート監視、そして適応型制御戦略を実現することで競争優位性をもたらし、イノベーションとオペレーショナルエクセレンスを推進します。

例えば、

- Endeavor Business Media, LLCが発表した記事によると、2024年5月、OPC FoundationはOPC UAを用いてITおよびクラウドプラットフォーム間の相互運用性を強化し、高度なデータ分析、デジタルツイン、AIアプリケーションを可能にするIT/クラウドイニシアチブを立ち上げました。AWSやMicrosoftなどの主要クラウドプロバイダーの支援を受けるこのイニシアチブは、クラウドベースのアプリケーション向けにOPC UAを最適化し、コスト削減と使いやすさの向上を実現します。クラウドベースの分析は、シームレスなデータ統合、AI主導の分析、安全で標準化された通信を確保することで、リアルタイムの産業用コントローラの洞察を強化し、予知保全、効率性の向上、よりスマートな産業オートメーションを実現するため、重要な市場機会となります。

モジュール式およびスケーラブルなコントローラの採用拡大

モジュール式でスケーラブルなコントローラの導入拡大は、柔軟性、費用対効果、そして将来性を兼ね備えた自動化ソリューションを実現することで、大きな市場機会を生み出しています。産業界は、大規模なオーバーホールをすることなく制御システムを容易にアップグレード・拡張できるため、運用効率の向上とダウンタイムの削減が可能になります。製造、エネルギー、産業分野における適応性の高い自動化への需要が高まる中、モジュール式コントローラに投資する企業は、高度なカスタマイズ、クラウドベースの分析機能とのシームレスな統合、そしてより優れたパフォーマンス最適化を実現し、進化するデジタル環境における長期的な成長を実現できます。

例えば、

- WTWH Media LLCが公開したブログによると、2024年9月、Applied Motion Products(AMP)はCPBD-ACリモートコントロールモジュールを発表し、CSM34コンベアスマートモーターの柔軟性と使いやすさを向上させました。このモジュールにより、動作プロファイルのリモート設定、リアルタイムシステム監視、コンベアの手動調整が可能になり、オペレーターがモーターの近くにいる必要がなくなります。統合された制御、ステータス表示、プッシュボタン機能により、配線の複雑さを軽減しながらコンベア操作を効率化します。これは、市場におけるモジュール式でスケーラブルなコントローラーの採用増加と合致しており、業界が適応性が高く、簡単にアップグレードでき、コスト効率の高いソリューションで自動化プロセスを最適化できるようにすることで、大きなビジネスチャンスをもたらします。

制約/課題

- サイバー脅威により産業用コントローラシステムの脆弱性が増加

IoTやクラウドベースの制御ソリューションを通じて産業システムの相互接続が進むにつれ、ランサムウェア、データ侵害、システム障害といったサイバー攻撃の標的となりやすくなっています。これらの脆弱性は、石油・ガス、製造業、発電といった重要産業において、深刻な経済的損失、生産停止、そして安全性の低下につながる可能性があります。さらに、堅牢なサイバーセキュリティ対策の導入や、進化する規制へのコンプライアンス遵守にかかる高額なコストは、市場の成長にとって更なる課題となっています。サイバー脅威の高度化は、産業オートメーションへの信頼を揺るがし続け、企業が高度な制御技術を本格的に導入することを阻んでいます。

例えば、

- TechTarget, Inc.が2024年7月に発表した記事によると、Dragosの研究者は、Modbus伝送制御プロトコルを悪用して運用技術環境を攻撃する、産業用制御システムに特化した新たなマルウェア「FrostyGoop」を特定しました。このマルウェアは、1月にウクライナのエネルギー供給会社を標的とした攻撃に関連し、Modbusコマンドを介してEncoコントローラーを操作することで、600棟以上の建物の暖房を妨害しました。世界中で4万6000台以上のシステムがModbusプロトコルを使用しているため、FrostyGoopはウイルス対策ソフトウェアでは検出されず、事前のシステム侵害も必要としないため、重大なサイバーセキュリティ上の脅威となります。

半導体不足によりコントローラーの製造とサプライチェーンが遅延

半導体不足は、コントローラー製造に深刻な影響を与え、サプライチェーンを混乱させ、市場にとって大きな課題となっています。重要な部品の供給不足により、生産遅延が増加し、リードタイムの延長とメーカーおよびエンドユーザーのコスト増加につながっています。このボトルネックは、高度なコントローラーを自動化に活用する様々な業界に影響を及ぼし、効率的な事業拡大の妨げとなっています。コントローラーの需要が高まり続ける中、企業はサプライチェーンの制約を乗り越え、代替調達戦略を模索し、半導体不足に伴うリスクを軽減するための長期的なソリューションに投資する必要があります。

例えば、

- 2024年4月、The Indian Express [P] Ltd.が発表した記事によると、台湾でマグニチュード7.4の強力な地震が発生し、半導体不足への新たな懸念が生じ、コントローラー製造や世界のサプライチェーンに影響を及ぼす可能性があるという。世界最大の半導体受託製造会社である台湾積体電路製造(TSMC)は、一部の工場で一時的に生産を停止したが、同日中に70%以上の操業を再開した。これは、世界のサプライチェーンが自然災害に対して依然として脆弱であることを浮き彫りにしており、こうした課題を軽減するために、多様な調達戦略と強靭な製造エコシステムの必要性を改めて浮き彫りにしている。

ますます相互接続性が高まるグローバル市場において、半導体不足はコントローラー製造とサプライチェーンにとって依然として大きな課題となっています。成熟プロセスノードの生産中断、業界を横断した需要の高まり、そして地政学的要因により、供給制約が生じ、産業オートメーション、自動車、その他の重要なセクターに影響を与えています。チップの入手遅延は、これらのコンポーネントに依存するメーカーにとって、生産の減速、コスト増加、そして拡張性の低下につながる可能性があります。需要が急増し、供給が不透明な状況下では、企業はリスクを軽減し、長期的な安定性を確保するために、サプライチェーンの多様化、戦略的パートナーシップ、代替技術への投資など、積極的な戦略を採用する必要があります。

世界の産業用コントローラ市場の展望

世界の産業用コントローラー市場は、タイプ、コンポーネント、制御、ネットワークタイプ、企業規模、アプリケーションに基づいて、6つの主要なセグメントに分類されています。これらのセグメントの成長は、業界における成長の少ないセグメントの分析に役立ち、ユーザーに貴重な市場概要と市場インサイトを提供し、コア市場アプリケーションを特定するための戦略的意思決定を支援します。

タイプ

- 分散制御システム(DCS)

- プログラマブルロジックコントローラ(PLC)

- プログラマブルオートメーションコントローラ(PAC)

- 監視制御およびデータ収集(SCADA)

コンポーネント

- ヒューマンマシンインターフェース(HMI)

- リモートターミナルユニット(RTU)

- ITとOT

- タイプ別

- ハードウェアシステム

- ソフトウェアシステム

- タイプ別

- プログラマブルオートメーションコントローラ

- 制御ループ

- その他

コントロール

- 閉ループ制御

- オープンループ制御

- オンオフ制御

- フィードフォワード制御

ネットワークタイプ

- 制御自動化技術向けイーサネット (ETHERCAT)

- モドバス

- 共通産業プロトコル(CIP)

- プロセスフィールドバス(Profibus)

- タイプ別

- RTUからMTUへ

- MTUからMTUへ

- RTUからRTUへ

- タイプ別

- オープンプラットフォームコミュニケーション(OPC)

- オペレーティングシステム別

- DCOM

- コム

- オレ

- オペレーティングシステム別

- 分散ネットワークプロトコル(Dnp3)

- ビルオートメーションおよび制御ネットワーク(BACNET)

企業規模

- 大企業

- 中規模企業

- 中小企業

応用

- 製造業

- タイプ別

- 分散制御システム(DCS)

- プログラマブルロジックコントローラ(PLC)

- プログラマブルオートメーションコントローラ(PAC)

- 監視制御およびデータ収集(SCADA)

- タイプ別

- 石油とガス

- タイプ別

- 分散制御システム(DCS)

- プログラマブルロジックコントローラ(PLC)

- プログラマブルオートメーションコントローラ(PAC)

- 監視制御およびデータ収集(SCADA)

- エンドユーザープロセス別

- 精製と加工

- 生産と抽出

- 輸送と保管

- 掘削と探査

- 展開タイプ別

- 陸上展開

- オフショア展開

- 機能別

- プロセスの自動化と制御

- リアルタイム監視とデータ収集

- 運用効率と最適化

- 安全とリスク管理

- タイプ別

- エネルギーと公益事業

- タイプ別

- 分散制御システム(DCS)

- プログラマブルロジックコントローラ(PLC)

- プログラマブルオートメーションコントローラ(PAC)

- 監視制御およびデータ収集(SCADA)

- タイプ別

- 自動車

- タイプ別

- 分散制御システム(DCS)

- プログラマブルロジックコントローラ(PLC)

- プログラマブルオートメーションコントローラ(PAC)

- 監視制御およびデータ収集(SCADA)

- タイプ別

- 食品加工および飲料

- タイプ別

- 分散制御システム(DCS)

- プログラマブルロジックコントローラ(PLC)

- プログラマブルオートメーションコントローラ(PAC)

- 監視制御およびデータ収集(SCADA)

- タイプ別

- 水と廃水

- タイプ別

- 分散制御システム(DCS)

- プログラマブルロジックコントローラ(PLC)

- プログラマブルオートメーションコントローラ(PAC)

- 監視制御およびデータ収集(SCADA)

- タイプ別

- 航空宇宙と航空

- タイプ別

- 分散制御システム(DCS)

- プログラマブルロジックコントローラ(PLC)

- プログラマブルオートメーションコントローラ(PAC)

- 監視制御およびデータ収集(SCADA)

- タイプ別

- その他

世界の産業用コントローラ市場の地域分析

世界の産業用コントローラ市場は、タイプ、コンポーネント、制御、ネットワークタイプ、企業規模、アプリケーションに基づいて6つの主要なセグメントに分割されています。

産業用コントローラー市場レポートの対象国は、米国、カナダ、メキシコ、ドイツ、英国、フランス、イタリア、スペイン、ロシア、トルコ、オランダ、ノルウェー、フィンランド、デンマーク、スウェーデン、ポーランド、スイス、ベルギー、その他ヨーロッパ諸国、中国、日本、インド、韓国、オーストラリア、インドネシア、タイ、マレーシア、シンガポール、フィリピン、その他アジア太平洋諸国、ブラジル、アルゼンチン、その他南米諸国、UAE、サウジアラビア、南アフリカ、エジプト、イスラエル、その他中東およびアフリカ諸国です。

アジア太平洋地域は、急速な工業化、強固な製造基盤、そして自動化とスマートファクトリーへの多額の投資により、世界の産業用コントローラ市場を牽引すると予想されています。この地域では、コンシューマーエレクトロニクス、自動車、半導体産業の成長が、高度な産業用コントローラの需要をさらに高めています。

北米は、テクノロジーと再生可能エネルギーへの多大な投資により、産業用コントローラ ソリューションの採用と拡大におけるリーダーシップをさらに強化しているため、世界の産業用コントローラ市場で最も急速に成長している地域です。

レポートの国別セクションでは、市場の現在および将来の動向に影響を与える個々の市場要因と市場規制の変更についても説明しています。下流および上流のバリューチェーン分析、技術トレンド、ポーターの5つの力の分析、ケーススタディといったデータポイントは、各国の市場シナリオを予測するための指標として活用されています。また、欧州における航空宇宙用接着剤・シーラントブランドの存在感と入手可能性、そして現地および国内ブランドとの激しい競争あるいは競争の少なさによって直面する課題、国内関税や貿易ルートの影響についても、国別データの予測分析において考慮されています。

世界の産業用コントローラ市場シェア

産業用コントローラ市場の競争環境は、競合他社の詳細情報を提供します。企業概要、財務状況、収益、市場ポテンシャル、研究開発への投資、新規市場への取り組み、生産拠点と設備、生産能力、強みと弱み、製品の発売、製品の幅広さと幅広さ、アプリケーションの優位性などの詳細が含まれます。上記のデータは、世界の自由空間光通信市場における企業の注力分野にのみ関連しています。

市場で活動している世界の産業用コントローラ市場のリーダーは次のとおりです。

- ABB(スイス)

- シーメンス(ドイツ)

- 日立産機システム株式会社(日本)

- ハネウェル・インターナショナル(米国)

- シュナイダーエレクトリック(フランス)

- 三菱電機株式会社(日本)

- GEグリッドソリューションズLLC(米国)

- エマーソン・エレクトリック社(米国)

- オムロン株式会社(日本)

- 川崎重工業株式会社(日本)

- ジェイテクト エレクトロニクス インド社株式会社(東京)

- ロックウェル・オートメーション(米国)

- 横河電機株式会社(日本)

- デルタエレクトロニクス株式会社(台湾)

- オーデュボンカンパニーズ(米国)

- ASROCK INDUSTRIAL(台湾)

- IDEC株式会社(日本)

- レッドライオン(米国)

- アスコン・テクノロジー(イタリア)

- WEINTEK USA (米国)

- アナハイム・オートメーション社(米国)

- サウスショアコントロールズ社(米国)

- ナショナルインスツルメンツ社(米国)

- メタサームファーネス株式会社(インド)

世界の産業用コントローラ市場の最新動向

- シーメンスは2024年5月、Automate 2024において、PLC、HMI、エッジデバイスを中央集中型システムに置き換えるソフトウェア定義ソリューションであるSimatic Automation Workstationを発表しました。フォード・モーター・カンパニーが最初に導入する予定です。このイノベーションは、ITとOTの統合、セキュリティ、拡張性を強化することでシーメンスの産業用コントローラーポートフォリオを強化し、製造業に自動化における柔軟性と効率性の向上をもたらします。

- エマソンは2024年10月、ナショナルインスツルメンツ(NI)の82億ドルの買収を完了しました。これにより、NIはエマソンの新たなテスト&計測部門に統合され、グローバルオートメーションにおけるリーダーシップをさらに強化します。この買収により、エマソンのオートメーションポートフォリオとの製品シナジー強化と、高成長の産業用ソフトウェアおよび制御ソリューションへのアクセス向上を通じて、NIの産業用コントローラ製品の市場リーチが拡大し、NIにとってメリットとなります。

- シーメンスは2024年4月、ハノーバーメッセ2024において、10年ぶりの新世代コントローラとなるSimatic S7-1200 G2を発表しました。2024年冬に発売予定のこのコントローラは、強化されたモーション制御、柔軟な安全性、そして向上したパフォーマンスを備え、シーメンスXceleratorと統合されています。これにより、OTとITの橋渡し、効率性の向上、そしてよりスマートな自動化を実現することで、シーメンスの産業用コントローラのラインナップが強化されます。

- エマソンは2023年10月、ナショナルインスツルメンツ(NI)の82億ドルの買収を完了しました。これにより、NIはエマソンの新たなテスト&計測部門に統合され、グローバルオートメーションにおけるリーダーシップをさらに強化します。この買収により、エマソンのオートメーションポートフォリオとの製品シナジー強化と、高成長の産業用ソフトウェアおよび制御ソリューションへのアクセス向上を通じて、NIの産業用コントローラ製品の市場リーチが拡大し、NIにとってメリットとなります。

SKU-

世界初のマーケットインテリジェンスクラウドに関するレポートにオンラインでアクセスする

- インタラクティブなデータ分析ダッシュボード

- 成長の可能性が高い機会のための企業分析ダッシュボード

- カスタマイズとクエリのためのリサーチアナリストアクセス

- インタラクティブなダッシュボードによる競合分析

- 最新ニュース、更新情報、トレンド分析

- 包括的な競合追跡のためのベンチマーク分析のパワーを活用

目次

1 INTRODUCTION

1.1 OBJECTIVES OF THE STUDY

1.2 MARKET DEFINITION

1.3 OVERVIEW OF GLOBAL INDUSTRIAL CONTROLLER MARKET

1.4 CURRENCY AND PRICING

1.5 LIMITATIONS

1.6 MARKETS COVERED

2 MARKET SEGMENTATION

2.1 MARKETS COVERED

2.2 GEOGRAPHICAL SCOPE

2.3 YEARS CONSIDERED FOR THE STUDY

2.4 DBMR TRIPOD DATA VALIDATION MODEL

2.5 PRIMARY INTERVIEWS WITH KEY OPINION LEADERS

2.6 DBMR MARKET POSITION GRID

2.7 MULTIVARIATE MODELING

2.8 TYPE TIMELINE CURVE

2.9 MARKET APPLICATION COVERAGE GRID

2.1 SECONDARY SOURCES

2.11 ASSUMPTIONS

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

4.1 PORTER’S FIVE FORCES

4.2 PESTEL ANALYSIS

4.2.1 POLITICAL

4.2.2 ECONOMIC

4.2.3 SOCIAL

4.2.4 TECHNOLOGICAL

4.2.5 ENVIRONMENTAL

4.2.6 LEGAL

4.3 RAW MATERIAL COVERAGE

4.4 PRODUCTION CONSUMPTION ANALYSIS

4.5 GLOBAL INDUSTRIAL CONTROLLER MARKET: IMPORT-EXPORT SCENARIO

4.5.1 IMPORT TRENDS: KEY PLAYERS AND MARKET DYNAMICS

4.5.2 EXPORT SCENARIO: GLOBAL SUPPLY CHAIN AND TRADE FLOW

4.6 TECHNOLOGICAL ADVANCEMENT BY MANUFACTURERS

4.7 VENDOR SELECTION CRITERIA

4.8 GLOBAL MARKET FEEDBACK TO THE O-PAS STRUCTURE

5 MARKET OVERVIEW

5.1 DRIVERS

5.1.1 MANUFACTURING EXPANSION INCREASES CONTROLLER SYSTEM DEMAND

5.1.2 GROWING NEED FOR REAL-TIME MONITORING BOOSTS SMART CONTROL SYSTEM ADOPTION

5.1.3 INDUSTRIAL ROBOTS RELY ON SOPHISTICATED AUTOMATION CONTROLLERS FOR OPTIMAL PERFORMANCE

5.1.4 IOT-ENABLED CONTROLLERS IMPROVE REAL-TIME PROCESS MONITORING

5.2 RESTRAINTS

5.2.1 CYBER THREATS INCREASE INDUSTRIAL CONTROLLER SYSTEM VULNERABILITIES

5.2.2 FREQUENT SOFTWARE UPDATES CAUSE OPERATIONAL DISRUPTIONS

5.3 OPPORTUNITIES

5.3.1 EDGE COMPUTING ENHANCES INDUSTRIAL CONTROLLER DATA PROCESSING SPEED

5.3.2 CLOUD-BASED ANALYTICS OPTIMIZE REAL-TIME INDUSTRIAL CONTROLLER INSIGHTS

5.3.3 GROWING ADOPTION OF MODULAR AND SCALABLE CONTROLLERS

5.4 CHALLENGES

5.4.1 SEMICONDUCTOR SHORTAGES DELAY CONTROLLER MANUFACTURING AND SUPPLY CHAINS

5.4.2 HUMAN-MACHINE COLLABORATION RISKS INCREASE WORKPLACE SAFETY CONCERNS

6 GLOBAL INDUSTRIAL CONTROLLER MARKET, BY TYPE

6.1 OVERVIEW

6.2 DISTRIBUTED CONTROL SYSTEM (DCS)

6.3 PROGRAMMABLE LOGIC CONTROLLER (PLC)

6.4 PROGRAMMABLE AUTOMATION CONTROLLER (PAC)

6.5 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

7 GLOBAL INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS

7.1 OVERVIEW

7.2 HUMAN MACHINE INTERFACE (HMI)

7.3 REMOTE TERMINAL UNIT (RTU)

7.4 IT AND OT

7.4.1 IT AND OT, BY TYPE

7.4.1.1 HARDWARE SYSTEMS

7.4.1.2 SOFTWARE SYSTEMS

7.5 PROGRAMMABLE AUTOMATION CONTROLLER

7.6 CONTROL LOOP

7.7 OTHERS

8 GLOBAL INDUSTRIAL CONTROLLER MARKET, BY CONTROL

8.1 OVERVIEW

8.2 CLOSED-LOOP CONTROL

8.3 OPEN-LOOP CONTROL

8.4 ON-OFF CONTROL

8.5 FEED-FORWARD CONTROL

9 GLOBAL INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE

9.1 OVERVIEW

9.2 ETHERNET FOR CONTROL AUTOMATION TECHNOLOGY (ETHERCAT)

9.3 MODBUS

9.4 COMMON INDUSTRIAL PROTOCOL (CIP)

9.5 PROCESS FILED BUS (PROFIBUS)

9.5.1 PROCESS FILED BUS (PROFIBUS), BY TYPE

9.5.1.1 RTU TO MTU

9.5.1.2 MTU TO MTU

9.5.1.3 RTU TO RTU

9.6 OPEN PLATFORM COMMUNICATION (OPC)

9.6.1 OPEN PLATFORM COMMUNICATION (OPC), BY OPERATING SYSTEM

9.6.1.1 DCOM

9.6.1.2 COM

9.6.1.3 OLE

9.7 DISTRUBUTED NETWORK PROTOCOL (DNP3)

9.8 BUILDING AUTOMATION AND CONTROL NETWORKS (BACNET)

10 GLOBAL INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE

10.1 OVERVIEW

10.2 LARGE ENTERPRISES

10.3 MEDIUM-SIZED ENTERPRISES

10.4 SMALL ENTERPRISES

11 GLOBAL INDUSTRIAL CONTROLLER MARKET, BY APPLICATION

11.1 OVERVIEW

11.2 MANUFACTURING

11.2.1 MANUFACTURING, BY TYPE

11.2.1.1 DISTRIBUTED CONTROL SYSTEM (DCS)

11.2.1.2 PROGRAMMABLE LOGIC CONTROLLER (PLC)

11.2.1.3 PROGRAMMABLE AUTOMATION CONTROLLER (PAC)

11.2.1.4 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

11.3 OIL AND GAS

11.3.1 OIL AND GAS, BY TYPE

11.3.1.1 DISTRIBUTED CONTROL SYSTEM (DCS)

11.3.1.2 PROGRAMMABLE LOGIC CONTROLLER (PLC)

11.3.1.3 PROGRAMMABLE AUTOMATION CONTROLLER (PAC)

11.3.1.4 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

11.3.2 OIL AND GAS, BY END-USER PROCESS

11.3.2.1 REFINING AND PROCESSING

11.3.2.2 PRODUCTION AND EXTRACTION

11.3.2.3 TRANSPORTATION AND STORAGE

11.3.2.4 DRILLING AND EXPLORATION

11.3.3 OIL AND GAS, BY DEPLOYMENT TYPE

11.3.3.1 ON-SHORE DEPLOYMENT

11.3.3.2 OFF-SHORE DEPLOYMENT

11.3.4 OIL AND GAS, BY FUNCTION

11.3.4.1 PROCESS AUTOMATION AND CONTROL

11.3.4.2 REAL-TIME MONITORING AND DATA ACQUISITION

11.3.4.3 OPERATIONAL EFFICIENCY AND OPTIMIZATION

11.3.4.4 SAFETY AND RISK MANAGEMENT

11.4 ENERGY AND UTILITIES

11.4.1 ENERGY AND UTILITIES, BY TYPE

11.4.1.1 DISTRIBUTED CONTROL SYSTEM (DCS)

11.4.1.2 PROGRAMMABLE LOGIC CONTROLLER (PLC)

11.4.1.3 PROGRAMMABLE AUTOMATION CONTROLLER (PAC)

11.4.1.4 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

11.5 AUTOMOTIVE

11.5.1 AUTOMOTIVE, BY TYPE

11.5.1.1 DISTRIBUTED CONTROL SYSTEM (DCS)

11.5.1.2 PROGRAMMABLE LOGIC CONTROLLER (PLC)

11.5.1.3 PROGRAMMABLE AUTOMATION CONTROLLER (PAC)

11.5.1.4 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

11.6 FOOD PROCESSING AND BEVERAGES

11.6.1 FOOD PROCESSING AND BEVERAGES, BY TYPE

11.6.1.1 DISTRIBUTED CONTROL SYSTEM (DCS)

11.6.1.2 PROGRAMMABLE LOGIC CONTROLLER (PLC)

11.6.1.3 PROGRAMMABLE AUTOMATION CONTROLLER (PAC)

11.6.1.4 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

11.7 WATER AND WASTEWATER

11.7.1 WATER AND WASTEWATER, BY TYPE

11.7.1.1 DISTRIBUTED CONTROL SYSTEM (DCS)

11.7.1.2 PROGRAMMABLE LOGIC CONTROLLER (PLC)

11.7.1.3 PROGRAMMABLE AUTOMATION CONTROLLER (PAC)

11.7.1.4 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

11.8 AEROSPACE AND AVIATION

11.8.1 AEROSPACE AND AVIATION, BY TYPE

11.8.1.1 DISTRIBUTED CONTROL SYSTEM (DCS)

11.8.1.2 PROGRAMMABLE LOGIC CONTROLLER (PLC)

11.8.1.3 PROGRAMMABLE AUTOMATION CONTROLLER (PAC)

11.8.1.4 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

11.9 OTHERS

12 GLOBAL INDUSTRIAL CONTROLLER MARKET, BY REGION

12.1 OVERVIEW

12.2 ASIA-PACIFIC

12.3 NORTH AMERICA

12.4 EUROPE

12.5 MIDDLE EAST AND AFRICA

12.6 SOUTH AMERICA

13 GLOBAL INDUSTRIAL CONTROLLER MARKET, COMPANY LANDSCAPE

13.1 COMPANY SHARE ANALYSIS: GLOBAL

13.2 COMPANY SHARE ANALYSIS: NORTH AMERICA

13.3 COMPANY SHARE ANALYSIS: EUROPE

13.4 COMPANY SHARE ANALYSIS: ASIA-PACIFIC

14 SWOT ANALYSIS

15 COMPANY PROFILES

15.1 ABB

15.1.1 COMPANY SNAPSHOT

15.1.2 REVENUE ANALYSIS

15.1.3 COMPANY SHARE ANALYSIS

15.1.4 PRODUCT PORTFOLIO

15.1.5 RECENT DEVELOPMENT

15.2 SIEMENS

15.2.1 COMPANY SNAPSHOT

15.2.2 REVENUE ANALYSIS

15.2.3 COMPANY SHARE ANALYSIS

15.2.4 PRODUCT PORTFOLIO

15.2.5 RECENT DEVELOPMENTS

15.3 HITACHI INDUSTRIAL EQUIPMENT SYSTEMS CO., LTD.

15.3.1 COMPANY SNAPSHOT

15.3.2 REVENUE ANALYSIS

15.3.3 COMPANY SHARE ANALYSIS

15.3.4 PRODUCT PORTFOLIO

15.3.5 RECENT DEVELOPMENT

15.4 HONEYWELL INTERNATIONAL INC.

15.4.1 COMPANY SNAPSHOT

15.4.2 REVENUE ANALYSIS

15.4.3 COMPANY SHARE ANALYSIS

15.4.4 PRODUCT PORTFOLIO

15.4.5 RECENT DEVELOPMENT

15.5 SCHNEIDER ELECTRIC

15.5.1 COMPANY SNAPSHOT

15.5.2 REVENUE ANALYSIS

15.5.3 COMPANY SHARE ANALYSIS

15.5.4 PRODUCT PORTFOLIO

15.5.5 RECENT DEVELOPMENT

15.6 ANAHEIM AUTOMATION, INC.

15.6.1 COMPANY SNAPSHOT

15.6.2 PRODUCT PORTFOLIO

15.6.3 RECENT DEVELOPMENT

15.7 ASCON TECNOLOGIC

15.7.1 COMPANY SNAPSHOT

15.7.2 PRODUCT PORTFOLIO

15.7.3 RECENT DEVELOPMENT

15.8 ASROCK INDUSTRIAL.

15.8.1 COMPANY SNAPSHOT

15.8.2 REVENUE ANALYSIS

15.8.3 PRODUCT PORTFOLIO

15.8.4 RECENT DEVELOPMENT

15.9 AUDUBON COMPANIES

15.9.1 COMPANY SNAPSHOT

15.9.2 PRODUCT PORTFOLIO

15.9.3 RECENT DEVELOPMENT

15.1 DELTA ELECTRONICS, INC.

15.10.1 COMPANY SNAPSHOT

15.10.2 REVENUE ANALYSIS

15.10.3 PRODUCT PORTFOLIO

15.10.4 RECENT DEVELOPMENT

15.11 EMERSON ELECTRIC CO.

15.11.1 COMPANY SNAPSHOT

15.11.2 REVENUE ANALYSIS

15.11.3 PRODUCT PORTFOLIO

15.11.4 RECENT DEVELOPMENTS

15.12 GE VERNOVA (AS A PART OF GENERAL ELECTRIC COMPANY)

15.12.1 COMPANY SNAPSHOT

15.12.2 REVENUE ANALYSIS

15.12.3 BUSINESS PORTFOLIO

15.12.4 RECENT DEVELOPMENT

15.13 IDEC CORPORATION

15.13.1 COMPANY SNAPSHOT

15.13.2 REVENUE ANALYSIS

15.13.3 BRAND PORTFOLIO

15.13.4 RECENT DEVELOPMENT

15.14 JTEKT ELECTRONICS CORPORATION

15.14.1 COMPANY SNAPSHOT

15.14.2 PRODUCT PORTFOLIO

15.14.3 RECENT DEVELOPMENT

15.15 KAWASAKI HEAVY INDUSTRIES, LTD.

15.15.1 COMPANY SNAPSHOT

15.15.2 REVENUE ANALYSIS

15.15.3 PRODUCT PORTFOLIO

15.15.4 RECENT DEVELOPMENTS

15.16 META THERM FURNACE PVT LTD

15.16.1 COMPANY SNAPSHOT

15.16.2 PRODUCT PORTFOLIO

15.16.3 RECENT DEVELOPMENT

15.17 MITSUBISHI ELECTRIC CORPORATION

15.17.1 COMPANY SNAPSHOT

15.17.2 REVENUE ANALYSIS

15.17.3 PRODUCT PORTFOLIO

15.17.4 RECENT DEVELOPMENTS

15.18 NATIONAL INSTRUMENTS CORP.

15.18.1 COMPANY SNAPSHOT

15.18.2 PRODUCT PORTFOLIO

15.18.3 RECENT DEVELOPMENT

15.19 OMRON CORPORATION

15.19.1 COMPANY SNAPSHOT

15.19.2 REVENUE ANALYSIS

15.19.3 PRODUCT PORTFOLIO

15.19.4 RECENT DEVELOPMENTS

15.2 RED LION

15.20.1 COMPANY SNAPSHOT

15.20.2 PRODUCT PORTFOLIO

15.20.3 RECENT DEVELOPMENT

15.21 ROCKWELL AUTOMATION

15.21.1 COMPANY SNAPSHOT

15.21.2 REVENUE ANALYSIS

15.21.3 PRODUCT PORTFOLIO

15.21.4 RECENT DEVELOPMENTS

15.22 SOUTH SHORE CONTROLS, INC

15.22.1 COMPANY SNAPSHOT

15.22.2 PRODUCT PORTFOLIO

15.22.3 RECENT DEVELOPMENT

15.23 WEINTEK USA

15.23.1 COMPANY SNAPSHOT

15.23.2 PRODUCT PORTFOLIO

15.23.3 RECENT DEVELOPMENT

15.24 YOKOGAWA ELECTRIC CORPORATION

15.24.1 COMPANY SNAPSHOT

15.24.2 REVENUE ANALYSIS

15.24.3 PRODUCT PORTFOLIO

15.24.4 RECENT DEVELOPMENT

16 QUESTIONNAIRE

17 RELATED REPORTS

表のリスト

TABLE 1 COMPARISON TABLE

TABLE 2 GLOBAL INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 3 GLOBAL DISTRIBUTED CONTROL SYSTEM (DCS) IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 4 GLOBAL PROGRAMMABLE LOGIC CONTROLLER (PLC) IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 5 GLOBAL PROGRAMMABLE AUTOMATION CONTROLLER (PAC) IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 6 GLOBAL SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA) IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 7 GLOBAL INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 8 GLOBAL HUMAN MACHINE INTERFACE (HMI) IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 9 GLOBAL REMOTE TERMINAL UNIT (RTU) IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 10 GLOBAL IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 11 GLOBAL IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 12 GLOBAL PROGRAMMABLE AUTOMATION CONTROLLER IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 13 GLOBAL CONTROL LOOP IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 14 GLOBAL OTHERS IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 15 GLOBAL INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 16 GLOBAL CLOSED-LOOP CONTROL IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 17 GLOBAL OPEN-LOOP CONTROL IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 18 GLOBAL ON-OFF CONTROL IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 19 GLOBAL FEED-FORWARD CONTROL IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 20 GLOBAL INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 21 GLOBAL ETHERNET FOR CONTROL AUTOMATION TECHNOLOGY (ETHERCAT) IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 22 GLOBAL MODBUS IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 23 GLOBAL COMMON INDUSTRIAL PROTOCOL (CIP) IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 24 GLOBAL PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 25 GLOBAL PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 26 GLOBAL OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 27 GLOBAL OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 28 GLOBAL DISTRIBUTED NETWORK PROTOCOL (DNP3) IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 29 GLOBAL BUILDING AUTOMATION AND CONTROL NETWORKS (BACNET) IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 30 GLOBAL INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 31 GLOBAL LARGE ENTERPRISES IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 32 GLOBAL MEDIUM-SIZED ENTERPRISES IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 33 GLOBAL SMALL ENTERPRISES IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 34 GLOBAL INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 35 GLOBAL MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 36 GLOBAL MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 37 GLOBAL OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 38 GLOBAL OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 39 GLOBAL OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 40 GLOBAL OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 41 GLOBAL OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 42 GLOBAL ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 43 GLOBAL ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 44 GLOBAL AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 45 GLOBAL AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 46 GLOBAL FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 47 GLOBAL FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 48 GLOBAL WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 49 GLOBAL WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 50 GLOBAL AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 51 GLOBAL AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 52 GLOBAL OTHERS IN INDUSTRIAL CONTROLLER MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 53 GLOBAL INDUSTRIAL CONTROLLER MARKET, BY REGION 2018-2032, USD (THOUSAND)

TABLE 54 ASIA-PACIFIC INDUSTRIAL CONTROLLER MARKET, BY COUNTRY, 2018-2032 (USD THOUSAND)

TABLE 55 ASIA-PACIFIC INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 56 ASIA-PACIFIC INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 57 ASIA-PACIFIC IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 58 ASIA-PACIFIC INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 59 ASIA-PACIFIC INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 60 ASIA-PACIFIC PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 61 ASIA-PACIFIC OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 62 ASIA-PACIFIC INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 63 ASIA-PACIFIC INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 64 ASIA-PACIFIC MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 65 ASIA-PACIFIC OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 66 ASIA-PACIFIC OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 67 ASIA-PACIFIC OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 68 ASIA-PACIFIC OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 69 ASIA-PACIFIC ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 70 ASIA-PACIFIC AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 71 ASIA-PACIFIC FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 72 ASIA-PACIFIC WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 73 ASIA-PACIFIC AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 74 CHINA INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 75 CHINA INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 76 CHINA IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 77 CHINA INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 78 CHINA INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 79 CHINA PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 80 CHINA OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 81 CHINA INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 82 CHINA INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 83 CHINA MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 84 CHINA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 85 CHINA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 86 CHINA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 87 CHINA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 88 CHINA ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 89 CHINA AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 90 CHINA FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 91 CHINA WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 92 CHINA AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 93 JAPAN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 94 JAPAN INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 95 JAPAN IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 96 JAPAN INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 97 JAPAN INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 98 JAPAN PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 99 JAPAN OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 100 JAPAN INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 101 JAPAN INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 102 JAPAN MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 103 JAPAN OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 104 JAPAN OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 105 JAPAN OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 106 JAPAN OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 107 JAPAN ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 108 JAPAN AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 109 JAPAN FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 110 JAPAN WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 111 JAPAN AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 112 SOUTH KOREA INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 113 SOUTH KOREA INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 114 SOUTH KOREA IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 115 SOUTH KOREA INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 116 SOUTH KOREA INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 117 SOUTH KOREA PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 118 SOUTH KOREA OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 119 SOUTH KOREA INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 120 SOUTH KOREA INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 121 SOUTH KOREA MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 122 SOUTH KOREA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 123 SOUTH KOREA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 124 SOUTH KOREA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 125 SOUTH KOREA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 126 SOUTH KOREA ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 127 SOUTH KOREA AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 128 SOUTH KOREA FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 129 SOUTH KOREA WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 130 SOUTH KOREA AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 131 INDIA INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 132 INDIA INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 133 INDIA IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 134 INDIA INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 135 INDIA INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 136 INDIA PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 137 INDIA OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 138 INDIA INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 139 INDIA INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 140 INDIA MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 141 INDIA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 142 INDIA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 143 INDIA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 144 INDIA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 145 INDIA ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 146 INDIA AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 147 INDIA FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 148 INDIA WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 149 INDIA AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 150 TAIWAN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 151 TAIWAN INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 152 TAIWAN IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 153 TAIWAN INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 154 TAIWAN INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 155 TAIWAN PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 156 TAIWAN OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 157 TAIWAN INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 158 TAIWAN INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 159 TAIWAN MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 160 TAIWAN OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 161 TAIWAN OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 162 TAIWAN OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 163 TAIWAN OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 164 TAIWAN ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 165 TAIWAN AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 166 TAIWAN FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 167 TAIWAN WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 168 TAIWAN AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 169 AUSTRALIA INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 170 AUSTRALIA INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 171 AUSTRALIA IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 172 AUSTRALIA INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 173 AUSTRALIA INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 174 AUSTRALIA PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 175 AUSTRALIA OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 176 AUSTRALIA INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 177 AUSTRALIA INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 178 AUSTRALIA MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 179 AUSTRALIA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 180 AUSTRALIA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 181 AUSTRALIA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 182 AUSTRALIA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 183 AUSTRALIA ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 184 AUSTRALIA AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 185 AUSTRALIA FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 186 AUSTRALIA WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 187 AUSTRALIA AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 188 INDONESIA INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 189 INDONESIA INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 190 INDONESIA IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 191 INDONESIA INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 192 INDONESIA INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 193 INDONESIA PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 194 INDONESIA OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 195 INDONESIA INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 196 INDONESIA INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 197 INDONESIA MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 198 INDONESIA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 199 INDONESIA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 200 INDONESIA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 201 INDONESIA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 202 INDONESIA ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 203 INDONESIA AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 204 INDONESIA FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 205 INDONESIA WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 206 INDONESIA AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 207 THAILAND INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 208 THAILAND INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 209 THAILAND IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 210 THAILAND INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 211 THAILAND INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 212 THAILAND PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 213 THAILAND OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 214 THAILAND INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 215 THAILAND INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 216 THAILAND MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 217 THAILAND OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 218 THAILAND OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 219 THAILAND OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 220 THAILAND OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 221 THAILAND ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 222 THAILAND AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 223 THAILAND FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 224 THAILAND WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 225 THAILAND AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 226 SINGAPORE INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 227 SINGAPORE INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 228 SINGAPORE IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 229 SINGAPORE INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 230 SINGAPORE INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 231 SINGAPORE PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 232 SINGAPORE OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 233 SINGAPORE INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 234 SINGAPORE INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 235 SINGAPORE MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 236 SINGAPORE OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 237 SINGAPORE OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 238 SINGAPORE OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 239 SINGAPORE OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 240 SINGAPORE ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 241 SINGAPORE AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 242 SINGAPORE FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 243 SINGAPORE WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 244 SINGAPORE AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 245 MALAYSIA INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 246 MALAYSIA INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 247 MALAYSIA IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 248 MALAYSIA INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 249 MALAYSIA INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 250 MALAYSIA PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 251 MALAYSIA OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 252 MALAYSIA INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 253 MALAYSIA INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 254 MALAYSIA MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 255 MALAYSIA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 256 MALAYSIA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 257 MALAYSIA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 258 MALAYSIA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 259 MALAYSIA ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 260 MALAYSIA AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 261 MALAYSIA FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 262 MALAYSIA WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 263 MALAYSIA AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 264 VIETNAM INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 265 VIETNAM INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 266 VIETNAM IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 267 VIETNAM INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 268 VIETNAM INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 269 VIETNAM PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 270 VIETNAM OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 271 VIETNAM INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 272 VIETNAM INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 273 VIETNAM MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 274 VIETNAM OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 275 VIETNAM OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 276 VIETNAM OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 277 VIETNAM OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 278 VIETNAM ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 279 VIETNAM AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 280 VIETNAM FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 281 VIETNAM WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 282 VIETNAM AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 283 PHILIPPINES INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 284 PHILIPPINES INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 285 PHILIPPINES IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 286 PHILIPPINES INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 287 PHILIPPINES INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 288 PHILIPPINES PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 289 PHILIPPINES OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 290 PHILIPPINES INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 291 PHILIPPINES INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 292 PHILIPPINES MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 293 PHILIPPINES OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 294 PHILIPPINES OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 295 PHILIPPINES OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 296 PHILIPPINES OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 297 PHILIPPINES ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 298 PHILIPPINES AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 299 PHILIPPINES FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 300 PHILIPPINES WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 301 PHILIPPINES AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 302 NEW ZEALAND INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 303 NEW ZEALAND INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 304 NEW ZEALAND IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 305 NEW ZEALAND INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 306 NEW ZEALAND INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 307 NEW ZEALAND PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 308 NEW ZEALAND OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 309 NEW ZEALAND INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 310 NEW ZEALAND INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 311 NEW ZEALAND MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 312 NEW ZEALAND OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 313 NEW ZEALAND OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 314 NEW ZEALAND OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 315 NEW ZEALAND OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 316 NEW ZEALAND ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 317 NEW ZEALAND AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 318 NEW ZEALAND FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 319 NEW ZEALAND WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 320 NEW ZEALAND AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 321 REST OF ASIA-PACIFIC INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 322 NORTH AMERICA INDUSTRIAL CONTROLLER MARKET, BY COUNTRY, 2018-2032 (USD THOUSAND)

TABLE 323 NORTH AMERICA INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 324 NORTH AMERICA INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 325 NORTH AMERICA IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 326 NORTH AMERICA INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 327 NORTH AMERICA INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 328 NORTH AMERICA PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 329 NORTH AMERICA OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 330 NORTH AMERICA INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 331 NORTH AMERICA INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 332 NORTH AMERICA MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 333 NORTH AMERICA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 334 NORTH AMERICA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 335 NORTH AMERICA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 336 NORTH AMERICA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 337 NORTH AMERICA ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 338 NORTH AMERICA AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 339 NORTH AMERICA FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 340 NORTH AMERICA WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 341 NORTH AMERICA AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 342 U.S. INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 343 U.S. INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 344 U.S. IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 345 U.S. INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 346 U.S. INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 347 U.S. PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 348 U.S. OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 349 U.S. INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 350 U.S. INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 351 U.S. MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 352 U.S. OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 353 U.S. OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 354 U.S. OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 355 U.S. OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 356 U.S. ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 357 U.S. AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 358 U.S. FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 359 U.S. WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 360 U.S. AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 361 CANADA INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 362 CANADA INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 363 CANADA IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 364 CANADA INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 365 CANADA INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 366 CANADA PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 367 CANADA OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 368 CANADA INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 369 CANADA INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 370 CANADA MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 371 CANADA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 372 CANADA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 373 CANADA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 374 CANADA OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 375 CANADA ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 376 CANADA AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 377 CANADA FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 378 CANADA WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 379 CANADA AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 380 MEXICO INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 381 MEXICO INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 382 MEXICO IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 383 MEXICO INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 384 MEXICO INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 385 MEXICO PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 386 MEXICO OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 387 MEXICO INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 388 MEXICO INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 389 MEXICO MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 390 MEXICO OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 391 MEXICO OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 392 MEXICO OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 393 MEXICO OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 394 MEXICO ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 395 MEXICO AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 396 MEXICO FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 397 MEXICO WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 398 MEXICO AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 399 EUROPE INDUSTRIAL CONTROLLER MARKET, BY COUNTRY, 2018-2032 (USD THOUSAND)

TABLE 400 EUROPE INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 401 EUROPE INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 402 EUROPE IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 403 EUROPE INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 404 EUROPE INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 405 EUROPE PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 406 EUROPE OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 407 EUROPE INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 408 EUROPE INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 409 EUROPE MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 410 EUROPE OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 411 EUROPE OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 412 EUROPE OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 413 EUROPE OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 414 EUROPE ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 415 EUROPE AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 416 EUROPE FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 417 EUROPE WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 418 EUROPE AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 419 GERMANY INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 420 GERMANY INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 421 GERMANY IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 422 GERMANY INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 423 GERMANY INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 424 GERMANY PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 425 GERMANY OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 426 GERMANY INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 427 GERMANY INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 428 GERMANY MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 429 GERMANY OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 430 GERMANY OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 431 GERMANY OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 432 GERMANY OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 433 GERMANY ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 434 GERMANY AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 435 GERMANY FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 436 GERMANY WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 437 GERMANY AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 438 U.K. INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 439 U.K. INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 440 U.K. IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 441 U.K. INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 442 U.K. INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 443 U.K. PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 444 U.K. OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 445 U.K. INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 446 U.K. INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 447 U.K. MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 448 U.K. OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 449 U.K. OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 450 U.K. OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 451 U.K. OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 452 U.K. ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 453 U.K. AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 454 U.K. FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 455 U.K. WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 456 U.K. AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 457 FRANCE INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 458 FRANCE INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 459 FRANCE IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 460 FRANCE INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 461 FRANCE INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 462 FRANCE PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 463 FRANCE OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 464 FRANCE INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 465 FRANCE INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 466 FRANCE MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 467 FRANCE OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 468 FRANCE OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 469 FRANCE OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 470 FRANCE OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 471 FRANCE ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 472 FRANCE AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 473 FRANCE FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 474 FRANCE WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 475 FRANCE AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 476 ITALY INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 477 ITALY INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 478 ITALY IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 479 ITALY INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 480 ITALY INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 481 ITALY PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 482 ITALY OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 483 ITALY INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 484 ITALY INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 485 ITALY MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 486 ITALY OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 487 ITALY OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 488 ITALY OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 489 ITALY OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 490 ITALY ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 491 ITALY AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 492 ITALY FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 493 ITALY WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 494 ITALY AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 495 NETHERLANDS INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 496 NETHERLANDS INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 497 NETHERLANDS IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 498 NETHERLANDS INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 499 NETHERLANDS INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)

TABLE 500 NETHERLANDS PROCESS FILED BUS (PROFIBUS) IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 501 NETHERLANDS OPEN PLATFORM COMMUNICATION (OPC) IN INDUSTRIAL CONTROLLER MARKET, BY OPERATING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 502 NETHERLANDS INDUSTRIAL CONTROLLER MARKET, BY ENTERPRISE SIZE, 2018-2032 (USD THOUSAND)

TABLE 503 NETHERLANDS INDUSTRIAL CONTROLLER MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 504 NETHERLANDS MANUFACTURING IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 505 NETHERLANDS OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 506 NETHERLANDS OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY END-USER PROCESS, 2018-2032 (USD THOUSAND)

TABLE 507 NETHERLANDS OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY DEPLOYMENT TYPE, 2018-2032 (USD THOUSAND)

TABLE 508 NETHERLANDS OIL AND GAS IN INDUSTRIAL CONTROLLER MARKET, BY FUNCTION, 2018-2032 (USD THOUSAND)

TABLE 509 NETHERLANDS ENERGY AND UTILITIES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 510 NETHERLANDS AUTOMOTIVE IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 511 NETHERLANDS FOOD PROCESSING AND BEVERAGES IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 512 NETHERLANDS WATER AND WASTEWATER IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 513 NETHERLANDS AEROSPACE AND AVIATION IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 514 SWITZERLAND INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 515 SWITZERLAND INDUSTRIAL CONTROLLER MARKET, BY COMPONENTS, 2018-2032 (USD THOUSAND)

TABLE 516 SWITZERLAND IT AND OT IN INDUSTRIAL CONTROLLER MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 517 SWITZERLAND INDUSTRIAL CONTROLLER MARKET, BY CONTROL, 2018-2032 (USD THOUSAND)

TABLE 518 SWITZERLAND INDUSTRIAL CONTROLLER MARKET, BY NETWORK TYPE, 2018-2032 (USD THOUSAND)