世界の食品ロボット加工食品市場規模、シェア、トレンド分析レポート

Market Size in USD Billion

CAGR :

%

USD

6.40 Billion

USD

16.42 Billion

2024

2032

USD

6.40 Billion

USD

16.42 Billion

2024

2032

| 2025 –2032 | |

| USD 6.40 Billion | |

| USD 16.42 Billion | |

|

|

|

|

加工食品アプリケーション市場における世界の食品ロボットのセグメンテーション、タイプ別(多関節型、直交型、SCARA型、並列型、円筒型、協働型、その他)、ペイロード別(低、中、重)、アプリケーション別(包装、再包装、パレタイジング、ピッキング、処理、その他) - 2032年までの業界動向と予測。

加工食品アプリケーションにおける食品ロボット市場規模

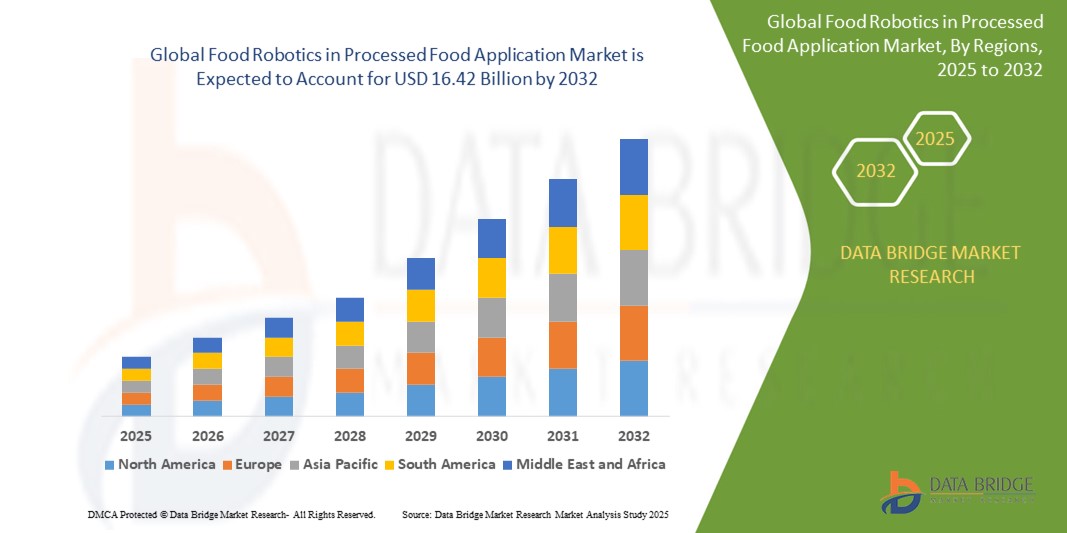

- 加工食品アプリケーション市場における世界の食品ロボットの規模は、2024年に64億米ドルと評価され、予測期間中に12.50%のCAGRで成長し、2032年までに164.2億米ドル に達すると予想されています。

- 市場の成長は、ロボット技術の進歩と加工食品や包装食品の需要の高まりに支えられ、効率を高め、人件費を削減し、製品の一貫性を向上させるために食品加工における自動化の導入が増加していることが主な要因です。

- さらに、高品質で安全、衛生的な食品に対する消費者の需要の高まりと、厳格な規制基準が相まって、食品ロボットは現代の食品加工業務にとって重要なソリューションとして位置付けられ、業界の成長を大幅に促進しています。

加工食品アプリケーション市場分析における食品ロボット

- 包装、パレタイジング、加工などの作業の自動化システムを網羅する食品ロボットは、その精度、スピード、そして加工食品用途における厳格な衛生基準を満たす能力により、食品・飲料業界にとってますます不可欠なものとなっています。

- 食品ロボットの需要の急増は、業務効率化の必要性、人件費の上昇、そして特に大量生産環境における食品製造の自動化の傾向の高まりによって推進されている。

- 加工食品用途における食品ロボット市場は、高度な製造インフラ、自動化技術の普及率の高さ、食品安全を確保する強力な規制枠組みに牽引され、2024年には欧州が38.5%という最大の収益シェアを獲得し、市場を席巻しました。ドイツと英国は主要な食品加工企業によるロボットソリューションへの多額の投資により、市場を牽引しています。

- アジア太平洋地域は、急速な工業化、加工食品の需要増加、中国、日本、インドなどの国における自動化への投資増加により、予測期間中に最も急速に成長する地域になると予想されています。

- 多関節型ロボットは、柔軟性と人間の腕の動きを模倣する能力により、市場収益シェア42.3%で最大のシェアを占め、食品加工における切断、骨抜き、包装、パレット積み込みなどの複雑な作業に最適です。狭い空間での精度と汎用性も、その優位性をさらに強化しています。

加工食品アプリケーション市場における食品ロボットのレポート範囲とセグメンテーション

|

属性 |

加工食品アプリケーションにおける食品ロボットの主要市場洞察 |

|

対象セグメント |

|

|

対象国 |

北米

ヨーロッパ

アジア太平洋

中東およびアフリカ

南アメリカ

|

|

主要な市場プレーヤー |

|

|

市場機会 |

|

|

付加価値データ情報セット |

データブリッジマーケットリサーチがまとめた市場レポートには、市場価値、成長率、セグメンテーション、地理的範囲、主要プレーヤーなどの市場シナリオに関する洞察に加えて、専門家による詳細な分析、価格設定分析、ブランドシェア分析、消費者調査、人口統計分析、サプライチェーン分析、バリューチェーン分析、原材料/消耗品の概要、ベンダー選択基準、PESTLE分析、ポーター分析、規制の枠組みも含まれています。 |

加工食品アプリケーション市場における食品ロボットの動向

「AIとビッグデータ分析の統合の拡大」

- 加工食品アプリケーションにおける世界の食品ロボット市場では、人工知能(AI)とビッグデータ分析の統合に向けた顕著な傾向が見られます。

- これらの技術は高度なデータ処理を容易にし、生産効率、設備の性能、品質管理指標に関する詳細な洞察を可能にします。

- AI駆動型ロボットソリューションは、機器の故障が業務に支障をきたす前に予測することで、予防保守をサポートし、ダウンタイムと保守コストを削減します。

- 例えば、企業はAIプラットフォームを活用して、リアルタイムの需要に基づいて梱包速度を調整したり、食品廃棄物を最小限に抑えるために仕分けパターンを分析したりするなど、ロボット操作を最適化しています。

- この傾向は、製造業者にとって食品ロボットシステムの魅力を高め、運用効率と厳格な食品安全基準への準拠を向上させます。

- AIアルゴリズムは、ピッキング精度、パッケージの一貫性、処理精度などのロボットタスクからのデータを処理し、パフォーマンスを最適化して高品質の出力を確保できます。

加工食品アプリケーション市場における食品ロボットの動向

ドライバ

「自動化と食品安全コンプライアンスの需要の高まり」

- 調理済み食品やインスタント食品を含む加工食品や包装食品に対する消費者の需要の高まりは、食品ロボット市場の主要な推進力となっている。

- ロボットシステムは、包装、ピッキング、加工などの作業を自動化し、人との接触や汚染のリスクを減らすことで食品の安全性を高めます。

- 特にヨーロッパでは、HACCPやISO 22000などの基準を設けた厳格な政府規制により、食品の安全性と衛生要件への準拠を確保するためにロボットの導入が加速しています。

- IoTと5G接続の進歩により、より高速なデータ転送とリアルタイム監視が可能になり、食品加工における高度なロボットアプリケーションをサポートします。

- 食品メーカーは、高まる生産需要に対応し、一貫した製品品質を維持するために、ロボットを標準ソリューションとして統合するケースが増えています。

抑制/挑戦

「導入コストの高さとデータセキュリティの懸念」

- ロボットのハードウェア、ソフトウェア、システム統合にかかる初期コストの高さは、特に新興市場の中小企業にとって大きな障壁となっている。

- 既存の生産ラインをロボットシステムで改造することは複雑で費用がかかり、専門的な知識とインフラのアップグレードが必要になる。

- ロボットシステムが機密性の高い運用データを収集するため、サイバー攻撃、データの不正使用、欧州のGDPRなどの規制への準拠に関する懸念が生じており、データセキュリティとプライバシーの問題は大きな課題となっている。

- 食品ロボットにおけるデータ処理に関する標準化された国際規制が欠如しているため、複数の地域で事業を展開するメーカーの業務が複雑化している。

- これらの要因により、コストに敏感な地域やデータプライバシーに対する意識が高まっている地域では市場の成長が鈍化する可能性がある。

加工食品アプリケーション市場における食品ロボットの適用範囲

市場は、タイプ、ペイロード、アプリケーションに基づいてセグメント化されています。

- タイプ別

加工食品用途における世界の食品ロボット市場は、タイプ別に、多関節型、直交型、スカラ型、平行型、円筒型、協働型、その他に分類されます。多関節型セグメントは、その柔軟性と人間の腕の動きを模倣する能力により、市場収益シェア42.3%と最大のシェアを占め、食品加工における切断、骨抜き、包装、パレタイジングなどの複雑な作業に最適です。また、限られたスペースでの高精度かつ汎用性も、その優位性をさらに強化しています。

協働ロボット(コボット)セグメントは、2025年から2032年にかけて最も高い成長率を示すことが予想されています。この成長は、作業者の安全性、プログラミングと導入の容易さへの注目の高まり、そして人間とロボットの協働が有益な食品加工施設における柔軟な自動化ソリューションの需要の高まりによって促進されています。

- ペイロード別

加工食品用途における世界の食品ロボット市場は、可搬重量に基づいて、低、中、重の3つに分類されます。中可搬重量セグメントは、主にバランスの取れた容量と柔軟性により、食品業界全体の様々な用途に非常に汎用性が高いことから、最大の市場収益シェアを占めると予想されています。

重量物積載セグメントは、加工食品用途において、より大容量でより重い食品を効率的に取り扱うための技術進歩と研究開発の向上により、大幅な成長が見込まれています。

- アプリケーション別

用途別に見ると、世界の加工食品向け食品ロボット市場は、包装、再包装、パレタイジング、ピッキング、加工、その他に分類されます。包装分野は、包装食品の需要増加と、ロボットによる効率的な管理、廃棄物の削減、生産能力の向上を可能にする高速、一貫性、衛生的な包装プロセスへのニーズに牽引され、最大の市場収益シェアを占めています。

加工セグメントは、2025年から2032年にかけて堅調な成長を遂げると予想されています。これは、切断、混合、選別などのさまざまな食品加工作業における精度、一貫性、衛生に対する重要なニーズによって推進されており、ロボットソリューションは優れたパフォーマンスを提供し、厳格な食品安全基準の維持に役立ちます。

加工食品アプリケーション市場における食品ロボットの地域分析

- 加工食品用途における食品ロボット市場は、高度な製造インフラ、自動化技術の普及率の高さ、食品安全を確保する強力な規制枠組みに牽引され、2024年には欧州が38.5%という最大の収益シェアを獲得し、市場を席巻しました。ドイツと英国は主要な食品加工企業によるロボットソリューションへの多額の投資により、市場を牽引しています。

- 消費者とメーカーは、特に高度な産業エコシステムを持つ地域において、生産精度の向上、人件費の削減、厳格な食品安全基準の遵守を確保するためのロボットソリューションを優先しています。

- 成長は、多関節ロボット、スカラロボット、協働ロボットなどのロボット技術の進歩と、大規模な食品加工工場と小規模施設の両方での導入の増加によって支えられています。

英国の食品ロボット加工食品市場における洞察

英国の食品ロボット市場は、都市部および郊外の食品加工施設における業務効率と製品の一貫性向上を目的とした自動化の需要に牽引され、大幅な成長が見込まれています。スマート製造への関心の高まりと、ロボットが人件費削減に果たす役割に対する認識の高まりが、ロボット導入を後押ししています。食品安全規制の進化も市場動向に影響を与え、自動化のニーズとコンプライアンスのバランスを取らざるを得ません。

ドイツの食品ロボット加工食品アプリケーション市場洞察

ドイツでは、食品加工・製造分野の先進性と、業務効率と持続可能性への高い関心から、食品ロボット市場が力強い成長を遂げると見込まれています。ドイツのメーカーは、生産性の向上とエネルギー効率の向上に貢献する、多関節型や協働型といった先進技術を搭載したロボットを好んでいます。これらのシステムを高級食品加工施設に導入し、アフターマーケットのアップグレードを行うことで、市場の持続的な成長が期待されます。

北米における加工食品アプリケーション市場における食品ロボットの洞察

北米は、堅調な食品加工業界と、業務効率の向上と厳格な安全基準への適合を目的とした自動化導入の増加に牽引され、世界の食品ロボット市場で大きなシェアを占めています。包装、パレタイジング、加工などの用途におけるロボットの需要は、食品生産における精度、拡張性、そして衛生管理の必要性によって高まっています。この地域をリードする米国は、スマート製造への投資の増加とロボット技術の進歩が市場拡大を支えています。

米国の食品ロボットによる加工食品アプリケーション市場洞察

米国の加工食品向け食品ロボット市場は、食品加工・包装における自動化への旺盛な需要に支えられ、大幅な成長が見込まれています。ロボットがスループットの向上と衛生基準の維持にもたらすメリットに対する認識の高まりが、市場拡大の原動力となっています。スマートファクトリーへのトレンドと、食品安全を促進する規制の強化も、ロボット導入をさらに後押ししています。新規設備と既存設備の改修の両方において、ロボットを統合することで、強固な市場エコシステムが形成されます。

アジア太平洋地域の加工食品アプリケーションにおける食品ロボット市場洞察

アジア太平洋地域は、中国、インド、日本などの国々における食品加工産業の拡大と自動化への投資増加に牽引され、最も高い成長率を達成すると予想されています。生産効率の向上、食品安全の確保、製品品質の向上といったロボット技術のメリットに対する認識の高まりが、需要を押し上げています。スマート製造と食品安全基準を推進する政府の取り組みも、高度なロボットシステムの導入をさらに促進しています。

日本の食品ロボットによる加工食品市場への応用に関する洞察

日本の食品ロボット市場は、生産効率と安全性を高める高品質で先進的なロボットシステムに対する消費者とメーカーの強い支持により、急速な成長が見込まれています。大手食品加工機器メーカーの存在と大規模施設へのロボット導入が市場浸透を加速させています。また、カスタマイズされた自動化ソリューションへの関心の高まりも成長に貢献しています。

中国の食品ロボット加工食品市場における洞察

中国は、急速な都市化、食品消費の増加、そして食品加工における自動化需要の高まりを背景に、アジア太平洋地域の食品ロボット市場で最大のシェアを占めています。同国では、中流階級の拡大とスマート製造への注力が、先進的なロボットシステムの導入を後押ししています。また、国内の強力な製造能力と競争力のある価格設定が、市場へのアクセスを向上させています。

加工食品アプリケーションにおける食品ロボットの市場シェア

加工食品アプリケーション業界における食品ロボットは、主に次のような定評のある企業によって主導されています。

- ABB(スイス)

- 川崎重工業株式会社(日本)

- 安川電機株式会社(日本)

- ロックウェル・オートメーション社(米国)

- ファナック株式会社(日本)

- 三菱電機株式会社(日本)

- ユニバーサルロボットA/S(デンマーク)

- KUKA AG(ドイツ)

- セイコーエプソン株式会社(日本)

- シュタウブリインターナショナルAG(スイス)

- 株式会社前川製作所(日本)

- バスティアンソリューションズ社(米国)

- マイコム OSI(米国)

- デンソー株式会社(日本)

- 東芝株式会社(日本)

- ストライカー(米国)

- アデプトテクノロジーズ社(米国)

- パナソニック株式会社(日本)

- コマウ(イタリア)

- ナチロボティックシステムズ社(米国)

加工食品アプリケーション市場における世界の食品ロボットの最近の動向は何ですか?

- LBXフードロボティクスは2025年2月、カナダ規格協会(CSA)の認証取得を受け、Bake Xpressホットフード自動販売機をカナダに展開すると発表しました。このマイルストーンにより、ホスピタリティ、小売、医療、教育など、多様な施設への迅速な導入が可能になり、個別の現場検査は不要になります。Bake Xpressは従来の加工食品向けではありませんが、コンパクトなロボットキオスクを通じて、焼きたての食事やペストリーをオンデマンドで提供することで、食品の調理と提供の自動化における大きな進歩を示しています。この動きは、無人環境で便利で高品質な食事を提供するというフードロボティクスの重要性が高まっていることを浮き彫りにしています。

- 2024年7月、Chef Roboticsは、食品製造業界における労働力不足への対応と生産性向上を目的とした、AIを搭載した初のフレキシブルフードロボットを発表しました。同社独自の食品加工ソフトウェア「ChefOS」を搭載したこのロボットは、多様な食材や分量を正確に処理し、多品種生産環境に適応します。従来の自動化とは異なり、Chefのシステムは部分的な自動化を提供し、既存のワークフローにシームレスに統合されます。Amy's Kitchen、Sunbasket、Chef Bombayなどの著名な顧客が既にこの技術を採用しており、一貫性、労働生産性、スループットの向上が報告されています。

- 英国を拠点とするロボット技術のイノベーターであるWootzanoは、2023年8月に米国での事業を正式に開始し、主力製品であるAvaraiロボットを市場に投入しました。収穫後の処理向けに設計されたAvaraiは、内蔵の電子皮膚とAIを搭載したコンピュータービジョンを活用し、ブドウやトマトなどの繊細な生鮮農産物を傷や損傷を与えることなく優しく扱います。この精密さは食品ロスを削減し、梱包効率を向上させるため、農産物梱包工場における人手不足の解消につながります。フレズノ郡経済開発公社やサンフランシスコ駐在英国総領事館などのパートナーの支援を受けたこの事業拡大は、Wootzanoのグローバル成長戦略における大きな節目となります。

- 斗山ロボティクスは2023年4月、食品・飲料業界向けにカスタマイズされた画期的なNSF認証協働ロボットシリーズ「Eシリーズ」を発表しました。接続軸間の隙間を密閉し、スリムで衛生的な構造を採用したこれらの協働ロボットは、厳格な安全基準を満たすと同時に、食品調理作業において卓越した柔軟性を提供します。5kgの可搬重量と約90cmのリーチを備えたEシリーズは、鶏肉のフライからコーヒーの抽出まで、様々な用途に対応でき、既に「ロバートチキン」や「ドクタープレッソ」などのコンセプトで導入されています。今回の発売は、効率的で衛生的、かつ適応性に優れたロボットソリューションによる食品生産の自動化に向けた重要な一歩となります。

- 2023年4月、ABBロボティクスは韓国の大手食品加工会社プルムワンと提携し、培養魚介類の養殖向けAI搭載ロボットソリューションの開発に着手しました。この提携は、細胞培養の取り扱いと検査の自動化に重点を置き、生産効率の向上、汚染リスクの低減、そして熟練した実験室作業員の反復作業からの解放を目指しています。ABBの協働ロボット(コボット)ポートフォリオは、作業員の安全な作業支援において重要な役割を果たします。一方、プルムワンはこの技術を活用し、2026年までに量産体制を確立する計画です。細胞培養食品にAIロボティクスを適用する初の企業となる可能性を秘めています。

SKU-

世界初のマーケットインテリジェンスクラウドに関するレポートにオンラインでアクセスする

- インタラクティブなデータ分析ダッシュボード

- 成長の可能性が高い機会のための企業分析ダッシュボード

- カスタマイズとクエリのためのリサーチアナリストアクセス

- インタラクティブなダッシュボードによる競合分析

- 最新ニュース、更新情報、トレンド分析

- 包括的な競合追跡のためのベンチマーク分析のパワーを活用

調査方法

データ収集と基準年分析は、大規模なサンプル サイズのデータ収集モジュールを使用して行われます。この段階では、さまざまなソースと戦略を通じて市場情報または関連データを取得します。過去に取得したすべてのデータを事前に調査および計画することも含まれます。また、さまざまな情報ソース間で見られる情報の不一致の調査も含まれます。市場データは、市場統計モデルと一貫性モデルを使用して分析および推定されます。また、市場シェア分析と主要トレンド分析は、市場レポートの主要な成功要因です。詳細については、アナリストへの電話をリクエストするか、お問い合わせをドロップダウンしてください。

DBMR 調査チームが使用する主要な調査方法は、データ マイニング、データ変数が市場に与える影響の分析、および一次 (業界の専門家) 検証を含むデータ三角測量です。データ モデルには、ベンダー ポジショニング グリッド、市場タイムライン分析、市場概要とガイド、企業ポジショニング グリッド、特許分析、価格分析、企業市場シェア分析、測定基準、グローバルと地域、ベンダー シェア分析が含まれます。調査方法について詳しくは、お問い合わせフォームから当社の業界専門家にご相談ください。

カスタマイズ可能

Data Bridge Market Research は、高度な形成的調査のリーダーです。当社は、既存および新規のお客様に、お客様の目標に合致し、それに適したデータと分析を提供することに誇りを持っています。レポートは、対象ブランドの価格動向分析、追加国の市場理解 (国のリストをお問い合わせください)、臨床試験結果データ、文献レビュー、リファービッシュ市場および製品ベース分析を含めるようにカスタマイズできます。対象競合他社の市場分析は、技術ベースの分析から市場ポートフォリオ戦略まで分析できます。必要な競合他社のデータを、必要な形式とデータ スタイルでいくつでも追加できます。当社のアナリスト チームは、粗い生の Excel ファイル ピボット テーブル (ファクト ブック) でデータを提供したり、レポートで利用可能なデータ セットからプレゼンテーションを作成するお手伝いをしたりすることもできます。