世界のコールドガススプレー装置市場規模、シェア、トレンド分析レポート

Market Size in USD Billion

CAGR :

%

USD

230.69 Million

USD

343.44 Million

2024

2032

USD

230.69 Million

USD

343.44 Million

2024

2032

| 2025 –2032 | |

| USD 230.69 Million | |

| USD 343.44 Million | |

|

|

|

|

世界のコールドガススプレー装置市場:タイプ別(低圧コールドガススプレー、高圧コールドガススプレー)、材質別(金属、合金、セラミックス、複合材料)、最終用途別(航空宇宙、自動車、石油・ガス、電子機器、ヘルスケア、防衛、その他)、用途別(コーティング、修理、積層造形、表面改質) - 2032年までの業界動向と予測

コールドガススプレー装置市場規模

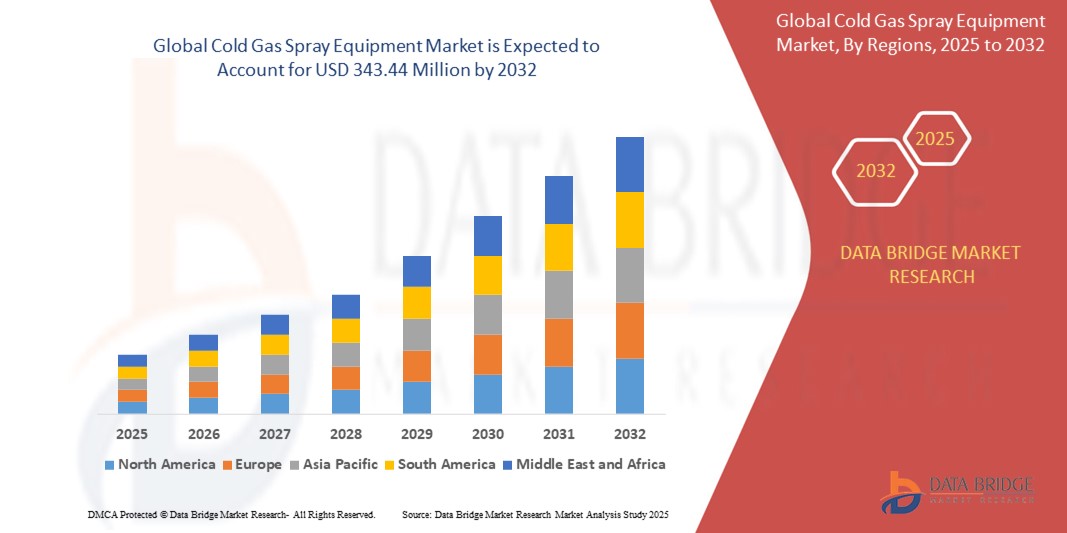

- 世界のコールドガススプレー装置市場は2024年に2億3,069万米ドルと評価され、 2032年までに3億4,344万米ドルに達すると予想されています。

- 2025年から2032年の予測期間中、市場は主にさまざまな産業用途における高度なコーティング技術の需要の増加により、5.10%のCAGRで成長すると予想されます。

- この成長は、高性能コーティングの需要の高まりなどの要因によって推進されています。

コールドガススプレー装置市場分析

- 世界のコールドガススプレー装置市場は、コーティング技術の進歩と耐久性のある高性能コーティングの需要増加により、大きな成長を遂げています。

- コールドガススプレー技術には、塗布中の熱変形を最小限に抑え、敏感な基板の完全性を維持するなど、いくつかの利点があります。

- この特性により、従来の熱スプレー法では扱いが難しい複雑な形状や複雑なデザインのコーティングに特に適しています。

- さらに、コールドガススプレーは、酸化を抑えながら材料を効果的に堆積させ、コーティングされた部品の性能と耐久性を向上させます。航空宇宙、自動車、電子機器などの業界では、製品の寿命と性能を重視する傾向が強まっており、コールドガススプレー技術の採用が急増すると予想されています。

- さらに、摩耗した部品を修復し、表面特性を向上させるこの技術の能力は、さまざまな用途で実行可能なソリューションとして位置付けられ、市場のさらなる成長を促進します。

- 全体的に、コールドガススプレーは製造と表面工学における大きな進歩を表しており、材料特性を向上させ、部品の寿命を延ばす多用途で効率的な方法を提供します。

レポートの範囲とコールドガススプレー装置市場のセグメンテーション

|

属性 |

コールドガススプレー装置の主要市場分析 |

|

対象セグメント |

|

|

対象国 |

北米

ヨーロッパ

アジア太平洋

中東およびアフリカ

南アメリカ

|

|

主要な市場プレーヤー |

|

|

市場機会 |

|

|

付加価値データ情報セット |

データブリッジマーケットリサーチがまとめた市場レポートには、市場価値、成長率、セグメンテーション、地理的範囲、主要プレーヤーなどの市場シナリオに関する洞察に加えて、輸出入分析、生産能力概要、生産消費分析、価格動向分析、気候変動シナリオ、サプライチェーン分析、バリューチェーン分析、原材料/消耗品概要、ベンダー選択基準、PESTLE分析、ポーター分析、規制枠組みも含まれています。 |

コールドガススプレー装置の市場動向

「コールドガススプレーコーティングにおけるナノテクノロジーの統合」

- コールドガススプレー装置市場における注目すべき傾向は、コーティングへのナノテクノロジーの統合の増加である。

- この進歩により、ナノ構造および非晶質材料の堆積が可能になり、特に高性能コーティングを必要とする産業で有益となる。

- 例えば、航空宇宙分野では、これらの高度なコーティングにより、重量を大幅に増やすことなく部品の耐久性と機能性を高めることができます。

- コールドガススプレー技術を使用してこのような材料を効果的に塗布する能力は、製品の性能と寿命を向上させようとしているさまざまな業界での採用を促進しています。

コールドガススプレー装置市場の動向

ドライバ

「航空宇宙・防衛分野における需要の高まり」

- 航空宇宙および防衛産業は、コールドガススプレー装置市場の重要な推進力となっている。

- コールドガススプレー技術は、タービンブレードや構造部品などの重要な部品のコーティングや修理にますます利用されています。

- この方法は、部品の寿命を延ばし、メンテナンスコストを削減し、これらの分野で極めて重要なパフォーマンスを向上させます。

- 航空宇宙および防衛用途における高価値部品の保守と改修に重点が置かれることで、コールドガススプレー装置の需要が高まっています。

機会

「積層造形プロセスへの導入」

- コールドガススプレー装置市場における新たな機会は、積層造形プロセスとの統合にある。

- コールドガススプレー技術は、3Dプリントされた部品の修復と改良に使用でき、積層造形部品の品質と耐久性を向上させるソリューションを提供します。

- この相乗効果は、複雑な形状と材料特性が重要となる航空宇宙などの産業で特に有益です。

- 積層造形とコールドガススプレー技術の組み合わせは、材料特性が改善された高性能部品を製造するための新たな道を切り開きます。

抑制/挑戦

「初期投資と運用コストが高い」

- コールドガススプレー装置市場における大きな制約は、技術に関連する初期投資と運用コストの高さである。

- 高圧ガスシステムや高度な制御ユニットなどの特殊機器には多額の資本支出が必要である。

- さらに、冷ガス噴霧システムの操作と保守には専門的な技術知識が必要であり、運用コストの増加につながる可能性があります。

- これらの財政的障壁は、特に小規模メーカーや予算が限られているメーカーにとって、コールドガススプレー技術の導入を制限する可能性がある。

コールドガススプレー装置市場の展望

市場は、タイプ、材質、最終用途、およびアプリケーションに基づいて分割されています。

|

セグメンテーション |

サブセグメンテーション |

|

タイプ別 |

|

|

素材別 |

|

|

最終用途別 |

|

|

アプリケーション別 |

|

コールドガススプレー装置市場の地域分析

「北米はコールドガススプレー装置市場における主要地域です」

- この地域の堅調な航空宇宙および防衛産業は、タービンブレードや構造部品などの重要な部品のコーティングや修理にコールドガススプレー技術を活用しており、大きな原動力となっています。

- 北米では、付加製造を含む高度な製造技術に重点を置いており、コールドガススプレー装置の需要がさらに高まっています。

- 大手企業や研究機関の存在はイノベーションを促進し、コールドガススプレー技術の能力と応用を強化します。

- この地域は、高性能コーティングソリューションへの継続的な投資により持続的な成長が期待され、リーダーシップを維持すると予想されています。

「アジア太平洋地域は最も高い成長率を記録すると予測される」

- アジア太平洋地域は、中国、日本、インドなどの国々の急速な工業化に牽引され、コールドガススプレー装置市場で最も高い成長率を記録しています。

- この地域の急成長中の航空宇宙産業と自動車産業では、部品の修理やコーティングにコールドガススプレー技術を採用するケースが増えており、性能と寿命が向上しています。

- 地域全体のインフラ開発への多額の投資は、耐久性と効率性に優れたコーティングソリューションの需要の高まりに貢献しています。

- コールドガススプレー技術と積層造形プロセスの統合により、高性能部品を製造する新たな機会が生まれます。

- 製造拠点の拡大と高度なコーティング技術の採用の増加により、アジア太平洋地域は世界のコールドガススプレー装置市場の主要プレーヤーになる準備ができています。

コールドガススプレー装置の市場シェア

市場競争環境は、競合他社ごとに詳細な情報を提供します。企業概要、財務状況、収益、市場ポテンシャル、研究開発投資、新規市場への取り組み、グローバルプレゼンス、生産拠点・設備、生産能力、強みと弱み、製品投入、製品群の幅広さ、アプリケーションにおける優位性などの詳細が含まれます。上記のデータは、各社の市場への注力分野にのみ関連しています。

市場で活動している主要なマーケットリーダーは次のとおりです。

- CenterLine (Windsor) Limited(カナダ)

- プラズマ技研株式会社(日本)

- TWI Ltd.(英国)

- スパイラリンクス・コーポレーション(米国)

- カイザーAG(リヒテンシュタイン)

- Impact Innovations GmbH(ドイツ)

- Flame Spray Technologies BV(オランダ)

- VRCメタルシステムズ(米国)

- アルトラッド(フランス)

- リンデPLC 2018(英国)

- OC Oerlikon Management AG (スイス)

- GTV Wear Protection GmbH(ドイツ)

- L3ハリステクノロジーズ社(米国)

- エアバス(英国)

世界のコールドガススプレー装置市場の最新動向

- 2023年3月、ポリマー加工、表面エンジニアリング、積層造形のリーダーであるエリコンは、Ririを買収しました。この戦略的買収により、エリコンの能力、特にコーティング技術の能力が強化され、製品ポートフォリオの拡大と市場における地位の強化が実現し、最終的には表面技術におけるイノベーションと顧客ソリューションの推進が可能になります。

- 2023年3月、産業ガスおよびエンジニアリング分野の有力企業であるリンデは、積層造形後工程向けの最先端ガス供給ソリューション「LINSPRAY Connect」を発表しました。この画期的なソリューションは、コールドスプレープロセスの信頼性と安全性を強化し、積層造形後工程における精度への高まる需要に対応することを目的としています。

- プラズマ技研株式会社は2021年、PCS-1000とポータブルコールドガススプレー装置を発表し、製品ラインナップにおける重要な節目となりました。この導入は、コールドガススプレー技術の多様な産業用途への適応性と有効性の向上に重点を置いた点において際立っています。PCS-1000は、正確な材料堆積を可能にする最先端の機能を備えており、熱影響を最小限に抑えながら優れたコーティングを実現します。

- EWIは2021年11月、コールドスプレー技術の可能性を探求し、発展させることを目的とした新たなコールドスプレー研究センターを設立しました。この取り組みは革新的な応用と機能強化に焦点を当て、製造プロセスと材料の改善につながる研究を推進し、最終的には最先端のソリューションを通じて様々な産業に利益をもたらします。

SKU-

世界初のマーケットインテリジェンスクラウドに関するレポートにオンラインでアクセスする

- インタラクティブなデータ分析ダッシュボード

- 成長の可能性が高い機会のための企業分析ダッシュボード

- カスタマイズとクエリのためのリサーチアナリストアクセス

- インタラクティブなダッシュボードによる競合分析

- 最新ニュース、更新情報、トレンド分析

- 包括的な競合追跡のためのベンチマーク分析のパワーを活用

調査方法

データ収集と基準年分析は、大規模なサンプル サイズのデータ収集モジュールを使用して行われます。この段階では、さまざまなソースと戦略を通じて市場情報または関連データを取得します。過去に取得したすべてのデータを事前に調査および計画することも含まれます。また、さまざまな情報ソース間で見られる情報の不一致の調査も含まれます。市場データは、市場統計モデルと一貫性モデルを使用して分析および推定されます。また、市場シェア分析と主要トレンド分析は、市場レポートの主要な成功要因です。詳細については、アナリストへの電話をリクエストするか、お問い合わせをドロップダウンしてください。

DBMR 調査チームが使用する主要な調査方法は、データ マイニング、データ変数が市場に与える影響の分析、および一次 (業界の専門家) 検証を含むデータ三角測量です。データ モデルには、ベンダー ポジショニング グリッド、市場タイムライン分析、市場概要とガイド、企業ポジショニング グリッド、特許分析、価格分析、企業市場シェア分析、測定基準、グローバルと地域、ベンダー シェア分析が含まれます。調査方法について詳しくは、お問い合わせフォームから当社の業界専門家にご相談ください。

カスタマイズ可能

Data Bridge Market Research は、高度な形成的調査のリーダーです。当社は、既存および新規のお客様に、お客様の目標に合致し、それに適したデータと分析を提供することに誇りを持っています。レポートは、対象ブランドの価格動向分析、追加国の市場理解 (国のリストをお問い合わせください)、臨床試験結果データ、文献レビュー、リファービッシュ市場および製品ベース分析を含めるようにカスタマイズできます。対象競合他社の市場分析は、技術ベースの分析から市場ポートフォリオ戦略まで分析できます。必要な競合他社のデータを、必要な形式とデータ スタイルでいくつでも追加できます。当社のアナリスト チームは、粗い生の Excel ファイル ピボット テーブル (ファクト ブック) でデータを提供したり、レポートで利用可能なデータ セットからプレゼンテーションを作成するお手伝いをしたりすることもできます。