世界の直交ロボット市場規模、シェア、トレンド分析レポート

Market Size in USD Billion

CAGR :

%

USD

112.55 Billion

USD

284.51 Billion

2024

2032

USD

112.55 Billion

USD

284.51 Billion

2024

2032

| 2025 –2032 | |

| USD 112.55 Billion | |

| USD 284.51 Billion | |

|

|

|

|

世界の直交ロボット市場のセグメンテーション、タイプ別(搬送ハンドリングロボット、ポジショニング、ユニットロードフォーメーションロボット、多関節ロボット、直交ロボット、スカラロボット、保管、識別、制御ロボット)、機能別(組立、梱包、輸送、配送、保管、廃棄物処理)、用途別(ピックアンドプレース、パレタイジング/デパレタイジング、梱包、製品/部品搬送、機械管理)、エンドユーザー別(自動車、化学、電気・電子、産業機械、食品・飲料、その他) - 2032年までの業界動向と予測

直交ロボット市場規模

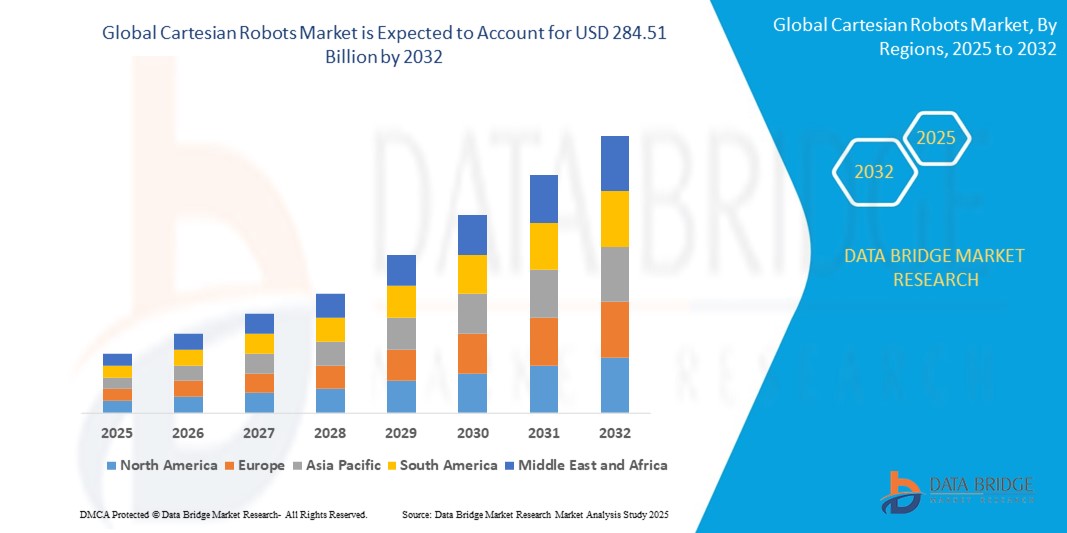

- 世界の直交ロボット市場規模は2024年に1125.5億米ドルと評価され、予測期間中に12.29%のCAGRで成長し、2032年には2845.1億米ドルに達すると予想されています。

- 市場の成長は、自動車、電子機器、産業機械などの製造業における精密駆動型自動化の需要の高まりによって主に推進されており、ロボットシステムの技術的進歩とスマートファクトリーソリューションの統合の増加に支えられています。

- さらに、業務効率の向上、人件費の削減、大量生産における一貫性の維持に対する圧力の高まりにより、特に直線運動と精度が求められる作業において、直交ロボットの導入が加速し、業界の成長を大幅に促進しています。

直交ロボット市場分析

- 直交ロボットは、直線X、Y、Z軸に沿って動作する産業用オートメーションシステムであり、ピックアンドプレース、組み立て、梱包、材料処理などのアプリケーションで高い精度、再現性、カスタマイズを提供します。

- 直交ロボットの需要の高まりは、主にそのコスト効率、プログラミングの容易さ、制約のある環境や構造化された環境への適応性によって推進されており、拡張性と精度の高い自動化システムを求める業界では好ましいソリューションとなっています。

- アジア太平洋地域は、急速な産業自動化、製造拠点の拡大、電子機器、自動車、機械部門でのロボット導入の増加により、2024年には直交ロボット市場の48.5%のシェアを占めて市場を支配した。

- 北米は、急速な技術導入、高い人件費、製造業全体での生産性向上のニーズの高まりにより、予測期間中に直交ロボット市場で最も急速に成長する地域になると予想されています。

- ピックアンドプレース分野は、電子機器、自動車、食品加工業界の組立ラインにおける基盤的な役割を担っており、2024年には35.6%の市場シェアを獲得し、市場を席巻しました。直交ロボットは、その精度、高速なサイクルタイム、そして繊細な部品を損傷なく取り扱う能力から、ピックアンドプレース用途で好まれています。

レポートの範囲と直交ロボット市場のセグメンテーション

|

属性 |

直交ロボットの主要市場洞察 |

|

対象セグメント |

|

|

対象国 |

北米

ヨーロッパ

アジア太平洋

中東およびアフリカ

南アメリカ

|

|

主要な市場プレーヤー |

|

|

市場機会 |

|

|

付加価値データ情報セット |

データブリッジマーケットリサーチがまとめた市場レポートには、市場価値、成長率、セグメンテーション、地理的範囲、主要企業などの市場シナリオに関する洞察に加えて、専門家による詳細な分析、地理的に表された企業別の生産量と生産能力、販売業者とパートナーのネットワークレイアウト、詳細かつ最新の価格動向分析、サプライチェーンと需要の不足分析も含まれています。 |

直交ロボット市場動向

「様々な業界で自動化の需要が増加」

- 世界の直交ロボット市場における重要な加速傾向は、製造業、自動車、電子機器、医薬品、食品飲料など、幅広い業界における自動化の需要の増加です。

- 例えば、ヤマハロボティクス、ABB、IAIコーポレーションなどの大手企業は、材料処理、組み立て、パレタイジング、梱包アプリケーションにおける正確でプログラム可能かつ拡張可能な自動化ソリューションのニーズに対応するために、直交ロボットの提供を拡大しています。

- IoT接続、3Dビジョンシステム、サプライチェーン自動化などの高度な技術の統合により、直交ロボットの機能が強化され、生産性の向上、品質管理の改善、人件費の削減が可能になります。

- インダストリー4.0へのトレンドとサプライチェーンのグローバル化は、企業が業務を合理化し、変化する市場の需要に迅速に対応しようとする中で、導入を促進しています。

- 直交ロボットの需要は急速に伸びており、柔軟性、拡張性、そして高精度で反復作業を自動化する能力により、2029年までに市場規模は102億3000万ドルに達すると予想されています。

直交ロボット市場の動向

ドライバ

「技術の進歩の加速」

- 継続的な技術進歩は、直交ロボット市場の大きな推進力となり、産業オートメーションにおける速度、積載量、精度の向上を可能にしています。

- 例えば、ボッシュ・レックスロスや三菱電機などの企業は、高度なアームエンドツール、スマートセンサー、そしてより安全な人間とロボットの相互作用のための協調機能を備えた次世代の直交ロボットを開発するために研究開発に投資している。

- デジタルツイン、AIベースの最適化、モジュラーロボットアーキテクチャの採用により、アプリケーションの範囲が拡大し、プログラミングと既存のワークフローへの統合が容易になります。

- 直交ロボットの汎用性と適応性は、大手メーカーと中小企業の両方にとって魅力的であり、電子機器、自動車、物流などのさまざまな分野の自動化をサポートしています。

- これらの進歩により、製造業者は業務効率の向上、ミスの削減、市場の変化への柔軟な対応が可能になります。

抑制/挑戦

「初期投資額が高い」

- 初期投資コストの高さは、特に中小企業や新規参入企業にとって、直交ロボット市場における大きな課題となっている。

- 例えば、ヤマハロボティクス、ABB、IAIコーポレーションなどの大手メーカーから高度な直交座標ロボットを購入して統合するには、機器、設置、従業員のトレーニングに多額の資本支出が必要です。

- 追加費用には、メンテナンス、カスタマイズ、既存の生産ラインとのシステム統合などがあり、組織の財務負担がさらに増加する可能性があります。

- この高い参入障壁は、特にコストに敏感な産業や自動化資金へのアクセスが限られている地域では、直交ロボットの導入を遅らせる可能性がある。

- この課題を克服するには、より手頃な価格のロボットソリューション、柔軟な資金調達オプションの開発、自動化に伴う長期的なコスト削減と生産性向上への意識の向上が必要となる。

直交ロボット市場の展望

市場は、タイプ、機能、アプリケーション、エンドユーザーに基づいてセグメント化されています。

- タイプ別

タイプ別に見ると、直交ロボット市場は、搬送ハンドリングロボット、位置決め・ユニットロード形成ロボット、多関節ロボット、直交ロボット、スカラロボット、保管・識別・制御ロボットに分類されます。直交ロボットセグメントは、その精度、費用対効果、そして様々な産業用タスクへのカスタマイズの容易さから、2024年には最大の市場収益シェアを占めました。これらのロボットは、シンプルな機械構造と拡張性から、CNC工作機械や3Dプリンティングなど、直線動作を必要とする用途で広く採用されています。限られたスペースでも高い再現性と低メンテナンス性で動作するため、産業界から直交システムが支持されており、運用コストの削減とスループットの向上に役立ちます。

スカラロボット分野は、電子機器および消費財製造における需要の高まりを背景に、2025年から2032年にかけて最も高い成長率を達成すると予想されています。スカラロボットは、コンパクトな設置面積と横方向移動の高速性が高く評価されており、特に高速ピックアンドプレースや小型部品の組立作業において高い評価を得ています。クリーンルーム環境やコンパクトな生産ラインへの導入が増加していることから、精密機器製造分野全体で急速に普及が進んでいます。

- 機能別

機能別に見ると、市場は組立、梱包、輸送、配送、保管、廃棄物処理に分類されます。組立分野は2024年に最大の市場シェアを占めました。これは、直交座標ロボットが、一貫した力の適用と高い位置決め精度が求められる作業に広く使用されているためです。自動車や電子機器などの業界では、回路基板やエンジン部品などの部品の組立において、均一性と低い誤差幅が重要となる直交座標ロボットが活用されています。

輸送分野は、イントラロジスティクスとスマート倉庫における自動化のトレンドに牽引され、2025年から2032年にかけて最も高いCAGRで成長すると予測されています。直交座標ロボットは、材料フローの合理化、人的ミスの削減、そして全体的な運用効率の向上を目的として、直線搬送システムへの導入が進んでいます。コンベアベースのシステムへの適応性とビジョン技術との統合性により、動的荷重輸送に最適です。

• 用途別

用途別に見ると、市場はピックアンドプレース、パレタイジング/デパレタイジング、梱包・包装、製品/部品搬送、マシンテンディングに分類されます。ピックアンドプレース分野は、電子機器、自動車、食品加工業界の組立ラインにおける基盤的な役割を担っており、2024年には35.6%と最大の収益シェアを占めました。直交座標型ロボットは、その精度、短いサイクルタイム、そして繊細な部品を損傷なく取り扱う能力から、ピックアンドプレース用途で好まれています。

パレタイジング/デパレタイジング分野は、物流およびFMCGセクターにおけるエンドオブライン自動化の需要増加に支えられ、2025年から2032年にかけて最も高いCAGRで成長すると予想されています。直交座標ロボットは高い可搬容量と構造化された直線運動を備えており、反復的な大量処理ワークフローにおける重量物やかさばる荷物の積み重ねや積み下ろしに最適です。

• エンドユーザーによる

エンドユーザー別に見ると、市場は自動車、化学、電気・電子、産業機械、食品・飲料、その他に分類されます。自動車分野は、自動車製造工場における精密組立や材料搬送作業において、直交ロボットの導入量が多いことから、2024年には市場を牽引しました。この分野では、品質管理の確保とサイクルタイムの短縮を目的とした自動化への注力により、直交ロボットはシャーシ組立ラインと部品組立ラインの両方に不可欠なものとなっています。

電気・電子機器分野は、微小部品の精密かつ繊細なハンドリングに対する需要の高まりを背景に、2025年から2032年にかけて最も高い成長率を記録すると予測されています。直交ロボットは、PCB組立、半導体製造、デバイス試験などにおいて広く活用されており、その直線運動と微細な制御により複雑な作業をサポートし、製品欠陥を最小限に抑えています。

直交ロボット市場の地域分析

- アジア太平洋地域は、産業オートメーションの急速な進展、製造拠点の拡大、電子機器、自動車、機械部門におけるロボットの採用増加により、2024年には48.5%という最大の収益シェアで直交ロボット市場を席巻しました。

- この地域におけるOEMの強力な存在、熟練した労働力、そしてスマートファクトリーを推進する政府の支援的な取り組みは、成長を促進する重要な要因です。

- 特に中国、日本、韓国では人件費が上昇しており、生産性と品質管理を向上させるために、高精度でコスト効率の高い直交座標ロボットシステムへの投資が産業界にさらに促進されている。

日本における直交ロボット市場の洞察

日本市場は、産業オートメーションにおける精度と信頼性への高い需要により、着実に拡大しています。日本のメーカーは、特に電子機器、自動車、半導体分野において、ロボット技術の革新に多大な投資を行っています。労働力の高齢化と人手不足により、コンパクトな環境での反復的な高精度作業に適した直交ロボットなどの自動化システムへの移行が加速しています。

中国直交ロボット市場に関する洞察

中国は、電子機器および自動車製造における優位性を背景に、2024年にはアジア太平洋地域の直交ロボット市場で最大のシェアを獲得しました。「中国製造2025」などの政府主導の取り組みは、産業用ロボットを含む先進的な製造技術の推進に取り組んでいます。中国企業はまた、柔軟な組み立てと材料処理のための費用対効果の高い直交ロボットシステムへの投資を進めており、効率性と国際競争力の向上を目指しています。

ヨーロッパの直交ロボット市場に関する洞察

ヨーロッパは、産業オートメーションへの投資増加と、自動車、航空宇宙、エレクトロニクス分野におけるロボット工学への旺盛な需要に支えられ、予測期間中に大幅な年平均成長率(CAGR)で成長すると予測されています。この地域は、成熟した産業基盤、エネルギー効率の高いソリューションへの注力、そしてスマート製造技術に対する規制支援の恩恵を受けています。特に、持続可能性、労働力の最適化、そして生産プロセスにおけるデジタルトランスフォーメーションを重視している国々で、成長は顕著です。

ドイツの直交ロボット市場に関する洞察

ドイツの直交ロボット市場は、確立された産業エコシステムと高度な自動化技術におけるリーダーシップにより、力強い成長を遂げています。自動車、機械、電子機器産業における高い導入率は、ドイツの優れたエンジニアリング力と精密製造への注力に支えられています。インダストリー4.0への注力は、スマートな生産環境に向けた直交ロボットシステムの導入を促進しています。

英国の直交ロボット市場の洞察

英国市場は、食品、医薬品、包装分野における柔軟でモジュール式の自動化ソリューションへの需要に支えられ、着実な成長が見込まれています。ブレグジット後の労働力不足と投入コストの上昇により、製造業は主要業務の自動化を迫られています。高い精度と適応性を備えた直交座標型ロボットは、コスト最適化と生産効率を重視する中小規模の産業で注目を集めています。

北米直交ロボット市場に関する洞察

北米は、急速な技術導入、高い人件費、そして製造業全体における生産性向上のニーズの高まりを背景に、2025年から2032年にかけて最も高いCAGRで成長すると予測されています。自動車、航空宇宙、家電産業におけるこの地域の強固な基盤は、直交座標型ロボットの需要を支えています。製造業の国内回帰への関心の高まりと、スマートファクトリーおよびAI統合型ロボットへの投資が相まって、米国とカナダ全土における導入が加速しています。

米国直交ロボット市場に関する洞察

米国は2024年に北米で最大の収益シェアを獲得しました。これは、精密製造、倉庫管理、自動検査システムにおける直交ロボットの導入拡大に支えられています。米国のイノベーションにおけるリーダーシップと、競争の激しい産業環境が相まって、企業は柔軟で高スループットのロボットシステムを導入しています。中小企業におけるスケーラブルな自動化への需要も、直交ロボットの市場浸透を後押ししています。

直交ロボットの市場シェア

直交ロボット業界は、主に次のような定評のある企業によって牽引されています。

- ABB(スイス)

- デンソーウェーブ株式会社(日本)

- 美的集団(中国)

- セイコーエプソン株式会社(日本)

- 芝浦機械株式会社(日本)

- ヤマハ発動機株式会社(日本)

- MKSインスツルメンツ(米国)

- KUKA AG(ドイツ)

- ギュデルグループAG(スイス)

- ボッシュ・レックスロスAG(ドイツ)

- AKRIBIS SYSTEMS(フランス)

- エアロテック社(米国)

- ストーンテクノロジーズリミテッド(英国)

- MoTeC Pty Ltd(オーストラリア)

- プロモットスイッチ(ドイツ)

- Advokatfirmaet BAHR AS (ノルウェー)

- Fibro, Inc.(ドイツ)

- パーカー・ハネフィン社(米国)

- スターオートメーション社(米国)

- ファナック(日本)

- コマウ(イタリア)

世界の直交ロボット市場の最新動向

- 2024年4月、オートマタはInterplast 2024への参加を発表し、ブラジルで100%製造された初の直交ロボットの発表という重要な節目を迎えました。このカスタマイズ可能でコスト効率の高い産業用マニピュレーターは、射出成形プロセスの自動化を合理化し、現地メーカーの柔軟性とアクセス性を向上させるように設計されています。この発表により、現地に密着した手頃な価格の自動化ソリューションを提供することで、国内生産能力の強化とラテンアメリカ市場における直交ロボットの導入促進が期待されます。

- KUKA AGは2021年4月、ロボットの操作と統合を簡素化することを目的とした次世代オペレーティングシステム「iiQKA.OS」の初版を発表しました。このプラットフォームは、完全なロボットエコシステムの基盤となり、ユーザーは互換性のあるハードウェア、アプリケーション、サービスと容易に接続・拡張することができます。iiQKA.OSの導入により、特に中小企業にとってロボット導入の障壁が大幅に低減され、ロボットシステムの使いやすさと拡張性が向上することで、直交座標ロボットの需要が拡大することが期待されます。

SKU-

世界初のマーケットインテリジェンスクラウドに関するレポートにオンラインでアクセスする

- インタラクティブなデータ分析ダッシュボード

- 成長の可能性が高い機会のための企業分析ダッシュボード

- カスタマイズとクエリのためのリサーチアナリストアクセス

- インタラクティブなダッシュボードによる競合分析

- 最新ニュース、更新情報、トレンド分析

- 包括的な競合追跡のためのベンチマーク分析のパワーを活用

調査方法

データ収集と基準年分析は、大規模なサンプル サイズのデータ収集モジュールを使用して行われます。この段階では、さまざまなソースと戦略を通じて市場情報または関連データを取得します。過去に取得したすべてのデータを事前に調査および計画することも含まれます。また、さまざまな情報ソース間で見られる情報の不一致の調査も含まれます。市場データは、市場統計モデルと一貫性モデルを使用して分析および推定されます。また、市場シェア分析と主要トレンド分析は、市場レポートの主要な成功要因です。詳細については、アナリストへの電話をリクエストするか、お問い合わせをドロップダウンしてください。

DBMR 調査チームが使用する主要な調査方法は、データ マイニング、データ変数が市場に与える影響の分析、および一次 (業界の専門家) 検証を含むデータ三角測量です。データ モデルには、ベンダー ポジショニング グリッド、市場タイムライン分析、市場概要とガイド、企業ポジショニング グリッド、特許分析、価格分析、企業市場シェア分析、測定基準、グローバルと地域、ベンダー シェア分析が含まれます。調査方法について詳しくは、お問い合わせフォームから当社の業界専門家にご相談ください。

カスタマイズ可能

Data Bridge Market Research は、高度な形成的調査のリーダーです。当社は、既存および新規のお客様に、お客様の目標に合致し、それに適したデータと分析を提供することに誇りを持っています。レポートは、対象ブランドの価格動向分析、追加国の市場理解 (国のリストをお問い合わせください)、臨床試験結果データ、文献レビュー、リファービッシュ市場および製品ベース分析を含めるようにカスタマイズできます。対象競合他社の市場分析は、技術ベースの分析から市場ポートフォリオ戦略まで分析できます。必要な競合他社のデータを、必要な形式とデータ スタイルでいくつでも追加できます。当社のアナリスト チームは、粗い生の Excel ファイル ピボット テーブル (ファクト ブック) でデータを提供したり、レポートで利用可能なデータ セットからプレゼンテーションを作成するお手伝いをしたりすることもできます。