Global Weighing Inspection Market

Taille du marché en milliards USD

TCAC :

%

USD

3.19 Billion

USD

4.40 Billion

2024

2032

USD

3.19 Billion

USD

4.40 Billion

2024

2032

| 2025 –2032 | |

| USD 3.19 Billion | |

| USD 4.40 Billion | |

|

|

|

|

Segmentation du marché mondial du pesage et de l'inspection, par type de produit (détecteurs de métaux, trieuses pondérales et systèmes de détection à rayons X), secteur d'activité (alimentaire et boissons, pharmaceutique, biens de consommation, automobile, produits dangereux, produits chimiques, plastiques et matériaux, etc.) - Tendances et prévisions du secteur jusqu'en 2032

Taille du marché du pesage et de l'inspection

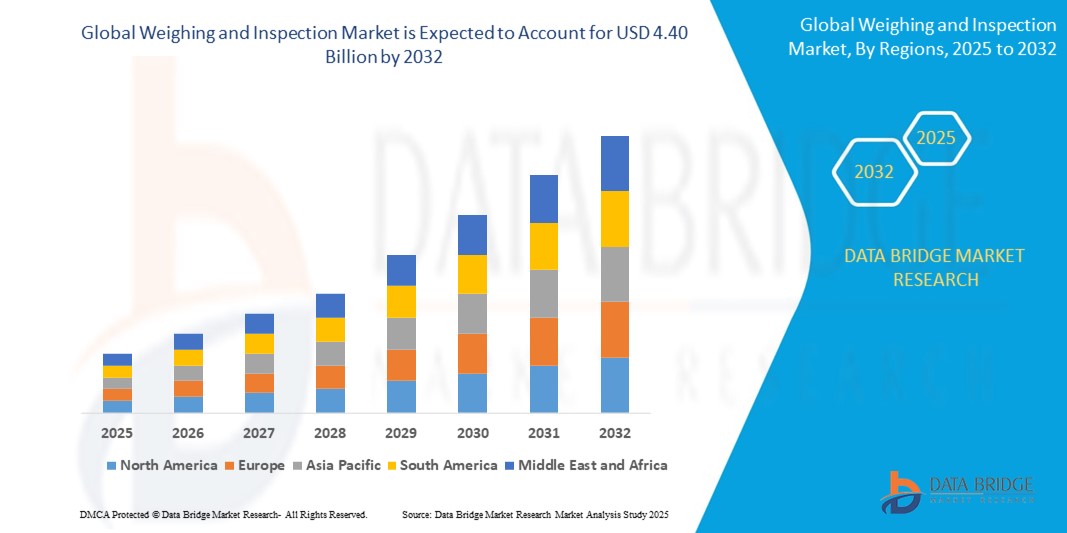

- La taille du marché mondial du pesage et de l'inspection était évaluée à 3,19 milliards USD en 2024 et devrait atteindre 4,40 milliards USD d'ici 2032 , à un TCAC de 4,10 % au cours de la période de prévision.

- Cette croissance est motivée par des facteurs tels que la demande croissante de contrôle de la qualité et d'inspection dans les industries manufacturières, les progrès technologiques dans les équipements de pesage et d'inspection et le besoin croissant de conformité à des réglementations strictes dans divers secteurs.

Analyse du marché du pesage et de l'inspection

- Le pesage et l'inspection désignent les procédés utilisés dans divers secteurs pour mesurer le poids des produits et assurer le contrôle qualité. Le pesage implique l'utilisation de balances ou de capteurs pour déterminer avec précision la masse des produits, garantissant ainsi leur homogénéité et le respect des exigences réglementaires.

- L'inspection, quant à elle, consiste à détecter les défauts, la contamination ou les irrégularités à l'aide d'outils tels que les rayons X, les détecteurs de métaux et les systèmes de vision. Ces processus sont essentiels dans des secteurs comme l'agroalimentaire, la pharmacie et l'industrie manufacturière, où des mesures précises et des normes de qualité sont essentielles pour garantir la sécurité, l'efficacité et la conformité aux réglementations industrielles.

- L'Amérique du Nord devrait dominer le marché du pesage et des inspections avec 36,2 % grâce à une infrastructure industrielle bien développée, englobant des secteurs tels que la fabrication, la logistique et les soins de santé.

- L'Asie-Pacifique devrait être la région connaissant la croissance la plus rapide sur le marché du pesage et de l'inspection au cours de la période de prévision en raison de la demande accrue d'équipements de pesage et d'inspection.

- Le segment des systèmes de détection à rayons X devrait dominer le marché avec une part de marché de 56,22 % en raison de leur capacité à détecter une large gamme de contaminants, notamment les métaux, les plastiques et le verre, dans les produits emballés.

Portée du rapport et segmentation du marché du pesage et de l'inspection

|

Attributs |

Informations clés sur le marché du pesage et de l'inspection |

|

Segments couverts |

|

|

Pays couverts |

Amérique du Nord

Europe

Asie-Pacifique

Moyen-Orient et Afrique

Amérique du Sud

|

|

Principaux acteurs du marché |

|

|

Opportunités de marché |

|

|

Ensembles d'informations de données à valeur ajoutée |

Outre les informations sur les scénarios de marché tels que la valeur marchande, le taux de croissance, la segmentation, la couverture géographique et les principaux acteurs, les rapports de marché organisés par Data Bridge Market Research comprennent également une analyse approfondie par des experts, une production et une capacité géographiquement représentées par entreprise, des configurations de réseau de distributeurs et de partenaires, une analyse détaillée et mise à jour des tendances des prix et une analyse des déficits de la chaîne d'approvisionnement et de la demande. |

Tendances du marché du pesage et de l'inspection

« Intégration de l'IA et de l'automatisation »

- L'adoption de l'intelligence artificielle (IA) dans les systèmes de pesage et d'inspection révolutionne le secteur en améliorant la précision et l'efficacité. Les algorithmes d'IA permettent l'analyse des données en temps réel, la maintenance prédictive et la détection des anomalies, réduisant ainsi les temps d'arrêt et améliorant la qualité des produits.

- Les industries intègrent de plus en plus de systèmes automatisés de pesage et d'inspection à leurs lignes de production. Cette évolution vers l'automatisation répond aux besoins d'un contrôle qualité constant, d'une cadence accrue et d'une réduction des erreurs humaines.

- L'Internet des objets (IoT) facilite la communication fluide entre les appareils de pesage et d'inspection, permettant une surveillance et un contrôle centralisés. Cette connectivité améliore l'efficacité opérationnelle et permet une prise de décision basée sur les données.

- La révolution en cours de l'Industrie 4.0 pousse les fabricants à adopter des technologies intelligentes, notamment l'IA et l'automatisation, pour rester compétitifs. Ces technologies sont essentielles pour accroître la productivité et respecter les normes réglementaires strictes.

- La capacité de collecter et d'analyser des données en temps réel permet de prendre des mesures correctives immédiates, de minimiser les défauts et de garantir le respect des normes de qualité. Cette capacité est particulièrement cruciale dans des secteurs comme l'agroalimentaire et la pharmacie.

Dynamique du marché du pesage et de l'inspection

Conducteur

« Conformité réglementaire rigoureuse »

- Les gouvernements du monde entier mettent en œuvre des réglementations strictes en matière de sécurité alimentaire qui exigent une pesée et une inspection précises des produits pour éviter la contamination et garantir la sécurité des consommateurs.

- L'industrie pharmaceutique est régie par des normes rigoureuses qui exigent une mesure et une inspection précises des produits pour maintenir l'efficacité et la sécurité

- Les fabricants sont obligés d'adopter des systèmes de pesage et d'inspection avancés pour répondre aux exigences d'assurance qualité, réduisant ainsi le risque de rappels de produits et améliorant la réputation de la marque.

- Les accords commerciaux internationaux nécessitent le respect de normes spécifiques, ce qui incite les entreprises à investir dans des équipements de pesage et d'inspection fiables pour faciliter les transactions transfrontalières fluides.

- Les réglementations environnementales croissantes encouragent les industries à adopter des pratiques durables, notamment l'utilisation de systèmes de pesage et d'inspection efficaces qui minimisent les déchets et la consommation d'énergie.

Opportunité

« Expansion dans les marchés émergents »

- Les pays de la région Asie-Pacifique, comme la Chine et l'Inde, connaissent une industrialisation rapide, ce qui entraîne une demande accrue d'équipements de pesage et d'inspection dans des secteurs comme la fabrication et la logistique.

- Les projets d’infrastructure en cours dans les marchés émergents nécessitent des systèmes d’inspection avancés pour garantir la qualité et la sécurité des matériaux de construction.

- Les gouvernements des économies émergentes offrent des incitations et des subventions pour encourager l'adoption de technologies modernes de pesage et d'inspection, créant ainsi un environnement de marché favorable.

- La sensibilisation croissante des consommateurs à la qualité et à la sécurité des produits incite les fabricants des marchés émergents à investir dans des systèmes d'inspection fiables pour répondre aux attentes.

- L'expansion des plateformes de commerce électronique dans les marchés émergents augmente la demande de systèmes d'inspection efficaces pour gérer l'augmentation des volumes de produits et assurer le contrôle de la qualité.

Retenue/Défi

« Coûts d'investissement initiaux élevés »

- Les coûts initiaux élevés associés à l’achat et à l’installation de systèmes de pesage et d’inspection avancés peuvent constituer un obstacle important pour les petites et moyennes entreprises (PME).

- L'entretien et l'étalonnage continus d'équipements sophistiqués augmentent les coûts opérationnels, ce qui a un impact sur la viabilité financière des entreprises aux budgets limités.

- Le besoin de formation spécialisée pour exploiter et entretenir des systèmes avancés entraîne des coûts supplémentaires et des investissements en temps, susceptibles de perturber les opérations régulières.

- Les entreprises peuvent hésiter à investir dans des équipements coûteux sans un retour sur investissement clair et immédiat, en particulier dans des conditions de marché volatiles.

- Les progrès rapides de la technologie peuvent rendre les équipements nouvellement achetés obsolètes, ce qui suscite des inquiétudes quant à la longévité et à la pérennité des investissements.

Portée du marché du pesage et de l'inspection

Le marché est segmenté en fonction du type de produit et du secteur d’activité.

|

Segmentation |

Sous-segmentation |

|

Par type de produit |

|

|

Par industrie |

|

En 2025, les systèmes de détection à rayons X devraient dominer le marché avec une part de marché plus importante dans le segment des types de produits.

Le segment des systèmes de détection par rayons X devrait dominer le marché du pesage et de l'inspection avec une part de marché de 40,5 % en 2025, grâce à sa capacité à détecter un large éventail de contaminants, notamment les métaux, les plastiques et le verre, dans les produits emballés. Leurs capacités avancées en font le segment à la croissance la plus rapide du marché des équipements d'inspection.

Le secteur des aliments et des boissons devrait représenter la plus grande part du marché industriel au cours de la période de prévision.

En 2025, le segment des aliments et des boissons devrait dominer le marché avec la plus grande part de marché de 50,5 % en raison de ses réglementations de sécurité strictes et du besoin d'assurance qualité dans la production de masse.

Analyse régionale du marché du pesage et de l'inspection

« L'Amérique du Nord détient la plus grande part du marché du pesage et de l'inspection »

- L'Amérique du Nord détient une part importante du marché mondial du pesage et de l'inspection, soit 36,20 %, les États-Unis représentant environ 21,1 % du marché d'ici 2033.

- La région dispose d'une infrastructure industrielle bien développée, englobant des secteurs tels que la fabrication, la logistique et les soins de santé, qui nécessitent tous des systèmes de pesage et d'inspection précis.

- Les normes réglementaires strictes dans des secteurs tels que l'industrie pharmaceutique et l'industrie agroalimentaire stimulent la demande d'équipements de pesage et d'inspection précis et fiables pour garantir la sécurité et la qualité des produits.

- L’Amérique du Nord est à l’avant-garde de l’adoption de technologies de pointe, notamment l’automatisation et la numérisation, dans les systèmes de pesage et d’inspection, améliorant ainsi l’efficacité et la précision opérationnelles.

- L'environnement économique stable de la région et les investissements continus dans le développement des infrastructures contribuent à une croissance soutenue du marché du pesage et de l'inspection.

« L'Asie-Pacifique devrait enregistrer le TCAC le plus élevé sur le marché du pesage et de l'inspection »

- Des pays comme la Chine et l'Inde connaissent une croissance industrielle rapide, ce qui entraîne une demande accrue d'équipements de pesage et d'inspection dans divers secteurs tels que la fabrication, la logistique et l'agriculture.

- L'urbanisation en cours dans les pays d'Asie-Pacifique entraîne un besoin d'infrastructures et de systèmes de transport efficaces, stimulant ainsi la demande de ponts-bascules et d'autres équipements d'inspection.

- Les politiques gouvernementales de soutien et les investissements dans l’automatisation industrielle et le développement des infrastructures créent des conditions favorables à l’expansion du marché dans la région.

- L’adoption croissante de technologies avancées, telles que les systèmes de pesage automatisés et les outils d’inspection numériques, améliore l’efficacité et la précision des opérations dans la région Asie-Pacifique.

Part de marché du pesage et de l'inspection

Le paysage concurrentiel du marché fournit des détails par concurrent. Il comprend la présentation de l'entreprise, ses données financières, son chiffre d'affaires, son potentiel de marché, ses investissements en recherche et développement, ses nouvelles initiatives commerciales, sa présence mondiale, ses sites et installations de production, ses capacités de production, ses forces et faiblesses, le lancement de nouveaux produits, leur ampleur et leur portée, ainsi que la domination de ses applications. Les données ci-dessus ne concernent que les activités des entreprises par rapport à leur marché.

Les principaux leaders du marché opérant sur le marché sont :

- Précia (France)

- WIPOTEC-OCS GmbH (Allemagne)

- MARCO LTD (Royaume-Uni)

- Marel (Islande)

- Thermo Fisher Scientific (États-Unis)

- Bizerte (Allemagne)

- MinebeaMitsumi Inc. (Japon)

- METTLER TOLEDO (Suisse)

- Sesotec GmbH (Allemagne)

- Anritsu (Japon)

- JBT (États-Unis)

- Heat and Control, Inc. (États-Unis)

- ISHIDA CO., LTD. (Japon)

- REHOO INDUSTRIAL LIMITED (Chine)

- Murata Machinery, Ltd. (Japon)

- Yangzhou Aerosol Machinery Equipment CO., LTD (Chine)

- MULTIVAC (Allemagne)

- YAMATO-SCALE (Japon)

- VARPE (Espagne)

- Fortress Technology Inc. (Canada)

- NIKKA DENSOK (Japon)

- Techik Instrument (Shanghai) (Chine)

Derniers développements sur le marché mondial du pesage et de l'inspection

- En septembre 2024, Blue HMI for Checkweighers a introduit une interface utilisateur avancée pour les trieuses pondérales dynamiques avec une navigation intuitive, un suivi de l'efficacité de l'équipement et une journalisation conviviale pour les audits.

- En septembre 2024, Mitus Metal Detector a lancé la technologie MiWave, une détection flexible et précise des contaminants métalliques pour divers produits.

- En août 2024, General Measure Technology a présenté le contrôleur de pesage statique GMC-P7 F8, un nouveau contrôleur de pesage statique pour une intégration facile dans les applications industrielles

- En août 2024, General Measure Technology lance le contrôleur de pesage pour systèmes d'alimentation linéaire GMC-X802CD, offrant des performances stables et précises

- En mai 2024, FUTEK Advanced Sensor Technology lance la cellule de charge miniature numérique LSB206 S-Beam Jr pour cellule de charge miniature offrant des capacités numériques améliorées pour des applications compactes et une mesure de force précise

- En avril, Satepesa SL lance STP-Camións System, un système de pesage numérique de camions conçu pour améliorer les opérations de transport et de logistique, garantissant efficacité et conformité

SKU-

Accédez en ligne au rapport sur le premier cloud mondial de veille économique

- Tableau de bord d'analyse de données interactif

- Tableau de bord d'analyse d'entreprise pour les opportunités à fort potentiel de croissance

- Accès d'analyste de recherche pour la personnalisation et les requêtes

- Analyse de la concurrence avec tableau de bord interactif

- Dernières actualités, mises à jour et analyse des tendances

- Exploitez la puissance de l'analyse comparative pour un suivi complet de la concurrence

Méthodologie de recherche

La collecte de données et l'analyse de l'année de base sont effectuées à l'aide de modules de collecte de données avec des échantillons de grande taille. L'étape consiste à obtenir des informations sur le marché ou des données connexes via diverses sources et stratégies. Elle comprend l'examen et la planification à l'avance de toutes les données acquises dans le passé. Elle englobe également l'examen des incohérences d'informations observées dans différentes sources d'informations. Les données de marché sont analysées et estimées à l'aide de modèles statistiques et cohérents de marché. De plus, l'analyse des parts de marché et l'analyse des tendances clés sont les principaux facteurs de succès du rapport de marché. Pour en savoir plus, veuillez demander un appel d'analyste ou déposer votre demande.

La méthodologie de recherche clé utilisée par l'équipe de recherche DBMR est la triangulation des données qui implique l'exploration de données, l'analyse de l'impact des variables de données sur le marché et la validation primaire (expert du secteur). Les modèles de données incluent la grille de positionnement des fournisseurs, l'analyse de la chronologie du marché, l'aperçu et le guide du marché, la grille de positionnement des entreprises, l'analyse des brevets, l'analyse des prix, l'analyse des parts de marché des entreprises, les normes de mesure, l'analyse globale par rapport à l'analyse régionale et des parts des fournisseurs. Pour en savoir plus sur la méthodologie de recherche, envoyez une demande pour parler à nos experts du secteur.

Personnalisation disponible

Data Bridge Market Research est un leader de la recherche formative avancée. Nous sommes fiers de fournir à nos clients existants et nouveaux des données et des analyses qui correspondent à leurs objectifs. Le rapport peut être personnalisé pour inclure une analyse des tendances des prix des marques cibles, une compréhension du marché pour d'autres pays (demandez la liste des pays), des données sur les résultats des essais cliniques, une revue de la littérature, une analyse du marché des produits remis à neuf et de la base de produits. L'analyse du marché des concurrents cibles peut être analysée à partir d'une analyse basée sur la technologie jusqu'à des stratégies de portefeuille de marché. Nous pouvons ajouter autant de concurrents que vous le souhaitez, dans le format et le style de données que vous recherchez. Notre équipe d'analystes peut également vous fournir des données sous forme de fichiers Excel bruts, de tableaux croisés dynamiques (Fact book) ou peut vous aider à créer des présentations à partir des ensembles de données disponibles dans le rapport.