Global Abrasive Waterjet Cutting Machine Market

Taille du marché en milliards USD

TCAC :

%

USD

1.26 Billion

USD

2.04 Billion

2024

2032

USD

1.26 Billion

USD

2.04 Billion

2024

2032

| 2025 –2032 | |

| USD 1.26 Billion | |

| USD 2.04 Billion | |

|

|

|

|

Segmentation du marché mondial des machines de découpe au jet d'eau abrasif, par type (machines de découpe au jet d'eau 3D, machines de découpe au micro-jet d'eau et machines de découpe au jet d'eau robotisées), application (découpe de métaux exotiques et de matériaux non traditionnels, art du verre ou du métal, découpe de céramique ou de pierre, découpe de joints, découpe de fibre de verre et découpe de produits en mousse), secteur (fabrication de métaux, automobile, aérospatiale, transformation des aliments, textile, fabrication de machines et dispositifs médicaux) - Tendances et prévisions du secteur jusqu'en 2032

Taille du marché des machines de découpe au jet d'eau abrasif

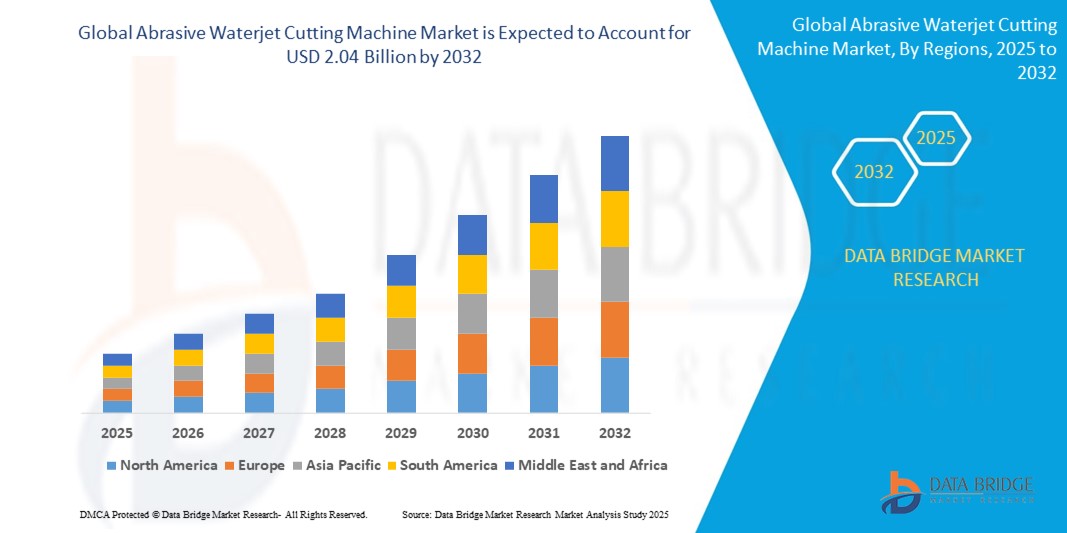

- La taille du marché mondial des machines de découpe au jet d'eau abrasif était évaluée à 1,26 milliard USD en 2024 et devrait atteindre 2,04 milliards USD d'ici 2032 , à un TCAC de 6,2 % au cours de la période de prévision.

- La croissance du marché est largement alimentée par l'adoption croissante de technologies de découpe de précision dans des secteurs tels que l'aérospatiale, l'automobile, la fabrication de métaux et l'électronique, où la demande de processus de découpe à froid de haute précision est essentielle pour éviter la distorsion thermique et la dégradation des matériaux.

- De plus, l'importance croissante accordée aux pratiques de fabrication propres, à l'automatisation et à la réduction des déchets de matériaux positionne les machines de découpe au jet d'eau abrasif comme une solution privilégiée par rapport aux méthodes de découpe thermique traditionnelles. Ces facteurs accélèrent le déploiement des systèmes à jet d'eau dans les usines mondiales, stimulant ainsi considérablement l'expansion du marché.

Analyse du marché des machines de découpe au jet d'eau abrasif

- Les machines de découpe au jet d'eau abrasif utilisent de l'eau à haute pression mélangée à des particules abrasives pour découper des matériaux durs tels que le métal, le verre, la pierre et les composites avec précision et sans génération de chaleur. Leur capacité de découpe à froid préserve l'intégrité du matériau, ce qui les rend idéales pour les industries exigeant des bords nets et sans bavures, ainsi que des tolérances strictes.

- La demande croissante de solutions de découpe flexibles, économes en énergie et respectueuses de l'environnement favorise l'adoption de systèmes de découpe au jet d'eau abrasif. Les industries se tournent de plus en plus vers ces machines pour leur capacité à traiter des géométries complexes, à automatiser et à réduire les besoins en usinage secondaire.

- L'Asie-Pacifique a dominé le marché des machines de découpe au jet d'eau abrasif avec une part de 36,15 % en 2024, en raison de l'industrialisation croissante, d'investissements importants dans les infrastructures de fabrication et de l'adoption croissante de l'usinage de précision dans des secteurs clés.

- L'Europe devrait être la région connaissant la croissance la plus rapide sur le marché des machines de découpe au jet d'eau abrasif au cours de la période de prévision en raison de la pression réglementaire croissante pour des processus industriels plus propres et de la demande de précision dans les secteurs de fabrication de pointe.

- Le segment des machines de découpe au jet d'eau 3D a dominé le marché avec une part de marché de 53,02 % en 2024, grâce à ses capacités de découpe polyvalentes sur des géométries tridimensionnelles complexes. Ces machines sont largement utilisées dans les industries exigeant des profils complexes sur des matériaux épais ou à angles multiples, comme l'aéronautique et l'automobile. Leur haute précision, leur capacité à maintenir l'intégrité structurelle sans déformation thermique et leur compatibilité avec une large gamme de matériaux contribuent à leur position dominante.

Portée du rapport et segmentation du marché des machines de découpe au jet d'eau abrasif

|

Attributs |

Aperçu du marché des machines de découpe au jet d'eau abrasif |

|

Segments couverts |

|

|

Pays couverts |

Amérique du Nord

Europe

Asie-Pacifique

Moyen-Orient et Afrique

Amérique du Sud

|

|

Acteurs clés du marché |

|

|

Opportunités de marché |

|

|

Ensembles d'informations de données à valeur ajoutée |

Outre les informations sur les scénarios de marché tels que la valeur marchande, le taux de croissance, la segmentation, la couverture géographique et les principaux acteurs, les rapports de marché organisés par Data Bridge Market Research comprennent également une analyse approfondie par des experts, une production et une capacité géographiquement représentées par entreprise, des configurations de réseau de distributeurs et de partenaires, une analyse détaillée et mise à jour des tendances des prix et une analyse des déficits de la chaîne d'approvisionnement et de la demande. |

Tendances du marché des machines de découpe au jet d'eau abrasif

« Automatisation croissante et intégration CNC »

- Le marché des machines de découpe au jet d'eau abrasif évolue rapidement à mesure que les technologies d'automatisation et de commande numérique par ordinateur (CNC) sont plus largement intégrées, permettant aux fabricants d'obtenir une plus grande précision, flexibilité et efficacité opérationnelle dans les opérations de découpe dans divers secteurs.

- Par exemple, OMAX Corporation déploie des systèmes de jet d'eau CNC avancés qui s'interfacent de manière transparente avec les logiciels de CAO/FAO, permettant une découpe automatisée et très précise de formes complexes dans les métaux, la céramique, le verre et les composites, réduisant ainsi les interventions manuelles et les erreurs de production.

- La demande de l'industrie pour des solutions robotisées et à jet d'eau multi-axes avancées augmente, facilitant la production de pièces complexes, courbes et tridimensionnelles nécessaires dans les secteurs de l'aérospatiale, de l'automobile et de la fabrication sur mesure.

- L'intégration de capteurs de surveillance en temps réel, d'appareils IoT et d'algorithmes de contrôle adaptatif aide les opérateurs à améliorer la planification de la maintenance, à prévoir l'usure des pièces et à optimiser les performances de coupe, ce qui rend ces machines plus attrayantes pour les applications à haut mélange et à faible volume.

- La tendance vers une production respectueuse de l'environnement favorise l'adoption de la technologie du jet d'eau en raison de sa génération de chaleur minimale, de la réduction des déchets de matériaux et des conditions de travail plus sûres par rapport aux procédés de découpe thermique ou mécanique traditionnels.

- Les fabricants investissent dans le développement d'interfaces de contrôle conviviales et d'aides à la maintenance, rendant les systèmes de découpe au jet d'eau abrasif plus accessibles aux techniciens qualifiés et aux nouveaux venus dans les ateliers de fabrication et de fabrication.

Dynamique du marché des machines de découpe au jet d'eau abrasif

Conducteur

« Augmentation des projets d'infrastructure »

- La croissance des investissements mondiaux dans les infrastructures, notamment dans les transports, l'énergie et les services publics, stimule considérablement la demande de machines de découpe au jet d'eau abrasif capables de couper avec précision une large gamme de matériaux de construction.

- Par exemple, Flow International Corporation fournit des systèmes de jet d'eau de grande capacité pour les projets d'infrastructure qui nécessitent une découpe personnalisée de l'acier, de la pierre et des matériaux composites, s'adaptant aux délais de projet serrés et aux besoins de conception divers.

- La capacité des découpeuses à jet d'eau abrasives à fournir des coupes précises et sans chaleur est essentielle pour la fabrication de composants utilisés dans la construction de ponts, de pipelines et de systèmes d'énergie renouvelable, conformément aux normes d'ingénierie modernes.

- Les financements gouvernementaux et privés sur les marchés émergents, associés à des projets de rénovation et de modernisation des infrastructures vieillissantes dans les régions développées, maintiennent une forte demande de solutions de découpe flexibles et à haut débit.

- La polyvalence et la compatibilité avec divers matériaux (métaux, béton, verre et composites avancés) permettent aux entrepreneurs et aux fabricants de rationaliser leurs opérations avec une plate-forme de coupe unique et haute performance.

Retenue/Défi

« Coûts de maintenance et d'exploitation »

- Un investissement initial élevé, associé à des dépenses d'exploitation et de maintenance continues, constitue un défi majeur pour les organisations qui cherchent à adopter ou à développer des technologies de découpe au jet d'eau abrasif.

- Par exemple, Hypertherm, Inc. et WARDJet Corporation soulignent que le remplacement fréquent des composants haute pression, des buses et des matériaux abrasifs, ainsi que les exigences des opérateurs qualifiés, sont des facteurs clés des coûts opérationnels continus dans les études de cas des clients.

- L'entretien de routine, y compris l'entretien de la pompe, les vérifications des composants et le nettoyage du système d'alimentation en abrasif, est essentiel à la fiabilité, mais peut entraîner des temps d'arrêt et une augmentation des coûts de main-d'œuvre et de pièces de rechange.

- La consommation d'énergie est importante pour les opérations à haute pression, et l'approvisionnement et l'élimination de l'eau et des abrasifs représentent également des dépenses récurrentes qui doivent être optimisées.

- Les entreprises opérant avec des marges faibles ou un capital limité peuvent être découragées par ces coûts cumulatifs, en particulier lorsqu'ils sont associés à des besoins de formation pour les fonctionnalités avancées de CNC et d'automatisation, ce qui a un impact sur l'adoption parmi les petits ateliers et sur les marchés en développement.

Portée du marché des machines de découpe au jet d'eau abrasif

Le marché est segmenté en fonction du type, de l’application et de l’industrie.

- Par type

Sur la base de leur type, le marché des machines de découpe au jet d'eau abrasif est segmenté en machines de découpe au jet d'eau 3D, micro-machines de découpe au jet d'eau et machines de découpe au jet d'eau robotisées. Le segment des machines de découpe au jet d'eau 3D a dominé le marché avec 53,02 % de chiffre d'affaires en 2024, principalement grâce à ses capacités de découpe polyvalentes sur des géométries tridimensionnelles complexes. Ces machines sont largement utilisées dans les industries exigeant des profils complexes sur des matériaux épais ou multi-angles, comme les composants aéronautiques et automobiles. Leur haute précision, leur capacité à maintenir l'intégrité structurelle sans déformation thermique et leur compatibilité avec une large gamme de matériaux contribuent à leur position dominante.

Le segment des machines robotisées de découpe au jet d'eau devrait connaître la croissance la plus rapide entre 2025 et 2032, porté par l'automatisation croissante de la production et le besoin croissant de systèmes de découpe flexibles et programmables. Les systèmes robotisés permettent une découpe à grande vitesse, répétable et multiaxes, particulièrement avantageuse pour les environnements à haut rendement. Leur adaptabilité à différentes tâches et leurs fonctionnalités de sécurité renforcées favorisent leur adoption croissante dans les secteurs de l'automobile et de la construction mécanique lourde.

- Par application

En fonction des applications, le marché est segmenté en : découpe de métaux exotiques et de matériaux non traditionnels, objets d'art en verre ou en métal, découpe de céramique ou de pierre, découpe de joints, découpe de fibre de verre et découpe de produits en mousse. Ce segment détenait la plus grande part de marché en 2024, en raison de la demande croissante de secteurs tels que l'aérospatiale, la défense et la fabrication de pointe, où des matériaux comme le titane, l'Inconel et les composites de carbone sont couramment utilisés. La technologie du jet d'eau abrasif est privilégiée pour sa découpe à froid, éliminant les zones affectées thermiquement et préservant les propriétés des matériaux.

Le segment des œuvres d'art en verre ou en métal devrait connaître le TCAC le plus élevé entre 2025 et 2032, porté par une utilisation croissante dans l'architecture décorative et les solutions de conception sur mesure. Les artistes et les fabricants privilégient de plus en plus la découpe au jet d'eau pour sa précision, permettant de traiter des matériaux délicats comme le verre et les métaux fins sans fissures ni déformations. La tendance à la personnalisation dans la décoration intérieure et la signalétique accélère encore la demande.

- Par industrie

Le marché est segmenté par secteur d'activité : fabrication métallique, automobile, aérospatiale, agroalimentaire, textile, fabrication de machines et dispositifs médicaux. Le segment de la fabrication métallique a dominé le marché en termes de chiffre d'affaires en 2024, grâce à l'utilisation généralisée de la découpe au jet d'eau pour une finition de bord de haute qualité et à sa capacité à traiter divers types de métaux. Les fabricants apprécient les machines à jet d'eau pour réduire les étapes de finition secondaire et maintenir des tolérances strictes sur les métaux lourds et légers.

Le secteur des dispositifs médicaux devrait connaître sa croissance la plus rapide entre 2025 et 2032, propulsé par la demande croissante de composants de micro-précision utilisés dans les instruments chirurgicaux et les implants. La micro-découpe par jet d'eau permet une découpe sans bavure ni contamination de matériaux sensibles tels que l'acier inoxydable et le titane, essentiels aux applications médicales. Le besoin d'outils mini-invasifs et de prototypage rapide soutient également l'expansion du secteur.

Analyse régionale du marché des machines de découpe au jet d'eau abrasif

- L'Asie-Pacifique a dominé le marché des machines de découpe au jet d'eau abrasif avec la plus grande part de revenus de 36,15 % en 2024, grâce à l'expansion de l'industrialisation, à des investissements importants dans les infrastructures de fabrication et à l'adoption croissante de l'usinage de précision dans des secteurs clés.

- Des pays comme la Chine, le Japon et l'Inde sont des contributeurs de premier plan, exploitant la technologie du jet d'eau pour la fabrication de composants complexes dans les secteurs de l'automobile, de l'aérospatiale, de l'électronique et de l'ingénierie lourde.

- La région bénéficie d'une chaîne d'approvisionnement robuste, de capacités de fabrication rentables et d'une demande croissante d'outils de coupe haute performance, consolidant la position de l'Asie-Pacifique en tant que leader mondial de la technologie de découpe au jet d'eau abrasif.

Aperçu du marché chinois des machines de découpe au jet d'eau abrasif

En 2024, la Chine représentait la plus grande part de marché des revenus de la région Asie-Pacifique, soutenue par son industrialisation à grande échelle, ses solides capacités de production nationales et la croissance rapide des secteurs de l'automobile et de la construction. En mettant l'accent sur les technologies de découpe propres et précises, les fabricants chinois adoptent de plus en plus de machines à jet d'eau abrasif pour améliorer la qualité de fabrication tout en maintenant l'efficacité. L'impulsion donnée par le gouvernement à la fabrication intelligente et la présence de fournisseurs d'équipements locaux proposant des prix compétitifs sont des facteurs clés de l'expansion du marché.

Aperçu du marché japonais des machines de découpe au jet d'eau abrasif

Le marché japonais des machines de découpe au jet d'eau abrasif connaît une croissance constante, porté par la réputation du pays en matière d'ingénierie de précision et par sa demande de méthodes de découpe non thermiques de haute précision. Les systèmes à jet d'eau sont largement utilisés dans des secteurs tels que l'électronique, l'automobile et l'aérospatiale, où des spécifications rigoureuses sont requises. L'accent mis par le Japon sur la production durable, la réduction des déchets de matériaux et l'intégration de technologies intelligentes dans la fabrication s'inscrit parfaitement dans les principaux avantages des machines de découpe au jet d'eau abrasif.

Aperçu du marché nord-américain des machines de découpe au jet d'eau abrasif

L'Amérique du Nord détient une part significative du marché des machines de découpe au jet d'eau abrasif, soutenue par une base industrielle mature et une forte demande dans les secteurs de l'aérospatiale, de la défense, de l'automobile et de l'ingénierie de précision. La région bénéficie d'une adoption précoce des technologies, d'importants investissements en R&D et d'une transition vers des pratiques de fabrication optimisées et automatisées. Les machines à jet d'eau abrasif sont appréciées pour leur précision, leur capacité à traiter des matériaux exotiques et composites, et leur nature athermique, qui réduit le risque de déformation des matériaux. Ces machines sont de plus en plus utilisées dans les environnements exigeants où des coupes nettes et des tolérances strictes sont essentielles.

Aperçu du marché américain des machines de découpe au jet d'eau abrasif

Les États-Unis dominent le marché nord-américain, portés par une forte adoption de technologies de fabrication avancées dans les secteurs de la défense, de l'aérospatiale et de la médecine. La demande d'outils de coupe précis et exempts de contamination est en hausse, notamment pour le prototypage et la fabrication de composants de haute précision. Soucieux de la productivité, de la sécurité et de l'efficacité énergétique, les fabricants américains adoptent les systèmes de découpe au jet d'eau abrasif comme moteur d'innovation essentiel. Le marché est également soutenu par un écosystème bien développé de fournisseurs d'équipements, d'intégrateurs de systèmes et d'instituts de recherche qui encouragent les améliorations technologiques en matière de découpe au jet d'eau.

Aperçu du marché européen des machines de découpe au jet d'eau abrasif

L'Europe devrait connaître la croissance la plus rapide du marché des machines de découpe au jet d'eau abrasif entre 2025 et 2032, principalement alimentée par la pression réglementaire croissante en faveur de procédés industriels plus propres et par l'exigence de précision dans les secteurs de la fabrication de pointe. La forte présence de la région dans les secteurs de l'automobile, de l'aérospatiale et de la fabrication de dispositifs médicaux favorise la transition vers des technologies de découpe à froid préservant l'intégrité des matériaux. Les fabricants européens adoptent les systèmes de découpe au jet d'eau pour respecter des normes environnementales strictes, réduire les déchets opérationnels et garantir la sécurité au travail. La région constate également une intégration croissante de l'automatisation et des commandes numériques, faisant des systèmes de découpe au jet d'eau abrasif un atout stratégique pour les lignes de production modernes.

Aperçu du marché allemand des machines de découpe au jet d'eau abrasif

Le marché allemand connaît une croissance rapide, porté par son leadership en matière de machines industrielles de haute technologie et d'automatisation. Les secteurs de pointe de l'automobile, de l'aéronautique et de l'ingénierie sont des utilisateurs clés des systèmes de découpe au jet d'eau, qui offrent des coupes précises, sans bavures et sans déformation thermique. Les fabricants allemands investissent dans des machines hautes performances, conformes à leurs engagements en matière de qualité, de durabilité et d'efficacité opérationnelle. Ces tendances, combinées à une culture de l'innovation, accélèrent le déploiement des systèmes de découpe au jet d'eau abrasif dans diverses applications.

Aperçu du marché britannique des machines de découpe au jet d'eau abrasif

Le marché britannique des machines de découpe au jet d'eau abrasif connaît une croissance soutenue, portée par une demande croissante de pièces métalliques sur mesure, de composants architecturaux et de fabrication de dispositifs médicaux. Les fabricants britanniques adoptent les systèmes de découpe au jet d'eau abrasif pour leur polyvalence dans la manipulation de divers matériaux et leur capacité à produire des géométries complexes sans dommage thermique. La tendance croissante à la numérisation de la fabrication et l'adoption des pratiques de l'Industrie 4.0 renforcent également l'attrait des technologies de découpe au jet d'eau intelligentes et pilotées par ordinateur.

Part de marché des machines de découpe au jet d'eau abrasif

L'industrie des machines de découpe au jet d'eau abrasif est principalement dirigée par des entreprises bien établies, notamment :

- Colfax Corporation (États-Unis)

- DARDI International Corporation (Chine)

- Omax Corporation (États-Unis)

- Flow International Corporation (États-Unis)

- Koike Aronson, Inc. (États-Unis)

- Systèmes de coupe Hornet (États-Unis)

- WARDJet, LLC (États-Unis)

- Waterjet Corporation srl (Italie)

- Hughes Pumps Ltd (Royaume-Uni)

- Solutions de coupe Semyx (États-Unis)

- TECHNI Waterjet (Australie)

- Waterjet Systems International (États-Unis)

- Resato International (Pays-Bas)

- Uhde High Pressure Technologies GmbH (Allemagne)

- MAXIMATOR JET SYSTÈMES DE DÉCOUPE AU JET D'EAU (Allemagne)

Derniers développements sur le marché mondial des machines de découpe au jet d'eau abrasif

- En août 2024, une start-up soutenue par l'IIT Madras a dévoilé la première machine à jet d'eau abrasif d'Inde, conçue pour découper des matériaux combustibles sans générer de chaleur. Avec un prix près d'un tiers inférieur à celui des systèmes existants, ce développement devrait révolutionner le marché indien en rendant les technologies de découpe avancées plus accessibles, notamment pour les secteurs des semi-conducteurs, de l'aviation, de la défense et du diamant, et en positionnant l'Inde comme un pôle de production potentiel pour des solutions de jet d'eau économiques.

- En mars 2024, Boeing, le géant américain de l'aérospatiale, est revenu sur sa décision de réduire la production de ses avions de combat F/A-18 Super Hornet d'ici l'année prochaine, après avoir obtenu un contrat portant sur la livraison de 17 appareils d'ici 2027. D'une valeur de 1,14 milliard de dollars, l'accord devrait être finalisé d'ici avril 2027, les premières livraisons débutant à l'hiver 2026. Dans le cadre de cet accord, Boeing fournira également un ensemble complet de données techniques comprenant des informations sur la maintenance, l'exploitation, l'installation et la formation afin de soutenir le maintien en puissance des F/A-18 et EA-18G pour l'US Navy.

- En août 2023, Elliott Matsuura Canada a annoncé de nouvelles ententes de distribution avec trois entreprises afin d'élargir sa gamme de produits au Canada. Parmi ces collaborations, le distributeur s'est associé à Mandelli, une entreprise fondée en 1932 possédant une vaste expérience dans la production de machines 5 axes et de systèmes de fabrication flexibles. Les centres d'usinage Mandelli seront désormais disponibles au Canada et cibleront des secteurs comme l'énergie, l'aérospatiale et la machinerie de précision.

- En septembre 2022, KMT Waterjet Systems Inc. a lancé la pompe KMT PRO 50, issue de sa technologie de jet d'eau nouvelle génération, améliorant considérablement les performances des systèmes de jet d'eau abrasif. En augmentant la vitesse de coupe de 40 % et en réduisant jusqu'à 50 % l'utilisation de grenat et la consommation d'énergie, cette innovation améliore l'efficacité opérationnelle et les économies de coûts, renforçant ainsi la compétitivité mondiale de KMT et établissant de nouvelles normes pour les systèmes de pompage haute pression sur le marché.

- En juillet 2022, OMAX Corporation a présenté le centre d'usinage par jet de précision OptiMAX, sa machine à jet d'eau abrasif la plus sophistiquée et la plus précise à ce jour. Grâce à une automatisation renforcée, une vitesse de traitement élevée et une fiabilité exceptionnelle, la série OptiMAX est en passe de relever les normes du secteur, renforçant ainsi la position d'OMAX sur les marchés américain et mondial, tout en répondant à la demande croissante de précision et de productivité dans le secteur manufacturier.

SKU-

Accédez en ligne au rapport sur le premier cloud mondial de veille économique

- Tableau de bord d'analyse de données interactif

- Tableau de bord d'analyse d'entreprise pour les opportunités à fort potentiel de croissance

- Accès d'analyste de recherche pour la personnalisation et les requêtes

- Analyse de la concurrence avec tableau de bord interactif

- Dernières actualités, mises à jour et analyse des tendances

- Exploitez la puissance de l'analyse comparative pour un suivi complet de la concurrence

Méthodologie de recherche

La collecte de données et l'analyse de l'année de base sont effectuées à l'aide de modules de collecte de données avec des échantillons de grande taille. L'étape consiste à obtenir des informations sur le marché ou des données connexes via diverses sources et stratégies. Elle comprend l'examen et la planification à l'avance de toutes les données acquises dans le passé. Elle englobe également l'examen des incohérences d'informations observées dans différentes sources d'informations. Les données de marché sont analysées et estimées à l'aide de modèles statistiques et cohérents de marché. De plus, l'analyse des parts de marché et l'analyse des tendances clés sont les principaux facteurs de succès du rapport de marché. Pour en savoir plus, veuillez demander un appel d'analyste ou déposer votre demande.

La méthodologie de recherche clé utilisée par l'équipe de recherche DBMR est la triangulation des données qui implique l'exploration de données, l'analyse de l'impact des variables de données sur le marché et la validation primaire (expert du secteur). Les modèles de données incluent la grille de positionnement des fournisseurs, l'analyse de la chronologie du marché, l'aperçu et le guide du marché, la grille de positionnement des entreprises, l'analyse des brevets, l'analyse des prix, l'analyse des parts de marché des entreprises, les normes de mesure, l'analyse globale par rapport à l'analyse régionale et des parts des fournisseurs. Pour en savoir plus sur la méthodologie de recherche, envoyez une demande pour parler à nos experts du secteur.

Personnalisation disponible

Data Bridge Market Research est un leader de la recherche formative avancée. Nous sommes fiers de fournir à nos clients existants et nouveaux des données et des analyses qui correspondent à leurs objectifs. Le rapport peut être personnalisé pour inclure une analyse des tendances des prix des marques cibles, une compréhension du marché pour d'autres pays (demandez la liste des pays), des données sur les résultats des essais cliniques, une revue de la littérature, une analyse du marché des produits remis à neuf et de la base de produits. L'analyse du marché des concurrents cibles peut être analysée à partir d'une analyse basée sur la technologie jusqu'à des stratégies de portefeuille de marché. Nous pouvons ajouter autant de concurrents que vous le souhaitez, dans le format et le style de données que vous recherchez. Notre équipe d'analystes peut également vous fournir des données sous forme de fichiers Excel bruts, de tableaux croisés dynamiques (Fact book) ou peut vous aider à créer des présentations à partir des ensembles de données disponibles dans le rapport.