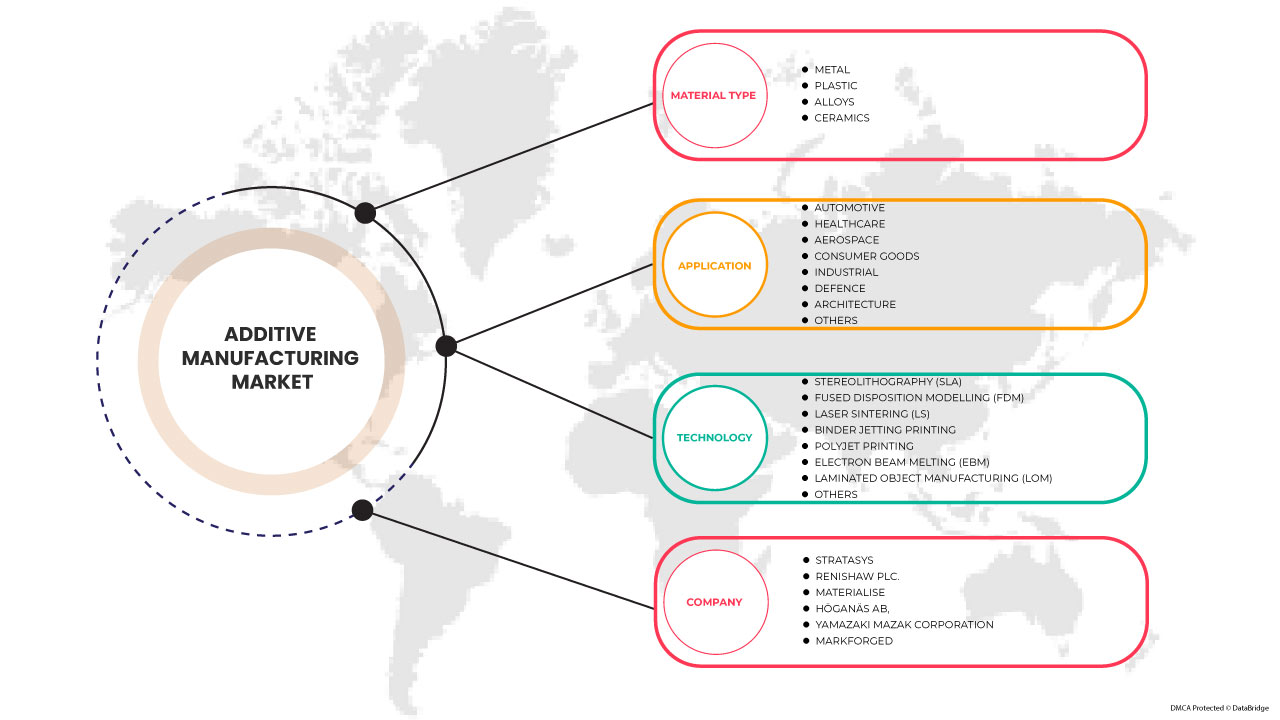

Marché de la fabrication additive en Asie-Pacifique, par type de matériau (métal, plastique, alliages et céramique), technologie (stéréolithographie (SLA), modélisation par disposition en fusion (FDM), frittage laser (LS), impression par jet de liant, impression Polyjet, fusion par faisceau d'électrons (EBM), fabrication d'objets laminés (LOM) et autres), applications (automobile, santé, aérospatiale, biens de consommation, industrie, défense, architecture et autres) Tendances du marché et prévisions jusqu'en 2030.

Analyse et taille du marché de la fabrication additive en Asie-Pacifique

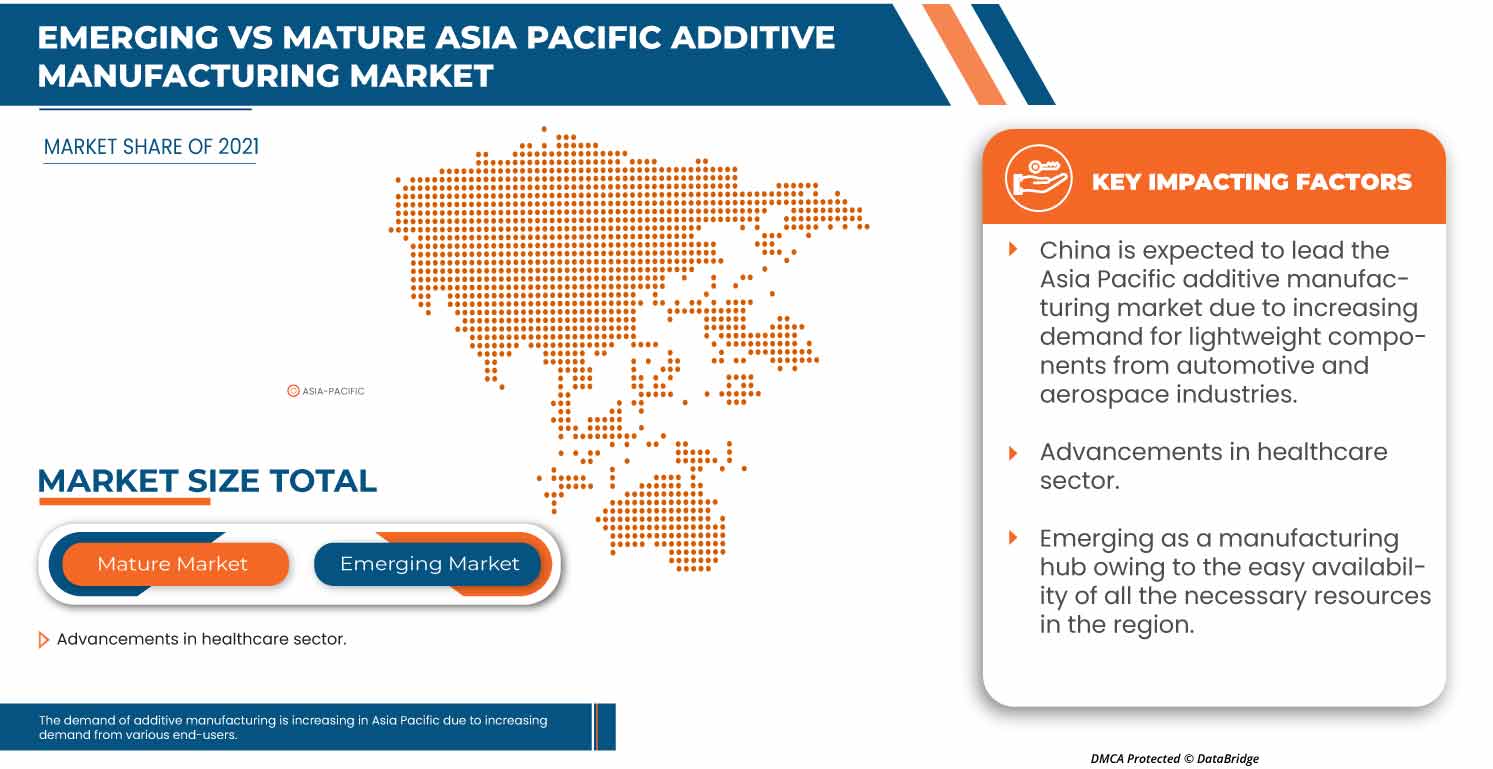

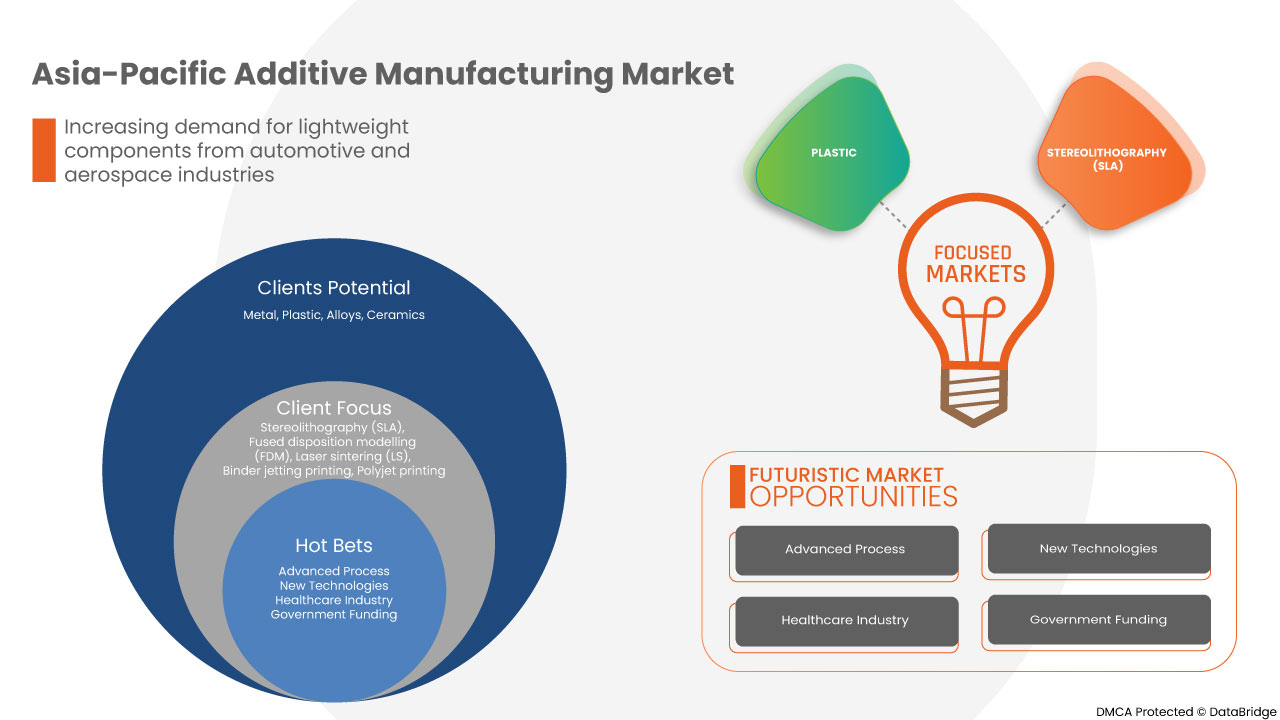

L'industrie de la fabrication additive concerne la conception, la production et la distribution de fils, de tissus, de vêtements et de vêtements. La matière première peut être du métal, du plastique, des alliages et de la céramique. Les industries de fabrication additive contribuent de manière significative à l'économie nationale de nombreux pays. La demande croissante de composants légers des catégories automobile et aérospatiale et les progrès des technologies d'impression 3D en métal ont considérablement augmenté la demande sur le marché de la fabrication additive en Asie-Pacifique.

Le rapport sur le marché de la fabrication additive en Asie-Pacifique fournit des détails sur la part de marché, les nouveaux développements et l'impact des acteurs du marché national et local, analyse les opportunités en termes de poches de revenus émergentes, de changements dans la réglementation du marché, d'approbations de produits, de décisions stratégiques, de lancements de produits, d'expansions géographiques et d'innovations technologiques sur le marché. Pour comprendre l'analyse et le scénario du marché, contactez-nous pour un briefing d'analyste. Notre équipe vous aidera à créer une solution d'impact sur les revenus pour atteindre votre objectif souhaité.

Le marché de la fabrication additive en Asie-Pacifique devrait connaître une croissance significative au cours de la période de prévision de 2023 à 2030. Data Bridge Market Research analyse que le marché croît avec un TCAC de 21,6 % au cours de la période de prévision de 2023 à 2030 et devrait atteindre 21 738,04 millions USD d'ici 2030. Le principal facteur à l'origine de la croissance du marché de la fabrication additive est la demande croissante de composants légers des industries automobile et aérospatiale.

|

Rapport métrique |

Détails |

|

Période de prévision |

2023 à 2030 |

|

Année de base |

2022 |

|

Années historiques |

2021 (personnalisable de 2020 à 2015) |

|

Unités quantitatives |

Chiffre d'affaires en millions USD |

|

Segments couverts |

Par type de matériau (métal, plastique, alliages et céramique), technologie (stéréolithographie (SLA), modélisation par disposition en fil fondu (FDM), frittage laser (LS), impression par jet de liant, impression Polyjet, fusion par faisceau d'électrons (EBM), fabrication d'objets laminés (LOM) et autres), application (automobile, santé, aérospatiale, biens de consommation, industrie, défense, architecture et autres). |

|

Pays couverts |

Japon, Chine, Corée du Sud, Inde, Singapour, Thaïlande, Indonésie, Malaisie, Philippines, Australie et Nouvelle-Zélande, et le reste de l'Asie-Pacifique. |

|

Acteurs du marché couverts |

ANSYS, Inc., Höganäs AB, EOS, ARBURG GmbH + Co KG, Stratasys, Renishaw plc., YAMAZAKI MAZAK CORPORATION, Materialise, Markforged, Titomic Limited., SLM Solutions, Proto Labs, ENVISIONTEC US LLC, Ultimaker BV, American Additive Manufacturing LLC, Optomec, Inc., 3D system Inc. et ExOne. (Une filiale de Desktop Metal, Inc.), entre autres. |

Définition du marché

La fabrication additive (FA) diffère de la méthode de production soustractive, qui consiste à extraire les matériaux inutiles d'un bloc de matériau. L'utilisation de la fabrication additive dans les applications industrielles fait généralement référence à l'impression 3D. La fabrication additive implique l'ajout de matériaux couche par couche pour former un objet tout en se référant à un fichier tridimensionnel à l'aide d'une imprimante 3D et d'un logiciel d'impression 3D. Une technologie de fabrication additive appropriée est sélectionnée parmi l'ensemble des technologies disponibles en fonction de l'application.

Dynamique du marché de la fabrication additive en Asie-Pacifique

Cette section traite de la compréhension des moteurs, des avantages, des opportunités, des contraintes et des défis du marché. Tout cela est discuté en détail ci-dessous :

Conducteurs

- Demande croissante de composants légers de la part des industries automobile et aérospatiale

Le secteur automobile et aérospatial exige de nombreux objectifs techniques et économiques interactifs en matière de performances fonctionnelles, de réduction des délais de livraison, de légèreté, de gestion des coûts et de livraison de composants critiques pour la sécurité. Pour répondre à la demande et compenser la consommation de carburant et la gestion des coûts, il faut améliorer les performances techniques et permettre de fabriquer une structure plus légère qui est directement liée à l'amélioration des performances économiques et techniques et qui aidera l'industrie aérienne à transporter plus de charge utile, ce qui améliorera directement ses revenus. Les technologies de fabrication additive, contrairement à la fabrication traditionnelle conventionnelle, utilisent une fabrication couche par couche à base de poudre ou de fil typique et de matériaux comme le polymère plastique, qui est léger.

- Avantages offerts par la fabrication additive dans diverses industries utilisatrices finales

Les industries comme l'aérospatiale font partie des industries qui ont utilisé des produits de fabrication additive pour leurs performances, et les pièces d'avion sont utilisées par des produits de fabrication additive qui sont légers et peuvent résister à des conditions environnementales difficiles, en raison de moins de matériaux requis et du processus de formation de matériaux couches par couches, les industries aérospatiales l'utilisent comme avantage pour la réduction du poids et la réduction des déchets, ce qui est très important pour la fabrication de pièces aérospatiales pour les grandes entreprises.

Dans le secteur médical en pleine innovation, l'utilisation de produits fabriqués par fabrication additive présente un grand avantage pour les médecins, les patients et les instituts de recherche. Grâce à la conception de prototypes fonctionnels fournis par les technologies de fabrication additive, il est très avantageux de créer une conception flexible de divers outils de sauvetage nécessaires à des fins chirurgicales et d'étude, d'outils utilisés dans les procédures dentaires, de modèles préopératoires pour les tomodensitogrammes, de guides de scie et de forage personnalisés, de boîtiers et d'instruments spécialisés.

- Personnalisation facile et production en masse grâce à la fabrication additive

La personnalisation par fabrication additive, contrairement à la fabrication traditionnelle, n'ajoute pas de coût supplémentaire pour la personnalisation et ne nécessite aucun moule ou outil spécifique pour la conception. Il suffit d'un prototype de conception 3D et peut être créé par le client lui-même en raison de la personnalisation facile et de la production rapide. La demande est élevée et nous pouvons produire en masse n'importe quel design unique sans entraver le coût et le temps lors de l'utilisation des imprimantes 3D. Non seulement elle permet une production personnalisée en masse, mais elle offre également au consommateur une expérience d'achat et de consommation unique qui lui donne le sentiment d'appartenance et la satisfaction du consommateur par rapport à son homologue qui ne propose pas de conception personnalisée. Elle permet également au consommateur d'acheter le design de son choix. Par exemple, NIKE, un fabricant de chaussures, vend ses chaussures sur son site Web avec un design 3D sur lequel le consommateur peut ajouter lui-même son choix de couleur sans trop d'hésitation. Cela ajoutera un avantage à la concurrence du marché car, grâce à ce système, il permet au fabricant de connaître son client.

- Augmentation de l'industrialisation et progrès de la technologie d'impression 3D en métal

Avec l'essor de l'industrialisation, il existe une demande énorme de produits d'impression 3D en métal dans des secteurs tels que l'aérospatiale, l'automobile, la santé et d'autres industries. Avec la demande de divers domaines pour des pièces dans l'aérospatiale pour leurs moteurs à réaction et d'autres pièces structurelles pour personnaliser les pièces dans l'industrie automobile afin de personnaliser la conception des chaussures et autres gadgets électroniques, il existe une demande pour le développement rigoureux des technologies d'impression 3D, qui fonctionneront plus efficacement et pourront produire le produit à un rythme beaucoup plus rapide et avec plus de précision. Ainsi, la demande d'avancées et de commodité des technologies de fabrication additive conduit à une augmentation de la demande de technologies d'impression 3D en métal.

Opportunités

- Progrès dans le secteur de la santé

Dans le domaine médical, chaque patient est unique et la fabrication additive a donc un fort potentiel d'utilisation pour des applications médicales personnalisées et sur mesure. Les implants personnalisés et les guides de scies pour modèles médicaux sont les produits cliniques médicaux les plus couramment utilisés. Dans le domaine dentaire, des produits de fabrication additive sont utilisés, comme des attelles, des appareils orthodontiques, des modèles dentaires et des guides de forage. Cependant, les produits de fabrication additive sont également utilisés pour fabriquer des tissus et des organes artificiels, qui peuvent être utilisés à des fins d'étude dans un institut de recherche ou entre les consultations entre médecins et patients. Avec le développement de la numérisation de l'imagerie médicale, la numérisation permet la reconstruction de modèles 3D à partir de l'anatomie des patients. Le flux de travail typique du dispositif médical personnalisé commence par l'imagerie ou la capture de la géométrie de l'anatomie du patient à l'aide de méthodes de numérisation 3D informatisée. Ces données peuvent être utilisées pour imprimer des modèles 3D de l'anatomie d'un patient ou pour créer des dispositifs ou des implants personnalisés.

- Augmenter le financement gouvernemental pour promouvoir la fabrication additive

La fabrication additive a un immense potentiel pour révolutionner le paysage de la fabrication et de la production industrielle grâce aux processus numériques, à la communication et à l'imagerie. La fabrication additive est une activité tendance qui bénéficie d'une forte demande de la part de diverses industries telles que l'aérospatiale, l'automobile, le secteur médical, l'électronique, la mode, etc. Voyant la possibilité potentielle de la contribution de ce secteur à l'économie nationale, les gouvernements de différents pays élaborent une stratégie différente pour soutenir et promouvoir cette industrie.

Contraintes/Défis

- Coûts élevés des équipements, des machines et manque de professionnels qualifiés

Les avantages de la fabrication additive ont ouvert de vastes horizons pour la création de formes et de composants 3D. Mais toutes les entreprises n’ont pas la capacité d’intégrer ce type d’activité à leurs processus commerciaux à moindre coût. Parmi les causes les plus courantes qui entravent l’avenir de la fabrication additive figurent le coût élevé des équipements et le manque de professionnels dans ce secteur.

Le prix moyen d’un équipement de fabrication additive se situe entre 300 000 et 1,5 million de dollars. Le coût des consommables industriels varie entre 100 et 150 dollars par pièce. Cependant, le prix final dépend du matériau choisi, comme le plastique, qui est considéré comme l’option la plus économique parmi tous les autres matériaux disponibles. Le temps nécessaire est également assez élevé, car il faut plus d’une heure pour imprimer un objet de 40 cm.

- Manque d'efficacité du logiciel

La fabrication additive utilisant le procédé de fusion laser sur lit de poudre (PBF) permet de créer des formes complexes et élaborées ainsi que des structures organiques qui étaient auparavant trop coûteuses ou complexes à réaliser à l'aide d'opérations de fabrication traditionnelles. Par exemple, les libertés de conception obtenues par la PBF laser pourraient être exploitées pour des composants légers afin de créer les structures en treillis les plus complexes pour une utilisation plus efficace des matériaux. Mais la PBF laser a ses inconvénients. Elle comprend des pièces à parois minces/à rapport hauteur/largeur élevé qui peuvent se briser pendant la fabrication, des structures de support difficiles à retirer, des effets de superposition sur la rugosité de la surface et différents paramètres de processus tels que les réglages laser pour les surfaces en surface par rapport aux surfaces en surface.

Développement récent

- En février, SLM Solutions a lancé SLM.Quality. Il s'agit d'une solution logicielle d'assurance qualité qui permet aux clients d'effectuer des évaluations de tâches de fabrication, des qualifications de processus et des certifications de pièces plus efficacement. Qu'il s'agisse de production de pièces uniques ou de production en série, les solutions SLM.Quality peuvent assister les clients industriels pendant le processus de qualification, en améliorant la traçabilité et la documentation des données de processus clés. Ce développement aidera l'entreprise à attirer davantage de clients.

- En février, SLM Solutions et Assembrix ont annoncé conjointement l’intégration réussie du logiciel Assembrix VMS avec les machines SLM Solutions du monde entier. Ce nouveau partenariat répondra à la demande croissante des équipementiers pour une fabrication additive distribuée sécurisée et permettra la création d’un écosystème de fabrication additive international fiable.

Portée du marché de la fabrication additive en Asie-Pacifique

Le marché de la fabrication additive en Asie-Pacifique est classé en fonction du type de matériau, de la technologie et de l'application. La croissance de ces segments vous aidera à analyser les principaux segments de croissance des industries et à fournir aux utilisateurs un aperçu précieux du marché et des informations sur le marché pour prendre des décisions stratégiques afin d'identifier les principales applications du marché.

Type de matériau

- Métaux

- Plastiques

- Alliages

- Céramique

Sur la base du type de matériau, le marché de la fabrication additive Asie-Pacifique est classé en quatre segments : métaux, plastiques, alliages et céramiques.

Technologie

- Stéréolithographie (SLA)

- Modélisation de la disposition fusionnée (FDM)

- Frittage laser (LS)

- Impression par jet de liant

- Impression Polyjet

- Fusion par faisceau d'électrons (EBM)

- Fabrication d'objets laminés (LOM)

- Autres

Sur la base de la technologie, le marché de la fabrication additive en Asie-Pacifique est classé en huit segments : stéréolithographie (SLA), modélisation par disposition fondue (FDM), frittage laser (LS), impression par jet de liant, impression Polyjet, fusion par faisceau d'électrons (EBM), fabrication d'objets laminés (LOM) et autres.

Application

- Automobile

- Soins de santé

- aérospatial

- Biens de consommation

- Industriel

- Défense

- Architecture

- Autres

Sur la base des applications, le marché de la fabrication additive en Asie-Pacifique est classé en huit segments : automobile, santé, aérospatiale, biens de consommation, industrie, défense, architecture et autres.

Analyse/perspectives régionales du marché de la fabrication additive en Asie-Pacifique

Le marché de la fabrication additive en Asie-Pacifique est segmenté en fonction du type de matériau, de la technologie et des applications.

Les pays du marché de la fabrication additive en Asie-Pacifique sont le Japon, la Chine, la Corée du Sud, l’Inde, Singapour, la Thaïlande, l’Indonésie, la Malaisie, les Philippines, l’Australie et la Nouvelle-Zélande, ainsi que le reste de l’Asie-Pacifique.

La Chine domine le marché de la fabrication additive en Asie-Pacifique en raison du développement avancé des technologies.

La section par pays du rapport fournit également des facteurs individuels ayant un impact sur le marché et des changements dans la réglementation du marché qui ont un impact sur les tendances actuelles et futures du marché. L'analyse des points de données en aval et en amont de la chaîne de valeur, les tendances techniques, l'analyse des cinq forces du porteur et les études de cas sont quelques-uns des indicateurs utilisés pour prévoir le scénario de marché pour les différents pays. En outre, la présence et la disponibilité des marques APAC et les défis auxquels elles sont confrontées en raison de la concurrence importante ou rare des marques locales et nationales, l'impact des tarifs nationaux et les routes commerciales sont pris en compte tout en fournissant une analyse prévisionnelle des données nationales.

Analyse du paysage concurrentiel et des parts de marché de la fabrication additive en Asie-Pacifique

Le paysage concurrentiel du marché de la fabrication additive en Asie-Pacifique fournit des détails par concurrents. Les détails inclus sont la présentation de l'entreprise, les finances de l'entreprise, les revenus générés, le potentiel du marché, les investissements dans la recherche et le développement, les nouvelles initiatives du marché, les sites et installations de production, les forces et les faiblesses de l'entreprise, le lancement de produits, les pipelines d'essais de produits, les approbations de produits, les brevets, la largeur et l'étendue du produit, la domination des applications, la courbe de survie technologique. Les points de données ci-dessus fournis ne concernent que l'orientation des entreprises liées au marché de la fabrication additive en Asie-Pacifique.

Français Certains des principaux acteurs opérant sur le marché de la fabrication additive en Asie-Pacifique sont SLM Solutions, Proto Labs, Stratasys, Renishaw plc., Materialise, Titomic Limited., Höganäs AB, YAMAZAKI MAZAK CORPORATION, Markforged, Ultimaker BV, Optomec, Inc., ExOne. (Une filiale de Desktop Metal, Inc.), American Additive Manufacturing LLC, ANSYS, Inc., ARBURG GmbH + Co KG, ENVISIONTEC US LLC, EOS et 3D Systems, Inc., entre autres.

SKU-

Accédez en ligne au rapport sur le premier cloud mondial de veille économique

- Tableau de bord d'analyse de données interactif

- Tableau de bord d'analyse d'entreprise pour les opportunités à fort potentiel de croissance

- Accès d'analyste de recherche pour la personnalisation et les requêtes

- Analyse de la concurrence avec tableau de bord interactif

- Dernières actualités, mises à jour et analyse des tendances

- Exploitez la puissance de l'analyse comparative pour un suivi complet de la concurrence

Table des matières

1 INTRODUCTION

1.1 OBJECTIVES OF THE STUDY

1.2 MARKET DEFINITION

1.3 OVERVIEW OF THE ASIA PACIFIC ADDITIVE MANUFACTURING MARKET

1.4 LIMITATIONS

1.5 MARKETS COVERED

2 MARKET SEGMENTATION

2.1 MARKETS COVERED

2.2 GEOGRAPHICAL SCOPE

2.3 YEARS CONSIDERED FOR THE STUDY

2.4 CURRENCY AND PRICING

2.5 DBMR TRIPOD DATA VALIDATION MODEL

2.6 TYPE LIFELINE CURVE

2.7 MULTIVARIATE MODELING

2.8 PRIMARY INTERVIEWS WITH KEY OPINION LEADERS

2.9 DBMR MARKET POSITION GRID

2.1 MARKET APPLICATION COVERAGE GRID

2.11 DBMR MARKET CHALLENGE MATRIX

2.12 DBMR VENDOR SHARE ANALYSIS

2.13 SECONDARY SOURCES

2.14 ASSUMPTIONS

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

4.1 PORTER'S FIVE FORCES:

4.1.1 THREAT OF NEW ENTRANTS:

4.1.2 THREAT OF SUBSTITUTES:

4.1.3 CUSTOMER BARGAINING POWER:

4.1.4 SUPPLIER BARGAINING POWER:

4.1.5 INTERNAL COMPETITION (RIVALRY):

4.2 PRODUCTION CONSUMPTION ANALYSIS

4.3 TECHNOLOGICAL ADVANCEMENT BY MANUFACTURERS

4.4 SUPPLY CHAIN ANALYSIS

5 REGULATORY FRAMEWORK

6 MARKET OVERVIEW

6.1 DRIVERS

6.1.1 INCREASING DEMAND FOR LIGHTWEIGHT COMPONENTS FROM THE AUTOMOTIVE AND AEROSPACE INDUSTRIES

6.1.2 ADVANTAGES OFFERED BY ADDITIVE MANUFACTURING IN VARIOUS END-USER INDUSTRIES

6.1.3 EASY CUSTOMIZATION AND BULK PRODUCTION USING ADDITIVE MANUFACTURING

6.1.4 RISE IN INDUSTRIALIZATION AND ADVANCEMENT IN 3D METAL PRINTING TECHNOLOGY

6.2 RESTRAINTS

6.2.1 HIGH COSTS OF EQUIPMENT, MACHINERY AND LACK OF SKILLED PROFESSIONAL

6.2.2 LACK OF SOFTWARE EFFICIENCY

6.3 OPPORTUNITIES

6.3.1 ADVANCEMENT IN THE HEALTHCARE SECTOR

6.3.2 INCREASING GOVERNMENT FUNDING TO PROMOTE ADDITIVE MANUFACTURING

6.4 CHALLENGES

6.4.1 ISSUES RELATED TO MATERIAL AVAILABILITY, DEVELOPMENT, VALIDATION, AND STANDARDIZATION

6.4.2 MISCONCEPTIONS AMONG SMALL AND MEDIUM-SCALE MANUFACTURERS ABOUT THE PROTOTYPING PROCESS

7 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE

7.1 OVERVIEW

7.2 METAL

7.2.1 METAL, BY MATERIAL TYPE

7.2.1.1 STEEL

7.2.1.2 ALUMINUM (ALUMIDE)

7.2.1.3 TITANIUM

7.2.1.4 SILVER

7.2.1.5 GOLD

7.2.1.6 OTHERS

7.3 PLASTIC

7.3.1 PLASTIC, BY MATERIAL TYPE

7.3.1.1 ACRYLONITRILE BUTADIENE STYRENE

7.3.1.2 POLYLACTIC ACID (PLA)

7.3.1.3 NYLON

7.3.1.4 PHOTOPOLYMERS

7.3.1.5 OTHERS

7.3.2 OTHERS, BY MATERIAL TYPE

7.3.2.1 POLYPROPYLENE

7.3.2.2 HIGH DENSITY POLYETHYLENE

7.3.2.3 POLYCARBONATE

7.3.2.4 POLYVINYL ALCOHOL

7.4 ALLOYS

7.4.1 ALLOYS, BY MATERIAL TYPE

7.4.1.1 TOOL STEELS AND MARAGING STEELS

7.4.1.2 COMMERCIALLY PURE TITANIUM AND ALLOYS

7.4.1.3 ALUMINUM ALLOYS

7.4.1.4 NICKEL-BASED ALLOYS

7.4.1.5 COBALT-CHROMIUM ALLOYS

7.4.1.6 COPPER-BASED ALLOYS

7.5 CERAMICS

7.5.1 CERAMICS, BY MATERIAL TYPE

7.5.1.1 GLASS

7.5.1.2 SILICA

7.5.1.3 QUARTZ

7.5.1.4 OTHERS

8 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY

8.1 OVERVIEW

8.2 STEREOLITHOGRAPHY (SLA)

8.3 FUSED DISPOSITION MODELLING (FDM)

8.4 LASER SINTERING (LS)

8.4.1 LASER SINTERING (LS), BY TECHNOLOGY

8.4.1.1 SELECTIVE LASER MELTING (SLM)

8.4.1.2 SELECTIVE LASER SINTERING (SLS)

8.4.1.3 DIRECT METAL LASER SINTERING

8.5 BINDER JETTING PRINTING

8.6 POLYJET PRINTING

8.7 ELECTRON BEAM MELTING (EBM)

8.8 LAMINATED OBJECT MANUFACTURING (LOM)

8.9 OTHERS

9 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET, BY APPLICATION

9.1 OVERVIEW

9.2 AUTOMOTIVE

9.3 HEALTHCARE

9.4 AEROSPACE

9.5 CONSUMER GOODS

9.6 INDUSTRIAL

9.7 DEFENCE

9.8 ARCHITECTURE

9.9 OTHERS

10 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET, BY REGION

10.1 ASIA PACIFIC

10.1.1 CHINA

10.1.2 JAPAN

10.1.3 INDIA

10.1.4 SOUTH KOREA

10.1.5 SINGAPORE

10.1.6 INDONESIA

10.1.7 THAILAND

10.1.8 HILIPPINES

10.1.9 AUSTRALIA & NEW ZEALAND

10.1.10 MALAYSIA

10.1.11 REST OF ASIA-PACIFIC

11 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET: COMPANY LANDSCAPE

11.1 COMPANY SHARE ANALYSIS: ASIA PACIFIC

11.2 CERTIFICATION

11.3 ACHIEVEMENT

11.4 LAUNCH

11.5 MERGER

12 SWOT ANALYSIS

13 COMPANY PROFILES

13.1 ANSYS, INC

13.1.1 COMPANY SNAPSHOT

13.1.2 REVENUE ANALYSIS

13.1.3 COMPANY SHARE ANALYSIS

13.1.4 PRODUCT PORTFOLIO

13.1.5 RECENT UPDATES

13.2 HÖGANÄS AB

13.2.1 COMPANY SNAPSHOT

13.2.2 COMPANY SHARE ANALYSIS

13.2.3 PRODUCT PORTFOLIO

13.2.4 RECENT UPDATE

13.3 EOS

13.3.1 COMPANY SNAPSHOT

13.3.2 COMPANY SHARE ANALYSIS

13.3.3 PRODUCT PORTFOLIO

13.3.4 RECENT UPDATES

13.4 ARBURG GMBH + CO KG

13.4.1 COMPANY SNAPSHOT

13.4.2 COMPANY SHARE ANALYSIS

13.4.3 PRODUCT PORTFOLIO

13.4.4 RECENT UPDATE

13.5 STRATASYS

13.5.1 COMPANY SNAPSHOT

13.5.2 REVENUE ANALYSIS

13.5.3 COMPANY SHARE ANALYSIS

13.5.4 PRODUCT PORTFOLIO

13.5.5 RECENT UPDATES

13.6 AMERICAN ADDITIVE MANUFACTURING LLC

13.6.1 COMPANY SNAPSHOT

13.6.2 PRODUCT PORTFOLIO

13.6.3 RECENT UPDATE

13.7 ENVISIONTEC US LLC

13.7.1 COMPANY SNAPSHOT

13.7.2 PRODUCT PORTFOLIO

13.7.3 RECENT UPDATE

13.8 EXONE. (A SUBSIDIARY OF DESKTOP METAL, INC.)

13.8.1 COMPANY SNAPSHOT

13.8.2 REVENUE ANALYSIS

13.8.3 PRODUCT PORTFOLIO

13.8.4 RECENT UPDATES

13.9 MATERIALISE

13.9.1 COMPANY SNAPSHOT

13.9.2 REVENUE ANALYSIS

13.9.3 PRODUCT PORTFOLIO

13.9.4 RECENT UPDATES

13.1 MARKFORGED

13.10.1 COMPANY SNAPSHOT

13.10.2 REVENUE ANALYSIS

13.10.3 PRODUCT PORTFOLIO

13.10.4 RECENT UPDATES

13.11 OPTOMEC, INC.

13.11.1 COMPANY SNAPSHOT

13.11.2 PRODUCT PORTFOLIO

13.11.3 RECENT UPDATE

13.12 PROTO LABS

13.12.1 COMPANY SNAPSHOT

13.12.2 REVENUE ANALYSIS

13.12.3 PRODUCT PORTFOLIO

13.12.4 ANNUAL REPORTS, AND SEC FILINGRECENT UPDATES

13.13 RENISHAW PLC.

13.13.1 COMPANY SNAPSHOT

13.13.2 REVENUE ANALYSIS

13.13.3 PRODUCT PORTFOLIO

13.13.4 RECENT UPDATES

13.14 SLM SOLUTIONS

13.14.1 COMPANY SNAPSHOT

13.14.2 REVENUE ANALYSIS

13.14.3 PRODUCT PORTFOLIO

13.14.4 RECENT UPDATES

13.15 TITOMIC LIMITED.

13.15.1 COMPANY SNAPSHOT

13.15.2 REVENUE ANALYSIS

13.15.3 PRODUCT PORTFOLIO

13.15.4 RECENT UPDATES

13.16 ULTIMAKER BV

13.16.1 COMPANY SNAPSHOT

13.16.2 PRODUCT PORTFOLIO

13.16.3 RECENT UPDATE

13.17 YAMAZAKI MAZAK CORPORATION

13.17.1 COMPANY SNAPSHOT

13.17.2 PRODUCT PORTFOLIO

13.17.3 RECENT UPDATES

13.18 3D SYSTEM, INC.

13.18.1 COMPANY SNAPSHOT

13.18.2 REVENUE ANALYSIS

13.18.3 PRODUCT PORTFOLIO

13.18.4 RECENT UPDATES

14 QUESTIONNAIRE

15 RELATED REPORTS

Liste des tableaux

TABLE 1 REGULATORY FRAMEWORK

TABLE 2 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 3 ASIA PACIFIC METAL IN ADDITIVE MANUFACTURING MARKET, BY REGION, 2021-2030 (USD MILLION)

TABLE 4 ASIA PACIFIC METAL IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 5 ASIA PACIFIC PLASTIC IN ADDITIVE MANUFACTURING MARKET, BY REGION, 2021-2030 (USD MILLION)

TABLE 6 ASIA PACIFIC PLASTIC IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 7 ASIA PACIFIC OTHERS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 8 ASIA PACIFIC ALLOYS IN ADDITIVE MANUFACTURING MARKET, BY REGION, 2021-2030 (USD MILLION)

TABLE 9 ASIA PACIFIC ALLOYS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 10 ASIA PACIFIC CERAMICS IN ADDITIVE MANUFACTURING MARKET, BY REGION, 2021-2030 (USD MILLION)

TABLE 11 ASIA PACIFIC CERAMICS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 12 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 13 ASIA PACIFIC STEREOLITHOGRAPHY (SLA) IN ADDITIVE MANUFACTURING MARKET, BY REGION, 2021-2030 (USD MILLION)

TABLE 14 ASIA PACIFIC FUSED DISPOSITION MODELLING (FDM) IN ADDITIVE MANUFACTURING MARKET, BY REGION, 2021-2030 (USD MILLION)

TABLE 15 ASIA PACIFIC LASER SINTERING (LS) IN ADDITIVE MANUFACTURING MARKET, BY REGION, 2021-2030 (USD MILLION)

TABLE 16 ASIA PACIFIC LASER SINTERING (LS) IN ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 17 ASIA PACIFIC BINDER JETTING PRINTING IN ADDITIVE MANUFACTURING MARKET, BY REGION, 2021-2030 (USD MILLION)

TABLE 18 ASIA PACIFIC POLYJET PRINTING IN ADDITIVE MANUFACTURING MARKET, BY REGION, 2021-2030 (USD MILLION)

TABLE 19 ASIA PACIFIC ELECTRON BEAM MELTING (EBM) IN ADDITIVE MANUFACTURING MARKET, BY REGION, 2021-2030 (USD MILLION)

TABLE 20 ASIA PACIFIC LAMINATED OBJECT MANUFACTURING (LOM) IN ADDITIVE MANUFACTURING MARKET, BY REGION, 2021-2030 (USD MILLION)

TABLE 21 ASIA PACIFIC OTHERS IN ADDITIVE MANUFACTURING MARKET, BY REGION, 2021-2030 (USD MILLION)

TABLE 22 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET, BY APPLICATION, 2021-2030 (USD MILLION)

TABLE 23 ASIA PACIFIC AUTOMOTIVE IN ADDITIVE MANUFACTURING MARKET, BY REGION, 2021-2030 (USD MILLION)

TABLE 24 ASIA PACIFIC HEALTHCARE IN ADDITIVE MANUFACTURING MARKET, BY REGION, 2021-2030 (USD MILLION)

TABLE 25 ASIA PACIFIC AEROSPACE IN ADDITIVE MANUFACTURING MARKET, BY REGION, 2021-2030 (USD MILLION)

TABLE 26 ASIA PACIFIC CONSUMER GOODS IN ADDITIVE MANUFACTURING MARKET, BY REGION, 2021-2030 (USD MILLION)

TABLE 27 ASIA PACIFIC INDUSTRIAL IN ADDITIVE MANUFACTURING MARKET, BY REGION, 2021-2030 (USD MILLION)

TABLE 28 ASIA PACIFIC DEFENCE IN ADDITIVE MANUFACTURING MARKET, BY REGION, 2021-2030 (USD MILLION)

TABLE 29 ASIA PACIFIC ARCHITECTURE IN ADDITIVE MANUFACTURING MARKET, BY REGION, 2021-2030 (USD MILLION)

TABLE 30 ASIA PACIFIC OTHERS IN ADDITIVE MANUFACTURING MARKET, BY REGION, 2021-2030 (USD MILLION)

TABLE 31 ASIA-PACIFIC ADDITIVE MANUFACTURING MARKET, BY COUNTRY, 2021-2030 (USD MILLION)

TABLE 32 ASIA-PACIFIC ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 33 ASIA-PACIFIC METAL IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 34 ASIA-PACIFIC PLASTIC IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 35 ASIA-PACIFIC OTHERS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 36 ASIA-PACIFIC ALLOYS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 37 ASIA-PACIFIC CERAMICS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 38 ASIA-PACIFIC ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 39 ASIA-PACIFIC LASER SINTERING (LS) IN ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 40 ASIA-PACIFIC ADDITIVE MANUFACTURING MARKET, BY APPLICATION, 2021-2030 (USD MILLION)

TABLE 41 CHINA ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 42 CHINA METAL IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 43 CHINA PLASTIC IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 44 CHINA OTHERS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 45 CHINA ALLOYS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 46 CHINA CERAMICS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 47 CHINA ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 48 CHINA LASER SINTERING (LS) IN ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 49 CHINA ADDITIVE MANUFACTURING MARKET, BY APPLICATION, 2021-2030 (USD MILLION)

TABLE 50 JAPAN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 51 JAPAN METAL IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 52 JAPAN PLASTIC IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 53 JAPAN OTHERS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 54 JAPAN ALLOYS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 55 JAPAN CERAMICS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 56 JAPAN ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 57 JAPAN LASER SINTERING (LS) IN ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 58 JAPAN ADDITIVE MANUFACTURING MARKET, BY APPLICATION, 2021-2030 (USD MILLION)

TABLE 59 INDIA ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 60 INDIA METAL IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 61 INDIA PLASTIC IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 62 INDIA OTHERS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 63 INDIA ALLOYS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 64 INDIA CERAMICS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 65 INDIA ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 66 INDIA LASER SINTERING (LS) IN ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 67 INDIA ADDITIVE MANUFACTURING MARKET, BY APPLICATION, 2021-2030 (USD MILLION)

TABLE 68 SOUTH KOREA ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 69 SOUTH KOREA METAL IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 70 SOUTH KOREA PLASTIC IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 71 SOUTH KOREA OTHERS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 72 SOUTH KOREA ALLOYS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 73 SOUTH KOREA CERAMICS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 74 SOUTH KOREA ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 75 SOUTH KOREA LASER SINTERING (LS) IN ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 76 SOUTH KOREA ADDITIVE MANUFACTURING MARKET, BY APPLICATION, 2021-2030 (USD MILLION)

TABLE 77 SINGAPORE ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 78 SINGAPORE METAL IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 79 SINGAPORE PLASTIC IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 80 SINGAPORE OTHERS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 81 SINGAPORE ALLOYS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 82 SINGAPORE CERAMICS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 83 SINGAPORE ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 84 SINGAPORE LASER SINTERING (LS) IN ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 85 SINGAPORE ADDITIVE MANUFACTURING MARKET, BY APPLICATION, 2021-2030 (USD MILLION)

TABLE 86 INDONESIA ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 87 INDONESIA METAL IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 88 INDONESIA PLASTIC IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 89 INDONESIA OTHERS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 90 INDONESIA ALLOYS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 91 INDONESIA CERAMICS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 92 INDONESIA ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 93 INDONESIA LASER SINTERING (LS) IN ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 94 INDONESIA ADDITIVE MANUFACTURING MARKET, BY APPLICATION, 2021-2030 (USD MILLION)

TABLE 95 THAILAND ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 96 THAILAND METAL IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 97 THAILAND PLASTIC IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 98 THAILAND OTHERS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 99 THAILAND ALLOYS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 100 THAILAND CERAMICS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 101 THAILAND ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 102 THAILAND LASER SINTERING (LS) IN ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 103 THAILAND ADDITIVE MANUFACTURING MARKET, BY APPLICATION, 2021-2030 (USD MILLION)

TABLE 104 PHILIPPINES ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 105 PHILIPPINES METAL IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 106 PHILIPPINES PLASTIC IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 107 PHILIPPINES OTHERS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 108 PHILIPPINES ALLOYS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 109 PHILIPPINES CERAMICS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 110 PHILIPPINES ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 111 PHILIPPINES LASER SINTERING (LS) IN ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 112 PHILIPPINES ADDITIVE MANUFACTURING MARKET, BY APPLICATION, 2021-2030 (USD MILLION)

TABLE 113 AUSTRALIA & NEW ZEALAND ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 114 AUSTRALIA & NEW ZEALAND METAL IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 115 AUSTRALIA & NEW ZEALAND PLASTIC IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 116 AUSTRALIA & NEW ZEALAND OTHERS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 117 AUSTRALIA & NEW ZEALAND ALLOYS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 118 AUSTRALIA & NEW ZEALAND CERAMICS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 119 AUSTRALIA & NEW ZEALAND ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 120 AUSTRALIA & NEW ZEALAND LASER SINTERING (LS) IN ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 121 AUSTRALIA & NEW ZEALAND ADDITIVE MANUFACTURING MARKET, BY APPLICATION, 2021-2030 (USD MILLION)

TABLE 122 MALAYSIA ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 123 MALAYSIA METAL IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 124 MALAYSIA PLASTIC IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 125 MALAYSIA OTHERS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 126 MALAYSIA ALLOYS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 127 MALAYSIA CERAMICS IN ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

TABLE 128 MALAYSIA ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 129 MALAYSIA LASER SINTERING (LS) IN ADDITIVE MANUFACTURING MARKET, BY TECHNOLOGY, 2021-2030 (USD MILLION)

TABLE 130 MALAYSIA ADDITIVE MANUFACTURING MARKET, BY APPLICATION, 2021-2030 (USD MILLION)

TABLE 131 REST OF ASIA-PACIFIC ADDITIVE MANUFACTURING MARKET, BY MATERIAL TYPE, 2021-2030 (USD MILLION)

Liste des figures

FIGURE 1 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET

FIGURE 2 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET: DATA TRIANGULATION

FIGURE 3 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET: DROC ANALYSIS

FIGURE 4 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET: ASIA PACIFIC VS REGIONAL MARKET ANALYSIS

FIGURE 5 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET: COMPANY RESEARCH ANALYSIS

FIGURE 6 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET: THE TYPE LIFE LINE CURVE

FIGURE 7 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET: MULTIVARIATE MODELLING

FIGURE 8 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET: INTERVIEW DEMOGRAPHICS

FIGURE 9 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET: DBMR MARKET POSITION GRID

FIGURE 10 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET: MARKET END-USER COVERAGE GRID

FIGURE 11 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET: THE MARKET CHALLENGE MATRIX

FIGURE 12 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET: VENDOR SHARE ANALYSIS

FIGURE 13 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET: SEGMENTATION

FIGURE 14 INCREASING DEMAND FOR LIGHTWEIGHT COMPONENTS FROM THE AUTOMOTIVE AND AEROSPACE INDUSTRIES IS EXPECTED TO DRIVE THE ASIA PACIFIC ADDITIVE MANUFACTURING MARKET IN THE FORECAST PERIOD

FIGURE 15 THE METAL SEGMENT IS EXPECTED TO ACCOUNT FOR THE LARGEST SHARE OF THE ASIA PACIFIC ADDITIVE MANUFACTURING MARKET IN 2022 & 2029

FIGURE 16 DRIVERS, RESTRAINTS, OPPORTUNITIES, AND CHALLENGES OF THE ASIA PACIFIC ADDITIVE MANUFACTURING MARKET

FIGURE 17 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET: BY MATERIAL TYPE, 2022

FIGURE 18 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET: BY TECHNOLOGY, 2022

FIGURE 19 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET: BY APPLICATION, 2022

FIGURE 20 ASIA-PACIFIC ADDITIVE MANUFACTURING MARKET: SNAPSHOT (2022)

FIGURE 21 ASIA-PACIFIC ADDITIVE MANUFACTURING MARKET: BY COUNTRY (2022)

FIGURE 22 ASIA-PACIFIC ADDITIVE MANUFACTURING MARKET: BY COUNTRY (2023 & 2030)

FIGURE 23 ASIA-PACIFIC ADDITIVE MANUFACTURING MARKET: BY COUNTRY (2022 & 2030)

FIGURE 24 ASIA-PACIFIC ADDITIVE MANUFACTURING MARKET: BY MATERIAL TYPE (2023-2030)

FIGURE 25 ASIA PACIFIC ADDITIVE MANUFACTURING MARKET: COMPANY SHARE 2022 (%)

Méthodologie de recherche

La collecte de données et l'analyse de l'année de base sont effectuées à l'aide de modules de collecte de données avec des échantillons de grande taille. L'étape consiste à obtenir des informations sur le marché ou des données connexes via diverses sources et stratégies. Elle comprend l'examen et la planification à l'avance de toutes les données acquises dans le passé. Elle englobe également l'examen des incohérences d'informations observées dans différentes sources d'informations. Les données de marché sont analysées et estimées à l'aide de modèles statistiques et cohérents de marché. De plus, l'analyse des parts de marché et l'analyse des tendances clés sont les principaux facteurs de succès du rapport de marché. Pour en savoir plus, veuillez demander un appel d'analyste ou déposer votre demande.

La méthodologie de recherche clé utilisée par l'équipe de recherche DBMR est la triangulation des données qui implique l'exploration de données, l'analyse de l'impact des variables de données sur le marché et la validation primaire (expert du secteur). Les modèles de données incluent la grille de positionnement des fournisseurs, l'analyse de la chronologie du marché, l'aperçu et le guide du marché, la grille de positionnement des entreprises, l'analyse des brevets, l'analyse des prix, l'analyse des parts de marché des entreprises, les normes de mesure, l'analyse globale par rapport à l'analyse régionale et des parts des fournisseurs. Pour en savoir plus sur la méthodologie de recherche, envoyez une demande pour parler à nos experts du secteur.

Personnalisation disponible

Data Bridge Market Research est un leader de la recherche formative avancée. Nous sommes fiers de fournir à nos clients existants et nouveaux des données et des analyses qui correspondent à leurs objectifs. Le rapport peut être personnalisé pour inclure une analyse des tendances des prix des marques cibles, une compréhension du marché pour d'autres pays (demandez la liste des pays), des données sur les résultats des essais cliniques, une revue de la littérature, une analyse du marché des produits remis à neuf et de la base de produits. L'analyse du marché des concurrents cibles peut être analysée à partir d'une analyse basée sur la technologie jusqu'à des stratégies de portefeuille de marché. Nous pouvons ajouter autant de concurrents que vous le souhaitez, dans le format et le style de données que vous recherchez. Notre équipe d'analystes peut également vous fournir des données sous forme de fichiers Excel bruts, de tableaux croisés dynamiques (Fact book) ou peut vous aider à créer des présentations à partir des ensembles de données disponibles dans le rapport.