Les centrifugeuses industrielles jouent un rôle crucial dans la séparation des systèmes triphasés et trouvent des applications dans diverses industries. Ils sont utilisés dans le traitement chimique pour séparer les liquides et les solides, la transformation des aliments pour la clarification et la purification, le traitement minier et minéral pour la concentration du minerai, les industries des carburants et des biocarburants pour la séparation des impuretés, le traitement des eaux usées pour la séparation solide-liquide et les industries des pâtes et papiers pour la fibre. récupération. Ces machines polyvalentes permettent des processus de séparation efficaces et précis, contribuant à améliorer la qualité des produits et l'efficacité des processus dans divers secteurs industriels.

Accéder au rapport complet @ https://www.databridgemarketresearch.com/reports/global-industrial-centrifuges-market

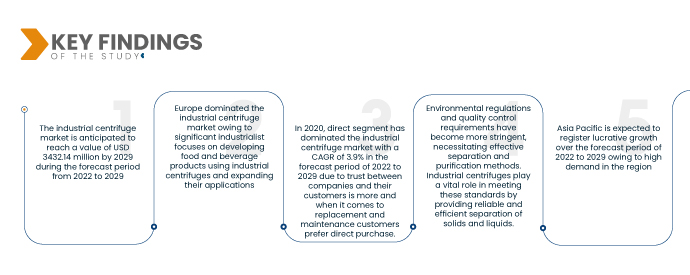

Data Bridge Market Research analyse que le Marché des centrifugeuses industrielles était évalué à 2 395,03 millions USD en 2021 et devrait atteindre la valeur de 3 432,14 millions USD d'ici 2029, avec un TCAC de 4,6% au cours de la période de prévision de 2022 à 2029. Alors que les activités industrielles continuent de se développer dans divers secteurs tels que les produits pharmaceutiques, Dans les domaines de la biotechnologie, de la transformation chimique, de l'alimentation et des boissons et du traitement des eaux usées, le besoin de processus efficaces de séparation et de filtration fournis par des centrifugeuses industrielles augmente.

Principales conclusions de l'étude

Les progrès technologiques devraient stimuler le taux de croissance du marché

Les progrès technologiques dans la technologie des centrifugeuses industrielles ont conduit à des améliorations notables en termes d’efficacité, d’automatisation et de facilité d’utilisation. Ces progrès ont considérablement amélioré les performances globales des centrifugeuses industrielles, les rendant plus attrayantes pour un large éventail d’industries. Avec une efficacité accrue, des fonctionnalités automatisées et des interfaces conviviales, les centrifugeuses industrielles offrent une productivité améliorée, des exigences de main-d'œuvre réduites et des opérations rationalisées, ce qui en fait un atout précieux pour diverses applications industrielles.

Portée du rapport et segmentation du marché

|

Mesure du rapport

|

Détails

|

|

Période de prévision

|

2022 à 2029

|

|

Année de référence

|

2021

|

|

Années historiques

|

2020 (personnalisable jusqu'en 2014-2019)

|

|

Unités quantitatives

|

Chiffre d'affaires en millions USD, volumes en unités, prix en USD

|

|

Segments couverts

|

Type d'équipement (centrifugeuse à sédimentation, centrifugeuse à filtrage), mode de fonctionnement (centrifugeuse par lots, centrifugeuse continue), conception (centrifugeuse horizontale, centrifugeuse verticale), utilisateur final (industrie alimentaire et des boissons, industrie pharmaceutique, industrie biotechnologique), canal de distribution (direct, indirect )

|

|

Pays couverts

|

États-Unis, Canada et Mexique en Amérique du Nord, Allemagne, Suède, Pologne, Danemark, France, Royaume-Uni, Pays-Bas, Suisse, Belgique, Russie, Italie, Espagne, Turquie, Reste de l'Europe en Europe, Chine, Japon, Inde, Corée du Sud, Singapour, Malaisie, Australie, Thaïlande, Indonésie, Philippines, Reste de l'Asie-Pacifique (APAC), Arabie Saoudite, Émirats arabes unis, Afrique du Sud, Égypte, Israël, Reste du Moyen-Orient et de l'Afrique (MEA) dans le cadre du Moyen-Orient et de l'Afrique (MEA), du Brésil, de l'Argentine et du reste de l'Amérique du Sud dans le cadre de l'Amérique du Sud.

|

|

Acteurs du marché couverts

|

ANDRITZ (Autriche), ALFA LAVAL (Suède), GEA Group Aktiengesellschaft (Allemagne), Mitsubishi Kakoki Kaisha, Ltd. (Japon), Thomas Broadbent & Sons Ltd (Royaume-Uni), FLSmidth (Danemark), Schlumberger Limited (États-Unis), Ferrum Ltd . (Suisse), Flottweg SE (Allemagne), SIEBTECHNIK TEMA GmbH (Allemagne), HEINKEL Process Technology GmbH (Allemagne), Gruppo Pieralisi - MAIP SpA (Italie), SPX Flow Inc. (États-Unis), HAUS Centrifuge Technologies (Turquie), Elgin Power and Separation Solutions (États-Unis), Dedert Corporation (États-Unis), US Centrifuge Systems (États-Unis), B&P Littleford (États-Unis)

|

|

Points de données couverts dans le rapport

|

En plus des informations sur les scénarios de marché tels que la valeur du marché, le taux de croissance, la segmentation, la couverture géographique et les principaux acteurs, les rapports de marché organisés par Data Bridge Market Research comprennent également une analyse approfondie d'experts, une production géographiquement représentée par l'entreprise et capacité, configuration du réseau de distributeurs et de partenaires, analyse détaillée et mise à jour des tendances des prix et analyse des déficits de la chaîne d'approvisionnement et de la demande.

|

Analyse sectorielle :

Le marché des centrifugeuses industrielles est segmenté en fonction du type d’équipement, du mode de fonctionnement, de la conception, de l’utilisateur final et du canal de distribution.

- Sur la base du type d’équipement, le marché des centrifugeuses industrielles est segmenté en centrifugeuse à sédimentation et centrifugeuse à filtrage. Le segment des centrifugeuses à sédimentation a dominé le marché des centrifugeuses industrielles avec un TCAC de 3,6 % au cours de la période de prévision de 2022 à 2029 en raison de l’énorme demande de décanteurs pour le processus de séparation dans diverses industries.

- Sur la base du mode de fonctionnement, le marché des centrifugeuses industrielles est segmenté en centrifugeuse par lots et centrifugeuse continue. Le segment des centrifugeuses continues a dominé le marché des centrifugeuses industrielles avec un TCAC de 3,2 % au cours de la période de prévision de 2022 à 2029 en raison du fait que les centrifugeuses continues fonctionnent en mode continu car les centrifugeuses continues fonctionnent en mode continu et ne nécessitent pas de processus par lots.

En 2022, le segment des centrifugeuses continues devrait dominer le segment des modes de fonctionnement du marché des centrifugeuses industrielles.

En 2022, le segment des centrifugeuses continues domine le marché des centrifugeuses industrielles en raison de facteurs tels que les centrifugeuses continues fonctionnent en mode continu et ne nécessitent pas de processus par lots, ce qui prend plus de temps avec un TCAC de 3,2 % au cours de la période de prévision de 2022 à 2029.

- Sur la base de la conception, le marché des centrifugeuses industrielles est segmenté en centrifugeuse horizontale et centrifugeuse verticale. Le segment des centrifugeuses verticales a dominé le marché des centrifugeuses industrielles avec un TCAC de 4,3 % au cours de la période de prévision de 2022 à 2029 en raison de facteurs selon lesquels elles sont utilisées de manière coûteuse pour la filtration de produits liquides tels que les boissons et consomment moins d’énergie que les centrifugeuses horizontales.

- Sur la base de l’utilisateur final, le marché des centrifugeuses industrielles est segmenté en industrie alimentaire et des boissons et industrie pharmaceutique et biotechnologique. Le segment de l’industrie des aliments et des boissons a dominé le marché des centrifugeuses industrielles avec une croissance de 4,3 % au cours de la période de prévision de 2022 à 2029 en raison de la forte demande des consommateurs.

En 2022, le segment de l’industrie agroalimentaire devrait dominer le segment des utilisateurs finaux sur le marché des centrifugeuses industrielles.

En 2022, le segment de l'industrie alimentaire et des boissons domine les centrifugeuses industrielles en raison de la forte demande des consommateurs et la demande de centrifugeuses dans l'industrie alimentaire et des boissons concerne davantage diverses applications avec un TCAC de 4,3 % au cours de la période de prévision de 2022 à 2029.

- Sur la base du canal de distribution, le marché des centrifugeuses industrielles est segmenté en direct et indirect. Le segment direct a dominé le marché des centrifugeuses industrielles avec un TCAC de 3,9 % au cours de la période de prévision de 2022 à 2029 en raison de la confiance accrue entre les entreprises et leurs clients et lorsqu'il s'agit de remplacement et de maintenance, les clients préfèrent l'achat direct.

Acteurs majeurs

Data Bridge Market Research reconnaît les sociétés suivantes comme les principaux acteurs du marché des centrifugeuses industrielles : ANDRITZ (Autriche), ALFA LAVAL (Suède), GEA Group Aktiengesellschaft (Allemagne), Mitsubishi Kakoki Kaisha, Ltd. (Japon), Thomas Broadbent. and Sons Ltd (Royaume-Uni), FLSmidth (Danemark), Schlumberger Limited (États-Unis), Ferrum Ltd. (Suisse), Flottweg SE (Allemagne), SIEBTECHNIK TEMA GmbH (Allemagne).

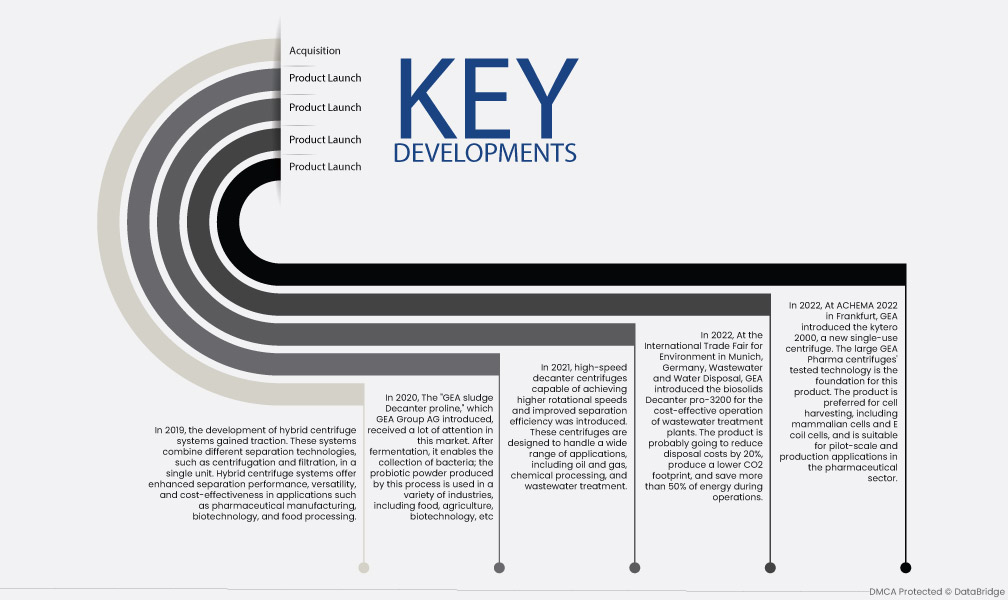

Développement du marché

- En 2022, lors du salon ACHEMA 2022 à Francfort, GEA a présenté la kytero 2000, une nouvelle centrifugeuse à usage unique. La technologie éprouvée des grandes centrifugeuses GEA Pharma constitue la base de ce produit. Le produit est préféré pour la récolte de cellules, y compris les cellules de mammifères et les cellules E coil, et convient aux applications à l'échelle pilote et de production dans le secteur pharmaceutique.

- En 2022, lors du salon international de l'environnement de Munich, en Allemagne, consacré aux eaux usées et à l'élimination des eaux usées, GEA a présenté le décanteur de biosolides pro-3200 pour le fonctionnement rentable des usines de traitement des eaux usées. Le produit va probablement réduire les coûts d'élimination de 20 %, produire une empreinte CO2 plus faible et économiser plus de 50 % d'énergie pendant les opérations.

- En 2021, les fabricants ont introduit des décanteurs centrifuges à grande vitesse capables d’atteindre des vitesses de rotation plus élevées et une efficacité de séparation améliorée. Ces centrifugeuses sont conçues pour gérer un large éventail d'applications, notamment le pétrole et le gaz, le traitement chimique et le traitement des eaux usées.

- En 2020, le « GEA sludge Decanter proline », introduit par GEA Group AG, a reçu beaucoup d'attention sur ce marché. Après fermentation, il permet la collecte de bactéries ; la poudre probiotique produite par ce procédé est utilisée dans diverses industries, notamment l'alimentation, l'agriculture, la biotechnologie, etc.

- En 2019, le développement de systèmes de centrifugation hybrides a pris de l’ampleur. Ces systèmes combinent différentes technologies de séparation, telles que la centrifugation et la filtration, dans une seule unité. Les systèmes de centrifugation hybrides offrent des performances de séparation, une polyvalence et une rentabilité améliorées dans des applications telles que la fabrication pharmaceutique, la biotechnologie et la transformation alimentaire.

Analyse régionale

Géographiquement, les pays couverts dans le rapport sur le marché des centrifugeuses industrielles sont les États-Unis, le CANADA ET LE MEXIQUE EN AMÉRIQUE DU NORD, L'ALLEMAGNE, la Suède, la Pologne, le Danemark, la France, le Royaume-Uni, les Pays-Bas, la Suisse, la Belgique, la Russie, l'Italie, l'Espagne, la Turquie et le reste de l'Europe. en Europe, Chine, Japon, Inde, Corée du Sud, Singapour, Malaisie, Australie, Thaïlande, Indonésie, Philippines, Reste de l'Asie-Pacifique (APAC) en Asie-Pacifique (APAC), Arabie Saoudite, Émirats Arabes Unis, Afrique du Sud, Égypte , Israël, le reste du Moyen-Orient et l'Afrique (MEA) dans le cadre du Moyen-Orient et de l'Afrique (MEA), le Brésil, l'Argentine et le reste de l'Amérique du Sud dans le cadre de l'Amérique du Sud.

Selon l’analyse de l’étude de marché Data Bridge :

L’Europe est la région dominante marché des centrifugeuses industrielles pendant la période de prévision 2022-2029

L'Europe domine le marché en raison de la forte concentration du pays sur le développement de produits alimentaires et de boissons utilisant des centrifugeuses industrielles et sur l'expansion de leurs applications. En mettant l'accent sur des processus efficaces de séparation et de purification, les industriels allemands tirent parti de la technologie des centrifugeuses pour améliorer la qualité des produits, améliorer l'efficacité de la production et répondre à des normes réglementaires strictes, stimulant ainsi la croissance du marché dans le pays.

On estime que l’Asie-Pacifique est la région à la croissance la plus rapide sur le marché des centrifugeuses industrielles la période de prévision 2022-2029

La Chine devrait connaître une croissance significative sur le marché des centrifugeuses industrielles en Asie-Pacifique de 2022 à 2029, alimentée par une concentration croissante sur la fabrication de centrifugeuses industrielles pour répondre à la forte demande dans la région. En outre, la demande croissante de centrifugeuses industrielles dans diverses industries de la région. Alors que les industries donnent la priorité à la fabrication de centrifugeuses industrielles, la Chine est en mesure de bénéficier de la demande croissante, en offrant des capacités de fabrication compétitives et en répondant aux besoins des industries à la recherche de solutions efficaces de séparation et de filtration, ce qui entraînera une expansion substantielle du marché dans le pays.

Pour des informations plus détaillées sur le rapport sur le marché des centrifugeuses industrielles, cliquez ici –https://www.databridgemarketresearch.com/reports/global-industrial-centrifuges-market