North America Machine Control System Market, By Technology (Global Navigation Satellite System (GNSS), Laser Scanners, GIS Collectors, Total Stations, Airborne Systems, and Others), Vehicle Equipment (Excavators, Loaders, Dozers, Scrapers, Graders, Rollers, Drillers and Pillars, Pavers and Cold Planers, and Others), Controller Type (Computer Numerical Control (CNC), Programmable Logic Controller (PLC), Programmable Automation Controller (PAC), Personal Computer (PC), Motion Controllers, and Others), Application (Motion and Control, Guidance and Automation, Mass Excavation, Spot-Bulldozing, and Others), Industry (Building and Construction, Agriculture, Mining, Transportation, Aerospace and Defense, Automotive, Marine, Waste Management, Utilities, and Others) Industry Trends and Forecast to 2029.

North America Machine Control System Market Analysis and Size

Manufacturers were continuously trying to increase the precision of work, enhance services, safety, and work with growing technology. The requirement for these reasons is being fulfilled by implementing the machine control system as they are used to provide enhanced, uninterrupted, free, and timely services at the industrial operations. The machine control system in various industries is being used widely due to the rising adoption of digital technologies in the industrial sector. It enables industries to enhance their operations and productivity. Machine control systems help end-users make better decisions around supply chain, machinery, assets performance, drilling, and others. The North America machine control system market is growing rapidly due to increasing digitization in various industries, which drives the demand for the machine control system. The companies are even launching new products to gain a larger market share.

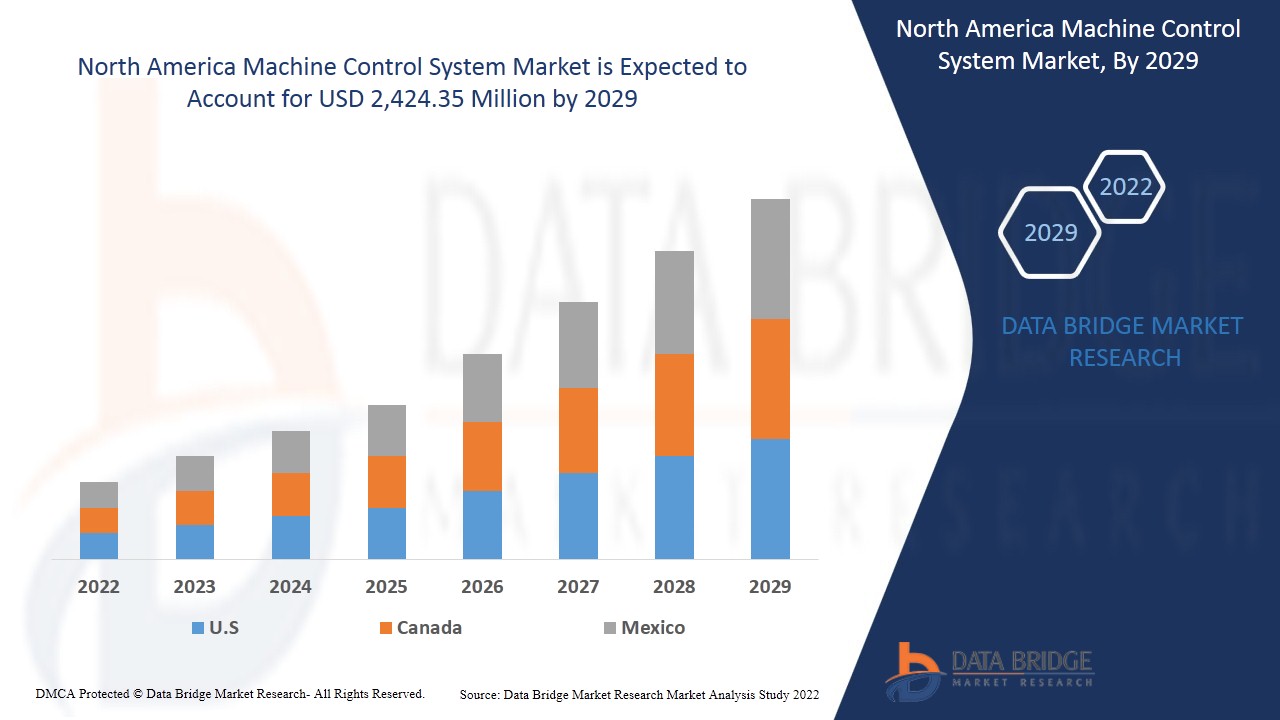

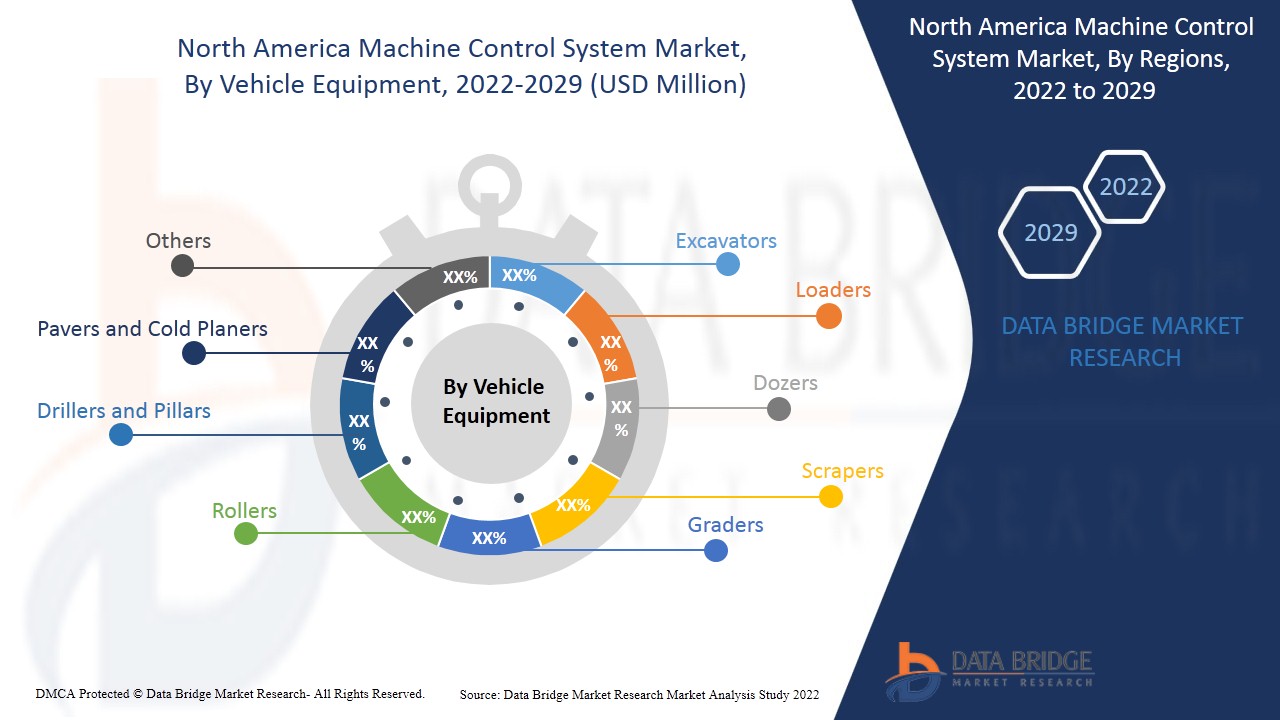

Data Bridge Market Research analyses that the North America machine control system market is expected to reach the value of USD 2,424.35 million by 2029, at a CAGR of 7.5% during the forecast period. Excavators are expected to dominate the North America machine control system market due to the capability of sensing the precise location of an excavator at all times relative to its environment, also helping the operator dig in the right spot.

North America Machine Control System Market Definition

El sistema de control de máquinas se refiere a la realización de actividades industriales y comerciales con un toque digital. Incluye varias soluciones y servicios que se desarrollan para optimizar y gestionar operaciones industriales, de infraestructura y actividades de producción. Ayuda a automatizar varias actividades basadas en aplicaciones, como la gestión de registros, el almacenamiento de datos, la supervisión, la racionalización de las actividades de producción, la gestión de la cadena de suministro, la gestión de activos, la gestión de riesgos y otras. También incluye tecnologías como sistemas de control de plantas, tecnologías GPS, banda ancha móvil, transporte automatizado, IA, blockchain, gemelo digital y otras.

|

Métrica del informe |

Detalles |

|

Período de pronóstico |

2022 a 2029 |

|

Año base |

2021 |

|

Años históricos |

2020 |

|

Unidades cuantitativas |

Ingresos en millones de USD, volúmenes en unidades, precios en USD |

|

Segmentos cubiertos |

Por tecnología (Sistema global de navegación por satélite (GNSS), escáneres láser, colectores GIS, estaciones totales, sistemas aerotransportados y otros), equipo del vehículo (excavadoras, cargadoras, topadoras, motoniveladoras, rodillos, perforadoras y pilares, pavimentadoras y perfiladoras en frío y otros), tipo de controlador (control numérico por computadora (CNC), controlador lógico programable (PLC), controlador de automatización programable (PAC), computadora personal (PC), controladores de movimiento y otros), aplicación (movimiento y control, guía y automatización, excavación masiva, bulldozing puntual y otros), industria (construcción, agricultura, minería, transporte, aeroespacial y defensa, automotriz, marina, gestión de residuos, servicios públicos y otros) |

|

Países cubiertos |

Estados Unidos, Canadá y México |

|

Actores del mercado cubiertos |

ABB, Topcon, Eos Positioning Systems, Inc. (Eos), maximatecc, Kobelco Construction Machinery Co., Ltd., SATEL, Trimble Inc., Hemisphere GNSS, Inc., MOBA MOBILE AUTOMATION AG, Belden Inc., Hexagon, RIB Group, James Fisher and Sons plc, Carlson Software, Challenger Geomatics Ltd., LIEBHERR, Schneider Electric, MITSUI & CO., LTD., Rockwell Automation, Inc., Komatsu Ltd., Coperion GmbH, Otto Bihler Maschinenfabrik GmbH & Co. KG, OMRON Corporation, ANDRITZ, Siemens, Honeywell International Inc., Machine Control Systems, entre otros. |

Dinámica del mercado de sistemas de control de maquinaria en América del Norte

En esta sección se aborda la comprensión de los factores impulsores, las ventajas, las oportunidades, las limitaciones y los desafíos del mercado. Todo esto se analiza en detalle a continuación:

- Necesidad creciente de precisión y exactitud en los sistemas de control

Las soluciones de control de máquinas aumentan la calidad del lugar de trabajo al simplificar, automatizar e integrar soluciones, lo que da como resultado menos errores y más tiempo en el trabajo. Las soluciones de control de máquinas permiten a los operadores adquirir conocimientos digitales y, al mismo tiempo, reducir el riesgo de cometer errores. Las interfaces gráficas 3D intuitivas con un diseño personalizado ayudan a los operadores a sentirse más seguros de su capacidad para realizar trabajos, lo que mejora el rendimiento.

- Aumento del crecimiento de los sistemas de control de máquinas inalámbricos

Es bien sabido que la población de América del Norte está aumentando a un ritmo sin precedentes. Las empresas están invirtiendo mucho en tecnología inalámbrica para ofrecer soluciones óptimas para los usuarios finales y los profesionales; a medida que la industria evoluciona, el enfoque aumentará en los equipos inalámbricos para lograr un mejor rendimiento y flexibilidad para trabajar. Se espera que el desarrollo de estas baterías inalámbricas equipadas con sistemas de control de máquinas impulse el mercado de sistemas de control de máquinas.

- Demanda creciente de tecnologías guiadas por máquinas en los países emergentes

La automatización y la inteligencia artificial (IA) están alterando las industrias e impulsarán la productividad, lo que resultará en un mayor desarrollo económico. En todo el mundo, la digitalización está ayudando a mejorar la seguridad, la productividad, la accesibilidad y la sostenibilidad de los sistemas energéticos. El sector de la construcción es fundamental para el desarrollo económico de los países emergentes. Como resultado, se han formado varias agencias dedicadas en muchos países para monitorear las actividades de construcción y profesionalizar el funcionamiento de los sitios de construcción, como la Junta de Desarrollo de la Industria de la Construcción (EE. UU.), la Junta de Desarrollo de Capital de Illinois (EE. UU.) En el sector de la construcción, se deben utilizar enfoques rentables y eficientes en el tiempo para proporcionar un entorno construido seguro, de alta calidad, sostenible y amigable. Como resultado, los sistemas de control de máquinas desempeñan un papel fundamental para garantizar la seguridad y la calidad en las obras de construcción en las naciones en desarrollo.

Las tecnologías guiadas por máquinas se centran habitualmente en el funcionamiento y el mantenimiento de una máquina o parte de ella. Hoy en día, las actividades de funcionamiento y mantenimiento que se llevan a cabo en una máquina se controlan completamente con la ayuda de diversas tecnologías, como la inteligencia artificial (IA), el aprendizaje automático (ML), etc. La adopción de esta tecnología ha reducido la intervención humana y ha aumentado la necesidad de tecnologías guiadas por máquinas en el mercado, lo que actúa como una oportunidad para el mercado de sistemas de control de máquinas de América del Norte.

- Requisito de inversión inicial elevada

El sistema de control de máquinas ofrece a las industrias precauciones de seguridad y diversos métodos como GNSS, GIS, escaneo láser y robots, entre otros. Las empresas que operan con industrias necesitan sistemas de control de máquinas para transferir materias primas de un lugar a otro. Se requiere un alto costo para la implementación efectiva de equipos de sistemas de control, lo que en última instancia aumenta el costo total de instalación, ya que esto es necesario para garantizar una planta segura. Estos instrumentos implican el manejo de mayores riesgos y entornos operativos críticos. Pero, el costo inicial del sistema es considerablemente alto, y los costos indirectos como licencias, certificación, instalación, costos de energía de mantenimiento y costos relacionados con la mano de obra técnica.

- Diseño de sistemas de control de máquinas ergonómicos y ligeros

Los sistemas de control de las máquinas deben ser de tamaño compacto y ligeros para que se puedan transportar fácilmente y utilizar de forma eficiente. El tamaño compacto permite a los trabajadores realizar una amplia gama de movimientos y aumenta la precisión de los sistemas de control de las máquinas. La herramienta ligera hace que sea más fácil de transportar por el lugar de trabajo. El desafío básico es que los sistemas de control de las máquinas son de construcción pesada; incluso las herramientas eléctricas inalámbricas tienen ranuras para baterías, lo que las hace voluminosas y difíciles de transportar.

Los sistemas de control de las máquinas pueden provocar diversos problemas de salud al usuario. Los sistemas de control de demolición provocan vibraciones elevadas durante su funcionamiento y un ligero movimiento incorrecto por parte del usuario puede romperle la columna vertebral y provocarle graves daños. Las lijadoras y cortadoras pueden producir polvo y piezas pequeñas que podrían dañar al usuario. Se debe dar especial importancia a la ergonomía de los sistemas de control de las máquinas para proteger al usuario de este tipo de accidentes.

Los sistemas de control de máquinas pueden causar graves accidentes y problemas de salud, y su peso tiende a dificultar su funcionamiento con plena eficiencia. Estos factores pueden representar un gran desafío para el mercado de sistemas de control de máquinas de América del Norte.

Impacto posterior al COVID-19 en el mercado de sistemas de control de maquinaria de América del Norte

La COVID-19 ha tenido un gran impacto en el mercado de sistemas de control de máquinas, ya que casi todos los países han optado por cerrar todas las instalaciones de producción, excepto las que se dedican a la producción de bienes esenciales. El gobierno ha tomado algunas medidas estrictas, como el cierre de la producción y la venta de bienes no esenciales, el bloqueo del comercio internacional y muchas más para evitar la propagación de la COVID-19. Las únicas empresas que se enfrentan a esta situación de pandemia son los servicios esenciales a los que se les permite abrir y ejecutar los procesos.

El crecimiento del mercado de sistemas de control de maquinaria en América del Norte se atribuye al aumento de los proyectos de construcción e infraestructura comerciales y residenciales, la adopción de herramientas eléctricas en los hogares para fines residenciales y de bricolaje, el aumento de las instalaciones de fabricación y el aumento de las operaciones de reparación y mantenimiento en todo el mundo. Sin embargo, factores como el aumento de los riesgos de seguridad y las preocupaciones debido al uso inadecuado de los sistemas de control de maquinaria están frenando el crecimiento del mercado. El cierre de las instalaciones de producción durante la pandemia ha tenido un impacto significativo en el mercado.

Los fabricantes están tomando diversas decisiones estratégicas para recuperarse tras la COVID-19. Los actores están llevando a cabo múltiples actividades de investigación y desarrollo para mejorar la tecnología involucrada en el sistema de control de máquinas. Con esto, las empresas traerán controladores avanzados y precisos al mercado. Además, el uso de sistemas de control de máquinas por parte de las autoridades gubernamentales en la gestión del agua, la agricultura, la oceanografía, la hidrología y la defensa y seguridad ha llevado al crecimiento del mercado.

Desarrollo reciente

- En diciembre de 2021, Honeywell International Inc. planeó adquirir US Digital Designs, Inc., ampliando las capacidades de comunicación de seguridad pública. Esta adquisición ha dado como resultado la expansión de la línea de soluciones de la empresa. Esta adquisición ayudó a la empresa a ampliar la cartera de productos y a mejorar los ingresos de la empresa.

Alcance del mercado de sistemas de control de maquinaria en América del Norte

El mercado de sistemas de control de maquinaria de América del Norte está segmentado en función de la tecnología, el equipamiento del vehículo, el tipo de controlador, la aplicación y la industria. El crecimiento entre estos segmentos le ayudará a analizar los segmentos de crecimiento reducido de las industrias y brindará a los usuarios una valiosa descripción general del mercado y conocimientos del mercado para ayudarlos a tomar decisiones estratégicas para identificar las principales aplicaciones del mercado.

Tecnología

- Sistema mundial de navegación por satélite (GNSS)

- Escáneres láser

- Recolectores de SIG

- Estaciones totales

- Sistemas aerotransportados

- Otros

Sobre la base de la tecnología, el mercado de sistemas de control de máquinas de América del Norte está segmentado en sistema global de navegación por satélite (GNSS), escáneres láser, colectores GIS, estaciones totales, sistemas aerotransportados y otros.

Equipamiento del vehículo

- Excavadoras

- Cargadores

- Bulldozers

- Raspadores

- Calificadores

- Rodillos

- Perforadores y pilares

- Pavimentadoras y cepilladoras en frío

- Otros

Sobre la base del equipamiento del vehículo, el mercado de sistemas de control de máquinas de América del Norte se ha segmentado en excavadoras, cargadoras, topadoras, motoniveladoras, rodillos, perforadoras y pilares, pavimentadoras y perfiladoras en frío, entre otros.

Tipo de controlador

- Control numérico por computadora (CNC)

- Controlador lógico programable (PLC)

- Controlador de automatización programable (PAC)

- Computadora personal (PC)

- Controladores de movimiento

- Otros

Sobre la base del tipo de controlador, el mercado de sistemas de control de máquinas de América del Norte se ha segmentado en control numérico por computadora (CNC), controlador lógico programable (PLC), controlador de automatización programable (PAC), computadora personal (PC), controladores de movimiento y otros.

Solicitud

- Movimiento y control

- Orientación y automatización

- Excavación masiva

- Bulldozer localizado

- Otros

Sobre la base de la aplicación, el mercado de sistemas de control de máquinas de América del Norte se ha segmentado en movimiento y control, guía y automatización, excavación masiva, bulldozing localizado y otros.

Industria

- Construcción y edificación

- Agricultura

- Minería

- Transporte

- Aeroespacial y Defensa

- Automotor

- Marina

- Gestión de residuos

- Utilidades

- Otros

Sobre la base de la industria, el mercado de sistemas de control de máquinas de América del Norte se ha segmentado en construcción y edificación, agricultura, minería, transporte, aeroespacial y defensa, automotriz, marino, gestión de residuos, servicios públicos y otros.

Análisis y perspectivas regionales del mercado de sistemas de control de maquinaria de América del Norte

Se analiza el mercado de sistemas de control de máquinas de América del Norte y se proporcionan información y tendencias sobre el tamaño del mercado por país, tecnología, equipo del vehículo, tipo de controlador, aplicación e industria como se menciona anteriormente.

Algunos de los países cubiertos en el informe del mercado de sistemas de control de máquinas de América del Norte son EE. UU., Canadá y México.

The U.S. is likely to dominate the North America machine control system market, this is attributable to the region's building and construction industries, as well as improvements in agricultural techniques. In addition, the use of these systems for highway construction projects has expanded in Canada. The demand in this region is projected to be driven by the increased demand for automation and process instrumentation in construction projects.

The country section of the report also provides individual market impacting factors and changes in market regulation that impact the current and future trends of the market. Data points like down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of North American brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs, and trade routes are considered while providing forecast analysis of the country data.

Competitive Landscape and North America Machine Control System Market Share Analysis

The North America machine control system market competitive landscape provides details by the competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, North America presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width, and breadth, application dominance. The above data points are only related to the companies' focus on the North America machine control system market.

Some of the Major Players Operating in the North America Machine Control System Market are:

- ABB

- Topcon

- Eos Positioning Systems, Inc. (Eos)

- maximatecc

- Kobelco Construction Machinery Co., Ltd.

- SATEL

- Trimble Inc.

- Hemisphere GNSS, Inc.

- MOBA MOBILE AUTOMATION AG

- Belden Inc.

- Hexagon

- RIB Group

- James Fisher and Sons plc

- Carlson Software

- Challenger Geomatics Ltd.

- LIEBHERR

- Schneider Electric

- MITSUI & CO., LTD.

- Rockwell Automation, Inc.

- Komatsu Ltd.

- Coperion GmbH

- Otto Bihler Maschinenfabrik GmbH & Co. KG

- OMRON Corporation

- ANDRITZ

- Siemens

- Honeywell International Inc.

- Machine Control Systems

Research Methodology: North America Machine Control System Market

La recopilación de datos y el análisis del año base se realizan mediante módulos de recopilación de datos con muestras de gran tamaño. Esta etapa incluye la obtención de información de mercado o datos relacionados a través de diversas fuentes y estrategias. Incluye el examen y la planificación de todos los datos adquiridos del pasado con antelación. Asimismo, incluye el examen de las inconsistencias de información observadas en diferentes fuentes de información. Los datos de mercado se analizan y estiman utilizando modelos estadísticos y coherentes de mercado. Además, el análisis de la participación de mercado y el análisis de tendencias clave son los principales factores de éxito en el informe de mercado. Para obtener más información, solicite una llamada de un analista o envíe su consulta.

La metodología de investigación clave que utiliza el equipo de investigación de DBMR es la triangulación de datos, que implica la extracción de datos, el análisis del impacto de las variables de datos en el mercado y la validación primaria (por parte de expertos de la industria). Además de esto, los modelos de datos incluyen una cuadrícula de posicionamiento de proveedores, un análisis de la línea de tiempo del mercado, una descripción general y una guía del mercado, una cuadrícula de posicionamiento de la empresa, un análisis de patentes, un análisis de precios, un análisis de la participación de mercado de la empresa, estándares de medición, análisis de América del Norte frente a la región y de la participación de los proveedores. Para saber más sobre la metodología de investigación, envíe una consulta para hablar con nuestros expertos de la industria.

SKU-

Obtenga acceso en línea al informe sobre la primera nube de inteligencia de mercado del mundo

- Panel de análisis de datos interactivo

- Panel de análisis de empresas para oportunidades con alto potencial de crecimiento

- Acceso de analista de investigación para personalización y consultas

- Análisis de la competencia con panel interactivo

- Últimas noticias, actualizaciones y análisis de tendencias

- Aproveche el poder del análisis de referencia para un seguimiento integral de la competencia

Tabla de contenido

1 INTRODUCTION

1.1 OBJECTIVES OF THE STUDY

1.2 MARKET DEFINITION

1.3 OVERVIEW OF NORTH AMERICA MACHINE CONTROL SYSTEM MARKET

1.4 CURRENCY AND PRICING

1.5 LIMITATIONS

1.6 MARKETS COVERED

2 MARKET SEGMENTATION

2.1 MARKETS COVERED

2.2 GEOGRAPHICAL SCOPE

2.3 YEARS CONSIDERED FOR THE STUDY

2.4 DBMR TRIPOD DATA VALIDATION MODEL

2.5 PRIMARY INTERVIEWS WITH KEY OPINION LEADERS

2.6 DBMR MARKET POSITION GRID

2.7 VENDOR SHARE ANALYSIS

2.8 MULTIVARIATE MODELING

2.9 TECHNOLOGY TIMELINE CURVE

2.1 MARKET APPLICATION COVERAGE GRID

2.11 SECONDARY SOURCES

2.12 ASSUMPTIONS

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

4.1 VALUE CHAIN ANALYSIS

4.1.1 OVERVIEW OF VALUE CHAIN ANALYSIS

4.1.2 VALUE CHAIN ANALYSIS FRAMEWORK

4.2 PESTLE ANALYSIS

4.3 PORTER’S FIVE FORCES MODEL

4.4 EVOLUTION OF MACHINE CONTROL SYSTEM WITH ARTIFICIAL INTELLIGENCE

5 MARKET OVERVIEW

5.1 DRIVERS

5.1.1 RISING NEED FOR ACCURACY AND PRECISION IN CONTROL SYSTEMS

5.1.2 INCREASE IN GROWTH OF CORDLESS MACHINE CONTROL SYSTEMS

5.1.3 INCREASE IN GROWTH OF INFRASTRUCTURE PROJECTS NORTH AMERICALY

5.1.4 EXPANSION OF MOTOR VEHICLE MAINTENANCE MARKET AS VEHICLE OWNERSHIP RATE INCREASES

5.2 RESTRAINTS

5.2.1 REQUIREMENT OF HIGH INITIAL INVESTMENT

5.2.2 FLUCTUATION IN PRICES OF RAW MATERIALS

5.2.3 LACK OF TECHNICAL EXPERTISE

5.3 OPPORTUNITIES

5.3.1 INCREASING DEMAND FOR MACHINE-GUIDED TECHNOLOGIES IN EMERGING NATIONS

5.3.2 SMART CONNECTIVITY IN MACHINE CONTROL SYSTEMS

5.3.3 TECHNOLOGICAL INNOVATIONS IN INDUSTRY 4.0

5.3.4 MACHINE CONTROL SYSTEMS MADE AVAILABLE ON E-COMMERCE PLATFORMS

5.4 CHALLENGES

5.4.1 DESIGNING ERGONOMIC AND LIGHTWEIGHT MACHINE CONTROL SYSTEMS

5.4.2 REGULATORY COMPLIANCE AND MACHINE CONTROL SYSTEM SAFETY

6 IMPACT OF COVID-19 ON THE NORTH AMERICA MACHINE CONTROL SYSTEM MARKET

6.1 ANALYSIS ON IMPACT OF COVID-19 ON THE MARKET

6.2 STRATEGIC DECISION BY MANUFACTURERS AFTER COVID-19

6.3 IMPACT ON PRICE

6.4 IMPACT ON DEMAND AND SUPPLY CHAIN

6.5 CONCLUSION

7 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET, BY TECHNOLOGY

7.1 OVERVIEW

7.2 NORTH AMERICA NAVIGATION SATELLITE SYSTEM (GNSS)

7.3 LASER SCANNERS

7.4 GIS COLLECTORS

7.5 TOTAL STATIONS

7.6 AIRBORNE SYSTEM

7.7 OTHERS

8 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET, BY VEHICLE EQUIPMENT

8.1 OVERVIEW

8.2 EXCAVATORS

8.3 LOADERS

8.4 DOZERS

8.5 SCRAPERS

8.6 GRADERS

8.7 ROLLERS

8.8 DRILLERS AND PILERS

8.9 PAVERS AND COLD PLANERS

8.1 OTHERS

9 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET, BY CONTROLLER TYPE

9.1 OVERVIEW

9.2 PROGRAMMABLE LOGIC CONTROLLER (PLC)

9.3 PROGRAMMABLE AUTOMATION CONTROLLER (PAC)

9.4 MOTION CONTROLLERS

9.5 COMPUTER NUMERICAL CONTROL (CNC)

9.6 PERSONAL COMPUTER (PC)

9.7 OTHERS

10 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET, BY APPLICATION

10.1 OVERVIEW

10.2 MONITORING AND CONTROL

10.3 GUIDANCE AND AUTOMATION

10.4 MASS EXCAVATION

10.5 SPOT-BULLDOZING

10.6 OTHERS

11 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET, BY INDUSTRY

11.1 OVERVIEW

11.2 BUILDING AND CONSTRUCTION

11.2.1 MONITORING AND CONTROL

11.2.2 GUIDANCE AND AUTOMATION

11.2.3 MASS EXCAVATION

11.2.4 SPOT-BULLDOZING

11.2.5 OTHERS

11.3 AGRICULTURE

11.3.1 MONITORING AND CONTROL

11.3.2 GUIDANCE AND AUTOMATION

11.3.3 MASS EXCAVATION

11.3.4 SPOT-BULLDOZING

11.3.5 OTHERS

11.4 MINING

11.4.1 MONITORING AND CONTROL

11.4.2 GUIDANCE AND AUTOMATION

11.4.3 MASS EXCAVATION

11.4.4 SPOT-BULLDOZING

11.4.5 OTHERS

11.5 TRANSPORTATION

11.6 AEROSPACE AND DEFENSE

11.7 AUTOMOTIVE

11.8 MARINE

11.8.1 MONITORING AND CONTROL

11.8.2 GUIDANCE AND AUTOMATION

11.8.3 MASS EXCAVATION

11.8.4 SPOT-BULLDOZING

11.8.5 OTHERS

11.9 WASTE MANAGEMENT

11.9.1 MONITORING AND CONTROL

11.9.2 GUIDANCE AND AUTOMATION

11.9.3 MASS EXCAVATION

11.9.4 SPOT-BULLDOZING

11.9.5 OTHERS

11.1 UTILITIES

11.10.1 MONITORING AND CONTROL

11.10.2 GUIDANCE AND AUTOMATION

11.10.3 MASS EXCAVATION

11.10.4 SPOT-BULLDOZING

11.10.5 OTHERS

11.11 OTHERS

12 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET, BY REGION

12.1 NORTH AMERICA

12.1.1 U.S.

12.1.2 CANADA

12.1.3 MEXICO

13 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET, COMPANY LANDSCAPE

13.1 COMPANY SHARE ANALYSIS: NORTH AMERICA

14 SWOT ANALYSIS

15 COMPANY PROFILE

15.1 MITSUI & CO., LTD.

15.1.1 COMPANY SNAPSHOT

15.1.2 REVENUE ANALYSIS

15.1.3 COMPANY SHARE ANALYSIS

15.1.4 PRODUCT PORTFOLIO

15.1.5 RECENT DEVELOPMENT

15.2 TRIMBLE INC.

15.2.1 COMPANY SNAPSHOT

15.2.2 REVENUE ANALYSIS

15.2.3 COMPANY SHARE ANALYSIS

15.2.4 PRODUCT PORTFOLIO

15.2.5 RECENT DEVELOPMENTS

15.3 ROCKWELL AUTOMATION, INC.

15.3.1 COMPANY SNAPSHOT

15.3.2 REVENUE ANALYSIS

15.3.3 COMPANY SHARE ANALYSIS

15.3.4 PRODUCT PORTFOLIO

15.3.5 RECENT DEVELOPMENTS

15.4 TOPCON

15.4.1 COMPANY SNAPSHOT

15.4.2 REVENUE ANALYSIS

15.4.3 COMPANY SHARE ANALYSIS

15.4.4 PRODUCT PORTFOLIO

15.4.5 RECENT DEVELOPMENTS

15.5 BELDEN INC.

15.5.1 COMPANY SNAPSHOT

15.5.2 REVENUE ANALYSIS

15.5.3 COMPANY SHARE ANALYSIS

15.5.4 PRODUCT PORTFOLIO

15.5.5 RECENT DEVELOPMENT

15.6 ABB

15.6.1 COMPANY SNAPSHOT

15.6.2 REVENUE ANALYSIS

15.6.3 PRODUCT PORTFOLIO

15.6.4 RECENT DEVELOPMENTS

15.7 ANDRITZ

15.7.1 COMPANY SNAPSHOT

15.7.2 REVENUE ANALYSIS

15.7.3 PRODUCT PORTFOLIO

15.7.4 RECENT DEVELOPMENT

15.8 CARLSON SOFTWARE

15.8.1 COMPANY SNAPSHOT

15.8.2 PRODUCT PORTFOLIO

15.8.3 RECENT DEVELOPMENTS

15.9 CHALLENGER GEOMATICS LTD.

15.9.1 COMPANY SNAPSHOT

15.9.2 PRODUCT PORTFOLIO

15.9.3 RECENT DEVELOPMENT

15.1 COPERION GMBH

15.10.1 COMPANY SNAPSHOT

15.10.2 PRODUCT PORTFOLIO

15.10.3 RECENT DEVELOPMENT

15.11 EOS POSITIONING SYSTEMS, INC. (EOS)

15.11.1 COMPANY SNAPSHOT

15.11.2 PRODUCT PORTFOLIO

15.11.3 RECENT DEVELOPMENTS

15.12 HEMISPHERE GNSS, INC.

15.12.1 COMPANY SNAPSHOT

15.12.2 PRODUCT PORTFOLIO

15.12.3 RECENT DEVELOPMENTS

15.13 HEXAGON

15.13.1 COMPANY SNAPSHOT

15.13.2 REVENUE ANALYSIS

15.13.3 PRODUCT PORTFOLIO

15.13.4 RECENT DEVELOPMENT

15.14 HONEYWELL INTERNATIONAL INC.

15.14.1 COMPANY SNAPSHOT

15.14.2 REVENUE ANALYSIS

15.14.3 PRODUCT PORTFOLIO

15.14.4 RECENT DEVELOPMENTS

15.15 JAMES FISHER AND SONS PLC

15.15.1 COMPANY SNAPSHOT

15.15.2 REVENUE ANALYSIS

15.15.3 PRODUCT PORTFOLIO

15.15.4 RECENT DEVELOPMENT

15.16 KOBELCO CONSTRUCTION MACHINERY CO., LTD.

15.16.1 COMPANY SNAPSHOT

15.16.2 PRODUCT PORTFOLIO

15.16.3 RECENT DEVELOPMENTS

15.17 KOMATSU LTD.

15.17.1 COMPANY SNAPSHOT

15.17.2 REVENUE ANALYSIS

15.17.3 PRODUCT PORTFOLIO

15.17.4 RECENT DEVELOPMENTS

15.18 LIEBHERR

15.18.1 COMPANY SNAPSHOT

15.18.2 REVENUE ANALYSIS

15.18.3 PRODUCT PORTFOLIO

15.18.4 RECENT DEVELOPMENT

15.19 L5 NAVIGATION SYSTEMS AB

15.19.1 COMPANY SNAPSHOT

15.19.2 PRODUCT PORTFOLIO

15.19.3 RECENT DEVELOPMENT

15.2 MAXIMATECC

15.20.1 COMPANY SNAPSHOT

15.20.2 PRODUCT PORTFOLIO

15.20.3 RECENT DEVELOPMENTS

15.21 MACHINE CONTROL SYSTEMS

15.21.1 COMPANY SNAPSHOT

15.21.2 PRODUCT PORTFOLIO

15.21.3 RECENT DEVELOPMENT

15.22 MICROVERSE AUTOMATION PVT. LTD.

15.22.1 COMPANY SNAPSHOT

15.22.2 PRODUCT PORTFOLIO

15.22.3 RECENT DEVELOPMENT

15.23 MOBA MOBILE AUTOMATION AG

15.23.1 COMPANY SNAPSHOT

15.23.2 PRODUCT PORTFOLIO

15.23.3 RECENT DEVELOPMENT

15.24 OMRON CORPORATION

15.24.1 COMPANY SNAPSHOT

15.24.2 REVENUE ANALYSIS

15.24.3 PRODUCT PORTFOLIO

15.24.4 RECENT DEVELOPMENT

15.25 OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

15.25.1 COMPANY SNAPSHOT

15.25.2 PRODUCT PORTFOLIO

15.25.3 RECENT DEVELOPMENT

15.26 RAPTORTECH.COM

15.26.1 COMPANY SNAPSHOT

15.26.2 PRODUCT PORTFOLIO

15.26.3 RECENT DEVELOPMENT

15.27 RIB GROUP

15.27.1 COMPANY SNAPSHOT

15.27.2 REVENUE ANALYSIS

15.27.3 PRODUCT PORTFOLIO

15.27.4 RECENT DEVELOPMENT

15.28 SATEL

15.28.1 COMPANY SNAPSHOT

15.28.2 PRODUCT PORTFOLIO

15.28.3 RECENT DEVELOPMENT

15.29 SCHNEIDER ELECTRIC

15.29.1 COMPANY SNAPSHOT

15.29.2 REVENUE ANALYSIS

15.29.3 PRODUCT PORTFOLIO

15.29.4 RECENT DEVELOPMENT

15.3 SIEMENS

15.30.1 COMPANY SNAPSHOT

15.30.2 REVENUE ANALYSIS

15.30.3 PRODUCT PORTFOLIO

15.30.4 RECENT DEVELOPMENTS

16 QUESTIONNAIRE

17 RELATED REPORTS

Lista de Tablas

TABLE 1 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET, BY TECHNOLOGY, 2020-2029 (USD MILLION)

TABLE 2 NORTH AMERICA NAVIGATION SATELLITE SYSTEM (GNSS) IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 3 NORTH AMERICA LASER SCANNERS IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 4 NORTH AMERICA GIS COLLECTORS IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 5 NORTH AMERICA TOTAL STATIONS IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 6 NORTH AMERICA AIRBORNE SYSTEM IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 7 NORTH AMERICA OTHERS IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 8 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET, BY VEHICLE EQUIPMENT, 2020-2029 (USD MILLION)

TABLE 9 NORTH AMERICA EXCAVATORS IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 10 NORTH AMERICA LOADERS IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 11 NORTH AMERICA DOZERS IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 12 NORTH AMERICA SCRAPERS IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 13 NORTH AMERICA GRADERS SYSTEM IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 14 NORTH AMERICA ROLLERS IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 15 NORTH AMERICA DRILLERS AND PILERS IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 16 NORTH AMERICA PAVERS AND COLD PLANERS IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 17 NORTH AMERICA OTHERS IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 18 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET, BY CONTROLLER TYPE, 2020-2029 (USD MILLION)

TABLE 19 NORTH AMERICA PROGRAMMABLE LOGIC CONTROLLER (PLC) IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 20 NORTH AMERICA PROGRAMMABLE AUTOMATION CONTROLLER (PAC) IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 21 NORTH AMERICA MOTION CONTROLLERS IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 22 NORTH AMERICA COMPUTER NUMERICAL CONTROL (CNC) IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 23 NORTH AMERICA PERSONAL COMPUTER (PC) IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 24 NORTH AMERICA OTHERS IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 25 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET, BY APPLICATION, 2020-2029 (USD MILLION)

TABLE 26 NORTH AMERICA MONITORING AND CONTROL IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 27 NORTH AMERICA GUIDANCE AND AUTOMATION IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 28 NORTH AMERICA MASS EXCAVATION IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 29 NORTH AMERICA SPOT-BULLDOZING IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 30 NORTH AMERICA OTHERS IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 31 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET, BY INDUSTRY, 2020-2029 (USD MILLION)

TABLE 32 NORTH AMERICA BUILDING AND CONSTRUCTION IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 33 NORTH AMERICA BUILDING AND CONSTRUCTION IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 34 NORTH AMERICA AGRICULTURE IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 35 NORTH AMERICA AGRICULTURE IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 36 NORTH AMERICA MINING IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 37 NORTH AMERICA MINING IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 38 NORTH AMERICA TRANSPORTATION IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 39 NORTH AMERICA AEROSPACE AND DEFENSE IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 40 NORTH AMERICA AUTOMOTIVE IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 41 NORTH AMERICA MARINE IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 42 NORTH AMERICA MARINE IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 43 NORTH AMERICA WASTE MANAGEMENT IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 44 NORTH AMERICA WASTE MANAGEMENT IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 45 NORTH AMERICA UTILITIES IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 46 NORTH AMERICA UTILITIES IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 47 NORTH AMERICA OTHERS IN MACHINE CONTROL SYSTEM MARKET, BY REGION, 2020-2029 (USD MILLION)

TABLE 48 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET, BY COUNTRY, 2020-2029 (USD MILLION)

TABLE 49 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET, BY TECHNOLOGY, 2020-2029 (USD MILLION)

TABLE 50 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET, BY VEHICLE EQUIPMENT, 2020-2029 (USD MILLION)

TABLE 51 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET, BY CONTROLLER TYPE, 2020-2029 (USD MILLION)

TABLE 52 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET, BY APPLICATION, 2020-2029 (USD MILLION)

TABLE 53 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET, BY INDUSTRY, 2020-2029 (USD MILLION)

TABLE 54 NORTH AMERICA BUILDING AND CONSTRUCTION IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 55 NORTH AMERICA AGRICULTURE IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 56 NORTH AMERICA MINING IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 57 NORTH AMERICA MARINE IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 58 NORTH AMERICA WASTE MANAGEMENT IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 59 NORTH AMERICA UTILITIES IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 60 U.S. MACHINE CONTROL SYSTEM MARKET, BY TECHNOLOGY, 2020-2029 (USD MILLION)

TABLE 61 U.S. MACHINE CONTROL SYSTEM MARKET, BY VEHICLE EQUIPMENT, 2020-2029 (USD MILLION)

TABLE 62 U.S. MACHINE CONTROL SYSTEM MARKET, BY CONTROLLER TYPE, 2020-2029 (USD MILLION)

TABLE 63 U.S. MACHINE CONTROL SYSTEM MARKET, BY APPLICATION, 2020-2029 (USD MILLION)

TABLE 64 U.S. MACHINE CONTROL SYSTEM MARKET, BY INDUSTRY, 2020-2029 (USD MILLION)

TABLE 65 U.S. BUILDING AND CONSTRUCTION IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 66 U.S. AGRICULTURE IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 67 U.S. MINING IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 68 U.S. MARINE IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 69 U.S. WASTE MANAGEMENT IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 70 U.S. UTILITIES IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 71 CANADA MACHINE CONTROL SYSTEM MARKET, BY TECHNOLOGY, 2020-2029 (USD MILLION)

TABLE 72 CANADA MACHINE CONTROL SYSTEM MARKET, BY VEHICLE EQUIPMENT, 2020-2029 (USD MILLION)

TABLE 73 CANADA MACHINE CONTROL SYSTEM MARKET, BY CONTROLLER TYPE, 2020-2029 (USD MILLION)

TABLE 74 CANADA MACHINE CONTROL SYSTEM MARKET, BY APPLICATION, 2020-2029 (USD MILLION)

TABLE 75 CANADA MACHINE CONTROL SYSTEM MARKET, BY INDUSTRY, 2020-2029 (USD MILLION)

TABLE 76 CANADA BUILDING AND CONSTRUCTION IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 77 CANADA AGRICULTURE IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 78 CANADA MINING IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 79 CANADA MARINE IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 80 CANADA WASTE MANAGEMENT IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 81 CANADA UTILITIES IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 82 MEXICO MACHINE CONTROL SYSTEM MARKET, BY TECHNOLOGY, 2020-2029 (USD MILLION)

TABLE 83 MEXICO MACHINE CONTROL SYSTEM MARKET, BY VEHICLE EQUIPMENT, 2020-2029 (USD MILLION)

TABLE 84 MEXICO MACHINE CONTROL SYSTEM MARKET, BY CONTROLLER TYPE, 2020-2029 (USD MILLION)

TABLE 85 MEXICO MACHINE CONTROL SYSTEM MARKET, BY APPLICATION, 2020-2029 (USD MILLION)

TABLE 86 MEXICO MACHINE CONTROL SYSTEM MARKET, BY INDUSTRY, 2020-2029 (USD MILLION)

TABLE 87 MEXICO BUILDING AND CONSTRUCTION IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 88 MEXICO AGRICULTURE IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 89 MEXICO MINING IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 90 MEXICO MARINE IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 91 MEXICO WASTE MANAGEMENT IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

TABLE 92 MEXICO UTILITIES IN MACHINE CONTROL SYSTEM MARKET, BY TYPE, 2020-2029 (USD MILLION)

Lista de figuras

FIGURE 1 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET: SEGMENTATION

FIGURE 2 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET: DATA TRIANGULATION

FIGURE 3 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET: DROC ANALYSIS

FIGURE 4 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET: NORTH AMERICA VS REGIONAL MARKET ANALYSIS

FIGURE 5 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET: COMPANY RESEARCH ANALYSIS

FIGURE 6 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET: INTERVIEW DEMOGRAPHICS

FIGURE 7 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET: DBMR MARKET POSITION GRID

FIGURE 8 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET: VENDOR SHARE ANALYSIS

FIGURE 9 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET: MARKET APPLICATION COVERAGE GRID

FIGURE 10 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET: SEGMENTATION

FIGURE 11 RISING NEED FOR ACCURACY AND PRECISION IN CONTROL SYSTEMS IS EXPECTED TO DRIVE NORTH AMERICA MACHINE CONTROL SYSTEM MARKET IN THE FORECAST PERIOD

FIGURE 12 TECHNOLOGY SEGMENT IS EXPECTED TO ACCOUNT FOR THE LARGEST SHARE OF NORTH AMERICA MACHINE CONTROL SYSTEM MARKET IN 2022 & 2029

FIGURE 13 ASIA-PACIFIC IS EXPECTED TO DOMINATE AND BE THE FASTEST-GROWING REGION IN THE NORTH AMERICA MACHINE CONTROL SYSTEM MARKET IN THE FORECAST PERIOD

FIGURE 14 DRIVERS, RESTRAINTS, OPPORTUNITIES, AND CHALLENGES OF NORTH AMERICA MACHINE CONTROL SYSTEM MARKET

FIGURE 15 REGIONAL SHARE OF NORTH AMERICA INFRASTRUCTURE INVESTMENT

FIGURE 16 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET: BY TECHNOLOGY, 2021

FIGURE 17 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET: BY VEHICLE EQUIPMENT, 2021

FIGURE 18 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET: BY CONTROLLER TYPE, 2021

FIGURE 19 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET: BY APPLICATION, 2021

FIGURE 20 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET: BY INDUSTRY, 2021

FIGURE 21 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET: SNAPSHOT (2021)

FIGURE 22 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET: BY COUNTRY (2021)

FIGURE 23 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET: BY COUNTRY (2022 & 2029)

FIGURE 24 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET: BY COUNTRY (2021 & 2029)

FIGURE 25 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET: BY TECHNOLOGY (2022-2029)

FIGURE 26 NORTH AMERICA MACHINE CONTROL SYSTEM MARKET: COMPANY SHARE 2021 (%)

Metodología de investigación

La recopilación de datos y el análisis del año base se realizan utilizando módulos de recopilación de datos con muestras de gran tamaño. La etapa incluye la obtención de información de mercado o datos relacionados a través de varias fuentes y estrategias. Incluye el examen y la planificación de todos los datos adquiridos del pasado con antelación. Asimismo, abarca el examen de las inconsistencias de información observadas en diferentes fuentes de información. Los datos de mercado se analizan y estiman utilizando modelos estadísticos y coherentes de mercado. Además, el análisis de la participación de mercado y el análisis de tendencias clave son los principales factores de éxito en el informe de mercado. Para obtener más información, solicite una llamada de un analista o envíe su consulta.

La metodología de investigación clave utilizada por el equipo de investigación de DBMR es la triangulación de datos, que implica la extracción de datos, el análisis del impacto de las variables de datos en el mercado y la validación primaria (experto en la industria). Los modelos de datos incluyen cuadrícula de posicionamiento de proveedores, análisis de línea de tiempo de mercado, descripción general y guía del mercado, cuadrícula de posicionamiento de la empresa, análisis de patentes, análisis de precios, análisis de participación de mercado de la empresa, estándares de medición, análisis global versus regional y de participación de proveedores. Para obtener más información sobre la metodología de investigación, envíe una consulta para hablar con nuestros expertos de la industria.

Personalización disponible

Data Bridge Market Research es líder en investigación formativa avanzada. Nos enorgullecemos de brindar servicios a nuestros clientes existentes y nuevos con datos y análisis que coinciden y se adaptan a sus objetivos. El informe se puede personalizar para incluir análisis de tendencias de precios de marcas objetivo, comprensión del mercado de países adicionales (solicite la lista de países), datos de resultados de ensayos clínicos, revisión de literatura, análisis de mercado renovado y base de productos. El análisis de mercado de competidores objetivo se puede analizar desde análisis basados en tecnología hasta estrategias de cartera de mercado. Podemos agregar tantos competidores sobre los que necesite datos en el formato y estilo de datos que esté buscando. Nuestro equipo de analistas también puede proporcionarle datos en archivos de Excel sin procesar, tablas dinámicas (libro de datos) o puede ayudarlo a crear presentaciones a partir de los conjuntos de datos disponibles en el informe.