Global Industry 4 0 Market

Tamaño del mercado en miles de millones de dólares

Tasa de crecimiento anual compuesta (CAGR) :

%

USD

146.70 Million

USD

583.30 Million

2024

2032

USD

146.70 Million

USD

583.30 Million

2024

2032

| 2025 –2032 | |

| USD 146.70 Million | |

| USD 583.30 Million | |

|

|

|

|

Segmentación del mercado global de la Industria 4.0 por tecnología (robótica industrial, blockchain, sensores industriales, impresión 3D industrial , visión artificial, realidad extendida (XR), ciberseguridad, Internet de las cosas (IdC), impresión 3D, interfaz hombre-máquina (HMI) avanzada, mantenimiento predictivo de big data, realidad aumentada y realidad virtual, inteligencia artificial, IA en la fabricación, gemelo digital , AGV y monitorización del estado de las máquinas), tamaño de la empresa (pequeñas y medianas empresas y grandes empresas), sector vertical (fabricación, servicios públicos, automoción, equipos eléctricos y electrónicos, equipos industriales, aeroespacial y defensa, electrónica y bienes de consumo, química y materiales, alimentación y agricultura, petróleo y gas, energía y electricidad, atención sanitaria y otros), componente (hardware, software, servicios y soluciones): tendencias y previsiones de la industria hasta 2032

Tamaño del mercado de la Industria 4.0

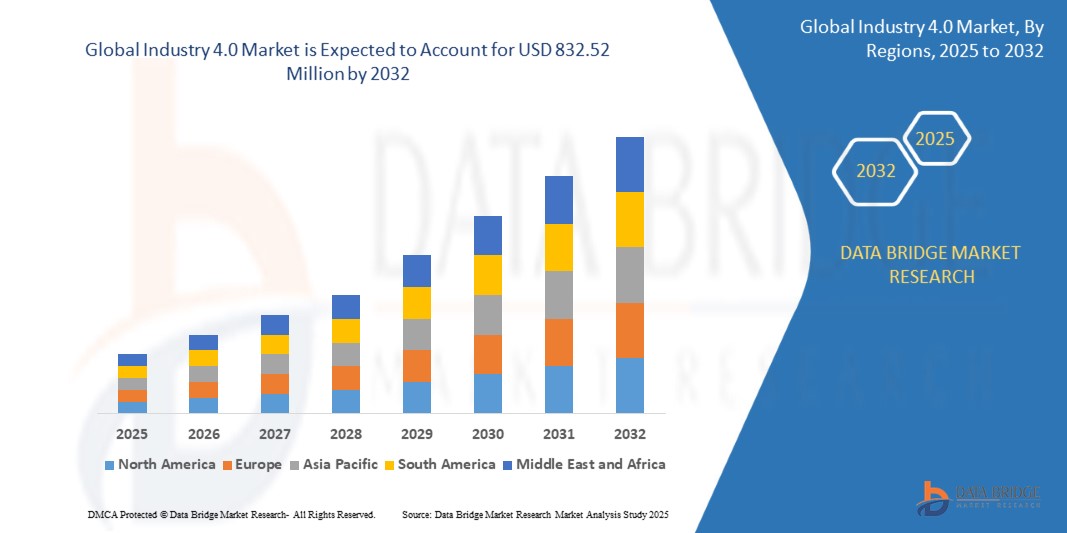

- El tamaño del mercado global de la Industria 4.0 se valoró en USD 195,30 millones en 2024 y se espera que alcance los USD 832,52 millones para 2032 , con una CAGR del 19,87 % durante el período de pronóstico.

- Este crecimiento está impulsado por factores como la creciente adopción de la automatización, la creciente demanda de soluciones de fabricación inteligente y los avances en tecnologías digitales, incluida la IA, la IoT y la robótica.

Análisis del mercado de la Industria 4.0

- Las tecnologías de la Industria 4.0 están transformando las operaciones industriales y de fabricación al integrar automatización inteligente, datos en tiempo real y análisis avanzados para optimizar la productividad, reducir costos y mejorar la toma de decisiones en sectores como la automoción, la electrónica, la energía y la atención médica.

- La demanda de soluciones de la Industria 4.0 está impulsada significativamente por la creciente necesidad de eficiencia operativa, mantenimiento predictivo y sistemas de producción flexibles para satisfacer las cambiantes demandas del mercado.

- Se espera que América del Norte domine el mercado de la industria 4.0 con la mayor participación de mercado del 30,7%, debido a la presencia de importantes proveedores de tecnología, la adopción temprana de la fabricación inteligente y las importantes inversiones en infraestructura digital.

- Se prevé que Asia-Pacífico sea la región con mayor crecimiento en el mercado de la industria 4.0 durante el período de pronóstico debido a la adopción generalizada de la automatización industrial. Se prevé que la implementación de tecnologías disruptivas, como el Internet de las Cosas (IoT), la IA y la robótica, impulse aún más este crecimiento.

- Se espera que el segmento de hardware domine el mercado con la mayor cuota de mercado, con un 50,01 %, debido a la creciente demanda de tecnologías inteligentes que puedan mejorar la eficiencia de fabricación, reducir el tiempo de inactividad y optimizar la calidad del producto. A medida que más empresas adopten la Industria 4.0, la demanda de componentes de hardware seguirá creciendo.

Alcance del informe y segmentación del mercado de la Industria 4.0

|

Atributos |

Perspectivas clave del mercado de la Industria 4.0 |

|

Segmentos cubiertos |

|

|

Países cubiertos |

América del norte

Europa

Asia-Pacífico

Oriente Medio y África

Sudamerica

|

|

Actores clave del mercado |

|

|

Oportunidades de mercado |

|

|

Conjuntos de información de datos de valor añadido |

Además de los conocimientos del mercado, como el valor de mercado, la tasa de crecimiento, los segmentos del mercado, la cobertura geográfica, los actores del mercado y el escenario del mercado, el informe de mercado elaborado por el equipo de investigación de mercado de Data Bridge incluye un análisis en profundidad de expertos, análisis de importación/exportación, análisis de precios, análisis de consumo de producción y análisis pestle. |

Tendencias del mercado de la Industria 4.0

Integración de IA, IoT y Edge Computing en Operaciones Industriales

- Una tendencia destacada en la evolución de la Industria 4.0 es la creciente convergencia de la Inteligencia Artificial (IA), la Internet de las Cosas (IoT) y la computación de borde dentro de los entornos industriales.

- Estas tecnologías están mejorando la toma de decisiones en tiempo real, permitiendo el mantenimiento predictivo y optimizando la utilización de activos en los sistemas de fabricación y producción.

- Por ejemplo, se están implementando sensores inteligentes integrados con computación de borde en las plantas de producción para recopilar y procesar datos localmente, lo que reduce la latencia y permite respuestas inmediatas a las anomalías, mejorando significativamente la eficiencia de la producción.

- Estos avances están transformando los flujos de trabajo industriales, impulsando la transformación digital en todos los sectores y fomentando el desarrollo de sistemas de producción altamente autónomos e inteligentes.

Dinámica del mercado de la Industria 4.0

Conductor

Creciente demanda de automatización y fabricación inteligente

- La creciente necesidad de eficiencia operativa, reducción del tiempo de inactividad y mejora de la calidad del producto está impulsando significativamente la adopción de tecnologías de la Industria 4.0 en diversas industrias.

- A medida que se intensifica la competencia global, los fabricantes buscan soluciones avanzadas como análisis impulsados por IA, robótica y comunicación de máquina a máquina para agilizar las operaciones y mejorar la productividad.

- El enfoque creciente en la personalización masiva, el monitoreo de datos en tiempo real y el mantenimiento predictivo está acelerando la transición hacia sistemas de fabricación inteligentes.

Por ejemplo,

- Según un informe de 2023 del Foro Económico Mundial, las fábricas inteligentes habilitadas por tecnologías de la Industria 4.0 han demostrado aumentos de hasta un 30% en la productividad y reducciones del 50% en el tiempo de inactividad, lo que destaca su potencial transformador.

- A medida que industrias de sectores como el automotriz, el aeroespacial, el farmacéutico y el electrónico adoptan la transformación digital, se espera que la demanda de soluciones de la Industria 4.0 aumente significativamente.

Oportunidad

Expansión de fábricas inteligentes y sistemas basados en IoT

- La creciente adopción de fábricas inteligentes, impulsada por la integración de dispositivos y sensores del Internet de las Cosas (IoT), representa una importante oportunidad de mercado en la Industria 4.0. Estos sistemas permiten la monitorización en tiempo real, el mantenimiento predictivo y la toma de decisiones basada en datos, mejorando así la productividad y la eficiencia general.

- Los sistemas habilitados para IoT facilitan una comunicación fluida entre máquinas, operadores y cadenas de suministro, lo que permite operaciones optimizadas y un menor tiempo de inactividad en los procesos de fabricación.

- Se espera que el cambio hacia sistemas inteligentes y conectados revolucione industrias como la automotriz, la aeroespacial y la electrónica, fomentando ciclos de producción más rápidos y soluciones personalizadas.

Por ejemplo,

- Un informe de Gartner de 2024 destaca que las empresas que implementan soluciones de fábrica inteligente basadas en IoT pueden aumentar la eficiencia operativa hasta en un 35%, al tiempo que reducen los costes de mantenimiento hasta en un 25%.

- A medida que aumenta la demanda de modelos de producción personalizados y flexibles, la tendencia de fábricas inteligentes habilitadas para IoT ofrece un enorme potencial de crecimiento para las empresas que buscan mejorar la agilidad operativa y mantener ventajas competitivas.

Restricción/Desafío

Altos costos de implementación y desafíos de infraestructura

- Los altos costos iniciales asociados con la implementación de tecnologías de la Industria 4.0, como sistemas de IoT, análisis impulsados por IA y soluciones de automatización, representan un desafío importante para las empresas, en particular para las pequeñas y medianas empresas (PYME).

- Las importantes inversiones necesarias para modernizar la infraestructura existente, integrar nuevas tecnologías y capacitar al personal pueden disuadir a muchas empresas de adoptar soluciones de la Industria 4.0, especialmente en los mercados emergentes.

- Esta barrera financiera puede conducir a tasas de adopción más lentas en sectores que carecen del capital necesario para invertir en tecnologías tan avanzadas, lo que podría retrasar la obtención de todos los beneficios de la transformación de la Industria 4.0.

Por ejemplo,

- Un informe de 2023 de la International Manufacturing Technology Show (IMTS) concluyó que muchos fabricantes, en particular las pymes, enfrentan dificultades para justificar el costo de la transición a fábricas digitales, citando preocupaciones sobre el retorno de la inversión (ROI) y la complejidad de las nuevas integraciones de sistemas.

- Como resultado, estos desafíos en términos de costo, integración y escalabilidad pueden restringir el ritmo al que las empresas pueden adoptar plenamente la Industria 4.0 y limitar su penetración más amplia en el mercado.

Alcance del mercado de la Industria 4.0

El mercado está segmentado en función de la tecnología, el tamaño de la empresa, la vertical y el componente.

|

Segmentación |

Subsegmentación |

|

Por tecnología |

|

|

Por tamaño de empresa |

|

|

Por Vertical |

|

|

Por componente |

|

Se proyecta que en 2025 el hardware dominará el mercado con la mayor participación en el segmento de componentes.

Se espera que el segmento de hardware domine el mercado de la Industria 4.0 con la mayor cuota de mercado, un 50,01 %, debido a la creciente demanda de tecnologías inteligentes que puedan mejorar la eficiencia de fabricación, reducir el tiempo de inactividad y optimizar la calidad del producto. A medida que más empresas adopten la Industria 4.0, la demanda de componentes de hardware seguirá creciendo.

Se espera que la fabricación represente la mayor participación durante el período de pronóstico en el segmento vertical.

En 2025, se prevé que el segmento manufacturero domine el mercado con la mayor cuota de mercado, un 31,01 %, gracias a una amplia gama de tecnologías que permiten a las empresas operar de forma más eficiente, reducir costes y mejorar la experiencia del cliente. La tecnología clave que impulsa el crecimiento de la industria manufacturera es el Internet de las Cosas (IoT). Los sensores basados en el IoT monitorizan el rendimiento de los equipos e identifican posibles problemas antes de que se conviertan en problemas graves.

Análisis regional del mercado de la Industria 4.0

Norteamérica posee la mayor participación en el mercado de la Industria 4.0

- América del Norte domina el mercado de la industria 4.0 con la mayor participación de mercado del 30,7%, debido a un fuerte enfoque en la innovación tecnológica, una infraestructura de fabricación bien establecida y altas tasas de adopción de tecnologías de automatización, IA e IoT.

- Estados Unidos domina el mercado de la industria 4.0 en América del Norte con la mayor participación de mercado del 28,1%, debido a sus sectores industriales avanzados, incluidos el automotriz, el aeroespacial y la electrónica, así como al aumento de las inversiones en transformación digital y tecnologías de fabricación inteligente.

- La presencia de grandes empresas tecnológicas y el elevado gasto en I+D fortalecen aún más el dominio de la región, impulsando la adopción en múltiples industrias.

- Las iniciativas gubernamentales y los entornos regulatorios favorables continúan apoyando el rápido crecimiento de las tecnologías de la Industria 4.0 en América del Norte, lo que la convierte en una región clave para la expansión del mercado.

Se proyecta que Asia-Pacífico registre la tasa de crecimiento anual compuesta (TCAC) más alta en el mercado de la Industria 4.0.

- Se espera que la región Asia-Pacífico sea testigo de la mayor tasa de crecimiento en el mercado de la industria 4.0, impulsada por los rápidos avances en las capacidades de fabricación, la creciente adopción de la automatización y la expansión de las aplicaciones industriales de IoT.

- Países como China, Japón e India están surgiendo como actores clave debido a importantes inversiones en automatización industrial, robótica e IA para mejorar la productividad de la fabricación.

- China, con su amplia base manufacturera, está adoptando las tecnologías de la Industria 4.0 para mantener su competitividad global en sectores como la electrónica y la automoción. India, por su parte, está avanzando en la modernización de su infraestructura manufacturera mediante soluciones digitales.

- Japón, conocido por su destreza tecnológica, sigue liderando la implementación de robótica e inteligencia artificial para optimizar sus operaciones industriales. El aumento del apoyo gubernamental y la inversión privada impulsa aún más el crecimiento de la Industria 4.0 en la región.

Cuota de mercado de la Industria 4.0

El panorama competitivo del mercado ofrece detalles por competidor. Se incluye información general de la empresa, sus estados financieros, ingresos generados, potencial de mercado, inversión en investigación y desarrollo, nuevas iniciativas de mercado, presencia global, plantas de producción, capacidad de producción, fortalezas y debilidades de la empresa, lanzamiento de productos, alcance y variedad de productos, y dominio de las aplicaciones. Los datos anteriores se refieren únicamente al enfoque de mercado de las empresas.

Los principales líderes del mercado que operan en el mercado son:

- 3D Systems (EE. UU.)

- ABB Ltd. (Suiza)

- Advantech Co., Ltd. (Taiwán)

- Basler AG (Alemania)

- Cisco Systems, Inc. (EE. UU.)

- Cognex Corporation (EE. UU.)

- Daifuku Co., Ltd. (Japón)

- Emerson Electric Co. (EE. UU.)

- General Electric Company (GE) (EE. UU.)

- Honeywell International Inc. (EE. UU.)

- IBM Corporation (EE. UU.)

- Intel Corporation (EE. UU.)

- John Bean Technologies Corporation (JBT) (EE. UU.)

- NVIDIA Corporation (EE. UU.)

- Siemens AG (Alemania)

- Stratasys Ltd. (Israel)

- Techman Robot Inc. (Taiwán)

- Universal Robots A/S (Dinamarca)

- Addverb Technologies Pvt. Ltd. (India)

- SEAT, SA (EE.UU.)

Últimos avances en el mercado global de la Industria 4.0

- En 2022, Panasonic Life Solutions India inauguró una planta de producción de vanguardia en Sri City, diseñada específicamente para la industria ECM. Esta planta, habilitada para la Industria 4.0, busca satisfacer la creciente demanda en India mediante la incorporación de automatización avanzada, tecnologías de fabricación inteligente y flujos de trabajo operativos optimizados. La integración estratégica de soluciones de la Industria 4.0 en esta planta refleja la tendencia global hacia la transformación digital en la fabricación y destaca el creciente papel de la India como contribuyente clave al mercado global de la Industria 4.0.

- En 2022, una alianza estratégica entre la Universidad Estatal de Youngstown y el Centro Nacional de Fabricación y Mecanizado de Defensa de la Universidad del Norte de Iowa obtuvo una financiación inicial de 10 millones de dólares. El programa desempeña un papel fundamental en la promoción de la integración de soluciones de la Industria 4.0, como la automatización, los gemelos digitales y la fabricación aditiva, contribuyendo no solo a las capacidades de defensa nacionales, sino también al avance general del mercado global de la Industria 4.0 mediante la innovación escalable y el desarrollo de la fuerza laboral.

- En febrero de 2021, Software AG y SAP SE firmaron una alianza estratégica para integrar S/4HANA Cloud de SAP con la plataforma de análisis TrendMiner de Software AG. La colaboración está diseñada para aprovechar los datos industriales generados por sensores y aplicar análisis avanzados para ofrecer información práctica en tiempo real a las empresas en proceso de transformación digital. Esta iniciativa impulsa la convergencia fluida de TI y TO (tecnología operativa), facilitando ecosistemas de fabricación más inteligentes y basados en datos, y acelerando la transición global hacia operaciones industriales inteligentes y conectadas.

- En febrero de 2021, ABB Ltd. presentó GoFa, un robot colaborativo diseñado para ayudar a los trabajadores a realizar tareas ergonómicamente exigentes y repetitivas. Este cobot de nueva generación está diseñado para satisfacer la creciente demanda de soluciones capaces de manejar cargas más pesadas, garantizando al mismo tiempo la seguridad y la flexibilidad operativas. El lanzamiento ejemplifica la integración de la robótica inteligente en los sistemas de fabricación, impulsando la colaboración hombre-máquina, reduciendo la tensión física de los trabajadores y acelerando la transición a instalaciones de producción inteligentes y automatizadas.

- En marzo de 2020, Cisco Systems Inc. y Microsoft Corporation establecieron una colaboración estratégica para facilitar la orquestación fluida de datos entre Cisco IoT Edge y Azure IoT Cloud. Esta alianza ofrece una solución IoT preintegrada del borde a la nube, que permite un flujo de datos eficiente y la obtención de información en tiempo real en entornos industriales conectados. Esta iniciativa promueve la integración de la computación en la nube y el borde, esencial para impulsar la automatización, el análisis predictivo y la toma de decisiones inteligente en las operaciones industriales modernas.

SKU-

Obtenga acceso en línea al informe sobre la primera nube de inteligencia de mercado del mundo

- Panel de análisis de datos interactivo

- Panel de análisis de empresas para oportunidades con alto potencial de crecimiento

- Acceso de analista de investigación para personalización y consultas

- Análisis de la competencia con panel interactivo

- Últimas noticias, actualizaciones y análisis de tendencias

- Aproveche el poder del análisis de referencia para un seguimiento integral de la competencia

Metodología de investigación

La recopilación de datos y el análisis del año base se realizan utilizando módulos de recopilación de datos con muestras de gran tamaño. La etapa incluye la obtención de información de mercado o datos relacionados a través de varias fuentes y estrategias. Incluye el examen y la planificación de todos los datos adquiridos del pasado con antelación. Asimismo, abarca el examen de las inconsistencias de información observadas en diferentes fuentes de información. Los datos de mercado se analizan y estiman utilizando modelos estadísticos y coherentes de mercado. Además, el análisis de la participación de mercado y el análisis de tendencias clave son los principales factores de éxito en el informe de mercado. Para obtener más información, solicite una llamada de un analista o envíe su consulta.

La metodología de investigación clave utilizada por el equipo de investigación de DBMR es la triangulación de datos, que implica la extracción de datos, el análisis del impacto de las variables de datos en el mercado y la validación primaria (experto en la industria). Los modelos de datos incluyen cuadrícula de posicionamiento de proveedores, análisis de línea de tiempo de mercado, descripción general y guía del mercado, cuadrícula de posicionamiento de la empresa, análisis de patentes, análisis de precios, análisis de participación de mercado de la empresa, estándares de medición, análisis global versus regional y de participación de proveedores. Para obtener más información sobre la metodología de investigación, envíe una consulta para hablar con nuestros expertos de la industria.

Personalización disponible

Data Bridge Market Research es líder en investigación formativa avanzada. Nos enorgullecemos de brindar servicios a nuestros clientes existentes y nuevos con datos y análisis que coinciden y se adaptan a sus objetivos. El informe se puede personalizar para incluir análisis de tendencias de precios de marcas objetivo, comprensión del mercado de países adicionales (solicite la lista de países), datos de resultados de ensayos clínicos, revisión de literatura, análisis de mercado renovado y base de productos. El análisis de mercado de competidores objetivo se puede analizar desde análisis basados en tecnología hasta estrategias de cartera de mercado. Podemos agregar tantos competidores sobre los que necesite datos en el formato y estilo de datos que esté buscando. Nuestro equipo de analistas también puede proporcionarle datos en archivos de Excel sin procesar, tablas dinámicas (libro de datos) o puede ayudarlo a crear presentaciones a partir de los conjuntos de datos disponibles en el informe.