La visión artificial industrial encuentra amplias aplicaciones en todas las industrias, incluidas la automotriz, la electrónica, la farmacéutica y más. Sus características clave incluyen cámaras de alta resolución, avanzadas sensoresy algoritmos inteligentes de procesamiento de imágenes, que permiten una detección precisa de defectos, control de calidad y verificación de productos. Las ventajas abarcan una mayor eficiencia de producción, una reducción del trabajo manual, una mayor consistencia del producto y una disminución de los residuos. Al optimizar los procesos de fabricación y garantizar el cumplimiento de los estándares de calidad, la visión artificial industrial contribuye significativamente al ahorro de costos, el aumento de la productividad y la excelencia operativa general.

Acceda al informe completo:https://www.databridgemarketresearch.com/reports/global-industrial-machine-vision-market

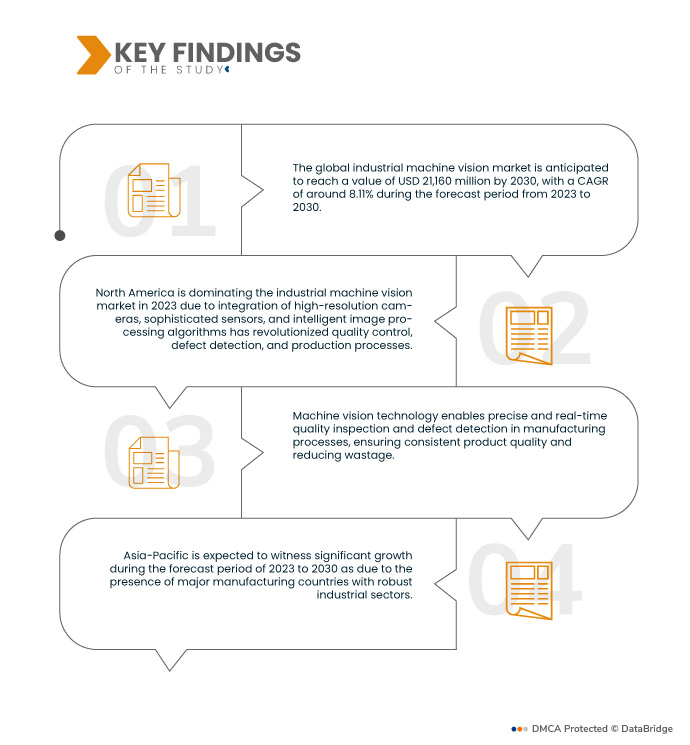

Data Bridge Market Research analiza que el Mercado mundial de visión artificial industrial está valorado en 11.150 millones de dólares en 2022 y se espera que alcance los 21.160 millones de dólares en 2030, registrando una tasa compuesta anual del 8,11% durante el período previsto de 2023 a 2030. La creciente adopción de iniciativas de automatización e Industria 4.0 en diversas industrias ha llevado a un La creciente demanda de sistemas de visión artificial para mejorar los procesos de producción, mejorar el control de calidad y aumentar la eficiencia.

Hallazgos clave del estudio

Se espera que los avances en las tecnologías de imágenes impulsen la tasa de crecimiento del mercado.

Los continuos avances en las tecnologías de imágenes, incluidas cámaras de alta resolución, sensores y sofisticados algoritmos de procesamiento de imágenes, han mejorado significativamente los sistemas de visión artificial. Estas mejoras han dado lugar a una mayor exactitud y precisión, lo que permite que los sistemas aborden tareas de inspección complejas con mayor eficiencia. Las capacidades mejoradas de la visión artificial desempeñan un papel crucial a la hora de mejorar el control de calidad, aumentar la productividad y garantizar procesos de fabricación consistentes y confiables en diversas industrias.

Alcance del informe y segmentación del mercado

|

Métrica de informe

|

Detalles

|

|

Período de pronóstico

|

2023 a 2030

|

|

Año base

|

2022

|

|

Años históricos

|

20201 (Personalizable para 2015-2020)

|

|

Unidades Cuantitativas

|

Ingresos en millones de dólares, volúmenes en unidades, precios en dólares

|

|

Segmentos cubiertos

|

Componente (hardware, software), tipo de producto (sistemas de visión artificial basados en PC, sistemas de visión basados en cámaras inteligentes), tecnología (láser, imágenes, aumentada), usuario final (automotriz, Electrónica de consumo, Electrónica y semiconductores, atención sanitaria, impresión, metales, madera y papel, alimentos y embalajes, caucho y plásticos, productos farmacéuticos, vidrio, maquinaria, fabricación de paneles solares), aplicaciones (garantía e inspección de calidad, posicionamiento y orientación, medición, identificación)

|

|

Países cubiertos

|

Estados Unidos, Canadá y México en Norteamérica, Alemania, Francia, Reino Unido, Países Bajos, Suiza, Bélgica, Rusia, Italia, España, Turquía, Resto de Europa en Europa, China, Japón, India, Corea del Sur, Singapur, Malasia, Australia, Tailandia, Indonesia, Filipinas, Resto de Asia-Pacífico (APAC) en Asia-Pacífico (APAC), Arabia Saudita, Emiratos Árabes Unidos, Sudáfrica, Egipto, Israel, Resto de Medio Oriente y África (MEA) como parte de Medio Oriente y África (MEA), Brasil, Argentina y Resto de Sudamérica como parte de Sudamérica.

|

|

Actores del mercado cubiertos

|

COGNEX CORPORATION (EE.UU.), Basler AG (Alemania), OMRON Corporation (Japón), KEYENCE CORPORATION (Japón), NATIONAL INSTRUMENTS CORP. (EE.UU.), Sony Semiconductor Solutions Corporation (Japón), Teledyne Technologies Inc. (EE.UU.), Allied Vision Technologies GmbH (Alemania), SICK AG (Alemania), Texas Instruments Incorporated (EE.UU.), Intel Corporation (EE.UU.), Baumer (Suiza), JAI A/S (Dinamarca), MVTEC SOFTWARE GMBH (Alemania), Tordivel AS (Noruega) , ISRA VISION AG (Alemania), FLIR Systems, Inc. (EE.UU.), AMETEK Surface Vision (EE.UU.), Qualitas Technologies Pvt Ltd (India) y Cadence Design Systems, Inc. (EE.UU.)

|

|

Puntos de datos cubiertos en el informe

|

Además de la información sobre escenarios de mercado como el valor de mercado, la tasa de crecimiento, la segmentación, la cobertura geográfica y los principales actores, los informes de mercado seleccionados por Data Bridge Market Research también incluyen análisis profundos de expertos, epidemiología de pacientes, análisis de tuberías, análisis de precios, y marco regulatorio

|

Análisis de segmentos:

El mercado de la visión artificial industrial está segmentado según el componente, el tipo de producto, la tecnología, el usuario final y la aplicación.

- Según los componentes, el mercado se segmenta en hardware y software.

- Según el tipo de producto, el mercado se segmenta en sistemas de visión artificial basados en PC y sistemas de visión basados en cámaras inteligentes.

- Sobre la base de la tecnología, el mercado se segmenta en láser, imágenes y aumentada.

- Según el usuario final, el mercado se segmenta en automoción, electrónica de consumo, electrónica y semiconductores, atención sanitaria, impresión, metales, madera y papel, alimentos y embalajes, caucho y plásticos, productos farmacéuticos, vidrio, maquinaria y fabricación de paneles solares.

- Sobre la base de la aplicación, el mercado se segmenta en control e inspección de calidad, posicionamiento y orientación, medición e identificación.

Principales actores

Data Bridge Market Research reconoce que las siguientes empresas como los principales actores del mercado de visión artificial industrial son COGNEX CORPORATION (EE. UU.), Basler AG (Alemania), OMRON Corporation (Japón), KEYENCE CORPORATION (Japón), NATIONAL INSTRUMENTS CORP. (EE.UU.), Sony Semiconductor Solutions Corporation (Japón), Teledyne Technologies Inc. (EE.UU.)

El desarrollo del mercado

- En marzo de 2021, Cognex presentó la serie DataMan 8700, que representa la próxima generación de lectores de códigos de barras portátiles. Esta última versión se basa en una plataforma completamente nueva y cuenta con un rendimiento de vanguardia. En particular, el dispositivo es excepcionalmente fácil de usar, lo que elimina la necesidad de configuración previa o capacitación del operador.

Análisis Regional

Geográficamente, los países cubiertos en el informe del mercado de visión artificial industrial son EE. UU., Canadá y México en América del Norte, Alemania, Francia, Reino Unido, Países Bajos, Suiza, Bélgica, Rusia, Italia, España, Turquía, resto de Europa en Europa, China, Japón, India, Corea del Sur, Singapur, Malasia, Australia, Tailandia, Indonesia, Filipinas, Resto de Asia-Pacífico (APAC), Arabia Saudita, Emiratos Árabes Unidos, Sudáfrica, Egipto, Israel, Resto de Medio Oriente y África (MEA) como parte de Medio Oriente y África (MEA), Brasil, Argentina y Resto de Sudamérica como parte de Sudamérica.

Según el análisis de investigación de mercado de Data Bridge:

América del Norte domina el mercado de visión artificial industrial durante el período de pronóstico 2023 -2030

En 2023, América del Norte domina el mercado de visión artificial industrial debido a la presencia de importantes actores clave en el mercado, lo que acelerará aún más el crecimiento durante el período previsto. Estos actores establecidos aportan experiencia, recursos y soluciones innovadoras, contribuyendo al desarrollo y adopción de tecnología de visión artificial de vanguardia en la región. Se espera que este sólido crecimiento del mercado continúe a medida que las industrias adopten la automatización y busquen una eficiencia operativa optimizada.

Se espera que Asia-Pacífico experimente un crecimiento significativo durante el período previsto de 2023 a 2030.

En 2023, se espera que Asia-Pacífico experimente un crecimiento significativo debido al aumento de nuevos participantes y nuevas empresas en el mercado que aportarán nuevas perspectivas y tecnologías innovadoras, lo que conducirá a una mayor competencia y una mayor expansión del mercado. A medida que más empresas reconozcan los beneficios de la visión artificial para mejorar la eficiencia de la producción y la calidad del producto, el mercado está preparado para un crecimiento sustancial en los próximos años.

Para obtener información más detallada sobre el mercado de la visión artificial industrial informe, haga clic aquí – https://www.databridgemarketresearch.com/reports/global-industrial-machine-vision-market