Global Food Robotics In Processed Food Application Market

Marktgröße in Milliarden USD

CAGR :

%

USD

6.40 Billion

USD

16.42 Billion

2024

2032

USD

6.40 Billion

USD

16.42 Billion

2024

2032

| 2025 –2032 | |

| USD 6.40 Billion | |

| USD 16.42 Billion | |

|

|

|

|

Globale Marktsegmentierung für Lebensmittelrobotik in verarbeiteten Lebensmitteln nach Typ (Gelenk-, kartesische, SCARA-, Parallel-, Zylindrische-, Kollaborative- und andere Typen), Nutzlast (Niedrig, Mittel und Schwer) und Anwendung (Verpackung, Umverpackung, Palettierung, Kommissionierung, Verarbeitung und andere) – Branchentrends und Prognose bis 2032.

Lebensmittelrobotik in verarbeiteten Lebensmitteln Marktgröße

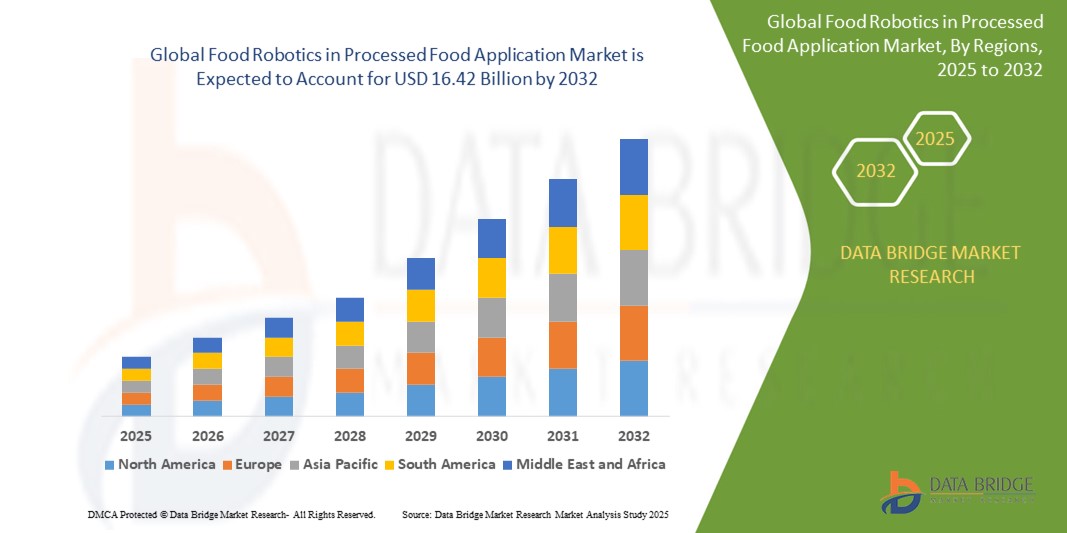

- Der globale Markt für Lebensmittelrobotik in verarbeiteten Lebensmitteln hatte im Jahr 2024 einen Wert von 6,40 Milliarden US-Dollar und dürfte bis 2032 16,42 Milliarden US-Dollar erreichen , bei einer CAGR von 12,50 % im Prognosezeitraum.

- Das Marktwachstum wird in erster Linie durch die zunehmende Automatisierung in der Lebensmittelverarbeitung vorangetrieben, um die Effizienz zu steigern, die Arbeitskosten zu senken und die Produktkonsistenz zu verbessern, angetrieben durch Fortschritte in der Robotertechnologie und die steigende Nachfrage nach verarbeiteten und verpackten Lebensmitteln

- Darüber hinaus macht die wachsende Nachfrage der Verbraucher nach qualitativ hochwertigen, sicheren und hygienischen Lebensmitteln in Verbindung mit strengen gesetzlichen Vorschriften die Lebensmittelrobotik zu einer wichtigen Lösung für moderne Lebensmittelverarbeitungsbetriebe und fördert das Branchenwachstum erheblich.

Marktanalyse für Lebensmittelrobotik in verarbeiteten Lebensmitteln

- Lebensmittelrobotik, die automatisierte Systeme für Aufgaben wie Verpackung, Palettierung und Verarbeitung umfasst, ist aufgrund ihrer Präzision, Geschwindigkeit und Fähigkeit, strenge Hygienestandards bei verarbeiteten Lebensmitteln einzuhalten, zunehmend ein fester Bestandteil der Lebensmittel- und Getränkeindustrie.

- Der Anstieg der Nachfrage nach Lebensmittelrobotern ist auf den Bedarf an Betriebseffizienz, steigende Arbeitskosten und den zunehmenden Trend zur Automatisierung in der Lebensmittelherstellung zurückzuführen, insbesondere in Umgebungen mit hoher Stückzahlproduktion.

- Europa dominierte den Markt für Lebensmittelrobotik in der Lebensmittelverarbeitung mit dem größten Umsatzanteil von 38,5 % im Jahr 2024. Dies ist auf eine fortschrittliche Fertigungsinfrastruktur, die hohe Akzeptanz von Automatisierungstechnologien und strenge regulatorische Rahmenbedingungen zur Gewährleistung der Lebensmittelsicherheit zurückzuführen. Deutschland und Großbritannien leisten wichtige Beiträge mit erheblichen Investitionen in Roboterlösungen durch große Lebensmittelverarbeitungsunternehmen.

- Der asiatisch-pazifische Raum dürfte im Prognosezeitraum die am schnellsten wachsende Region sein, angetrieben durch die schnelle Industrialisierung, die steigende Nachfrage nach verarbeiteten Lebensmitteln und steigende Investitionen in die Automatisierung in Ländern wie China, Japan und Indien.

- Das Segment der Gelenkarbeitsgeräte dominierte mit 42,3 % den größten Marktanteil. Dies ist auf die Flexibilität und die Fähigkeit zurückzuführen, menschliche Armbewegungen nachzuahmen. Dadurch eignet es sich ideal für komplexe Aufgaben wie Schneiden, Entbeinen, Verpacken und Palettieren in der Lebensmittelverarbeitung. Seine Präzision und Vielseitigkeit in engen Räumen untermauern seine Dominanz zusätzlich.

Berichtsumfang und Marktsegmentierung für Lebensmittelrobotik in verarbeiteten Lebensmitteln

|

Eigenschaften |

Lebensmittelrobotik in verarbeiteten Lebensmitteln: Wichtige Markteinblicke |

|

Abgedeckte Segmente |

|

|

Abgedeckte Länder |

Nordamerika

Europa

Asien-Pazifik

Naher Osten und Afrika

Südamerika

|

|

Wichtige Marktteilnehmer |

|

|

Marktchancen |

|

|

Wertschöpfungsdaten-Infosets |

Zusätzlich zu den Einblicken in Marktszenarien wie Marktwert, Wachstumsrate, Segmentierung, geografische Abdeckung und wichtige Akteure enthalten die von Data Bridge Market Research kuratierten Marktberichte auch ausführliche Expertenanalysen, Preisanalysen, Markenanteilsanalysen, Verbraucherumfragen, demografische Analysen, Lieferkettenanalysen, Wertschöpfungskettenanalysen, eine Übersicht über Rohstoffe/Verbrauchsmaterialien, Kriterien für die Lieferantenauswahl, PESTLE-Analysen, Porter-Analysen und regulatorische Rahmenbedingungen. |

Markttrends für Lebensmittelrobotik in verarbeiteten Lebensmitteln

„Zunehmende Integration von KI und Big Data Analytics“

- Der globale Markt für Lebensmittelrobotik in verarbeiteten Lebensmittelanwendungen erlebt einen bemerkenswerten Trend zur Integration von künstlicher Intelligenz (KI) und Big Data-Analyse

- Diese Technologien ermöglichen eine fortschrittliche Datenverarbeitung und ermöglichen detaillierte Einblicke in die Produktionseffizienz, die Anlagenleistung und die Kennzahlen der Qualitätskontrolle.

- KI-gesteuerte Roboterlösungen unterstützen die proaktive Wartung, indem sie Geräteausfälle vorhersagen, bevor sie den Betrieb stören, und so Ausfallzeiten und Wartungskosten reduzieren.

- Beispielsweise nutzen Unternehmen KI-Plattformen, um Roboterabläufe zu optimieren, etwa indem sie die Verpackungsgeschwindigkeit an die Echtzeitnachfrage anpassen oder Sortiermuster analysieren, um Lebensmittelabfälle zu minimieren.

- Dieser Trend steigert die Attraktivität von Lebensmittelrobotersystemen für Hersteller, verbessert die Betriebseffizienz und die Einhaltung strenger Lebensmittelsicherheitsstandards

- KI-Algorithmen können Daten aus Roboteraufgaben verarbeiten, wie z. B. Kommissionierpräzision, Verpackungskonsistenz und Verarbeitungsgenauigkeit, um die Leistung zu optimieren und eine hohe Ausgabequalität sicherzustellen.

Marktdynamik für Lebensmittelrobotik in verarbeiteten Lebensmitteln

Treiber

„Steigende Nachfrage nach Automatisierung und Einhaltung der Lebensmittelsicherheit“

- Die wachsende Verbrauchernachfrage nach verarbeiteten und verpackten Lebensmitteln, einschließlich Fertiggerichten und Convenience-Produkten, ist ein wichtiger Treiber für den Markt für Lebensmittelrobotik

- Robotersysteme erhöhen die Lebensmittelsicherheit durch die Automatisierung von Aufgaben wie Verpackung, Kommissionierung und Verarbeitung und reduzieren so den menschlichen Kontakt und das Kontaminationsrisiko.

- Strenge staatliche Vorschriften, insbesondere in Europa mit Standards wie HACCP und ISO 22000, beschleunigen den Einsatz von Robotern, um die Einhaltung der Anforderungen an Lebensmittelsicherheit und Hygiene zu gewährleisten.

- Fortschritte im IoT und in der 5G-Konnektivität ermöglichen schnellere Datenübertragung und Echtzeitüberwachung und unterstützen anspruchsvolle Roboteranwendungen in der Lebensmittelverarbeitung

- Lebensmittelhersteller integrieren zunehmend Roboter als Standardlösungen, um den steigenden Produktionsanforderungen gerecht zu werden und eine gleichbleibende Produktqualität zu gewährleisten.

Einschränkung/Herausforderung

„Hohe Implementierungskosten und Bedenken hinsichtlich der Datensicherheit“

- Die hohen Anschaffungskosten für Roboter-Hardware, -Software und -Systemintegration stellen insbesondere für kleine und mittlere Unternehmen in Schwellenländern eine erhebliche Hürde dar.

- Die Nachrüstung bestehender Produktionslinien mit Robotersystemen kann komplex und teuer sein und erfordert spezielles Fachwissen und Infrastruktur-Upgrades

- Datensicherheit und Datenschutz stellen eine große Herausforderung dar, da Robotersysteme sensible Betriebsdaten erfassen, was Bedenken hinsichtlich Cyberangriffen, Datenmissbrauch und der Einhaltung von Vorschriften wie der DSGVO in Europa aufkommen lässt.

- Das Fehlen standardisierter globaler Vorschriften für den Umgang mit Daten in der Lebensmittelrobotik erschwert den Betrieb für Hersteller, die in mehreren Regionen tätig sind

- Diese Faktoren können das Marktwachstum in kostensensiblen Regionen oder Gebieten mit erhöhtem Bewusstsein für Datenschutz verlangsamen

Marktumfang der Lebensmittelrobotik in verarbeiteten Lebensmitteln

Der Markt ist nach Typ, Nutzlast und Anwendung segmentiert.

- Nach Typ

Der globale Markt für Lebensmittelrobotik in der Lebensmittelverarbeitung ist nach Typ in Gelenkroboter, kartesische Roboter, Scara-Roboter, Parallelroboter, Zylinderroboter, kollaborative Roboter und weitere Roboter unterteilt. Das Gelenkrobotersegment dominierte mit 42,3 % den größten Marktanteil. Dies ist auf seine Flexibilität und die Fähigkeit zurückzuführen, menschliche Armbewegungen nachzuahmen. Dadurch eignet es sich ideal für komplexe Aufgaben wie Schneiden, Entbeinen, Verpacken und Palettieren in der Lebensmittelverarbeitung. Seine Präzision und Vielseitigkeit in engen Räumen untermauern seine Dominanz zusätzlich.

Das Segment der kollaborativen Roboter (Cobots) wird voraussichtlich zwischen 2025 und 2032 die höchste Wachstumsrate aufweisen. Dieses Wachstum wird durch den zunehmenden Fokus auf Arbeitssicherheit, einfache Programmierung und Bereitstellung sowie die steigende Nachfrage nach flexiblen Automatisierungslösungen in Lebensmittelverarbeitungsanlagen vorangetrieben, in denen die Mensch-Roboter-Zusammenarbeit von Vorteil ist.

- Nach Nutzlast

Der globale Markt für Lebensmittelrobotik in der Lebensmittelverarbeitung wird anhand der Nutzlast in niedrige, mittlere und hohe Nutzlasten unterteilt. Das mittlere Nutzlastsegment dürfte den größten Marktanteil halten, vor allem aufgrund seiner ausgewogenen Kapazität und Flexibilität, die es für verschiedene Anwendungen in der Lebensmittelindustrie vielseitig einsetzbar macht.

Im Segment der Schwerlasttransporte wird ein deutliches Wachstum erwartet, das auf den technologischen Fortschritt und verbesserte Forschung und Entwicklung im Bereich der effizienten Handhabung größerer Mengen und schwererer Lebensmittelprodukte in der Lebensmittelverarbeitung zurückzuführen ist.

- Nach Anwendung

Der globale Markt für Lebensmittelrobotik in der Lebensmittelverarbeitung ist nach Anwendungsbereichen segmentiert: Verpackung, Umverpackung, Palettierung, Kommissionierung, Verarbeitung und weitere. Das Verpackungssegment hält den größten Marktanteil, angetrieben durch die steigende Nachfrage nach verpackten Lebensmitteln und den Bedarf an schnellen, konsistenten und hygienischen Verpackungsprozessen, die Roboter effizient bewältigen können. Dies reduziert Abfall und erhöht die Produktionskapazität.

Für das Verarbeitungssegment wird von 2025 bis 2032 ein starkes Wachstum erwartet. Grund dafür ist der hohe Bedarf an Präzision, Konsistenz und Hygiene bei verschiedenen Aufgaben der Lebensmittelverarbeitung, wie etwa Schneiden, Mischen und Sortieren. Roboterlösungen bieten hier eine überlegene Leistung und helfen, strenge Lebensmittelsicherheitsstandards einzuhalten.

Regionale Analyse des Marktes für Lebensmittelrobotik in verarbeiteten Lebensmitteln

- Europa dominierte den Markt für Lebensmittelrobotik in der Lebensmittelverarbeitung mit dem größten Umsatzanteil von 38,5 % im Jahr 2024. Dies ist auf eine fortschrittliche Fertigungsinfrastruktur, die hohe Akzeptanz von Automatisierungstechnologien und strenge regulatorische Rahmenbedingungen zur Gewährleistung der Lebensmittelsicherheit zurückzuführen. Deutschland und Großbritannien leisten wichtige Beiträge mit erheblichen Investitionen in Roboterlösungen durch große Lebensmittelverarbeitungsunternehmen.

- Verbraucher und Hersteller bevorzugen Roboterlösungen, um die Produktionspräzision zu verbessern, die Arbeitskosten zu senken und die Einhaltung strenger Lebensmittelsicherheitsstandards zu gewährleisten, insbesondere in Regionen mit fortschrittlichen industriellen Ökosystemen.

- Das Wachstum wird durch Fortschritte in der Robotertechnologie, darunter Gelenk-, SCARA- und kollaborative Roboter, sowie durch die zunehmende Verbreitung sowohl in großen Lebensmittelverarbeitungsanlagen als auch in kleineren Betrieben unterstützt.

Markteinblick in Lebensmittelrobotik in verarbeiteten Lebensmitteln in Großbritannien

Der britische Markt für Lebensmittelrobotik wird voraussichtlich deutlich wachsen. Dies wird durch die Nachfrage nach Automatisierung zur Verbesserung der Betriebseffizienz und Produktkonsistenz in städtischen und vorstädtischen Lebensmittelverarbeitungsbetrieben vorangetrieben. Das zunehmende Interesse an intelligenter Fertigung und das wachsende Bewusstsein für die Rolle der Robotik bei der Senkung der Arbeitskosten fördern die Akzeptanz. Auch die sich entwickelnden Vorschriften zur Lebensmittelsicherheit beeinflussen die Markttrends und sorgen für ein Gleichgewicht zwischen Automatisierungsbedarf und Compliance.

Markteinblick in Lebensmittelrobotik für verarbeitete Lebensmittel in Deutschland

In Deutschland wird ein starkes Wachstum im Markt für Lebensmittelrobotik erwartet. Dies ist auf die fortschrittliche Lebensmittelverarbeitung und -herstellung sowie den hohen Fokus auf betriebliche Effizienz und Nachhaltigkeit zurückzuführen. Deutsche Hersteller bevorzugen technologisch fortschrittliche Roboter, beispielsweise Gelenk- und kollaborative Roboter, die die Produktivität steigern und zur Energieeffizienz beitragen. Die Integration dieser Systeme in hochwertige Lebensmittelverarbeitungsanlagen und Nachrüstungen unterstützen ein nachhaltiges Marktwachstum.

Markteinblick in Lebensmittelrobotik in verarbeiteten Lebensmitteln in Nordamerika

Nordamerika hält einen bedeutenden Anteil am globalen Markt für Lebensmittelrobotik. Dieser Anteil wird durch eine robuste Lebensmittelverarbeitungsindustrie und den zunehmenden Einsatz von Automatisierung zur Verbesserung der Betriebseffizienz und zur Einhaltung strenger Sicherheitsstandards angetrieben. Die Nachfrage nach Robotik in Anwendungen wie Verpackung, Palettierung und Verarbeitung wird durch den Bedarf an Präzision, Skalierbarkeit und Hygiene in der Lebensmittelproduktion angetrieben. Die USA sind führend in der Region. Wachsende Investitionen in intelligente Fertigung und technologische Fortschritte in der Robotik unterstützen das Marktwachstum.

Markteinblick in die Lebensmittelrobotik in der Lebensmittelverarbeitung in den USA

Der US-Markt für Lebensmittelrobotik in der Lebensmittelverarbeitung wird voraussichtlich deutlich wachsen, angetrieben durch die starke Nachfrage nach Automatisierung in der Lebensmittelverarbeitung und -verpackung. Das wachsende Bewusstsein für die Vorteile der Robotik bei der Verbesserung des Durchsatzes und der Einhaltung von Hygienestandards treibt das Marktwachstum voran. Der Trend zu intelligenten Fabriken und zunehmende Vorschriften zur Lebensmittelsicherheit fördern die Akzeptanz zusätzlich. Die Integration von Robotik sowohl in Neuanlagen als auch in die Nachrüstung bestehender Anlagen schafft ein robustes Marktökosystem.

Markteinblicke für Lebensmittelrobotik in verarbeiteten Lebensmitteln im asiatisch-pazifischen Raum

Der asiatisch-pazifische Raum wird voraussichtlich das höchste Wachstum verzeichnen, angetrieben durch die wachsende Lebensmittelindustrie und steigende Investitionen in die Automatisierung in Ländern wie China, Indien und Japan. Das zunehmende Bewusstsein für die Vorteile der Robotik zur Verbesserung der Produktionseffizienz, der Lebensmittelsicherheit und der Produktqualität steigert die Nachfrage. Regierungsinitiativen zur Förderung intelligenter Fertigungs- und Lebensmittelsicherheitsstandards fördern den Einsatz fortschrittlicher Robotersysteme zusätzlich.

Markteinblick in Lebensmittelrobotik in verarbeiteten Lebensmitteln in Japan

Der japanische Markt für Lebensmittelrobotik dürfte aufgrund der starken Präferenz von Verbrauchern und Herstellern für hochwertige, technologisch fortschrittliche Robotersysteme, die die Produktionseffizienz und -sicherheit steigern, ein rasantes Wachstum verzeichnen. Die Präsenz großer Hersteller von Lebensmittelverarbeitungsanlagen und die Integration von Robotern in Großanlagen beschleunigen die Marktdurchdringung. Das steigende Interesse an maßgeschneiderten Automatisierungslösungen trägt ebenfalls zum Wachstum bei.

Markteinblick in Lebensmittelrobotik für verarbeitete Lebensmittel in China

China hält den größten Anteil am Markt für Lebensmittelrobotik im asiatisch-pazifischen Raum. Grund hierfür sind die rasante Urbanisierung, der steigende Lebensmittelkonsum und die wachsende Nachfrage nach Automatisierung in der Lebensmittelverarbeitung. Die wachsende Mittelschicht des Landes und der Fokus auf intelligente Fertigung unterstützen die Einführung fortschrittlicher Robotersysteme. Starke inländische Fertigungskapazitäten und wettbewerbsfähige Preise verbessern die Marktzugänglichkeit.

Marktanteil der Lebensmittelrobotik in verarbeiteten Lebensmitteln

Die Lebensmittelrobotik in der Lebensmittelverarbeitungsindustrie wird hauptsächlich von etablierten Unternehmen angeführt, darunter:

- ABB (Schweiz)

- Kawasaki Heavy Industries, Ltd. (Japan)

- YASKAWA ELECTRIC CORPORATION (Japan)

- Rockwell Automation, Inc. (USA)

- FANUC CORPORATION (Japan)

- Mitsubishi Electric Corporation (Japan)

- Universal Robots A/S (Dänemark)

- KUKA AG (Deutschland)

- Seiko Epson Corporation (Japan)

- Stäubli International AG (Schweiz)

- MAYEKAWA MFG. CO., LTD. (Japan)

- Bastian Solutions, Inc. (USA)

- MYCOM OSI (USA)

- DENSO CORPORATION (Japan)

- Toshiba Corporation (Japan)

- Stryker (USA)

- Adept Technologies Inc. (USA)

- Panasonic Corporation (Japan)

- Comau (Italien)

- Nachi Robotic Systems, Inc. (USA)

Was sind die jüngsten Entwicklungen auf dem globalen Markt für Lebensmittelrobotik in verarbeiteten Lebensmitteln?

- Im Februar 2025 gab LBX Food Robotics die Expansion seiner Bake Xpress-Kioske für warme Speisen nach Kanada bekannt, nachdem die Zertifizierung der Canadian Standards Association (CSA) erreicht worden war. Dieser Meilenstein ermöglicht eine schnelle Einführung in verschiedenen Bereichen – wie Gastronomie, Einzelhandel, Gesundheitswesen und Bildungswesen – ohne dass individuelle Vor-Ort-Inspektionen erforderlich sind. Obwohl Bake Xpress keine traditionelle Anwendung für verarbeitete Lebensmittel darstellt, stellt es einen bedeutenden Fortschritt in der automatisierten Lebensmittelzubereitung und -ausgabe dar und bietet frisch gebackene Mahlzeiten und Gebäck auf Abruf über einen kompakten Roboterkiosk. Dieser Schritt unterstreicht die wachsende Bedeutung der Lebensmittelrobotik für die Bereitstellung praktischer, hochwertiger Mahlzeiten in unbeaufsichtigten Umgebungen.

- Im Juli 2024 stellte Chef Robotics den ersten KI-gesteuerten, flexiblen Lebensmittelroboter seiner Art vor, der dem Arbeitskräftemangel entgegenwirken und die Produktion in der Lebensmittelherstellung steigern soll. Angetrieben von ChefOS, der firmeneigenen Lebensmittelmanipulationssoftware, passt sich der Roboter an Produktionsumgebungen mit hoher Produktvielfalt an und verarbeitet präzise unterschiedliche Zutaten und Portionsgrößen. Im Gegensatz zur herkömmlichen Automatisierung bietet das System von Chef eine Teilautomatisierung, die sich nahtlos in bestehende Arbeitsabläufe integriert. Namhafte Kunden wie Amy's Kitchen, Sunbasket und Chef Bombay setzen die Technologie bereits ein und berichten von Verbesserungen bei Konsistenz, Arbeitsproduktivität und Durchsatz.

- Im August 2023 nahm der britische Robotik-Innovator Wootzano offiziell seinen Betrieb in den USA auf und brachte seinen Flaggschiff-Roboter Avarai auf den Markt. Der für Nachernteanwendungen entwickelte Avarai nutzt eingebettete elektronische Haut und KI-gestützte Computervision, um empfindliche Frischprodukte – wie Trauben und Tomaten – schonend und ohne Druckstellen oder Beschädigungen zu behandeln. Diese Präzision reduziert Lebensmittelverluste und steigert die Verpackungseffizienz, wodurch dem Arbeitskräftemangel in den Verpackungshallen entgegengewirkt wird. Die Expansion, unterstützt von Partnern wie der Fresno County Economic Development Corporation und dem Britischen Generalkonsulat in San Francisco, markiert einen wichtigen Meilenstein in Wootzanos globaler Wachstumsstrategie.

- Im April 2023 stellte Doosan Robotics seine E-SERIES vor, eine bahnbrechende Produktlinie NSF-zertifizierter kollaborativer Roboter speziell für die Lebensmittel- und Getränkeindustrie. Dank abgedichteter Achsen und schlanker, hygienischer Bauweise erfüllen diese Cobots strenge Sicherheitsstandards und bieten gleichzeitig außergewöhnliche Flexibilität bei der Lebensmittelzubereitung. Mit einer Nutzlast von 5 kg und einer Reichweite von fast 90 cm eignet sich die E-SERIES für vielfältige Anwendungen – vom Hähnchenbraten bis zum Kaffeekochen – und wird bereits in Konzepten wie Robert Chicken und Dr. Presso eingesetzt. Diese Markteinführung markiert einen bedeutenden Schritt zur Automatisierung der Lebensmittelproduktion mit effizienten, hygienischen und anpassungsfähigen Roboterlösungen.

- Im April 2023 startete ABB Robotics eine Kooperation mit Pulmuone, einem führenden koreanischen Lebensmittelverarbeitungsunternehmen, um KI-gestützte Roboterlösungen für die Zucht von Meeresfrüchten im Labor zu entwickeln. Die Partnerschaft konzentriert sich auf die Automatisierung der Handhabung und Prüfung von Zellkulturen, um die Produktionseffizienz zu steigern, Kontaminationsrisiken zu reduzieren und qualifizierte Labormitarbeiter von repetitiven Aufgaben zu entlasten. ABBs Portfolio an kollaborativen Robotern (Cobots) wird eine Schlüsselrolle bei der sicheren Unterstützung menschlicher Bediener spielen. Pulmuone plant, diese Technologie bis 2026 für die Massenproduktion zu nutzen und damit möglicherweise als erstes Unternehmen KI-Robotik für zellkultivierte Lebensmittel einzusetzen.

SKU-

Erhalten Sie Online-Zugriff auf den Bericht zur weltweit ersten Market Intelligence Cloud

- Interaktives Datenanalyse-Dashboard

- Unternehmensanalyse-Dashboard für Chancen mit hohem Wachstumspotenzial

- Zugriff für Research-Analysten für Anpassungen und Abfragen

- Konkurrenzanalyse mit interaktivem Dashboard

- Aktuelle Nachrichten, Updates und Trendanalyse

- Nutzen Sie die Leistungsfähigkeit der Benchmark-Analyse für eine umfassende Konkurrenzverfolgung

Forschungsmethodik

Die Datenerfassung und Basisjahresanalyse werden mithilfe von Datenerfassungsmodulen mit großen Stichprobengrößen durchgeführt. Die Phase umfasst das Erhalten von Marktinformationen oder verwandten Daten aus verschiedenen Quellen und Strategien. Sie umfasst die Prüfung und Planung aller aus der Vergangenheit im Voraus erfassten Daten. Sie umfasst auch die Prüfung von Informationsinkonsistenzen, die in verschiedenen Informationsquellen auftreten. Die Marktdaten werden mithilfe von marktstatistischen und kohärenten Modellen analysiert und geschätzt. Darüber hinaus sind Marktanteilsanalyse und Schlüsseltrendanalyse die wichtigsten Erfolgsfaktoren im Marktbericht. Um mehr zu erfahren, fordern Sie bitte einen Analystenanruf an oder geben Sie Ihre Anfrage ein.

Die wichtigste Forschungsmethodik, die vom DBMR-Forschungsteam verwendet wird, ist die Datentriangulation, die Data Mining, die Analyse der Auswirkungen von Datenvariablen auf den Markt und die primäre (Branchenexperten-)Validierung umfasst. Zu den Datenmodellen gehören ein Lieferantenpositionierungsraster, eine Marktzeitlinienanalyse, ein Marktüberblick und -leitfaden, ein Firmenpositionierungsraster, eine Patentanalyse, eine Preisanalyse, eine Firmenmarktanteilsanalyse, Messstandards, eine globale versus eine regionale und Lieferantenanteilsanalyse. Um mehr über die Forschungsmethodik zu erfahren, senden Sie eine Anfrage an unsere Branchenexperten.

Anpassung möglich

Data Bridge Market Research ist ein führendes Unternehmen in der fortgeschrittenen formativen Forschung. Wir sind stolz darauf, unseren bestehenden und neuen Kunden Daten und Analysen zu bieten, die zu ihren Zielen passen. Der Bericht kann angepasst werden, um Preistrendanalysen von Zielmarken, Marktverständnis für zusätzliche Länder (fordern Sie die Länderliste an), Daten zu klinischen Studienergebnissen, Literaturübersicht, Analysen des Marktes für aufgearbeitete Produkte und Produktbasis einzuschließen. Marktanalysen von Zielkonkurrenten können von technologiebasierten Analysen bis hin zu Marktportfoliostrategien analysiert werden. Wir können so viele Wettbewerber hinzufügen, wie Sie Daten in dem von Ihnen gewünschten Format und Datenstil benötigen. Unser Analystenteam kann Ihnen auch Daten in groben Excel-Rohdateien und Pivot-Tabellen (Fact Book) bereitstellen oder Sie bei der Erstellung von Präsentationen aus den im Bericht verfügbaren Datensätzen unterstützen.