في وقت سابق، كان كل شيء يحتاج إلى المراقبة والتحكم يدويًا من قبل العمال الموجودين في أرضية الإنتاج، الأمر الذي كان يستغرق وقتًا طويلاً للغاية ويزيد من فرصة حدوث المزيد من الأخطاء البشرية. وتدريجياً، بدأت الشركات في تحويل مواقع إنتاجها إلى مصانع رقمية. لعبت الصناعة 4.0 دورًا مهمًا في أتمتة المصانع باستخدام مكونات مختلفة مثل أجهزة الكمبيوتر والبرامج. في عصر اليوم حيث تحتاج الصناعات إلى التعامل مع عمليات أكثر تعقيدًا وتتطلب إنتاجًا فعالاً، من الضروري لأي صناعة أن تكون قادرة على المنافسة وأن تظل محدثة للاتجاهات الرقمية. ومن ثم، أصبحت تطبيقات الكمبيوتر الصناعية أكثر أهمية من أي وقت مضى لأنها تخلق فرصًا هائلة لسوق العرض خلال الفترة المتوقعة.

الوصول إلى التقرير الكامل @ https://www.databridgemarketresearch.com/reports/global-rugged-industrial-display-market

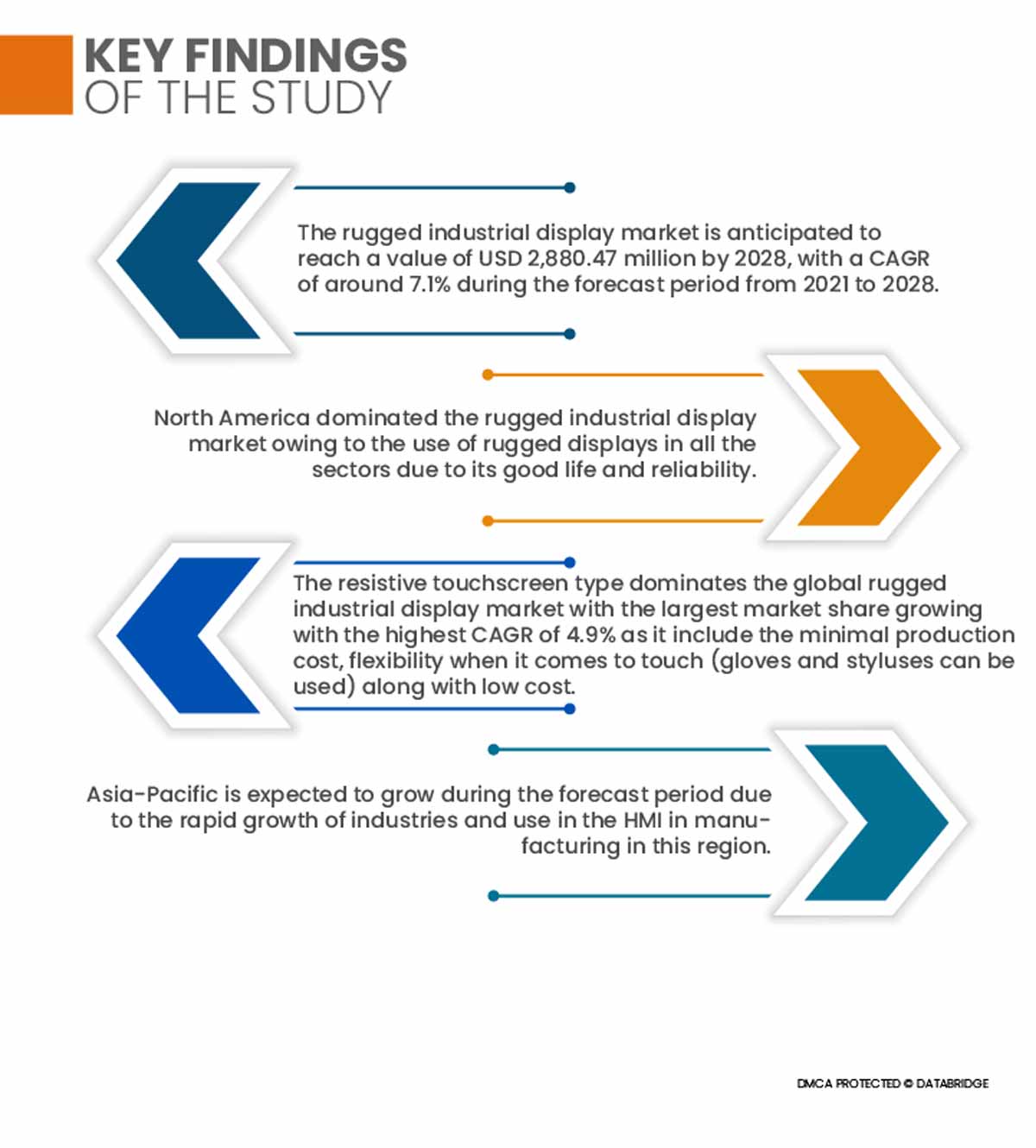

تحلل أبحاث سوق Data Bridge أنه من المتوقع أن ينمو سوق شاشات العرض الصناعية القوية بمعدل نمو سنوي مركب قدره 7.1٪ في الفترة المتوقعة من 2021 إلى 2028 ومن المتوقع أن يصل إلى 2,880.47 مليون دولار أمريكي بحلول عام 2028. وتساعد الأكشاك أيضًا في توفير التدريب للموظفين من خلال الدمج جميع المهام التدريبية على جهاز واحد، مثل مقاطع الفيديو والاختبارات والنماذج. ويساعد ذلك على توفير الوقت الذي يقضيه كل من المدير والموظف الجديد وتوفير الأموال التي يتم إنفاقها على طباعة العديد من الصفحات الورقية لكل شخص. وبالتالي، تساعد هذه العوامل على تعزيز تطبيقات الأكشاك في الصناعة التحويلية وغيرها من الصناعات ذات البيئة القاسية ولديها عدد كبير من الموظفين في المصنع لإدارتها، مما يؤدي إلى تسريع سوق العرض الصناعية الوعرة.

من المتوقع أن يؤدي الطلب المرتفع على واجهة الإنسان والآلة (HMI) عبر مختلف الصناعات إلى زيادة معدل نمو السوق

إن واجهة HMI المستخدمة في الصناعات هي في الغالب شاشات العرض أو شاشات اللمس التي تربط المستخدمين بالآلات أو الأنظمة أو الأجهزة. يستخدم المستخدم النهائي أو المشغل أجهزة HMI للتحكم في الآلات وأتمتتها، بالإضافة إلى خطوط الإنتاج. يمكن أن تكون أجهزة HMI عبارة عن شاشات عرض بسيطة مثبتة على الأجهزة في المصنع، أو شاشات لمس متقدمة، أو لوحات تحكم تدعم اللمس المتعدد، أو أجهزة كمبيوتر مزودة بلوحات مفاتيح، أو أزرار ضغط، أو أجهزة محمولة، أو أجهزة لوحية. HMI يعزز أداء النظام العام للنباتات. ولذلك، فإن الطلب على HMI آخذ في الارتفاع حيث أصبحت أتمتة المصانع حاجة للشركات لإكمال مهامها بكفاءة أكبر والحصول على مزايا تنافسية في السوق. علاوة على ذلك، فإن HMI قادرة على فعل العجائب في مجال الرعاية الصحية والأتمتة الصناعية والصناعات العسكرية والدفاعية حيث تلبي خبرة التصميم والتكامل جميع احتياجات الصناعات. ولذلك، من المتوقع أن يؤدي الطلب المتزايد على HMI إلى تسارع الطلب خلال الفترة المتوقعة.

نطاق التقرير وتقسيم السوق

|

تقرير المقياس

|

تفاصيل

|

|

فترة التنبؤ

|

2021 إلى 2028

|

|

سنة الأساس

|

2020

|

|

سنوات تاريخية

|

2019 (قابل للتخصيص حتى 2018 - 2013)

|

|

الوحدات الكمية

|

الإيرادات بمليون دولار أمريكي، الأحجام بالوحدات، التسعير بالدولار الأمريكي

|

|

القطاعات المغطاة

|

حسب التكنولوجيا (LCD، LED، OLED، شاشة عرض الورق الإلكتروني)، حجم العرض (8 بوصة - 11 بوصة، 11 بوصة - 12 بوصة، 13 بوصة - 18 بوصة، 19 بوصة - 25 بوصة، 40 بوصة - أعلى)، الدقة ( 1920*1200، 1920*1080، 1280*1024، 1024*768، 800*600، 1366*768، أخرى)، التثبيت (تركيب اللوحة، تركيب الحامل، التثبيت على الحائط، التثبيت على الذراع، الإطار المفتوح، أخرى) )، نوع الشاشة التي تعمل باللمس (مقاومة، PCAP، تعمل باللمس بالأشعة تحت الحمراء، سعوية)، التطبيق (الطبي، HMI، الأتمتة الصناعية، الأكشاك/نقاط البيع، اللافتات الرقمية، التصوير والألعاب/اليانصيب)، العمودي (النفط والغاز، التصنيع، المواد الكيميائية، الطاقة والأدوات الطاقة والتعدين والمعادن والنقل والجيش والدفاع وغيرها)

|

|

البلدان المشمولة

|

الولايات المتحدة، كندا، المكسيك، البرازيل، الأرجنتين، بقية أمريكا الجنوبية، ألمانيا، فرنسا، إيطاليا، المملكة المتحدة، بلجيكا، إسبانيا، روسيا، تركيا، هولندا، سويسرا، بقية أوروبا، اليابان، الصين، الهند، كوريا الجنوبية، أستراليا، سنغافورة وماليزيا وتايلاند وإندونيسيا والفلبين وبقية دول آسيا والمحيط الهادئ والإمارات العربية المتحدة والمملكة العربية السعودية ومصر وجنوب أفريقيا وإسرائيل وبقية دول الشرق الأوسط وأفريقيا

|

|

تغطية لاعبي السوق

|

سامسونج (كوريا الجنوبية)، شركة روكويل أوتوميشن (الولايات المتحدة)، شركة باناسونيك (اليابان)، شركة إن إي سي (اليابان)، شنايدر إلكتريك (فرنسا)، سيمنز (ألمانيا)، جنرال إلكتريك (الولايات المتحدة)، شركة إيمرسون إلكتريك ( الولايات المتحدة)، Advantech Co., Ltd. (تايوان)، Innolux Corporation (تايوان)، Pepperl+Fuchs SE (ألمانيا)، Planar (الولايات المتحدة)، AU Optronics Corp. (تايوان)، LG Display Co., Ltd. (كوريا الجنوبية) Japan Display Inc. (اليابان)، General Digital Corporation (الولايات المتحدة)، BOE Technology UK Limited (المملكة المتحدة)، TRICOMTEK CO.,LTD. (تايوان)، وشركة Tianma Microelectronics Co., Ltd. (الصين)، وشركة Shenzhen TOPWAY Technology Co., Ltd. (الصين).

|

|

نقاط البيانات المشمولة في التقرير

|

بالإضافة إلى رؤى السوق مثل القيمة السوقية ومعدل النمو وقطاعات السوق والتغطية الجغرافية واللاعبين في السوق وسيناريو السوق، يتضمن تقرير السوق الذي ينظمه فريق أبحاث السوق Data Bridge أيضًا تحليلًا متعمقًا للخبراء والاستيراد / التصدير التحليل، تحليل التسعير، تحليل استهلاك الإنتاج، وتحليل المدقة.

|

تحليل القطاع:

عالمي سوق العرض الصناعي الوعرة مقسمة إلى سبعة قطاعات بارزة تعتمد على التكنولوجيا وحجم العرض والدقة والتركيب ونوع الشاشة التي تعمل باللمس والتطبيق والوضع الرأسي.

- على أساس التكنولوجيا، يتم تقسيم سوق شاشات العرض الصناعية القوية إلى شاشات LCD وLED وOLED وشاشات الورق الإلكتروني. يتم تقسيم LED أيضًا إلى مجموعة كاملة وإضاءة مباشرة وإضاءة حافة. يتم تقسيم OLED أيضًا إلى شاشة AMOLED وشاشة PMOLED. في عام 2021، يهيمن قطاع تكنولوجيا شاشات الكريستال السائل على سوق شاشات العرض الصناعية القوية العالمية وينمو بأعلى معدل نمو سنوي مركب يبلغ 4.5%.

يهيمن قطاع تكنولوجيا شاشات الكريستال السائل على سوق شاشات العرض الصناعية العالمية

في عام 2021، يهيمن قطاع تكنولوجيا شاشات الكريستال السائل على سوق شاشات العرض الصناعية القوية العالمية، حيث ينمو بأعلى معدل نمو سنوي مركب يبلغ 4.5٪ في الفترة المتوقعة من 2021 إلى 2028 بسبب العوامل العديدة التي تشمل استهلاك طاقة أقل، والتكلفة المنخفضة سواء من حيث الشركات المصنعة أيضًا. كمستهلكين وحجمها الصغير مقارنة بالتقنيات الأخرى.

- على أساس حجم العرض، يتم تقسيم السوق الصناعية القوية إلى 8 بوصات - 11 بوصة، و11 بوصة - 12 بوصة، و13 بوصة - 18 بوصة، و19 بوصة - 25 بوصة، و40 بوصة - أعلاه. في عام 2021، يهيمن القطاع مقاس 13 بوصة - 18 بوصة على سوق شاشات العرض الصناعية القوية العالمية، حيث ينمو بأعلى معدل نمو سنوي مركب يبلغ 4.8٪ في الفترة المتوقعة من 2021 إلى 2028. ويعتبر الحجم الأمثل للوحة المتكاملة وواجهة المستخدم البشرية (HMI).

- على أساس الدقة، يتم تقسيم سوق شاشات العرض الصناعية القوية إلى 1920*1200، 1920*1080، 1280*1024، 1024*768، 800*600، 1366*768 وغيرها. في عام 2021، تمتلك الدقة 1024*768 الحد الأقصى من الحصة في سوق شاشات العرض الصناعية القوية العالمية التي تنمو بأعلى معدل نمو سنوي مركب يبلغ 4.8% في الفترة المتوقعة من 2021 إلى 2028 نظرًا لنسبة العرض إلى الارتفاع البالغة 4:3 والتي تعد مثالية للبرامج القديمة والمستخدمين. واجهة HMI مما يؤدي إلى تحسين معدل الاستخدام في التطبيقات الصناعية المتنوعة.

- على أساس التركيب، يتم تقسيم سوق شاشات العرض الصناعية القوية إلى تركيب الألواح، والتركيب على الرف، والتركيب على الحائط، والتركيب على الذراع، والإطار المفتوح وغيرها. في عام 2021، سيحظى قطاع تركيب الألواح بأكبر حصة سوقية متنامية مع أعلى معدل نمو سنوي مركب يبلغ 4.8%

يتمتع قطاع تركيب اللوحات بأكبر حصة سوقية متنامية مع أعلى معدل نمو سنوي مركب يبلغ 4.8%

في عام 2021، سيحظى قطاع تركيب اللوحات بأكبر حصة في السوق، حيث ينمو بأعلى معدل نمو سنوي مركب يبلغ 4.8% في الفترة المتوقعة من 2021 إلى 2028. وتعد الشاشات مثالية لتركيب جميع أحجام شاشات العرض مع المنتجات المحصورة في المساحات المخصصة للشاشات الكبيرة. مرافق الانتاج. علاوة على ذلك، يدعم هذا النوع من التركيب تقنيات اللمس سواء السعوية أو المقاومة.

- على أساس نوع الشاشة التي تعمل باللمس، يتم تقسيم سوق شاشات العرض الصناعية القوية إلى شاشات مقاومة، وPCAP، وشاشات تعمل باللمس تعمل بالأشعة تحت الحمراء، وشاشات سعوية. في عام 2021، يهيمن نوع شاشة اللمس المقاومة على سوق شاشات العرض الصناعية القوية العالمية مع نمو أكبر حصة في السوق بأعلى معدل نمو سنوي مركب يبلغ 4.9٪ في الفترة المتوقعة من 2021 إلى 2028 حيث أنها تتضمن الحد الأدنى من تكلفة الإنتاج والمرونة عندما يتعلق الأمر باللمس (القفازات). ويمكن استخدام الأقلام) إلى جانب التكلفة المنخفضة.

- على أساس التطبيق، يتم تقسيم سوق شاشات العرض الصناعية القوية إلى الطبية، وواجهة التفاعل بين البشر (HMI)، والأتمتة الصناعية، والأكشاك/نقاط البيع، واللافتات الرقمية، والتصوير، والألعاب/اليانصيب. يتم تقسيم كل قطعة إلى حجم وحجم. في عام 2021، يمتلك قطاع HMI أكبر حصة سوقية تنمو بأعلى معدل نمو سنوي مركب يبلغ 4.5٪ في الفترة المتوقعة من 2021 إلى 2028 بسبب عامل مثل الاعتماد على نطاق واسع في القطاع الصناعي مثل النفط والغاز والصناعات التحويلية حيث يتمتع بالقدرة لتوفير التشغيل الذكي للآلات ذات الأداء العام العالي.

- على أساس عمودي، يتم تقسيم سوق شاشات العرض الصناعية الوعرة إلى النفط والغاز والتصنيع والكيماويات والطاقة والتعدين والمعادن والنقل والجيش والدفاع وغيرها. في عام 2021، يهيمن قطاع التصنيع على السوق بشكل عام مع نمو أكبر حصة سوقية بأعلى معدل نمو سنوي مركب يبلغ 3.9٪ في الفترة المتوقعة من 2021 إلى 2028 حيث يتم استخدامه بشكل رئيسي في كل من الصناعات والمصانع لعملية الأتمتة عبر النظام الذكي مما يؤدي إلى تعزيز الإنتاجية الإجمالية للعديد من العمليات. إضافة إلى ذلك، تؤدي الزيادة في اعتماد نظام إنترنت الأشياء في ظل الصناعة 4.0 أيضًا إلى زيادة الإنتاج إلى الحد الأقصى بطريقة فعالة.

اللاعبين الرئيسيين

تعترف Data Bridge Market Research بالشركات التالية باعتبارها شركات العرض الصناعية القوية الرئيسية الجهات الفاعلة في السوق في سوق شاشات العرض الصناعية القوية هي سامسونج (كوريا الجنوبية)، وشركة روكويل أوتوميشن (الولايات المتحدة)، وشركة باناسونيك (اليابان)، وشركة إن إي سي (اليابان)، وشنايدر إلكتريك (فرنسا)، وسيمنز (ألمانيا)، وجنرال إلكتريك (الولايات المتحدة). ).، Emerson Electric Co. (الولايات المتحدة)، Advantech Co., Ltd. (تايوان)، Innolux Corporation (تايوان)، Pepperl+Fuchs SE (ألمانيا)، Planar (الولايات المتحدة)، AU Optronics Corp. (تايوان)، LG Display Co. ., Ltd. (كوريا الجنوبية) Japan Display Inc. (اليابان)، General Digital Corporation (الولايات المتحدة)، BOE Technology UK Limited (المملكة المتحدة)، TRICOMTEK CO.,LTD. (تايوان)، وشركة Tianma Microelectronics Co., Ltd. (الصين)، وشركة Shenzhen TOPWAY Technology Co., Ltd. (الصين).

تطوير السوق

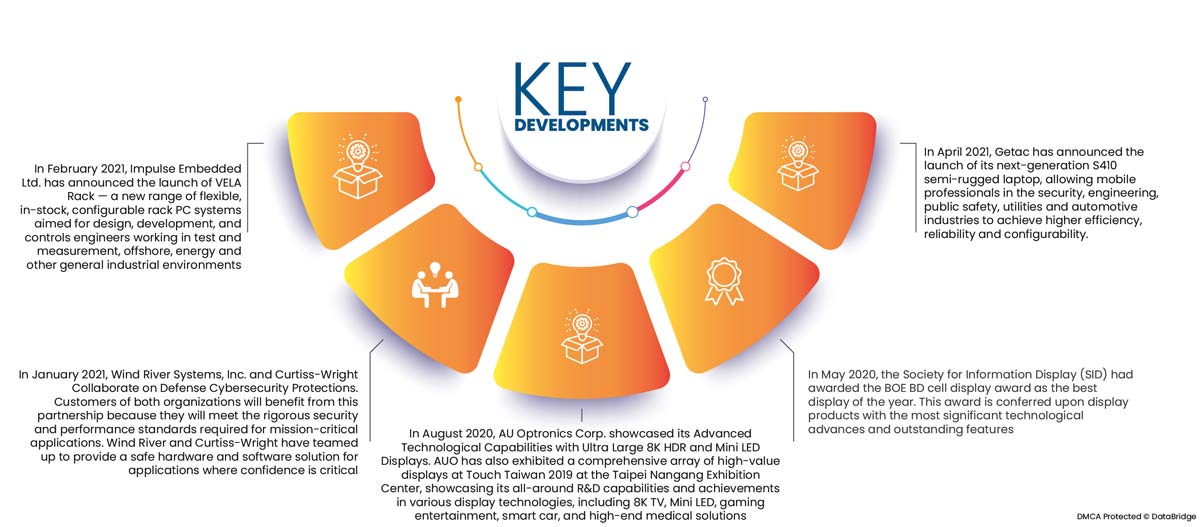

- في فبراير 2021، أعلنت شركة Impulse Embedded Ltd. عن إطلاق VELA Rack - وهي مجموعة جديدة من أنظمة أجهزة الكمبيوتر الشخصية المرنة والمتوفرة والقابلة للتكوين والتي تستهدف مهندسي التصميم والتطوير والتحكم العاملين في مجالات الاختبار والقياس والبحرية والطاقة والنقل. البيئات الصناعية العامة الأخرى

- في يناير 2021، تعاونت شركة Wind River Systems, Inc. وشركة Curtiss-Wright في حماية الأمن السيبراني الدفاعي. وسيستفيد عملاء كلتا المؤسستين من هذه الشراكة لأنهم سيستوفون معايير الأمان والأداء الصارمة المطلوبة للتطبيقات ذات المهام الحرجة. لقد تعاونت Wind River وCirtiss-Wright لتوفير حلول الأجهزة والبرامج الآمنة للتطبيقات التي تعتبر الثقة فيها أمرًا بالغ الأهمية

- في أغسطس 2020، عرضت شركة AU Optronics Corp. قدراتها التكنولوجية المتقدمة من خلال شاشات العرض الكبيرة جدًا بدقة 8K HDR وشاشات Mini LED. عرضت AUO أيضًا مجموعة شاملة من شاشات العرض عالية القيمة في معرض Touch Taiwan 2019 في مركز تايبيه نانغانغ للمعارض، حيث عرضت قدراتها الشاملة في مجال البحث والتطوير وإنجازاتها في تقنيات العرض المختلفة، بما في ذلك تلفزيون 8K، وMini LED، وترفيه الألعاب، والسيارة الذكية، والحلول الطبية الراقية

- في مايو 2020، منحت جمعية عرض المعلومات (SID) جائزة العرض الخلوي BOE BD كأفضل عرض لهذا العام. تُمنح هذه الجائزة لمنتجات العرض ذات التقدم التكنولوجي الكبير والميزات المتميزة.

- في أبريل 2021، أعلنت Getac عن إطلاق الجيل التالي من الكمبيوتر المحمول S410 شبه المتين، مما يسمح للمحترفين المتنقلين في مجالات الأمن والهندسة والسلامة العامة والمرافق وصناعات السيارات بتحقيق كفاءة أعلى وموثوقية وقابلية للتكوين. يتميز جهاز S410 الجديد بأداء محسّن طوال اليوم وشاشة عرض رائعة جديدة وزيادة في الذاكرة والمعالجة.

- في أبريل 2020، أعلنت Getac عن إطلاق الجيل التالي من الكمبيوتر اللوحي K120 المتين تمامًا، والمصمم للمحترفين في مجال التنقل في الصناعات الصعبة مثل السلامة العامة والتصنيع والبنية التحتية والدفاع والنقل والموارد الطبيعية والنفط والغاز.

التحليل الإقليمي

جغرافيًا، الدول المشمولة في تقرير سوق شاشات العرض الصناعية القوية هي الولايات المتحدة وكندا والمكسيك في أمريكا الشمالية وألمانيا والسويد وبولندا والدنمارك وإيطاليا والمملكة المتحدة وفرنسا وإسبانيا وهولندا وبلجيكا وسويسرا وتركيا وروسيا وبقية دول العالم. أوروبا في أوروبا واليابان والصين والهند وكوريا الجنوبية ونيوزيلندا وفيتنام وأستراليا وسنغافورة وماليزيا وتايلاند وإندونيسيا والفلبين وبقية آسيا والمحيط الهادئ (APAC) في آسيا والمحيط الهادئ (APAC) والبرازيل والأرجنتين، بقية أمريكا الجنوبية كجزء من أمريكا الجنوبية والإمارات العربية المتحدة والمملكة العربية السعودية وعمان وقطر والكويت وجنوب أفريقيا وبقية الشرق الأوسط وأفريقيا (MEA) كجزء من الشرق الأوسط وأفريقيا (MEA).

وفقًا لتحليل أبحاث سوق Data Bridge:

أمريكا الشمالية هي المنطقة المهيمنة في سوق العرض الصناعي الوعرة خلال فترة التوقعات

سيطرت أمريكا الشمالية على سوق شاشات العرض الصناعية القوية بسبب استخدام شاشات العرض القوية في جميع القطاعات نظرًا لعمرها الجيد وموثوقيتها. ستستمر أمريكا الشمالية في السيطرة على سوق شاشات العرض الصناعية الوعرة من حيث الحصة السوقية وإيرادات السوق وستستمر في ازدهار هيمنتها خلال الفترة المتوقعة. ويرجع ذلك إلى ارتفاع الاستهلاك والصناعات والاعتماد في القطاع العسكري والدفاعي في هذه المنطقة.

آسيا والمحيط الهادئ من المقدر أن تكون المنطقة الأسرع نموًا في سوق شاشات العرض الصناعية الوعرة

من المتوقع أن تنمو منطقة آسيا والمحيط الهادئ خلال الفترة المتوقعة بسبب النمو السريع للصناعات واستخدام مؤشر HMI في التصنيع في هذه المنطقة. بالإضافة إلى ذلك، من المتوقع أن تؤدي تطوراتها في الصناعات والميزانية العسكرية والدفاعية إلى دفع معدل نمو السوق في هذه المنطقة.

التقدم التكنولوجي وتطور أجهزة العرض عالية الدقة في السوق

شهد سوق العرض الصناعي تحسينات تكنولوجية هائلة في العقد الماضي. كانت أنظمة العرض التقليدية المعتمدة على تقنية أنبوب أشعة الكاثود (CRT) كبيرة وتشغل مساحة كبيرة، وبالتالي لم تكن قادرة على تلبية احتياجات التطبيقات الصناعية. وفي نهاية المطاف، تحولت أجهزة العرض من كونها كبيرة وتشغل مساحة كبيرة إلى كونها صغيرة وذات إطار ضيق. تعد الدقة العالية، والمتانة، والاستقرار البيئي، وسهولة القراءة، ونطاق درجة الحرارة الواسع، والصلابة، وزيادة نسبة التباين، وسطوع الشاشة الأعلى، وانخفاض استهلاك الطاقة، كلها من المزايا التي تتمتع بها أجهزة العرض هذه الآن. وقد أدى ذلك إلى إنشاء شاشات عرض صناعية مثالية للصناعات الخطرة والكارثية مثل النفط والغاز والتعدين وتوليد الطاقة والأغذية والمشروبات والأدوية والمواد الكيميائية.

للحصول على معلومات أكثر تفصيلاً حول سوق العرض الصناعي الوعرة التقرير اضغط هنا – https://www.databridgemarketresearch.com/reports/global-rugged-industrial-display-market