يتميز المحمل المركب بحقيقة أنه مصنوع من مواد مختلفة، بما في ذلك الألياف المقواة بالراتنج. يتم تضمين مواد التشحيم والمواد الكيميائية التي تقلل الاحتكاك. يمكن أيضًا تعديل المحامل المركبة لتلبية الاحتياجات المحددة في التطبيقات المختلفة، مثل مقاومة درجات الحرارة العالية. يتم استخدام المحامل المركبة في تكنولوجيا الطاقة الناشئة، مثل تدوير المرايا في أبراج الطاقة الشمسية. يمكنها تحمل الأوزان، ومقاومة للعوامل الجوية والتآكل، ولها معامل احتكاك منخفض وثابت. يمكن تصميم المحامل المركبة لتلبية الاحتياجات المحددة لمختلف التطبيقات، بما في ذلك مقاومة التآكل ودرجات الحرارة العالية.

الوصول إلى التقرير الكامل @ https://www.databridgemarketresearch.com/reports/global-composite-bearings-market

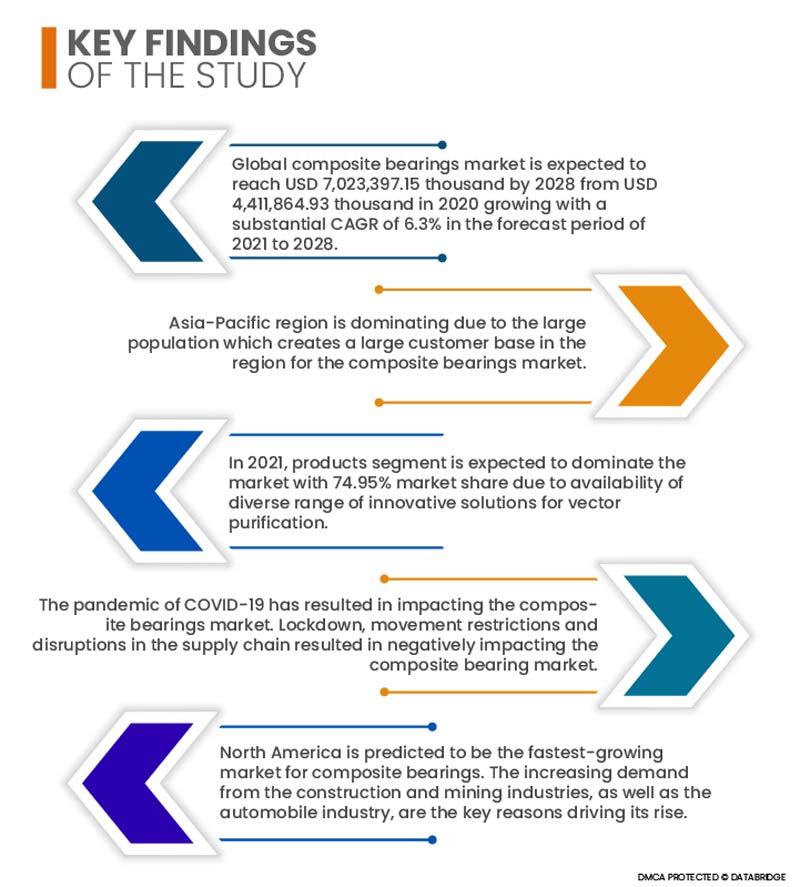

من المتوقع أن يصل سوق المحامل المركبة العالمية إلى 7,023,397.15 ألف دولار أمريكي بحلول عام 2028 من 4,411,864.93 ألف دولار أمريكي في عام 2020، وينمو بمعدل نمو سنوي مركب كبير قدره 6.3٪ في الفترة المتوقعة من 2021 إلى 2028. من أجل تحسين الخواص الميكانيكية لمنتجات المحامل المركبة، غالبًا ما يتم مزج أنواع مختلفة من الراتنجات مع معدلات الاحتكاك، بما في ذلك الجرافيت أو PTFE أو كبريتيد الموليبدينوم. يزداد الطلب على منتجات المحامل المركبة في جميع المناطق بسبب بعض الخصائص المهمة للمادة، مثل انخفاض امتصاص الماء، وثبات الأبعاد العالي، والمقاومة العالية للمذيبات، ومعامل الاحتكاك المنخفض. والأهم من ذلك أيضًا، أن المحامل المركبة تساعد في تقليل التآكل في الماكينة. أصبحت المحامل المركبة حاسمة في تطبيقات الطيران والسيارات والبناء والتعدين بسبب الوزن الخفيف والخصائص الفائقة والصيانة المنخفضة وعمر المنتج الطويل وهذه بعض محددات نمو السوق المهمة الأخرى.

الارتفاع في استخدام المحامل عبر مجموعة واسعة من التطبيقات الصناعية على مستوى العالم ومن المتوقع أن يقود معدل نمو السوق

يتم إنتاج المحامل المركبة من مواد مكونة من مكونات مختلفة تهدف إلى نقل معامل احتكاك منخفض، وثبات عالي الأبعاد، ومقاومة عالية للمذيبات. تتمتع المحامل المركبة بمجموعة واسعة من التطبيقات نظرًا لقدرتها العالية على التحمل، ومقاومة التآكل، وخصائص التشحيم الذاتي، وخصائص مقاومة التآكل. يتم استخدام المحامل المركبة في كل صناعة تقريبًا تستخدم الأجزاء المتحركة والآلات. وبالتالي، فإن الطلب المتزايد على الجودة والأداء في مختلف القطاعات الصناعية والمتعلقة بالمستهلكين سيعزز سوق المحامل المركبة العالمية.

نطاق التقرير وتقسيم السوق

|

تقرير المقياس

|

تفاصيل

|

|

فترة التنبؤ

|

2021 إلى 2028

|

|

سنة الأساس

|

2020

|

|

سنوات تاريخية

|

2019 (قابل للتخصيص حتى 2012 - 2017)

|

|

الوحدات الكمية

|

الإيرادات بالدولار الأمريكي، الأحجام بالوحدات، التسعير بالدولار الأمريكي

|

|

القطاعات المغطاة

|

نوع المنتج (مصفوفة ألياف ومصفوفة معدنية)، المادة (مركب بولي تيترا فلورو إيثيلين (PTFE) ومركب بولي أوكسي ميثيلين (POM)، الشكل (شجيرات أسطوانية، وشجيرات ذات حواف، وألواح منزلقة، وغسالات دفع وغسالات ذات حواف)، وقناة التوزيع (غير متصل وعبر الإنترنت)، التطبيقات (البناء والتعدين، السيارات، الفضاء، الزراعة، البحرية، الطاقة المتجددة، الأغذية والمشروبات، معدات الصالات الرياضية، النفط والغاز، الصناعة الهيدروليكية وغيرها)

|

|

البلدان المشمولة

|

الولايات المتحدة وكندا والمكسيك في أمريكا الشمالية وألمانيا وفرنسا والمملكة المتحدة وهولندا وسويسرا وبلجيكا وروسيا وإيطاليا وإسبانيا وتركيا وبقية أوروبا في أوروبا والصين واليابان والهند وكوريا الجنوبية وسنغافورة وماليزيا وأستراليا، تايلاند، إندونيسيا، الفلبين، بقية دول آسيا والمحيط الهادئ (APAC) في منطقة آسيا والمحيط الهادئ (APAC)، المملكة العربية السعودية، الإمارات العربية المتحدة، جنوب أفريقيا، مصر، إسرائيل، وبقية دول الشرق الأوسط وأفريقيا (MEA) كجزء من الشرق الأوسط وأفريقيا (MEA) والبرازيل والأرجنتين وبقية أمريكا الجنوبية كجزء من أمريكا الجنوبية.

|

|

تغطية لاعبي السوق

|

شركة Polygon (الهند)، Schaeffler AG (ألمانيا)، Huntsman International LLC (الولايات المتحدة)، HyComp LLC (الولايات المتحدة)، GGB (المملكة المتحدة)، SGL Carbon (ألمانيا)، CIP Composites (الولايات المتحدة)، شركة Rexnord (الولايات المتحدة)، Tenneco Inc. (الولايات المتحدة)، SPAULDING COMPOSITES (الولايات المتحدة)، TIODIZE Co., Inc. (الولايات المتحدة)، Trelleborg AB (السويد)، شركة KOR-PAK (الولايات المتحدة)، RBC Bearings Incorporated (الولايات المتحدة)، TriStar Plastics Corp. (الولايات المتحدة)، SKF (السويد)، وQuality Pacific Manufacturing, Inc. (الولايات المتحدة)، وFTL Technology (الهند)، وTechnoslide (جنوب أفريقيا)، وRheinmetall Automotive AG (ألمانيا) وغيرها.

|

|

نقاط البيانات التي يغطيها التقرير

|

بالإضافة إلى رؤى السوق مثل القيمة السوقية ومعدل النمو وقطاعات السوق والتغطية الجغرافية واللاعبين في السوق وسيناريو السوق، يتضمن تقرير السوق الذي أعده فريق أبحاث السوق Data Bridge تحليلاً متعمقًا للخبراء وتحليل الاستيراد / التصدير، تحليل التسعير، وتحليل استهلاك الإنتاج، وسيناريو السلسلة المناخية.

|

تحليل القطاع:

عالمي سوق المحامل المركبة يتم تقسيمها إلى خمسة قطاعات بارزة تعتمد على نوع المنتج والمواد والشكل وقناة التوزيع والتطبيق.

- بناءً على نوع المنتج، يتم تقسيم سوق المحامل المركبة إلى مصفوفة ألياف ومصفوفة معدنية. في عام 2021، من المتوقع أن يهيمن قطاع المصفوفة المعدنية على سوق المحامل المركبة العالمية بحصة سوقية تبلغ 64.73٪ حيث يمكن تشكيل المصفوفة المعدنية بسهولة وفقًا لمنتجات الصناعات المختلفة مما يزيد الطلب عليها عالميًا. وفي منطقة آسيا والمحيط الهادئ، يزداد الطلب على قطاع المصفوفة المعدنية في الصين والهند بسبب الزيادة في إنتاج منتجات محركات السيارات.

- على أساس المواد، يتم تقسيم سوق المحامل المركبة إلى مركب بولي رباعي فلورو الإيثيلين (PTFE) ومركب بولي أوكسي ميثيلين (POM). في عام 2021، من المتوقع أن يهيمن الجزء المركب من بولي تيترا فلورو إيثيلين (PTFE) على سوق المحامل المركبة العالمية بحصة سوقية تبلغ 75.04٪ حيث يتم استخدام مركب بولي تيترا فلورو إيثيلين (PTFE) في تصنيع العديد من المنتجات الداخلية للسيارات. في منطقة آسيا والمحيط الهادئ، يهيمن الجزء المركب من بولي تيترا فلورو إيثيلين (PTFE) حيث توجد تكنولوجيا إنتاج مركب بولي تيترا فلورو إيثيلين (PTFE) في المنطقة.

- على أساس الشكل، يتم تقسيم سوق المحامل المركبة إلى شجيرات أسطوانية، وشجيرات ذات حواف، وألواح منزلقة، وغسالات دفع، وغسالات ذات حواف. في عام 2021، من المتوقع أن يهيمن قطاع الشجيرات الأسطوانية على سوق المحامل المركبة العالمية بحصة سوقية تبلغ 39.45٪ حيث يتم استخدام شكل الشجيرات الأسطوانية لتقليل الاهتزازات والضوضاء الناتجة عن المحرك. في منطقة آسيا والمحيط الهادئ، يؤدي وجود مساحة كبيرة للزراعة إلى زيادة الطلب على قطاع الشجيرات الأسطوانية عالية الجودة في المنطقة. في أمريكا الشمالية، يهيمن قطاع الشجيرات الأسطوانية على السوق حيث يتم استخدام الشجيرات الأسطوانية بشكل أكبر في توربينات الرياح وفي محركات الطاقة المتجددة الأخرى.

- على أساس قناة التوزيع، يتم تقسيم سوق المحامل المركبة إلى متصل بالإنترنت وغير متصل. في عام 2021، من المتوقع أن يهيمن القطاع غير المتصل بالإنترنت على سوق المحامل المركبة العالمية بحصة سوقية تبلغ 89.68٪ حيث يشارك غير المتصلين بالإنترنت في التصنيع بالجملة وبيع منتجات المحامل المركبة، مما يجعل القطاع غير المتصل بالإنترنت يهيمن على المنطقة. في منطقة آسيا والمحيط الهادئ، تؤدي الأعداد الكبيرة من التجار غير المتصلين بالإنترنت في المنطقة إلى جعل القطاع غير المتصل بالإنترنت يهيمن على المنطقة. في أمريكا الشمالية، يهيمن القطاع غير المتصل بالإنترنت على السوق نظرًا لأن الطلب على حجم معين من المحمل المركب وفقًا لمتطلبات المحرك يجعل القطاع غير المتصل بالإنترنت هو المهيمن في المنطقة.

- على أساس التطبيق، يتم تقسيم سوق المحامل المركبة إلى البناء والتعدين والسيارات والفضاء والزراعة والبحرية والطاقة المتجددة والأغذية والمشروبات ومعدات الصالة الرياضية والنفط والغاز والصناعات الهيدروليكية وغيرها. في عام 2021، من المتوقع أن يهيمن قطاع السيارات على سوق المحامل المركبة العالمية بحصة سوقية تبلغ 23.34% حيث يتم استخدام عدة أنواع وأحجام من منتجات المحامل المركبة في محرك السيارات، مما يجعل تطبيقات السيارات تهيمن عالميًا. وفي منطقة آسيا والمحيط الهادئ، يؤدي العدد الكبير من السكان في الهند والصين إلى زيادة الطلب على سيارات الركاب ووسائل النقل العام، مما يجعل قطاع السيارات مهيمناً في المنطقة. وفي أمريكا الشمالية، يتمتع الناس بقدرة شرائية أكبر ويفضلون شراء أحدث السيارات، مما يجعل قطاع السيارات يهيمن على المنطقة.

تهيمن السيارات على قطاع التطبيقات في سوق المحامل المركبة

في عام 2021، سيبرز قطاع السيارات باعتباره القطاع المهيمن بحصة سوقية تبلغ 23.3٪. ويرجع ذلك إلى العدد المتزايد من منافسات السيارات ومعرض السيارات لإكسسوارات المحرك، مما يجعل قطاع السيارات يهيمن على المنطقة. وفي الشرق الأوسط وأفريقيا، يؤدي استيراد وتصدير المواد الخام أو السلع تامة الصنع عبر الطرق إلى زيادة الطلب على المركبات الثقيلة، مما يجعل قطاع السيارات يهيمن على المنطقة.

اللاعبين الرئيسيين

تعترف أبحاث سوق Data Bridge بالشركات التالية باعتبارها اللاعبين الرئيسيين في سوق المحامل المركبة في السوق وهي HyComp LLC (الولايات المتحدة)، وGGB (المملكة المتحدة)، وRexnord Corporation (الولايات المتحدة)، وTenneco Inc. (الولايات المتحدة)، وTrelleborg AB (السويد)، وRBC. Bearings Incorporated (الولايات المتحدة)، وTriStar Plastics Corp. (الولايات المتحدة)، وRheinmetall Automotive AG (ألمانيا).

تطوير السوق

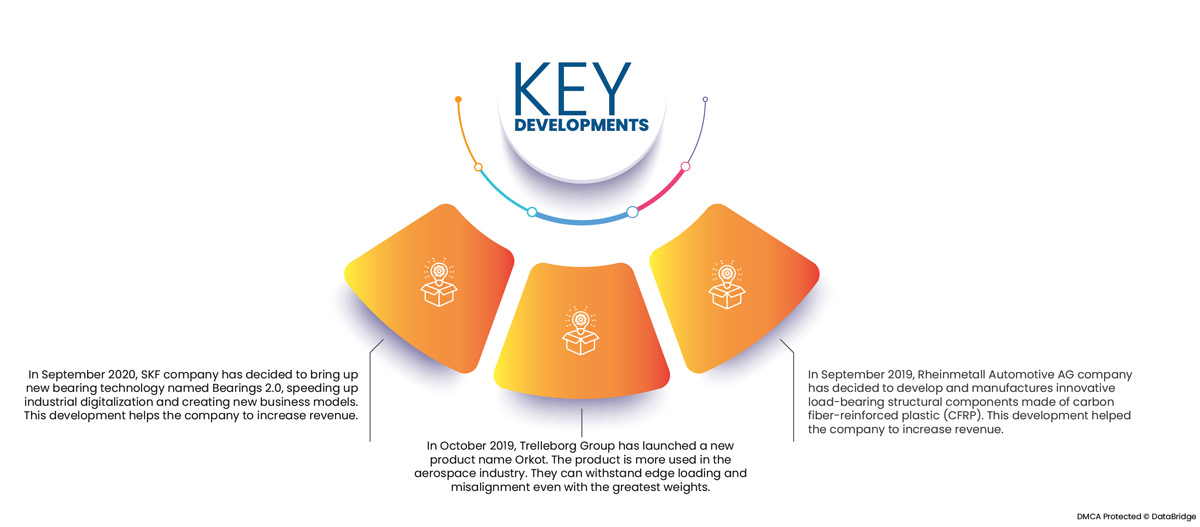

- في سبتمبر 2020، قررت شركة SKF طرح تقنية تحمل جديدة تسمى Bearings 2.0، لتسريع عملية الرقمنة الصناعية وإنشاء نماذج أعمال جديدة. سيتم تسليط الضوء على المواضيع التالية: التكهنات وفوائد التنبؤ الدقيق بأداء المحامل؛ نماذج الحياة، مثل GBLM (نموذج حياة المحمل المعمم) من SKF، والذي يمكن استخدامه الآن لاختيار المحامل الهجينة؛ الاقتصاد الدائري والطلب على إعادة تصنيع وإعادة تدوير المواد ذات الصلة بالمحامل؛ والاقتصاد الدائري والطلب على إعادة تصنيع وإعادة تدوير المواد ذات الصلة بالمحامل. سيتم مناقشة أحدث التطورات في محامل الكرات الأخدود العميق وتطبيقاتها في السيارات الكهربائية. وهذا التطور يساعد الشركة على زيادة الإيرادات.

- في أكتوبر 2019، أطلقت مجموعة Trelleborg منتجًا جديدًا يحمل اسم Orkot. يتم استخدام المنتج أكثر في صناعة الطيران. يمكنها تحمل تحميل الحواف وعدم المحاذاة حتى مع الأوزان الكبيرة، وهي مناسبة بشكل خاص لتركيبات التجميد دون أن تتكسر. إن الدرجة القياسية لـ Orkot® TLMM عبارة عن مصفوفة راتينج متصلدة بالحرارة مع تقوية القماش المنسوج ومواد التشحيم الصلبة. يمكن استخدام المادة مع كل من الماء والتزييت بالزيت، ويمكن أيضًا تجفيفها لفترات قصيرة من الوقت. وهذا التطور يساعد الشركة على زيادة الإيرادات.

- في سبتمبر 2019، قررت شركة Rheinmetall Automotive AG تطوير وتصنيع مكونات هيكلية مبتكرة حاملة للأوزان مصنوعة من البلاستيك المقوى بألياف الكربون (CFRP). وقد ساعد هذا التطور الشركة على زيادة الإيرادات.

التحليل الإقليمي

جغرافيًا، الدول المشمولة في تقرير سوق المحامل المركبة هي الولايات المتحدة وكندا والمكسيك في أمريكا الشمالية وألمانيا وفرنسا والمملكة المتحدة وهولندا وسويسرا وبلجيكا وروسيا وإيطاليا وإسبانيا وتركيا وبقية أوروبا في أوروبا والصين واليابان. والهند وكوريا الجنوبية وسنغافورة وماليزيا وأستراليا وتايلاند وإندونيسيا والفلبين وبقية دول آسيا والمحيط الهادئ (APAC) والمملكة العربية السعودية والإمارات العربية المتحدة وجنوب أفريقيا ومصر وإسرائيل وبقية دول الشرق الأوسط شرق وأفريقيا (MEA) كجزء من الشرق الأوسط وأفريقيا (MEA)، والبرازيل والأرجنتين وبقية أمريكا الجنوبية كجزء من أمريكا الجنوبية.

وفقًا لتحليل أبحاث سوق Data Bridge:

منطقة آسيا والمحيط الهادئ هي المنطقة المهيمنة في المحامل المركبة سوق خلال الفترة المتوقعة 2021 - 2028

تهيمن منطقة آسيا والمحيط الهادئ بسبب العدد الكبير من السكان، مما يخلق قاعدة عملاء كبيرة في المنطقة لسوق المحامل المركبة. كما أن النمو والتوسع في مختلف قطاعات المستخدم النهائي سيعزز مرة أخرى نمو السوق.

تشير التقديرات إلى أن أمريكا الشمالية هي المنطقة الأسرع نموًا في المحامل المركبة سوق الفترة المتوقعة 2021 - 2028

على مدى السنوات الخمس المقبلة، من المتوقع أن تكون أمريكا الشمالية السوق الأسرع نموًا للمحامل المركبة. يعد الطلب المتزايد من صناعات البناء والتعدين وصناعة السيارات من الأسباب الرئيسية وراء ارتفاعها. يتم استخدام هذه المحامل المتطورة في معدات البناء والتعدين لأنها توفر استقرار التشغيل في المواقف الصعبة، مما يؤدي إلى زيادة عمر المنتج، وكفاءة المعدات، وانخفاض تكاليف الصيانة.

تحليل تأثير كوفيد-19

أدى جائحة COVID-19 إلى التأثير على سوق المحامل المركبة. أدى الإغلاق والقيود على الحركة والاضطرابات في سلسلة التوريد إلى التأثير سلبًا على السوق المحامل المركبة. أدى الإغلاق المؤقت للأنشطة الاقتصادية والقيود التي فرضتها الحكومة على الأنشطة الاقتصادية إلى عرقلة معدل نمو السوق.

للحصول على معلومات أكثر تفصيلاً حول المحامل المركبة سوق التقرير اضغط هنا – https://www.databridgemarketresearch.com/reports/global-composite-bearings-market