Global Vertical Packaging Machine Market

Market Size in USD Billion

CAGR :

%

USD

17.41 Billion

USD

23.46 Billion

2025

2033

USD

17.41 Billion

USD

23.46 Billion

2025

2033

| 2026 –2033 | |

| USD 17.41 Billion | |

| USD 23.46 Billion | |

|

|

|

|

What is the Global Vertical Packaging Machines Market Size and Growth Rate?

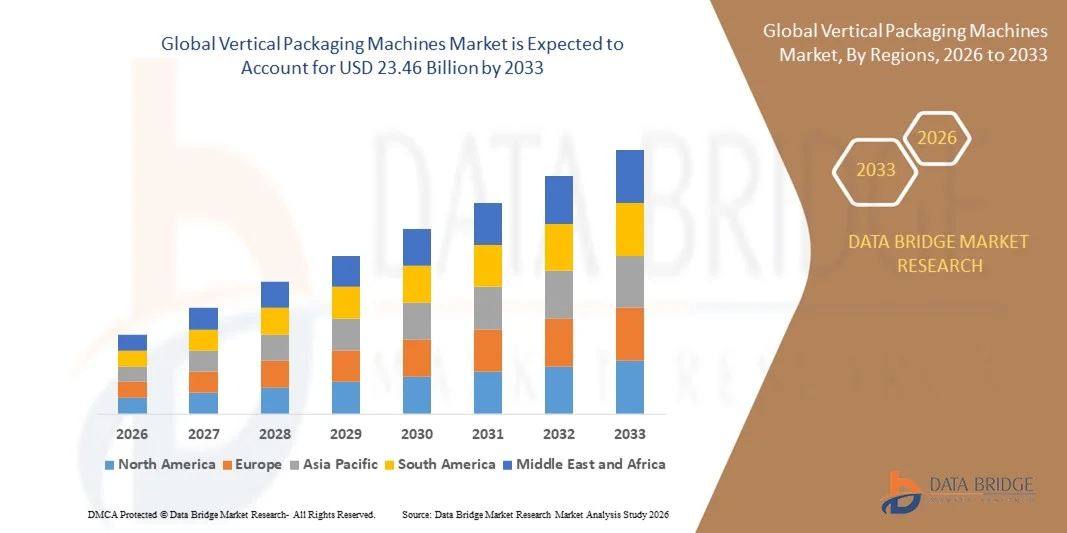

- The global vertical packaging machines market size was valued at USD 17.41 billion in 2025 and is expected to reach USD 23.46 billion by 2033, at a CAGR of 3.80% during the forecast period

- Rising urbanization, modernization, and globalization is driving the growth in the vertical packaging machines market value. Growing demand for automated packaging solutions by pharmaceuticals and consumer goods industries and growth and expansion of food and beverages industry will further induce growth in the vertical packaging machines market value

What are the Major Takeaways of Vertical Packaging Machines Market?

- Surging research and development proficiencies, rising industrialization and manufacturing activities around the globe, growing demand for flexible and cost effective packaging solutions, increased proliferation of e-commerce industry and growing demand for high speed packaging machines are some other vertical packaging machines market growth determinants

- However, lack of technological advancements in the underdeveloped economies will create hindrances for the vertical packaging machines market growth rate. Fluctuations in the prices of raw materials and high initial cost of maintenance will further dampen the vertical packaging machines market growth rate

- North America dominated the vertical packaging machines market with an estimated 43.03% revenue share in 2025, driven by strong demand from food & beverage processing, pharmaceuticals, and consumer packaged goods industries across the U.S. and Canada

- Asia-Pacific is projected to register the fastest CAGR of 8.69% from 2026 to 2033, driven by rapid growth in food processing, pharmaceutical manufacturing, FMCG production, and expanding retail sectors across China, India, Japan, South Korea, and Southeast Asia

- The Solid Vertical Packaging Machines segment dominated the market with an estimated 42.6% share in 2025, driven by their extensive use in packaging snacks, grains, confectionery, frozen foods, and solid pharmaceutical products

Report Scope and Vertical Packaging Machines Market Segmentation

|

Attributes |

Vertical Packaging Machines Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

What is the Key Trend in the Vertical Packaging Machines Market?

Increasing Shift Toward High-Speed, Compact, and Automated Vertical Packaging Machines

- The vertical packaging machines market is witnessing strong adoption of high-speed, compact, and flexible vertical form-fill-seal (VFFS) systems designed to support diverse packaging formats, shorter changeover times, and high-throughput production requirements

- Manufacturers are introducing servo-driven, PLC-controlled, and digitally integrated machines that offer improved accuracy, reduced material waste, and compatibility with smart factory environments

- Growing demand for space-efficient, cost-effective, and easy-to-operate packaging solutions is driving adoption across food & beverage, pharmaceuticals, personal care, and consumer goods manufacturing facilities

- For instance, companies such as Bosch, ProMach, Ishida, Premier Tech, and KraussMaffei have upgraded their vertical packaging portfolios with enhanced speeds, intelligent controls, and improved sealing technologies

- Increasing need for automation, consistent packaging quality, and faster production cycles is accelerating the shift toward advanced vertical packaging machines

- As packaging lines become more automated and product diversification increases, vertical packaging machines will remain critical for efficient, scalable, and high-speed packaging operations

What are the Key Drivers of Vertical Packaging Machines Market?

- Rising demand for efficient, reliable, and automated packaging equipment to support growing consumption of packaged and ready-to-eat food products

- For instance, in 2025, leading manufacturers such as Bosch, ProMach, and Ishida enhanced their vertical packaging machines with higher speeds, servo-based motion control, and improved sealing accuracy

- Growing adoption of automation in food processing, pharmaceuticals, and FMCG manufacturing across the U.S., Europe, and Asia-Pacific is boosting demand for vertical packaging solutions

- Advancements in machine vision, servo motors, smart sensors, and digital control systems have improved machine performance, flexibility, and operational efficiency

- Rising focus on sustainable packaging, material reduction, and recyclable packaging films is creating demand for machines capable of handling a wide range of eco-friendly materials

- Supported by investments in manufacturing automation, smart factories, and packaging line modernization, the Vertical Packaging Machines market is expected to witness steady long-term growth

Which Factor is Challenging the Growth of the Vertical Packaging Machines Market?

- High costs associated with advanced, fully automated, and high-speed vertical packaging machines limit adoption among small and mid-sized manufacturers

- For instance, during 2024–2025, fluctuations in steel prices, electronic component shortages, and longer equipment lead times increased overall machine manufacturing and procurement costs

- Complexity in machine setup, maintenance, and integration with existing production lines increases the need for skilled operators and technical training

- Limited awareness in emerging markets regarding automation benefits and return on investment slows adoption of advanced vertical packaging solutions

- Competition from horizontal packaging machines, contract packaging services, and low-cost manual systems creates pricing pressure and affects differentiation

- To overcome these challenges, manufacturers are focusing on modular machine designs, cost-optimized automation, remote monitoring, and after-sales support to expand global adoption of vertical packaging machines

How is the Vertical Packaging Machines Market Segmented?

The market is segmented on the basis of application type, product type, and end use industry.

- By Application Type

On the basis of application type, the vertical packaging machines market is segmented into Powder Vertical Packaging Machines, Liquid Vertical Packaging Machines, Solid Vertical Packaging Machines, and Others. The Solid Vertical Packaging Machines segment dominated the market with an estimated 42.6% share in 2025, driven by their extensive use in packaging snacks, grains, confectionery, frozen foods, and solid pharmaceutical products. These machines offer high speed, precise weighing, and compatibility with multi-head weighers, making them ideal for mass production environments. Strong demand from food & beverage manufacturers and FMCG brands further supports dominance.

The Liquid Vertical Packaging Machines segment is expected to grow at the fastest CAGR from 2026 to 2033, supported by rising consumption of sauces, beverages, oils, and liquid pharmaceuticals. Advancements in leak-proof sealing, hygienic design, and accurate volumetric filling are accelerating adoption, particularly in dairy, beverage, and personal care industries.

- By Product Type

On the basis of product type, the vertical packaging machines market is segmented into 3-Side Sealed, 4-Side Sealed, and Others. The 3-Side Sealed segment dominated the market with around 48.1% share in 2025, owing to its cost efficiency, simpler machine configuration, and widespread usage for sachets and pouches in food, pharmaceuticals, and consumer goods. These machines enable high-speed production with reduced material usage, making them attractive for large-scale packaging operations.

The 4-Side Sealed segment is projected to register the fastest CAGR from 2026 to 2033, driven by increasing demand for premium packaging, improved shelf appeal, and better barrier protection. Growth in pharmaceuticals, nutraceuticals, and personal care products—where precise sealing and enhanced product safety are critical—is further boosting adoption of 4-side sealed vertical packaging machines.

- By End Use Industry

On the basis of end use industry, the vertical packaging machines market is segmented into Food and Beverages, Pharmaceuticals, Consumer Products, and Others. The Food and Beverages segment dominated the market with a 54.3% share in 2025, supported by high demand for packaged foods, ready-to-eat meals, snacks, and frozen products. Increasing urbanization, changing consumer lifestyles, and growth of retail and e-commerce channels continue to fuel adoption. Vertical packaging machines offer speed, consistency, and flexibility required for high-volume food packaging.

The Pharmaceuticals segment is expected to grow at the fastest CAGR from 2026 to 2033, driven by rising demand for unit-dose packaging, strict regulatory requirements, and growth in OTC and prescription drug production. Emphasis on hygiene, accuracy, and tamper-proof packaging is accelerating investments in advanced vertical packaging solutions.

Which Region Holds the Largest Share of the Vertical Packaging Machines Market?

- North America dominated the vertical packaging machines market with an estimated 43.03% revenue share in 2025, driven by strong demand from food & beverage processing, pharmaceuticals, and consumer packaged goods industries across the U.S. and Canada. High adoption of automated, high-speed, and hygienic packaging solutions supports large-scale production requirements while ensuring compliance with strict quality and safety standards

- Leading manufacturers in North America are introducing high-speed, compact, and digitally controlled vertical packaging machines with servo-driven systems, PLC-based automation, and smart monitoring features, strengthening regional technological leadership. Continuous investment in automation, Industry 4.0, and sustainable packaging further fuels long-term market growth

- Presence of advanced manufacturing infrastructure, strong OEM ecosystems, skilled workforce availability, and high capital investment capacity continues to reinforce North America’s dominance in the global Vertical Packaging Machines market

U.S. Vertical Packaging Machines Market Insight

The U.S. is the largest contributor in North America, supported by strong growth in packaged food, ready-to-eat meals, pharmaceuticals, and personal care products. Increasing adoption of automation, demand for flexible packaging formats, and focus on productivity optimization drive widespread deployment of vertical packaging machines across food processors and contract manufacturers. Strong presence of global OEMs and system integrators further accelerates market expansion.

Canada Vertical Packaging Machines Market Insight

Canada contributes steadily to regional growth, driven by rising demand for packaged food, frozen products, and pharmaceutical packaging. Investments in food processing modernization, growing export-oriented production, and adoption of energy-efficient packaging equipment support increased deployment of vertical packaging machines across the country.

Asia-Pacific Vertical Packaging Machines Market

Asia-Pacific is projected to register the fastest CAGR of 8.69% from 2026 to 2033, driven by rapid growth in food processing, pharmaceutical manufacturing, FMCG production, and expanding retail sectors across China, India, Japan, South Korea, and Southeast Asia. Rising urbanization, changing consumption patterns, and increasing adoption of automation in manufacturing facilities significantly boost demand for vertical packaging machines.

China Vertical Packaging Machines Market Insight

China leads the Asia-Pacific market due to massive food and beverage production volumes, strong pharmaceutical manufacturing capacity, and rapid automation adoption. Competitive local manufacturing, cost-effective machinery, and strong export demand accelerate market penetration domestically and internationally.

Japan Vertical Packaging Machines Market Insight

Japan shows stable growth supported by advanced manufacturing practices, high-quality standards, and demand for precision packaging in food, pharmaceuticals, and specialty products. Emphasis on reliability, compact machine design, and automation drives adoption of premium vertical packaging solutions.

India Vertical Packaging Machines Market Insight

India is emerging as a high-growth market, driven by expansion of packaged food, dairy, pharmaceuticals, and FMCG sectors. Government initiatives supporting food processing, rising investments in manufacturing automation, and growing domestic consumption accelerate demand for vertical packaging machines.

South Korea Vertical Packaging Machines Market Insight

South Korea contributes significantly due to strong demand from food processing, cosmetics, and pharmaceutical industries. Advanced manufacturing capabilities, focus on smart factories, and rising export-oriented production support sustained growth in vertical packaging machine adoption.

Which are the Top Companies in Vertical Packaging Machines Market?

The vertical packaging machines industry is primarily led by well-established companies, including:

- Robert Bosch GmbH (Germany)

- Ishida Ltd. (Japan)

- Imanpack Packaging and Eco Solutions S.p.A. (Italy)

- Premier Tech Ltd. (Canada)

- Jornen Machinery Co., Ltd. (China)

- TÉCNICAS MECÁNICAS ILERDENSES, S.L. (Spain)

- Kizui Packaging Machinery Co. & Boecker (Germany)

- ProMach (U.S.)

- Magnum Group (U.S.)

- KraussMaffei (Germany)

- SIPA S.p.A. (Italy)

- IBO SRL (Italy)

- RESILUX NV (Belgium)

- SGT (France)

- Taiwan Hon Chuan (Taiwan)

- Logoplaste (Portugal)

What are the Recent Developments in Global Vertical Packaging Machines Market?

- In November 2024, EndFlex introduced the Boxxer Kartnr-V, an automatic vertical cartoning machine equipped with a manual loading station, engineered to deliver high precision, operational efficiency, and packaging flexibility. The system vertically forms cartons, loads containers, and securely closes chipboard cartons while supporting tuck, auto-lock, and glued carton formats, along with quick-change features for multiple carton sizes, strengthening productivity and versatility in secondary packaging operations

- In February 2023, Mespack and Famartec launched an integrated vertical form-fill-seal and cartoning solution tailored for the pharmaceutical industry, addressing the need for end-to-end automated production lines. The solution complies with GMP, GMP5, and FDA 21 CFR Part 11 requirements and meets documentation standards such as DQ, IQ, OQ, RA, PQ, and EN1020 material certifications, enhancing regulatory compliance and operational reliability for pharma manufacturers

- In January 2023, Massman Companies completed the acquisition of Ultra Packaging Inc., a Chicago-based specialist in vertical and horizontal automated cartoning machines serving food, personal care, pharmaceutical, and cosmetic industries. With Ultra Packaging’s portfolio of high-speed continuous-motion systems ranging from manual to fully robotic configurations, the acquisition expanded Massman’s technology capabilities and strengthened its position in the automated packaging equipment market

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Vertical Packaging Machine Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Vertical Packaging Machine Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Vertical Packaging Machine Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.