Global Styrene Market

Market Size in USD Billion

CAGR :

%

USD

62.58 Billion

USD

80.14 Billion

2024

2032

USD

62.58 Billion

USD

80.14 Billion

2024

2032

| 2025 –2032 | |

| USD 62.58 Billion | |

| USD 80.14 Billion | |

|

|

|

|

Styrenel Market Analysis

The styrene market is experiencing significant growth, driven by its widespread use in packaging, construction, automotive, and consumer goods industries. Styrene-based materials such as polystyrene (PS), expanded polystyrene (EPS), and acrylonitrile butadiene styrene (ABS) are in high demand due to their lightweight, durability, and cost-effectiveness. The increasing adoption of sustainable and bio-based styrene alternatives is transforming the industry, with companies investing in plant-based styrene production and advanced recycling technologies to enhance sustainability. The rapid expansion of the e-commerce and food packaging sectors is fueling the demand for polystyrene-based packaging solutions, while the automotive industry’s shift toward lightweight materials is boosting the use of ABS and styrene-butadiene rubber (SBR). Technological advancements such as catalytic styrene production, AI-driven quality control, and polymer innovation are improving production efficiency and product performance. In addition, the growth of 5G networks and electronic applications is increasing the demand for high-performance styrenic polymers in electrical insulation. With rising regulatory emphasis on recyclability and environmental impact, the styrene market is witnessing a transition toward circular economy initiatives and green chemistry innovations.

Styrenel Market Size

The global styrenel market size was valued at USD 62.58 billion in 2024 and is projected to reach USD 80.14 billion by 2032, with a CAGR of 3.14% during the forecast period of 2025 to 2032. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework.

Styrenel Market Trends

“Rising Demand for Sustainable and Recycled Styrene-Based Materials”

One key trend shaping the styrene market is the rising demand for sustainable and recycled styrene-based materials. With increasing regulatory pressure and consumer awareness regarding environmental impact, companies are investing in advanced recycling technologies and bio-based styrene production. For instance, INEOS Styrolution has launched the "LIFE ABSolutely Circular" project to produce ABS plastic from recycled feedstock, reducing dependency on virgin styrene. Similarly, LG Chem is developing plant-based acrylonitrile butadiene styrene (ABS), promoting eco-friendly alternatives in the automotive and electronics industries. The adoption of chemical recycling techniques, such as depolymerization, is enabling manufacturers to convert used styrenic plastics into raw monomers, ensuring a closed-loop production cycle. As sustainability continues to drive market transformation, industries such as packaging, construction, and consumer goods are increasingly shifting toward low-carbon, recyclable, and bio-based styrene solutions, reinforcing the industry's commitment to a circular economy.

Report Scope and Styrenel Market Segmentation

|

Attributes |

Styrenel Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E., South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America |

|

Key Market Players |

Chevron Corporation (U.S.), SABIC (Saudi Arabia), TotalEnergies (France), Dow (U.S.), DSM (Netherlands), NOVA Chemicals Corporate (Canada), Bayer AG (Germany), Ashland (U.S.), Alpek S.A.B. de C.V. (Mexico), Trinseo (U.S.), Covestro AG (Germany), Synthos (Poland), BASF (Germany), Versalis S.p.A. (Italy), INEOS Styrolution Group GmbH (Germany), LG Chem (South Korea), Alibaba (China), Mitsubishi Chemical Group Corporation (Japan), Perlite Construction Co (Turkey) |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Styrenel Market Definition

Styrene is an organic compound classified as a volatile, colorless liquid hydrocarbon with the chemical formula C₈H₈. It is primarily used as a building block for manufacturing various polymers and copolymers, including polystyrene (PS), expanded polystyrene (EPS), acrylonitrile butadiene styrene (ABS), and styrene-butadiene rubber (SBR).

Styrenel Market Dynamics

Drivers

- Growing Demand for Packaging Materials

The increasing reliance on polystyrene (PS) and expanded polystyrene (EPS) in food packaging, e-commerce, and protective packaging is significantly driving the growth of the styrene market. As online shopping and takeaway food services continue to expand, the demand for lightweight, cost-effective, and insulating packaging solutions has surged. EPS is widely used for temperature-sensitive food products, while PS provides rigid and transparent packaging for consumer goods. For instance, McDonald's has incorporated EPS-based food containers to maintain the freshness of its products. Similarly, Amazon and other e-commerce giants use EPS protective packaging to safeguard fragile items during shipping. The growing focus on sustainable alternatives is also encouraging companies to invest in recycled and biodegradable styrene-based packaging. This increasing demand makes packaging one of the primary market drivers for styrene-based materials.

- Rising Adoption in Automotive & Construction Sectors

The automotive industry’s transition toward lightweight materials to enhance fuel efficiency and reduce emissions is significantly increasing the use of acrylonitrile butadiene styrene (ABS) and styrene-butadiene rubber (SBR). ABS is a preferred material for automotive interiors, dashboards, and trim components due to its durability, impact resistance, and lightweight properties. For instance, Tesla and BMW integrate ABS components to improve vehicle efficiency while maintaining design flexibility. In the construction sector, EPS and extruded polystyrene (XPS) are widely used for thermal insulation, soundproofing, and energy-efficient building solutions. Germany's passive house movement has promoted the use of EPS insulation panels to minimize energy consumption in buildings. With rising infrastructure development and green building initiatives worldwide, the demand for styrene-based materials in automotive and construction continues to be a strong market driver.

Opportunities

- Increasing Advancements in Sustainable & Recycled Styrene Production

The increasing focus on sustainability and circular economy solutions is driving the development of bio-based styrene and advanced recycling technologies. Companies are striving to reduce their reliance on virgin styrene by utilizing recycled feedstock and plant-based alternatives. For instance, INEOS Styrolution has launched its "LIFE ABSolutely Circular" project, which aims to produce ABS plastic from recycled styrene monomers, enabling a closed-loop recycling system. Similarly, LG Chem is developing plant-derived acrylonitrile butadiene styrene (ABS), offering an eco-friendly alternative to traditional petroleum-based plastics. These innovations provide businesses with a sustainable supply chain, helping them comply with strict environmental regulations such as the EU’s Green Deal and Extended Producer Responsibility (EPR) initiatives. The increasing demand for green polymers presents a lucrative market opportunity for companies that invest in sustainable styrene-based materials.

- Increasing Technological Innovations in Polymer Manufacturing

Cutting-edge advancements in catalytic processes, AI-driven quality control, and polymer modifications are significantly enhancing the durability, flexibility, and overall performance of styrene-based materials. Manufacturers are leveraging AI-powered analytics and machine learning algorithms to optimize polymer synthesis, reduce waste, and improve product consistency. For instance, Dow and BASF have introduced next-generation catalysts that enhance the efficiency of styrene production while lowering energy consumption. In addition, the integration of AI-driven defect detection systems in polymer manufacturing ensures high-quality output, reducing material wastage. These innovations are expanding the applications of styrene-based products across industries such as automotive, construction, and electronics. Companies investing in advanced polymer technology can capitalize on growing demand for high-performance materials, making technological innovation a key market opportunity.

Restraints/Challenges

- Stringent Regulations

One of the biggest challenges in the styrenel market is the increasing regulatory pressure due to environmental concerns surrounding emissions, hazardous waste, and the non-biodegradable nature of styrenic plastics. Governments and regulatory bosdies are tightening restrictions on the production and disposal of styrenic materials, pushing companies to adopt sustainable alternatives or face penalties. For instance, the European Union’s Single-Use Plastics Directive aims to reduce plastic waste by banning certain styrenic-based single-use items such as food containers and cutlery. In addition, several U.S. states, including California, have introduced restrictions on expanded polystyrene (EPS) foam used in food packaging due to its environmental impact. As a result, manufacturers are under pressure to innovate and comply with evolving regulations, increasing costs and operational challenges in the market.

- Rise of Biodegradable and Sustainable Plastics

The shift toward biodegradable and sustainable plastics presents a significant challenge to the Styrenel market, particularly in industries such as packaging and consumer goods. With increasing awareness of plastic pollution, consumers and businesses are opting for eco-friendly materials such as bioplastics, paper-based alternatives, and compostable polymers over traditional styrenics such as polystyrene and ABS. For instance, major fast-food chains such as McDonald’s and Starbucks have phased out polystyrene packaging in favor of paper-based or plant-derived alternatives. Similarly, biodegradable cutlery and food containers made from PLA (polylactic acid) or PHA (polyhydroxyalkanoates) are gaining market traction, reducing the demand for styrenic-based materials. This growing preference for sustainable solutions forces styrenics manufacturers to rethink their product offerings, invest in green technologies, or risk losing market share to environmentally friendly substitutes.

This market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Impact and Current Market Scenario of Raw Material Shortage and Shipping Delays

Data Bridge Market Research offers a high-level analysis of the market and delivers information by keeping in account the impact and current market environment of raw material shortage and shipping delays. This translates into assessing strategic possibilities, creating effective action plans, and assisting businesses in making important decisions. Apart from the standard report, we also offer in-depth analysis of the procurement level from forecasted shipping delays, distributor mapping by region, commodity analysis, production analysis, price mapping trends, sourcing, category performance analysis, supply chain risk management solutions, advanced benchmarking, and other services for procurement and strategic support.

Expected Impact of Economic Slowdown on the Pricing and Availability of Products

When economic activity slows, industries begin to suffer. The forecasted effects of the economic downturn on the pricing and accessibility of the products are taken into account in the market insight reports and intelligence services provided by DBMR. With this, our clients can typically keep one step ahead of their competitors, project their sales and revenue, and estimate their profit and loss expenditures.

Styrenel Market Scope

The market is segmented on the basis of product type and end user. The growth amongst these segments will help you analyse meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Product Type

- Polystyrene (PS)

- Expanded Polystyrene (EPS)

- Acrylonitrile Butadiene Styrene (ABS)

End User

- Packaging

- Construction

- Consumer Goods

- Automotive

- Others

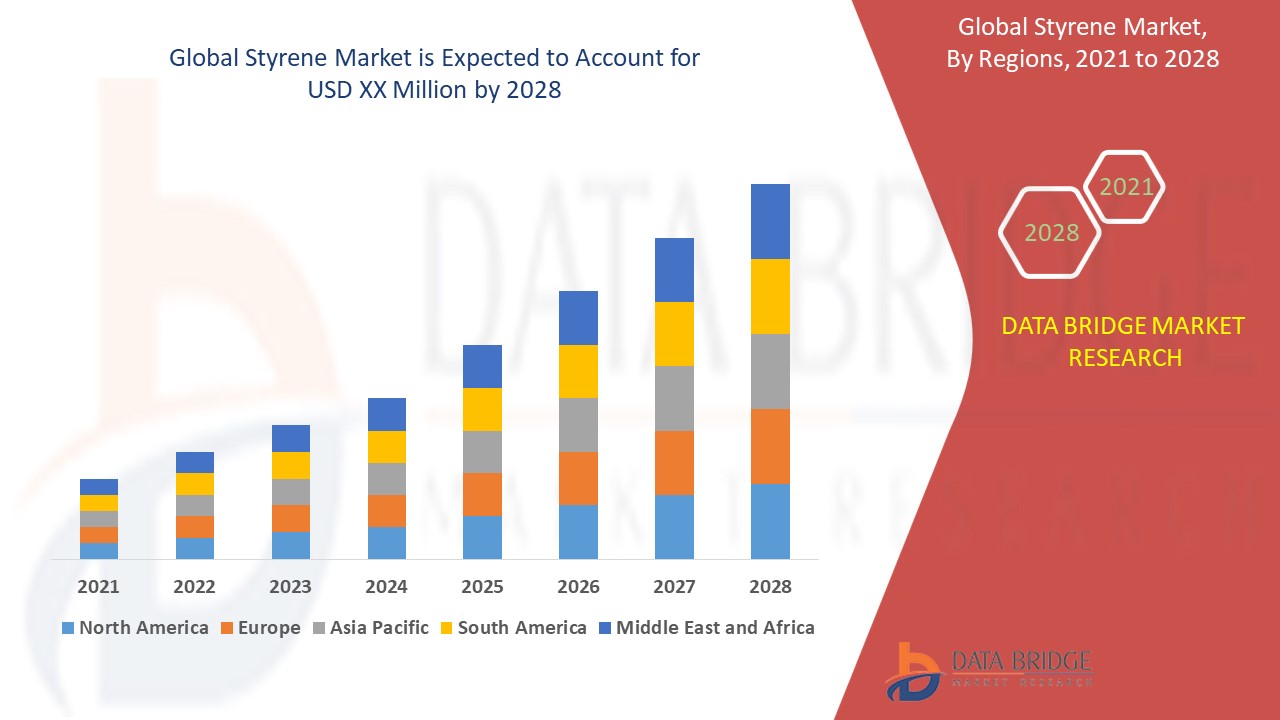

Styrenel Market Regional Analysis

The market is analysed and market size insights and trends are provided by country, product type, and end user as referenced above.

The countries covered in the market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E., South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

Asia-Pacific dominates the styrene market primarily due to the growing demand for styrene-based materials in the expanding food packaging industry. The increasing consumption of ready-to-eat and packaged foods has led to a surge in the use of polystyrene and expanded polystyrene (EPS) for durable and cost-effective packaging solutions. In addition, the rising trend of disposable consumer products, driven by urbanization and changing lifestyles, is further fueling the market's growth in the region. This steady expansion is expected to continue, supported by advancements in manufacturing, increasing industrial applications, and strong economic development across key Asia-Pacific countries.

North America is expected to experience fastest growth in the styrene market, driven by the presence of major industry players and ongoing advancements in polymer manufacturing. The increasing adoption of styrene-based materials across industries such as packaging, automotive, and construction is contributing to the region's expanding market. In addition, the rising demand for lightweight and durable plastics in consumer goods and industrial applications is accelerating styrene consumption. This growth trajectory is further supported by technological innovations, sustainability initiatives, and the strong focus on research and development within the region.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Styrenel Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

Styrenel Market Leaders Operating in the Market Are:

- Chevron Corporation (U.S.)

- SABIC (Saudi Arabia)

- TotalEnergies (France)

- Dow (U.S.)

- DSM (Netherlands)

- NOVA Chemicals Corporate (Canada)

- Bayer AG (Germany)

- Ashland (U.S.)

- Alpek S.A.B. de C.V. (Mexico)

- Trinseo (U.S.)

- Covestro AG (Germany)

- Synthos (Poland)

- BASF (Germany)

- Versalis S.p.A. (Italy)

- INEOS Styrolution Group GmbH (Germany)

- LG Chem (South Korea)

- Alibaba (China)

- Mitsubishi Chemical Group Corporation (Japan)

- Perlite Construction Co (Turkey)

Latest Developments in Styrenel Market

- In December 2022, LG Chem announced its plans to introduce a new acrylonitrile butadiene styrene (ABS) product derived from plant-based sources. Through this innovation, the company has reinforced its position in the market

- In March 2022, Repsol partnered with Ravago to establish the largest polypropylene (PP) compounding plant for manufacturing polycarbonate/acrylonitrile butadiene styrene (PC-ABS) for the automotive sector in Morocco. This collaboration has expanded Repsol’s global presence

- In January 2022, INEOS Styrolution commenced operations of a 50,000-ton ABS production facility in Wingles, France, enhancing the company’s product portfolio and strengthening its market presence

- In June 2021, Nexeo Plastics and Covestro introduced the Polycarbonate/ABS 3D printing filament Addigy FPB 2684 3D, which is now available through Nexeo Plastics’ distribution platform. This launch marks the company’s continued investment in 3D printing product development and expansion of support services

- In January 2021, INEOS Styrolution initiated the construction of a demonstration plant in Antwerp, Belgium, to test the production of ABS plastic from recycled feedstock. The project, named "LIFE ABSolutely Circular," aims to highlight the environmental and economic benefits of advanced recycling technologies for achieving a circular economy in plastics

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Styrene Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Styrene Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Styrene Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.