Global Smart Factory Market

Market Size in USD Billion

CAGR :

%

USD

34.06 Billion

USD

102.74 Billion

2024

2032

USD

34.06 Billion

USD

102.74 Billion

2024

2032

| 2025 –2032 | |

| USD 34.06 Billion | |

| USD 102.74 Billion | |

|

|

|

|

Smart Factory Market Size

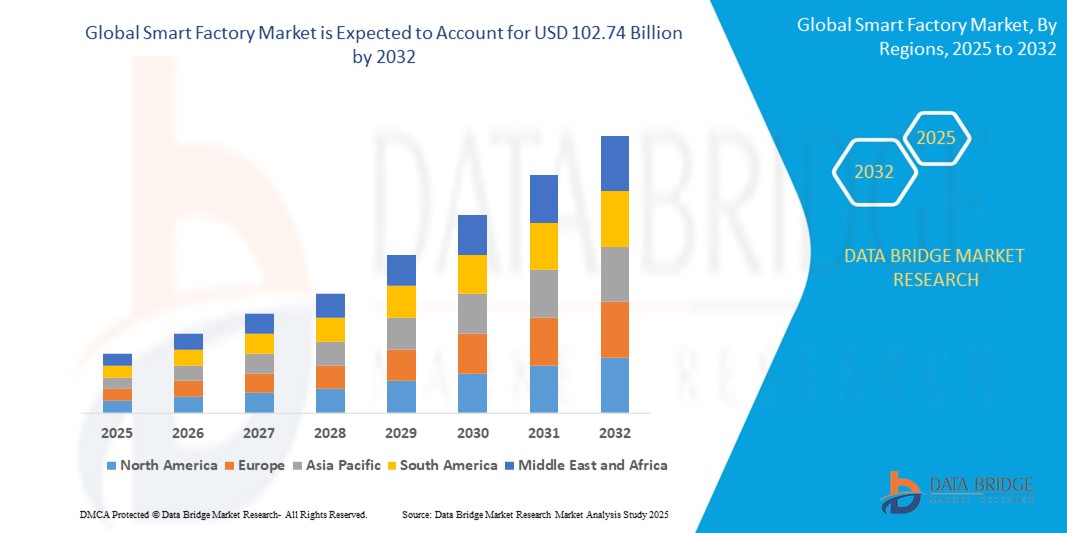

- The global smart factory market was valued at USD 34.06 billion in 2024 and is expected to reach USD 102.74 billion by 2032

- During the forecast period of 2025 to 2032 the market is likely to grow at a CAGR of 14.80%, primarily driven by rising demand for industrial automation

- This growth is driven by factors such as labour shortages, demand for consistent quality, and faster production

Smart Factory Market Analysis

- A smart factory is a highly digitized and connected production facility that uses advanced technologies such as AI, IoT, robotics, and data analytics to autonomously optimize manufacturing processes and improve operational efficiency

- Market growth is fueled by increasing demand for industrial automation, real-time data analytics, improved productivity, and cost-efficiency across manufacturing operations

- The market is advancing through innovations in AI-driven predictive maintenance, robotics, digital twins, and seamless integration of cyber-physical systems

- For instance, companies such as Siemens and Rockwell Automation are developing intelligent automation platforms that combine edge computing and AI to optimize factory performance and reduce downtime

- The smart factory market is expected to grow significantly, driven by Industry 4.0 adoption, sustainability goals, and the rising need for flexible, high-efficiency production systems

Report Scope and Smart Factory Market Segmentation

|

Attributes |

Smart Factory Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. |

Smart Factory Market Trends

“Increasing Integration of Artificial Intelligence”

- One prominent trend in the global smart factory market is the increasing integration of artificial intelligence

- This trend is driven by the need for real-time decision-making, predictive maintenance, improved process efficiency, and enhanced product quality through data-driven insights

- For instance, Bosch and Fanuc are deploying AI-enabled solutions in smart factories to enable self-optimizing machines, enhance quality control with vision systems, and streamline predictive maintenance for uninterrupted operations

- The growing focus on intelligent automation, coupled with advancements in machine learning and computer vision, is accelerating the adoption of AI across smart factories

- As manufacturers continue to pursue higher agility, scalability, and efficiency, the integration of AI is expected to remain a key trend, fueling innovation, enabling smarter production lines, and shaping the future of industrial operations

Smart Factory Market Dynamics

Driver

“Rise in the Usage of IoT Solutions”

- The rise in the usage of IoT solutions is a key driver of growth in the smart factory market. As industries look to optimize operations, IoT enables seamless connectivity and data exchange across machines, sensors, and production systems, driving efficiency and real-time decision-making

- This shift is particularly noticeable in industries such as automotive, manufacturing, and logistics, where IoT is enhancing automation, improving predictive maintenance, and enabling smart inventory management

- With increasing demands for operational efficiency, cost reduction, and real-time insights, manufacturers are adopting IoT solutions to create connected ecosystems that monitor performance, detect anomalies, and improve product quality

- The integration of IoT with cloud computing and AI is transforming how manufacturers collect and analyze data, leading to smarter production processes, reduced downtime, and better resource utilization

- Companies in the smart factory space are investing in advanced IoT infrastructure, cloud platforms, and edge computing to enable the next generation of connected manufacturing

For instance,

- Cisco and IBM are providing IoT solutions that integrate data from sensors and devices, enabling manufacturers to enhance operational visibility and streamline production workflows

- Honeywell offers IoT-enabled platforms that provide real-time monitoring and predictive analytics to optimize factory performance

- As the demand for connected, data-driven manufacturing grows, the adoption of IoT solutions is expected to remain a key driver, shaping the future of smart factory operations

Opportunity

“Integration of Blockchain Technology”

- The integration of blockchain technology presents a significant opportunity in the smart factory market. Blockchain can enhance the transparency, security, and efficiency of manufacturing processes by securely tracking and managing data across the entire supply chain

- Blockchain allows for real-time, tamper-proof tracking of goods, from raw materials to finished products, which helps in preventing fraud, ensuring compliance, and enhancing product traceability

- This technology also enables decentralized control, allowing manufacturers to securely share data between machines, suppliers, and customers, reducing inefficiencies and errors

For instance,

- Companies such as IBM and Maersk are using blockchain for supply chain management, enabling real-time tracking and verification of shipments, ensuring transparency in manufacturing logistics

- VeChain and Walmart are leveraging blockchain to track the origin of products, enhancing food safety, quality control, and supply chain reliability

- As blockchain technology continues to advance, its adoption in smart factories is expected to grow, offering manufacturers improved security, operational transparency, and better supply chain coordination, driving market expansion

Restraint/Challenge

“Workforce Skill Enhancement and Retraining”

- Workforce skill enhancement and retraining present a notable challenge in the smart factory market. As companies adopt advanced technologies such as AI, robotics, and IoT, the demand for skilled labor capable of operating and maintaining these systems is increasing

- Issues such as a lack of technical expertise, insufficient training programs, and resistance to change can hinder the seamless integration of smart factory solutions, particularly in industries with a traditional workforce

- This challenge is especially significant in regions where technical education and upskilling opportunities are limited, and where workers may be unfamiliar with cutting-edge technologies or digital tools

For instance,

- Manufacturers that fail to invest in continuous training or provide clear pathways for workforce development may struggle to adapt, risking inefficiencies and decreased productivity in their smart factories

- Without comprehensive training, clear career advancement opportunities, and effective onboarding for new technologies, workforce-related challenges may slow down the adoption of smart factory solutions and limit the market's growth potential

Smart Factory Market Scope

The market is segmented on the basis of component, connectivity, and industry vertical.

|

Segmentation |

Sub-Segmentation |

|

By Component |

|

|

By Connectivity |

|

|

By Industry Vertical |

|

Smart Factory Market Regional Analysis

“North America is the Dominant Region in the Smart Factory Market”

- North America dominates the smart factory market, driven by a robust presence of multinational corporations investing heavily in research and development of industrial technologies, such as IoT, AI, and cloud computing

- U.S. holds a significant share due to its advanced industrial sector, high investments in automation, and a well-established technology ecosystem that accelerates the adoption of smart factory solutions

- Companies in North America continue to lead in innovation, focusing on integrating AI and IoT to optimize production processes, reduce costs, and enhance manufacturing efficiency

- With its strong technological infrastructure, a skilled workforce, and the ongoing push for Industry 4.0 adoption, North America is expected to remain the dominant region in the smart factory market through the forecast period of 2025 to 2032

“Asia-Pacific is Projected to Register the Highest Growth Rate”

- Asia-Pacific is expected to witness the highest growth rate in the smart factory market, driven by rapid industrialization, government initiatives, and increasing adoption of IoT and automation technologies across key sectors

- Countries such as China, Japan, and South Korea are leading the regional growth, with strong governmental support for smart manufacturing and the advancement of the industrial sector through digital transformation

- The increasing focus on smart manufacturing, coupled with rising investments in industrial IoT, AI, and robotics, is accelerating the growth of the smart factory market in emerging economies such as India, Vietnam, and Indonesia

- With its dynamic manufacturing base, technological advancements, and favorable regulatory frameworks, Asia-Pacific is poised to be the fastest-growing region for the smart factory market through 2032

Smart Factory Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- Siemens (Germany)

- General Electric Company (U.S.)

- ABB (Switzerland)

- Rockwell Automation (U.S.)

- Schneider Electric (France)

- Honeywell International Inc. (U.S.)

- FANUC Corporation (Japan)

- Mitsubishi Electric Corporation (Japan)

- Emerson Electric Co. (U.S.)

- Yokogawa Electric Corporation (Japan)

- Bosch Limited (India)

- Stratasys (U.S.)

- TE Connectivity (Switzerland)

- Texas Instruments Incorporated (U.S.)

- KUKA AG (Germany)

- SAP SE (Germany)

- HP Development Company, L.P. (U.S.)

- OMRON Corporation (Japan)

- Dassault Systèmes SE (France)

Latest Developments in Global Smart Factory Market

- In January 2023, Siemens, a global technology leader, announced its acquisition of Company X, a leading provider of advanced industrial automation solutions. Siemens aims to strengthen its position with this strategic move in the smart factory market and expand its portfolio of digital solutions for manufacturing

- In November 2022, GENERAL ELECTRIC (GE), a global leader in industrial innovation, unveiled its latest suite of smart factory solutions designed to revolutionize manufacturing processes and drive operational excellence. These advanced solutions leverage cutting-edge technologies to enhance productivity, efficiency, and flexibility in factories

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Smart Factory Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Smart Factory Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Smart Factory Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.