Global Pyrolytic Boron Nitride Market

Market Size in USD Million

CAGR :

%

USD

223.66 Million

USD

351.13 Million

2024

2032

USD

223.66 Million

USD

351.13 Million

2024

2032

| 2025 –2032 | |

| USD 223.66 Million | |

| USD 351.13 Million | |

|

|

|

|

Pyrolytic Boron Nitride Market Size

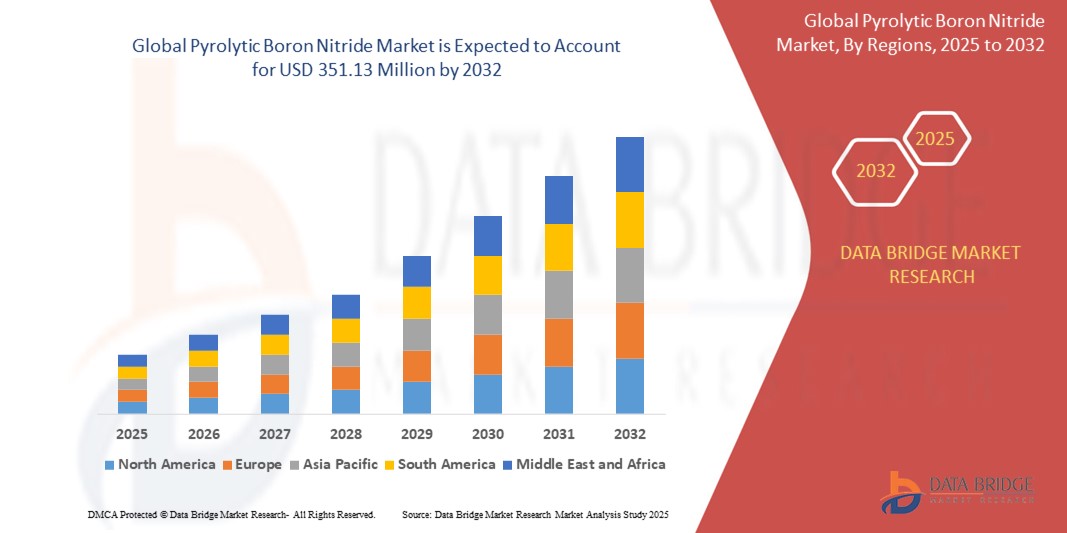

- The global pyrolytic boron nitride market was valued at USD 223.66 million in 2024 and is expected to reach USD 351.13 million by 2032

- During the forecast period of 2025 to 2032 the market is likely to grow at a CAGR of 5.80 % primarily driven by the increasing demand for high-performance materials in electronics and semiconductor applications

- This growth is driven by factors such as the superior thermal stability, chemical inertness, and electrical insulation properties

Pyrolytic Boron Nitride Market Analysis

- Pyrolytic Boron Nitride is a high-performance material made through chemical vapor deposition, offering excellent thermal stability, electrical insulation, and resistance to corrosion, making it ideal for use in industries such as semiconductors, aerospace, and electronics

- The pyrolytic boron nitride market is experiencing steady growth as it becomes an essential material in high-performance electronics

- For instance, companies such as Samsung and Nichia use it in metal organic chemical vapor deposition reactors for manufacturing advanced light-emitting diodes

- In the semiconductor industry, high-purity pyrolytic boron nitride is widely used in wafer carriers and susceptors because of its ability to resist high temperatures and chemical exposure such as leading manufacturers such as GlobalFoundries and SK Hynix rely on it in their production processes

- In the energy sector, pyrolytic boron nitride plays a key role in fusion energy research, it is used in plasma-facing components of experimental reactors such as the ITER project, which aims to develop clean and sustainable nuclear fusion technology

- The aerospace industry uses pyrolytic boron nitride in electric propulsion systems, specifically in Hall-effect thrusters, where it provides thermal insulation and durability

- For instance, NASA integrates this material into satellite and space probe designs to ensure long-term performance in extreme environments

- In the medical field, pyrolytic boron nitride is used in devices that demand high purity and thermal resistance

- For instance, companies such as Siemens Healthineers and GE Healthcare apply it in magnetic resonance imaging systems and precision surgical tools to enhance reliability and safety

Report Scope and Pyrolytic Boron Nitride Market Segmentation

|

Attributes |

Pyrolytic Boron Nitride Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Pyrolytic Boron Nitride Market Trends

“Increasing Use in Semiconductor Manufacturing Processes”

- There is an increasing use of pyrolytic boron nitride in semiconductor manufacturing processes due to its exceptional thermal stability and non-reactive nature

- For instance, it is used in chemical vapor deposition equipment and wafer carriers by major chip manufacturers such as Intel and TSMC to ensure clean, stable, and high-precision fabrication environments

- Pyrolytic boron nitride is becoming a preferred material in the production of semiconductors that require ultra-clean processing conditions

- For instance, in processes such as etching and ion implantation, the material's resistance to chemical attack helps prevent contamination, ensuring the high yield and quality of microchips

- Its high purity and consistent performance make it ideal for use in insulation and shielding components within semiconductor tools

- For instance, equipment manufacturers are integrating pyrolytic boron nitride into chamber liners and shields to extend equipment life and maintain product integrity

- The move toward smaller, more advanced nodes in semiconductor technology is pushing the need for materials that can tolerate high thermal loads without degrading

- For instance, pyrolytic boron nitride is used in 3 nanometer and 5 nanometer chip fabrication lines to manage heat and reduce the risk of defects

- As the demand for high-performance computing and mobile devices increases, semiconductor fabs are investing in materials such as pyrolytic boron nitride that can support high-volume, high-precision manufacturing

Pyrolytic Boron Nitride Market Dynamics

Driver

“Increasing Demand for High-Purity Materials in Advanced Manufacturing”

- The growing demand for high-purity materials in industries such as semiconductors is a key driver for the pyrolytic boron nitride market

- For instance, major semiconductor manufacturers such as Intel use PBN in wafer carriers and chemical vapor deposition systems due to its resistance to high temperatures and corrosive chemicals

- PBN's exceptional thermal stability and electrical insulation properties are crucial in aerospace applications

- For instance, NASA uses it in satellite components and propulsion systems where it withstands extreme temperatures and provides critical insulation under high thermal stress

- The renewable energy sector is also benefiting from PBN's durability, it is used in advanced battery systems and solar panel substrates to improve efficiency and extend the life of energy storage solutions, supporting the transition to cleaner energy

- In semiconductor fabrication, PBN is critical for ensuring the quality and consistency of microchips, manufacturers such as TSMC rely on PBN to maintain high material purity and prevent contamination in their production lines

- As industries demand materials capable of performing in extreme conditions, the adoption of PBN is increasing, positioning it as a material of choice for high-performance applications across sectors such as aerospace, energy, and electronics

Opportunity

“Expansion in Emerging Applications”

- The aerospace industry is increasingly utilizing pyrolytic boron nitride (PBN) for components exposed to extreme environments, such as thermal shields and insulating layers in propulsion systems

- For instance, aerospace companies such as Boeing and SpaceX are investigating PBN for use in next-generation spacecraft and satellite technologies

- The semiconductor sector is exploring PBN in wafer processing and epitaxial growth systems due to its excellent chemical inertness and thermal conductivity

- For instance, leading chip manufacturers are incorporating PBN in MOCVD (metal-organic chemical vapor deposition) equipment to enhance the precision and lifespan of processing tools

- The renewable energy sector is adopting PBN in high-efficiency solar cells and thermoelectric generators, where heat dissipation and material stability are crucial

- For instance, startups focusing on solar innovation are testing PBN-based substrates to boost energy conversion rates and device durability

- PBN is also gaining traction in the defense industry for its role in electronic warfare systems and advanced sensor technologies that require stable performance under high thermal loads

- For instance, defense research labs are leveraging PBN for ruggedized sensors and electronic packaging that can withstand harsh operational conditions

- As emerging sectors demand materials with high purity, thermal resilience, and non-reactivity, the versatility of PBN continues to drive its adoption into new frontiers beyond traditional applications

Restraint/Challenge

“High Production Costs”

- A significant challenge facing the pyrolytic boron nitride (PBN) market is the high production costs associated with its manufacturing processes

- For instance, the complex chemical vapor deposition process and the need for high-purity raw materials contribute to elevated expenses, making PBN less accessible for cost-sensitive applications

- The high cost of PBN limits its widespread adoption, particularly in industries where budget constraints are a concern

- For instance, small-scale manufacturers in industries such as consumer electronics may find it difficult to integrate PBN into their products due to its premium price

- Moreover, PBN faces competition from alternative materials such as aluminium nitride and silicon carbide, which offer similar thermal and electrical properties at potentially lower costs or with easier processing requirements

- For instance, companies in the semiconductor industry may opt for aluminium nitride over PBN for its cost-effectiveness and ease of processing

- These alternatives may appeal to industries seeking cost-effective solutions, posing a challenge for PBN's market penetration

- For instance, in power electronics, manufacturers may choose silicon carbide for its lower cost and comparable thermal management capabilities

- To overcome these barriers, manufacturers must focus on developing more efficient production techniques and demonstrating the unique advantages of PBN

- For instance, efforts in automation, material recycling, and scaling chemical vapor deposition could reduce costs and enhance competitiveness without compromising PBN’s high-performance characteristics

Pyrolytic Boron Nitride Market Scope

The market is segmented on the basis of product type, application, and end-use industry

|

Segmentation |

Sub-Segmentation |

|

By Product Type |

|

|

By Application |

|

|

By End-Use Industry |

|

Pyrolytic Boron Nitride Market Regional Analysis

“North America is the Dominant Region in the Pyrolytic Boron Nitride Market”

- North America is the dominating region in the pyrolytic boron nitride market due to its strong presence in high-end manufacturing sectors such as semiconductors, aerospace, and defence

- The region benefits from a well-established infrastructure and a high level of technological advancement, which supports the adoption of high-performance materials such as pyrolytic boron nitride

- For instance, major semiconductor companies in the U.S. actively integrate pyrolytic boron nitride in their production equipment for its thermal and chemical stability

- Aerospace programs in the region continue to rely on this material for insulation in propulsion systems and satellite components

- The strong research and development ecosystem further contributes to the region’s leadership in the market, enabling continuous material innovation and industrial application

“Asia-Pacific is Projected to Register the Highest Growth Rate”

- Asia Pacific is the fastest growing region in the pyrolytic boron nitride market owing to the rapid expansion of its electronics and semiconductor industries

- Countries such as China, South Korea, Japan, and India are significantly increasing their manufacturing capacities and investing in next-generation technologies

- For instance, several electronics manufacturers in this region are using pyrolytic boron nitride in miniaturized electronic components due to its excellent thermal management properties

- The demand is also rising in sectors such as renewable energy and advanced ceramics, where the material’s durability and performance under extreme conditions are essential

- The region’s focus on industrial growth and innovation continues to drive this upward trend in usage and production

Pyrolytic Boron Nitride Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- Momentive Performance Materials Inc. (U.S.)

- Denka Company Limited (Japan)

- CeramTec GmbH (Germany)

- Tosoh Corporation (Japan)

- H.C. Starck Solutions (U.S.)

- Kyocera Corporation (Japan)

- Saint-Gobain Ceramic Materials (France)

- Nippon Carbon Co., Ltd. (Japan)

- 3M Company (U.S.)

- SGL Carbon SE (Germany)

- Mitsubishi Materials Corporation (Japan)

- Advanced Ceramic Materials, Inc. (U.S.)

- Mersen Group (France)

- Aremco Products, Inc. (U.S.)

- Eris Technology (Japan)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Pyrolytic Boron Nitride Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Pyrolytic Boron Nitride Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Pyrolytic Boron Nitride Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.