Global Precision Ball Screw Market

Market Size in USD Billion

CAGR :

%

USD

1.78 Billion

USD

2.80 Billion

2024

2032

USD

1.78 Billion

USD

2.80 Billion

2024

2032

| 2025 –2032 | |

| USD 1.78 Billion | |

| USD 2.80 Billion | |

|

|

|

|

What is the Global Precision Ball Screw Market Size and Growth Rate?

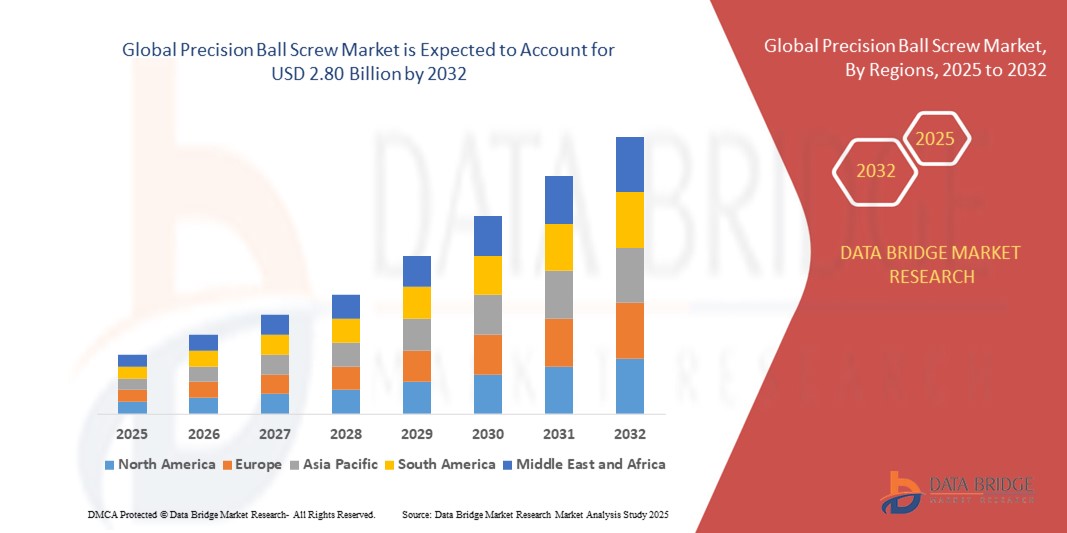

- The global precision ball screw market size was valued at USD 1.78 billion in 2024 and is expected to reach USD 2.80 billion by 2032, at a CAGR of 5.80% during the forecast period

- The essential factors contributing to the growth of the global precision ball screw market in the forecast period include increasing demand for high-precision motion control systems across various industries such as automotive, aerospace, and electronics

- In addition, technological advancements in manufacturing processes, leading to improved product quality and performance, contribute to market growth. Moreover, the rising trend of automation and robotics in industrial applications further fuels the demand for precision ball screws

What are the Major Takeaways of Precision Ball Screw Market?

- The increasing adoption of automation across various industries, including automotive, aerospace, electronics, and healthcare, is a significant driver for the demand for precision ball screws. These industries rely on automated machinery and robotics systems for increased efficiency, productivity, and precision in their operations

- Precision ball screws play a crucial role in these systems by providing precise linear motion control, enabling smooth and accurate movement of components. Whether it's in CNC machinery on a factory floor, flight control systems in aircraft, precision medical devices, or robotic assembly lines, the need for reliable and high-precision linear motion drives the demand for precision ball screws, thus fuelling the growth of the market

- Asia-Pacific dominated the precision ball screw market with the largest revenue share of 41.5% in 2024, driven by its strong manufacturing base, rapid industrialization, and expansion in sectors such as automotive, electronics, and semiconductors

- North America precision ball screw market is expected to grow at the fastest CAGR of 10.8% during 2025–2032, propelled by the region’s strong focus on automation, aerospace, defense, and EV manufacturing

- The Ground segment dominated the market with the largest revenue share of 58.4% in 2024, owing to its superior precision, high load-bearing capacity, and wide adoption in critical applications such as aerospace, semiconductor, and advanced CNC machinery

Report Scope and Precision Ball Screw Market Segmentation

|

Attributes |

Precision Ball Screw Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

What is the Key Trend in the Precision Ball Screw Market?

Growing Adoption of Automation and Robotics

- A significant and accelerating trend in the global precision ball screw market is the expanding role of automation and robotics across industries such as automotive, aerospace, and electronics. Precision ball screws are increasingly integrated into CNC machinery, industrial robots, and semiconductor equipment to deliver high accuracy and efficiency

- For instance, HIWIN Corporation offers precision ball screws designed for robotic arms and CNC machines, supporting smoother linear motion with minimal backlash. Similarly, Bosch Rexroth has developed advanced ball screw assemblies tailored for high-speed, high-precision machining applications

- Precision ball screws enable enhanced positioning accuracy, energy efficiency, and reduced maintenance compared to traditional mechanical systems. Their role in robotics ensures higher productivity and consistency in automated processes

- The integration of ball screws with smart manufacturing systems and Industry 4.0 platforms is further driving innovation, allowing predictive maintenance and real-time monitoring for reduced downtime

- This trend towards automation-driven demand is reshaping end-user expectations, with industries prioritizing reliability, accuracy, and longer lifecycle performance. Companies such as THK Co. Ltd. and SKF are investing heavily in R&D to design ball screws with improved load capacity and longer service life, catering to next-generation industrial automation needs

- The demand for precision ball screws as critical motion control components is rapidly increasing, making them indispensable for the evolution of smart factories and automated production systems

What are the Key Drivers of Precision Ball Screw Market?

- The growing penetration of CNC machines and industrial automation across manufacturing sectors is a major driver of precision ball screw demand

- For instance, in May 2024, Schaeffler AG introduced its next-generation precision ball screws with improved energy efficiency for machine tools, strengthening its position in the automation-driven manufacturing industry

- Increasing demand for high-precision machining in semiconductor and aerospace industries is accelerating adoption, as ball screws deliver low friction, accurate linear motion, and enhanced load-bearing capacity

- Furthermore, the shift towards electric vehicles (EVs) and renewable energy applications is opening new opportunities, as precision ball screws are used in battery production equipment, solar panel assembly, and robotics

- Rising investments in infrastructure modernization and smart factories worldwide, combined with the need for energy-efficient, durable, and cost-effective motion solutions, continue to fuel growth in the precision ball screw market

Which Factor is Challenging the Growth of the Precision Ball Screw Market?

- The high manufacturing cost and price sensitivity associated with precision ball screws pose a significant challenge to wider adoption, especially among small- and medium-sized manufacturers

- For instance, the production of high-accuracy ball screws involves advanced grinding and heat treatment processes, which elevate costs compared to alternative motion control systems

- The availability of low-cost substitutes such as belt drives or hydraulic actuators in certain applications also hinders broader penetration of ball screws in cost-sensitive industries

- In addition, wear and maintenance issues in high-speed and heavy-load applications can impact long-term reliability, leading to increased demand for regular servicing and replacements

- Companies such as Nidec Corporation and Kuroda Precision Industries are addressing these concerns by developing advanced surface treatments and lubrication technologies to extend service life and reduce operational costs

- Overcoming these challenges by offering cost-optimized designs, expanding affordable product lines, and emphasizing durability will be critical to sustain market growth in the coming years

How is the Precision Ball Screw Market Segmented?

The market is segmented on the basis of type, communication protocol, unlocking mechanism, and application.

- By Product Type

On the basis of product type, the precision ball screw market is segmented into Ground and Rolled ball screws. The Ground segment dominated the market with the largest revenue share of 58.4% in 2024, owing to its superior precision, high load-bearing capacity, and wide adoption in critical applications such as aerospace, semiconductor, and advanced CNC machinery. Ground ball screws are preferred in industries where accuracy, smooth motion, and durability are paramount, driving their consistent demand.

The Rolled segment is projected to witness the fastest CAGR of 8.9% from 2025 to 2032, driven by cost-effectiveness, faster production cycles, and suitability for general industrial and automotive applications. With advancements in rolling techniques improving accuracy, rolled ball screws are gaining traction in mid-range automation and manufacturing processes, particularly in emerging markets where affordability and scalability are key priorities.

- By Sales Channel

On the basis of sales channel, the precision ball screw market is segmented into Offline and Online. The Offline segment dominated the market with the largest revenue share of 67.3% in 2024, as manufacturers and distributors traditionally rely on direct sales, partnerships, and industrial supply chains to cater to large-scale clients such as automotive, aerospace, and electronics companies. Offline channels remain essential for offering customized solutions, after-sales service, and technical consultation.

The Online segment is anticipated to grow at the fastest CAGR of 10.5% during 2025–2032, driven by digitalization and the increasing preference of SMEs and individual buyers for e-commerce platforms. Online platforms provide price transparency, broader product accessibility, and convenience of bulk ordering, particularly for standard ball screw models. The rising shift towards e-marketplaces for industrial components highlights the growing importance of digital distribution in global supply networks.

- By Raw Material

On the basis of raw material, the precision ball screw market is segmented into Alloy Steel and Stainless Steel. The Alloy Steel segment held the largest revenue share of 61.8% in 2024, primarily due to its strength, hardness, and cost-efficiency, making it the preferred choice in high-load industrial machinery and automotive manufacturing. Alloy steel ball screws are widely used in heavy-duty applications where robustness and wear resistance are essential.

The Stainless Steel segment is projected to grow at the fastest CAGR of 9.2% from 2025 to 2032, owing to its superior corrosion resistance, durability, and suitability for applications in medical devices, laboratories, and semiconductor equipment. The demand for stainless steel ball screws is particularly rising in cleanroom environments and industries requiring precision with resistance to contamination, ensuring long-term reliability. This shift reflects the market’s growing focus on specialized, high-performance materials tailored to niche applications.

- By Application

On the basis of application, the precision ball screw market is segmented into Semiconductor, Laboratory, Medical, and Others. The Semiconductor segment dominated the market with the largest revenue share of 44.6% in 2024, driven by the critical use of precision ball screws in wafer processing, lithography, and assembly equipment where high positioning accuracy and repeatability are essential. The growing demand for advanced microchips and the expansion of semiconductor fabrication plants worldwide continue to fuel this segment’s dominance.

The Medical segment is expected to register the fastest CAGR of 10.1% from 2025 to 2032, supported by the increasing adoption of ball screws in surgical robots, imaging systems, and diagnostic devices requiring precision motion. The laboratory segment also shows steady demand, particularly for testing and calibration equipment. The rapid expansion of healthcare technologies and automation in medical systems positions this segment as a critical growth driver for the market.

Which Region Holds the Largest Share of the Precision Ball Screw Market?

- Asia-Pacific dominated the precision ball screw market with the largest revenue share of 41.5% in 2024, driven by its strong manufacturing base, rapid industrialization, and expansion in sectors such as automotive, electronics, and semiconductors

- The region benefits from robust demand for CNC machinery, robotics, and semiconductor equipment, where precision ball screws are critical for accuracy and performance

- Supportive government initiatives in countries such as China, Japan, and South Korea aimed at promoting smart manufacturing and automation have further accelerated adoption

- In addition, cost competitiveness, presence of leading manufacturers, and rising exports of industrial machinery from the region establish Asia-Pacific as the dominant hub for precision ball screw production and consumption

China Precision Ball Screw Market Insight

China precision ball screw market captured the largest revenue share of 52% in 2024 within Asia-Pacific, driven by the nation’s vast manufacturing ecosystem, especially in automotive, electronics, and machine tools. The government’s “Made in China 2025” initiative continues to strengthen domestic production capacity and innovation. Chinese manufacturers are increasingly adopting automation and robotics, fueling demand for precision motion control solutions. Moreover, cost-efficient local suppliers combined with strong demand from infrastructure and EV sectors position China as a global leader in precision ball screw adoption.

Japan Precision Ball Screw Market Insight

Japan precision ball screw market is projected to grow at a steady CAGR, fueled by the country’s reputation as a leader in high-precision engineering and robotics. Japan’s advanced semiconductor and automotive industries drive strong demand for ground ball screws used in CNC machines and robotic systems. Leading Japanese companies such as THK Co. Ltd. and Kuroda Precision Industries continue to innovate in high-load and high-accuracy products. In addition, Japan’s focus on automation in response to labor shortages and its export-driven economy ensures long-term demand for precision ball screws.

India Precision Ball Screw Market Insight

India precision ball screw market is set to expand at a notable CAGR during the forecast period, driven by rapid industrialization, growth in automotive manufacturing, machine tools, and electronics assembly, and government programs such as “Make in India.” Increasing investments in infrastructure, renewable energy, and defense sectors are creating new demand for precision motion solutions. The rising number of SMEs adopting CNC technology for machining applications also supports market growth. As India strengthens its position as a manufacturing hub, demand for rolled and cost-effective ball screws is expected to surge.

Which Region is the Fastest Growing in the Precision Ball Screw Market?

North America precision ball screw market is expected to grow at the fastest CAGR of 10.8% during 2025–2032, propelled by the region’s strong focus on automation, aerospace, defense, and EV manufacturing. Adoption of Industry 4.0 practices and investments in semiconductor fabs in the U.S. are significantly driving demand. The U.S. in particular accounts for a dominant share of North America, supported by leading machine tool manufacturers, defense projects, and rising adoption of robotics across industries. The presence of global players such as Barnes Industries and Bosch Rexroth (regional operations) further strengthens North America’s growth trajectory.

U.S. Precision Ball Screw Market Insight

U.S. precision ball screw market dominated North America’s revenue share in 2024, driven by strong demand from aerospace, defense, automotive, and semiconductor industries. The rapid adoption of CNC machinery, robotics, and EV production systems is fueling the need for high-precision motion control solutions. Investments in new semiconductor fabs under the CHIPS and Science Act and growth in aerospace manufacturing are particularly significant drivers. Moreover, the U.S. is witnessing rising demand for automation in healthcare and medical device manufacturing, further expanding ball screw applications. The presence of leading manufacturers such as Barnes Industries and regional operations of global players such as Bosch Rexroth and Schaeffler strengthens domestic supply capabilities.

Which are the Top Companies in Precision Ball Screw Market?

The precision ball screw industry is primarily led by well-established companies, including:

- Barnes Industries Inc. (U.S.)

- Bosch Rexroth (Germany)

- HIWIN Corporation (Taiwan)

- Koyo Machinery (U.S.)

- Kuroda Precision Industries (Japan)

- Nidec Corporation (Japan)

- PSR Group (Belgium)

- Schaeffler AG (Germany)

- SKF (Sweden)

- THK Co. Ltd. (Japan)

What are the Recent Developments in Global Precision Ball Screw Market?

- In November 2022, HIWIN Corporation introduced its FB Series Ball Splines, designed with enhanced precision and flexibility to handle combined stroke and rotation tasks, enabling greater versatility across industrial applications. This launch strengthens HIWIN’s position as a leader in advanced motion control solutions

- In July 2022, PBC Linear, a Pacific Bearing Company, expanded its portfolio by adding Miniature Metric Ball Screw Assemblies, combining precision-rolled screws with compact nuts for high performance at an economical cost. This development highlights the company’s commitment to delivering cost-effective yet reliable linear motion technologies

- In June 2022, NSK Ltd. announced a new ball screw technology engineered to significantly extend lifespan in high-load drive applications, addressing the growing demand from manufacturers transitioning toward electric-driven designs. This innovation is expected to generate new revenue opportunities and enhance NSK’s competitive edge

- In May 2021, Ewellix, formerly SKF Motion Technologies, unveiled a new high-precision large ball screw range for automation and heavy-duty applications, designed to improve reliability, extend service life, and achieve 25% higher speed limits with reduced noise. This introduction reinforces Ewellix’s focus on supporting demanding automation requirements

- In March 2021, Ewellix, formerly SKF Motion Technologies, launched a smooth-running, high-accuracy ball screw range tailored for heavy-duty and automation applications, delivering enhanced machine performance and longer service life with low operational noise. This release underlined Ewellix’s strategy of enhancing product performance and durability

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Precision Ball Screw Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Precision Ball Screw Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Precision Ball Screw Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.