Global Pharmaceutical Processing Equipment Market

Market Size in USD Billion

CAGR :

%

USD

16.42 Billion

USD

33.72 Billion

2024

2032

USD

16.42 Billion

USD

33.72 Billion

2024

2032

| 2025 –2032 | |

| USD 16.42 Billion | |

| USD 33.72 Billion | |

|

|

|

|

Pharmaceutical Processing Equipment Market Analysis

The global pharmaceutical processing equipment market is driven by global rise in chronic diseases such as cardiovascular diseases, cancer, and respiratory disorders is further increasing the demand for pharmaceutical products. However, one restraint for market growth is the raw material shortages are a major concern in pharmaceutical processing equipment manufacturing, as specialized materials may be scarce or hard to source, leading to production delays and higher costs. An opportunity in this market lies in the modern technologies such as automation, robotics, PAT, and continuous manufacturing enhance operational efficiency, reduce production costs, and boost product quality, presenting a significant market growth. One challenge is the high demand for specialized expertise makes it challenging for companies to recruit and retain qualified professionals, resulting in increased competition and higher labor costs.

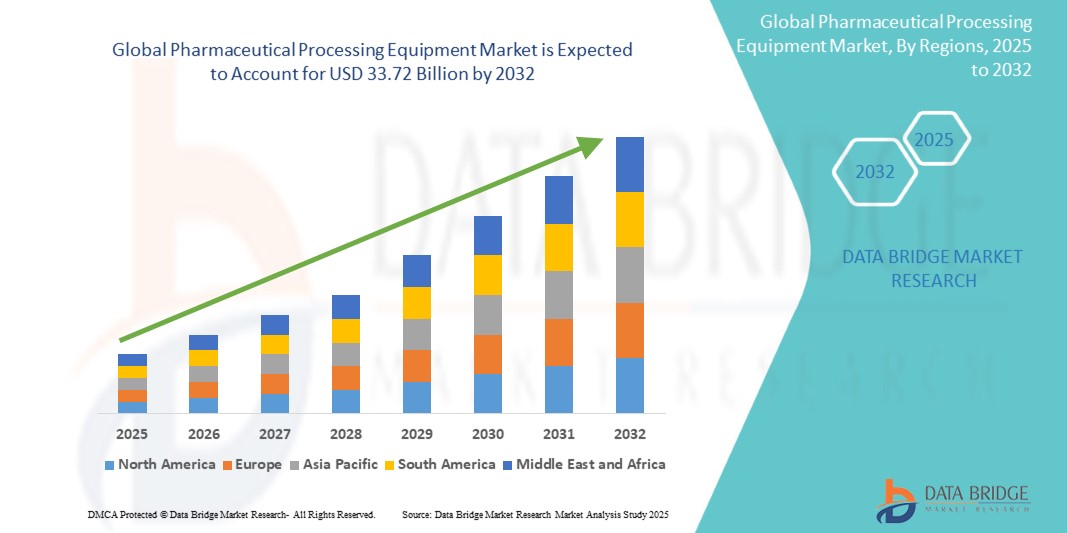

Pharmaceutical Processing Equipment Market Size

The global pharmaceutical processing equipment size was valued at USD 16.42 billion in 2024 and is projected to reach USD 33.72 billion by 2032, with a CAGR of 9.41 % during the forecast period of 2025 to 2032. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include depth expert analysis, patient epidemiology, pipeline analysis, pricing analysis, and regulatory framework.

Report Scope and Pharmaceutical Processing Equipment Market Segmentation

|

Attributes |

Pharmaceutical Processing Equipment Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E., South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America |

|

Key Market Players |

Thermo Fisher Scientific Inc., ALFA LAVAL, GEA Group Aktiengsellschaft, SPX FLOW, Inc., I.M.A. INDUSTRIA MACCHINE AUTOMATICHE S.P.A, ACG, Syntegon Technology GmbH, Paul Mueller Company, FREUND Corp., Gansons, Alexanderwerk AG, B&P Littleford, Chamunda Pharma Machinery, Prism Pharma Machinery, SaintyCo Nicomac Srl, United Pharmatek USA, ADINATH INTERNATIONAL, NU PHARMA ENGINEERS & CONSULTANT, and Senieer |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include depth expert analysis, patient epidemiology, pipeline analysis, pricing analysis, and regulatory framework. |

Pharmaceutical Processing Equipment Market Definition

Pharmaceutical processing equipment comprises a diverse range of specialized machinery and tools essential for the manufacturing, handling, and preparation of pharmaceutical products. This equipment is designed to meet stringent regulatory standards and ensure the safety, efficacy, and quality of pharmaceutical formulations. Key categories of pharmaceutical processing equipment include mixing and blending machines, which amalgamate active pharmaceutical ingredients (APIs) with excipients to create homogeneous mixtures. Milling and size reduction equipment reduces particle sizes of raw materials to achieve desired characteristics for further processing or formulation. Tablet compression and capsule filling machines automate the production of tablets and capsules, ensuring precise dosing and uniformity.

This equipment is pivotal in adhering to Good Manufacturing Practices (GMP) and regulatory requirements, enhancing efficiency and ensuring the consistency and safety of pharmaceutical products delivered to patients and healthcare providers.

Pharmaceutical Processing Equipment Market Dynamics

Drivers

- Increase Demand for Pharmaceutical Products

The growing demand for pharmaceutical products is driven by several factors, including a global population increase that requires more healthcare services and medications, leading to a greater need for pharmaceutical production to treat a range of health conditions.

The aging population, particularly in developed nations, is driving up the demand for pharmaceuticals. Elderly individuals typically require more medications to manage age-related ailments such as hypertension, diabetes, and arthritis. Consequently, this demographic change is driving the need for pharmaceuticals and, subsequently, pharmaceutical processing equipment.

- Growing Demand for High Containment Equipment

High containment equipment is essential in ensuring the safe handling and production of Highly Potent Active Pharmaceutical Ingredients (HPAPIs) and other hazardous substances. This demand is primarily driven by several key factors.

There is an increasing focus on developing and manufacturing specialty drugs, including those used in oncology, immunotherapy, and other treatments involving HPAPIs. These drugs require stringent safety measures to protect workers and the environment from exposure to hazardous substances during the manufacturing process. High containment equipment, such as isolators and barrier systems, provides the necessary level of protection and contamination control, making them indispensable in modern pharmaceutical production facilities

Opportunities

- Integration of Advanced Manufacturing Technologies

Advanced manufacturing technologies offer a transformative opportunity in the global pharmaceutical processing equipment market. Modern technologies such as automation, robots, Process Analytical Technology (PAT) and continuous manufacturing can be integrated to improve operational effectiveness, lower production costs, and improve product quality. Pharmaceutical firms can keep up with changing market demands, stay competitive, and encourages industry innovation by adopting these IoT, robotics and PAT technologies.

Restraints/Challenges

- Supply Chain Disruptions

Supply chain disruptions present a significant restraint for the global pharmaceutical processing equipment market. These disruptions can stem from various sources, including raw material shortages, logistics challenges, and geopolitical issues, all of which can impede the availability and timely delivery of essential equipment.

Raw material shortages are a primary concern. The manufacturing of pharmaceutical processing equipment often relies on specialized materials, which may be scarce or difficult to source. When the supply of these materials is interrupted, production delays and increased costs can ensue. For example, the availability of high-grade stainless steel, critical for its corrosion resistance and durability in pharmaceutical environments, can be affected by global supply constraints.

This market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Pharmaceutical Processing Equipment Market Scope

The market is segmented on the basis of equipment, dosage type, processing type, application, end user, and distribution channel. The growth amongst these segments will help you analyse meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Equipment

- Mixers

- Blenders

- Granulators

- Pumps

- Heat Exchangers

- Others

Dosage Type

- Solid Dosage Processing Equipment

- Liquid Dosage Processing Equipment

- Semi-Solid Dosage Processing Equipment

Processing Type

- Upstream Processing

- Downstream Processing

Application

- Mixing & blending

- Granulation

- Drying

- Tablet compression

- Capsule filling

- Others

End User

- Pharmaceutical & Biopharmaceutical Companies

- Contract Research Organization

- R&D Laboratories

- Others

Distribution Channel

- Direct Tenders

- Retail Sales

- Others

Pharmaceutical Processing Equipment Market Regional Analysis

The market is analysed and market size insights and trends are provided by country, equipment, dosage type, processing type, application, end user, and distribution channel as referenced above.

The countries covered in the market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E., South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

North America is expected to dominate the market due to its advanced infrastructure, strong R&D capabilities, stringent regulatory standards, and significant investment in innovation and technology. U.S. is expected to dominate in the North America market due to advanced infrastructure, robust regulatory framework, extensive R&D investment, and significant market size.

U.K. is expected to dominate in the Europe market due to its strong regulatory standards, cutting-edge research institutions, strategic geographic location, and a history of innovation in pharmaceutical development.

China is expected to dominate in the Asia-Pacific market due to its lower manufacturing costs, expansive production capabilities, a large domestic market, and government support for industry growth.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Pharmaceutical Processing Equipment Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

Pharmaceutical Processing Equipment Market Leaders Operating in the Market Are:

- Thermo Fisher Scientific Inc.

- ALFA LAVAL

- GEA Group Aktiengesellschaft

- SPX FLOW, Inc.

- I.M.A. INDUSTRIA MACCHINE AUTOMATICHE S.P.A

- ACG

- Syntegon Technology GmbH

- Paul Mueller Company

- FREUND Corp.

- Gansons

- Alexanderwerk AG

- B&P Littleford

- Chamunda Pharma Machinery

- Prism Pharma Machinery

- SaintyCo

- Nicomac Srl

- United Pharmatek USA

- ADINATH INTERNATIONAL

- NU PHARMA ENGINEERS & CONSULTANT

- Senieer

Latest Developments in Pharmaceutical Processing Equipment Market

- In November 2023, Thermo Fisher Scientific and Flagship Pioneering have partnered to develop and scale multiproduct platforms quickly. This collaboration aims to create new companies focusing on innovative tools for the biotech industry, leveraging the expertise of both organizations to accelerate therapy development

- In August 2023, Thermo Fisher Scientific has acquired CorEvitas, a provider of real-world evidence, to enhance its Laboratory Products and Biopharma Services segment. This acquisition strengthens Thermo Fisher's position in providing regulatory-grade data for medical treatments, contributing to its growth and innovation in the healthcare sector

- In January 2024, EcoDataCenter achieves an industry first by deploying Alfa Laval heat exchangers made from recycled steel, produced without new CO2 emissions from SSAB, marking a significant milestone in reducing carbon emissions and highlighting the importance of collaboration in sustainability efforts. This advancement will enhance the company's environmental reputation, reduce its carbon footprint, and set a new standard for sustainable practices in the industry

- In May 2024, GEA continues to expand its portfolio of pharmaceutical spray dryers. At ACHEMA in Frankfurt (June 10-14, 2024, Hall 4.0, Stand G66), GEA will present the new GEA ASEPTICSD spray dryers. They are specially designed for pharmaceutical spray drying applications. From antibiotics, vaccines, hormones and allergens to monoclonal antibodies, therapeutic peptides and proteins, blood products and powders for parenteral infusions, the spray dryers offer versatile solutions. The spray dryers can also be designed to handle organic solvents, allowing the use of a variety of carriers within the formulation

- In January 2024, SPX FLOW's Anhydro brand introduced the SmartDry System, utilizing advanced technology for precise control in variable production environments. This "Plug-and-Produce" system enhances automation, saving costs and optimizing production efficiency. This release enhances SPX FLOW's reputation for innovative solutions, attracting customers looking for advanced, automated systems to improve their spray drying processes, thereby increasing the company's market share and revenue

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.