Global Packaging Automation Market

Market Size in USD Billion

CAGR :

%

USD

74.56 Billion

USD

128.10 Billion

2024

2032

USD

74.56 Billion

USD

128.10 Billion

2024

2032

| 2025 –2032 | |

| USD 74.56 Billion | |

| USD 128.10 Billion | |

|

|

|

Packaging Automation Market Analysis

The packaging automation market is expanding rapidly as businesses increasingly prioritize efficiency, cost reduction, and product safety. With AI-driven solutions and robotics transforming packaging operations, companies are investing in smart technologies to streamline workflows and enhance productivity. The integration of IoT enables real-time monitoring and optimization, allowing organizations to make data-driven decisions for improved efficiency. Sustainability trends are also shaping the industry, driving the adoption of eco-friendly automated packaging solutions that align with regulatory standards and consumer expectations. As the demand for faster and safer deliveries grows, automation is becoming essential for maintaining operational scalability and adaptability in a dynamic market. To stay competitive, businesses are focusing on agility, leveraging strategic collaborations and technological advancements to enhance automation capabilities. The ongoing digital transformation is further optimizing processes, reinforcing long-term growth and resilience, while organizations that embrace automation gain a significant competitive advantage through increased reliability, efficiency, and responsiveness to market changes.

Packaging Automation Market Size

The packaging automation market size was valued at USD 74.56 billion in 2024 and is projected to reach USD 128.10 billion by 2032, with a CAGR of 7.00% during the forecast period of 2025 to 2032. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework.

Packaging Automation Market Trends

“Increase in the Disposable Income and Living Standards”

The rise in disposable income and living standards is increasing demand for high-quality packaging. As consumers prefer premium, convenient, and sustainable solutions, businesses are turning to automation. Automated systems ensure precision, speed, and efficiency, meeting evolving market expectations seamlessly. For instance, luxury brands invest in smart packaging to enhance product security and appeal. With urbanization accelerating, mass-market production requires automation to maintain consistency and efficiency. Advanced robotics and AI enable faster, more adaptive packaging for both premium and everyday products. The integration of IoT further optimizes supply chains, ensuring product safety and real-time monitoring. Higher spending power is also driving e-commerce growth, increasing the need for automated fulfillment. Smart packaging innovations, such as QR-coded authentication, enhance consumer trust and engagement. As market demands shift toward sustainability, automation helps businesses meet regulatory and environmental standards. Companies investing in automated packaging solutions gain a competitive edge in a rapidly evolving landscape.

Report Scope and Packaging Automation Market Segmentation

|

Attributes |

Packaging Automation Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America |

|

Key Market Players |

Rockwell Automation (U.S.), ABB (Switzerland), Mitsubishi Electric Corporation (Japan), Schneider Electric (France), Emerson Electric Co. (U.S.), Swisslog Holding AG (Switzerland), Siemens (Germany), Ochre Digi Media Pvt Ltd. (India), Kollmorgen (U.S.), BEUMER Group (Germany), Robert Bosch GmbH (Germany), Coesia S.p.A (Italy), Krones AG (Germany), Tetra Pak International S.A. (Switzerland), Graphic Packaging International, LLC (U.S.) |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Packaging Automation Market Definition

Packaging automation refers to the use of advanced machinery to streamline packaging operations. It enhances productivity, efficiency, and accuracy while minimizing labour dependency and costs. Automated systems help manufacturers optimize workflows, ensuring faster and more consistent packaging processes. The market for packaging automation is expanding as industries seek higher operational efficiency. Rising consumer demand for quality, convenience, and sustainability is increasing adoption across sectors. Businesses implement automated machines to reduce manual errors and improve packaging speed. E-commerce expansion further boosts the need for reliable and high-speed packaging solutions. Smart technologies, including AI and IoT, enable real-time monitoring and process optimization. Automated packaging ensures cost savings, scalability, and compliance with industry regulations.

Packaging Automation Market Dynamics

Drivers

- Rising Need for Supply Chain Integration

The rising need for supply chain integration is fueling the adoption of packaging automation. As businesses scale operations, seamless coordination between production, packaging, and distribution becomes essential. Automated packaging systems enable real-time data sharing, ensuring accurate inventory tracking and demand forecasting. With IoT-driven solutions, manufacturers gain better visibility into packaging workflows and logistics. This integration reduces bottlenecks, minimizes errors, and enhances overall supply chain efficiency. For instance, e-commerce companies rely on automated packaging to handle high-order volumes efficiently. By synchronizing packaging with distribution, businesses improve delivery speed and reduce operational delays. AI-powered analytics further optimize packaging processes, supporting predictive maintenance and reducing downtime. Enhanced automation allows companies to adapt quickly to changing market demands and supply fluctuations. Smart packaging solutions also support sustainability efforts by minimizing material waste and energy consumption. As global supply chains grow more complex, automation remains a key factor in maintaining competitiveness. Companies leveraging integrated automation achieve greater scalability, cost efficiency, and market responsiveness.

- Growing Preference for Automated Packaging Over Traditional Methods

The growing preference for automated packaging over traditional methods is reshaping manufacturing and logistics. As businesses prioritize efficiency, they seek faster, more precise, and cost-effective packaging solutions. Automated systems reduce human errors, ensuring consistent quality while minimizing material waste and production delays. For instance, food and beverage companies use automated sealing to enhance hygiene and extend shelf life. Traditional methods struggle to meet rising production demands, making automation essential for scalability. AI and robotics further optimize packaging speed, accuracy, and customization to meet diverse market needs. E-commerce expansion increases demand for automated sorting, labeling, and packaging to improve fulfillment efficiency. Smart technologies, such as RFID tagging, enhance traceability, inventory management, and supply chain coordination. Automation also supports sustainability by reducing excess material usage and energy consumption. Businesses adopting automated packaging gain a competitive edge through improved productivity and cost savings. As industries evolve, automation continues to be a key driver of operational growth.

Opportunities

- Increasing Customized Packaging Automation Solutions

The growing need for customized packaging automation solutions is creating new opportunities in the market. Businesses aim to enhance brand identity and efficiency by adopting tailored automation systems. Advanced robotics and AI enable high-speed, personalized packaging without compromising quality or precision. For instance, e-commerce companies utilize automated packaging to create right-sized boxes, reducing material waste. Consumers increasingly prefer unique, sustainable, and premium packaging, making flexibility in automation essential. Smart technologies, including IoT and AI, allow real-time modifications to meet specific packaging needs. Industries such as pharmaceuticals and cosmetics require precision-driven automation for personalized product packaging. Modular automation systems offer scalability, helping manufacturers quickly respond to shifting market demands. Customization also optimizes supply chain operations by reducing excess inventory and improving production timelines. Companies embracing adaptable automation gain a competitive advantage in an evolving business landscape.

- Growth in the E-Commerce and Retail Sectors

The expansion of e-commerce and retail sectors is creating significant opportunities for packaging automation. With the rise in online shopping, businesses must adopt faster and more efficient packaging solutions. Automated systems enhance fulfillment speed, improve accuracy, and ensure consistency in high-volume operations. For instance, major e-commerce companies implement automated sorting and packing to manage peak demand efficiently. Retailers are also integrating automation to lower labor costs and streamline packaging workflows. The growing consumer expectation for quick and eco-friendly deliveries is increasing automation adoption. Smart technologies such as AI and IoT enable waste reduction and customized packaging solutions. By automating packaging processes, businesses can enhance product safety and minimize errors. The shift towards omnichannel retailing requires flexible and scalable packaging automation systems. Companies that invest in automation gain an advantage by improving supply chain efficiency and responsiveness. With the continuous growth of e-commerce and retail, automation will become essential for improving efficiency, optimizing operations, and maintaining a competitive edge.

Restraints/Challenges

- Rising Requirement of High-Level Maintenance

The increasing need for high-level maintenance is a major restraint on packaging automation adoption. As automated systems become more advanced, regular servicing and technical expertise are essential for smooth operations. Businesses must allocate resources for skilled personnel or rely on specialized service providers for upkeep. For instance, robotics-driven packaging lines require frequent software updates and mechanical adjustments to prevent disruptions. The integration of AI and IoT further adds complexity, making maintenance more demanding and time-consuming. Any unexpected breakdowns can lead to costly delays, affecting overall productivity and supply chain efficiency. Small and mid-sized companies often struggle with the financial burden of ongoing maintenance and repairs. Downtime caused by system servicing reduces operational effectiveness, creating concerns about long-term cost efficiency. The need for continuous upgrades adds further expenses, making automation adoption challenging for some businesses.

- Increasing Capital Cost

The increasing capital cost presents a significant challenge for the adoption of packaging automation. Businesses must make substantial upfront investments in advanced machinery, software, and system integration. High-tech solutions, such as AI-driven robotics and IoT-enabled packaging systems, further raise initial costs. Small and mid-sized enterprises often struggle to allocate sufficient budgets for automation implementation. For instance, installing fully automated packaging lines requires not only purchasing equipment but also training personnel. Additional expenses arise from system customization, maintenance infrastructure, and periodic software upgrades. The financial burden is intensified by the need for scalable solutions that can adapt to market demands. Long payback periods and uncertain returns on investment make decision-making more complex for businesses. Some companies delay automation adoption due to concerns over cost recovery and profitability. Securing financing options and adopting phased automation strategies can help businesses mitigate capital cost challenges. Despite the high investment, long-term efficiency gains and cost savings justify automation adoption.

This market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Impact and Current Market Scenario of Raw Material Shortage and Shipping Delays

Data Bridge Market Research offers a high-level analysis of the market and delivers information by keeping in account the impact and current market environment of raw material shortage and shipping delays. This translates into assessing strategic possibilities, creating effective action plans, and assisting businesses in making important decisions.

Apart from the standard report, we also offer in-depth analysis of the procurement level from forecasted shipping delays, distributor mapping by region, commodity analysis, production analysis, price mapping trends, sourcing, category performance analysis, supply chain risk management solutions, advanced benchmarking, and other services for procurement and strategic support.

Expected Impact of Economic Slowdown on the Pricing and Availability of Products

When economic activity slows, industries begin to suffer. The forecasted effects of the economic downturn on the pricing and accessibility of the products are taken into account in the market insight reports and intelligence services provided by DBMR. With this, our clients can typically keep one step ahead of their competitors, project their sales and revenue, and estimate their profit and loss expenditures.

Packaging Automation Market Scope

The market is segmented on the basis of product type, application, end-user industry, and function. The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Product Type

- Filling

- Labelling

- Decorating & Coding

- Case Handling

- Bottling Line

- Palletizing

- Wrapping & Bundling

- Others

Application

- Wrapping

- Capping

- Filling

- Labeling

- Palletizing

- Others

End-User Industry

- Food

- Beverage

- Pharmaceutical

- Industrial & Chemicals

- Others

Function

- Case Packaging

- Palletizing

Packaging Automation Market Regional Analysis

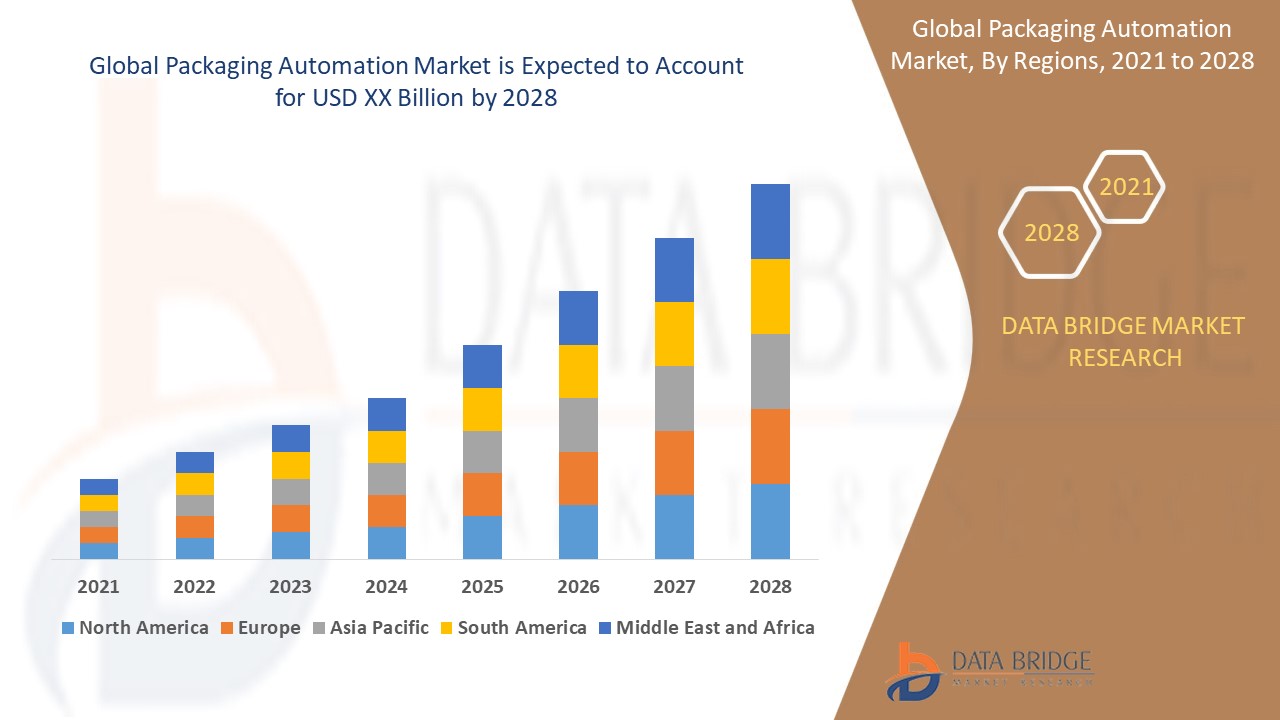

The market is analysed and market size insights and trends are provided by country, product type, application, end-user industry, and function as referenced above.

The countries covered in the market report are U.S., Canada, Mexico in North America, Germany, Sweden, Poland, Denmark, Italy, U.K., France, Spain, Netherland, Belgium, Switzerland, Turkey, Russia, Rest of Europe in Europe, Japan, China, India, South Korea, New Zealand, Vietnam, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in Asia-Pacific (APAC), Brazil, Argentina, Rest of South America as a part of South America, U.A.E, Saudi Arabia, Oman, Qatar, Kuwait, South Africa, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA).

Asia-Pacific is expected to dominate the market due to rapid urbanization, increased household purchasing power, a rapidly growing e-commerce sector, and supportive government policies on energy conservation and technological advancements. Notably, China stands as the primary revenue generator within APAC, attributed to its vast manufacturing base, growing population, rising disposable income, and the need to reduce packaging expenses.

Europe is expected to be the fastest growing due to high demand for automated, adaptable, and efficient packaging machinery across various industries, including food, beverage, chemical, personal care, and pharmaceuticals. The increasing consumption of packaged food due to sedentary lifestyles and the availability of advanced automation technologies further bolster this expansion.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Packaging Automation Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

Packaging Automation Market Leaders Operating in the Market Are:

- Rockwell Automation (U.S.)

- ABB (Switzerland)

- Mitsubishi Electric Corporation (Japan)

- Schneider Electric (France)

- Emerson Electric Co. (U.S.)

- Swisslog Holding AG (Switzerland)

- Siemens (Germany)

- Ochre Digi Media Pvt Ltd. (India)

- Kollmorgen (U.S.)

- BEUMER Group (Germany)

- Robert Bosch GmbH (Germany)

- Coesia S.p.A (Italy)

- Krones AG (Germany)

- Tetra Pak International S.A. (Switzerland)

- Graphic Packaging International, LLC (U.S.)

Latest Developments in Packaging Automation Market

- In April 2024, Swiss technology group Bühler, in partnership with Canada’s Premier Tech, launched the CHRONOS OMP-2090 B, an advanced packaging automation solution. Designed for powders and non-free-flowing materials, it enhances efficiency and precision in packaging operations. Its fully automated system ensures high productivity, exceptional accuracy, and seamless handling of various products. Additionally, the solution prioritizes both product integrity and operational safety, addressing the industry's growing demand for reliable and efficient bagging technologies

- In August 2022, Maxpack Machinery LLC announced the launch of Leap by Maxpack, an innovative packaging automation solution designed to enhance accessibility for businesses. This offering aligns with the growing Buy Now, Pay Later trend, enabling companies to invest in automation with flexible payment options. As the packaging automation market expands, flexible financing solutions such as Leap are expected to drive wider adoption, fostering innovation and operational efficiency

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Packaging Automation Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Packaging Automation Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Packaging Automation Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.