Global Offline Automated Optical Inspection System Market

Market Size in USD Billion

CAGR :

%

USD

643.20 Billion

USD

3,665.35 Billion

2021

2029

USD

643.20 Billion

USD

3,665.35 Billion

2021

2029

| 2022 –2029 | |

| USD 643.20 Billion | |

| USD 3,665.35 Billion | |

|

|

|

|

Offline Automated Optical Inspection System Market Analysis and Size

The offline automated optical inspection system allows for easy and accurate inspection in electronic assemblies and printed board circuits. The rising number of applications and rising usage of the automated optical inspection system for integrated circuits will create growth opportunities for the market over the forecasted period.

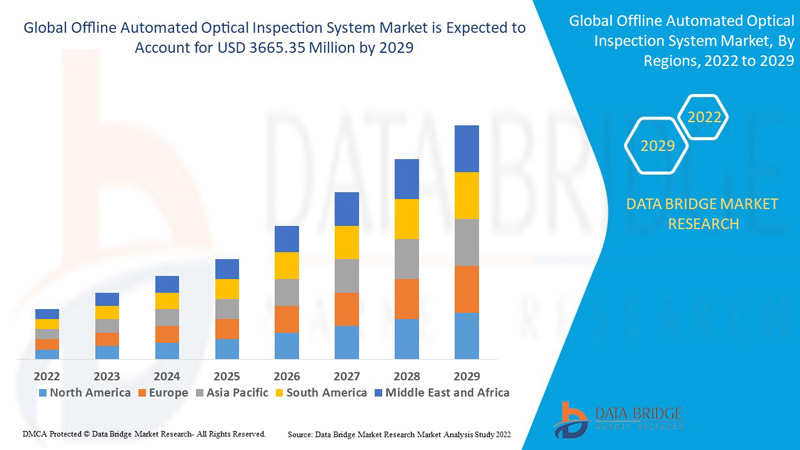

Global offline automated optical inspection system market was valued at USD 643.20 million in 2021 and is expected to reach USD 3665.35 million by 2029, registering a CAGR of 24.30% during the forecast period of 2022-2029. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand.

Offline Automated Optical Inspection System Market Scope and Segmentation

|

Report Metric |

Details |

|

Forecast Period |

2022 to 2029 |

|

Base Year |

2021 |

|

Historic Years |

2020 (Customizable to 2014 - 2019) |

|

Quantitative Units |

Revenue in USD Billion, Volumes in Units, Pricing in USD |

|

Segments Covered |

Application (Fabrication Phase, Assembly Phase), System (Elements of Automated Optical Inspection, Defect Detection Process, Others), Type (2D Automated Optical Inspection System, 3D Automated Optical Inspection System), Industry (Consumer Electronics, Telecommunication, Automotive, Medical Devices, Aerospace and Defense, Industrial Electronics, Energy and Power) |

|

Countries Covered |

U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America |

|

Market Players Covered |

KOH YOUNG TECHNOLOGY inc. (South Korea), Test Research, Inc. (Taiwan), OMRON Corporation (Japan), Viscom AG (Germany), SAKI CORPORATION. (Japan), Nordson Corporation (U.S.), DAIICHI JITSUGYO CO., LTD. (U.S.), KLA Corporation. (U.S.), CyberOptics (U.S.), GÖPEL electronic GmbH. (Germany), MIRTEC CO., LTD. (U.S.), SMTnet (U.S.), Camtek (Israel), Vi TECHNOLOGY (U.S.), DCB Automation (U.K.), Pemtron Europe GmbH (Germany), Stratus Vision GmbH (Germany), MEK Marantz Electronics Ltd (U.S.), Chroma ATE Inc. (China) |

|

Market Opportunities |

|

Market Definition

A power supply and an end device are linked together using a patch cable, also known as a patch cord, to route signals between non-networked devices like headphones and microphones, it transports telephonic, audio, and video signals. It is easily accessible in a wide range of colours and is shorter than other traditional networking cables.

Global Offline Automated Optical Inspection System Market Dynamics

This section deals with understanding the market drivers, advantages, opportunities, restraints and challenges. All of this is discussed in detail as below:

Drivers

- Rising need for high speed Printed Board Circuits (PCBs)

The rising need for the miniature devices and high speed printed board circuits (PCBs) is the primary factor driving the growth of the offline automated optical inspection system market over the forecasted period. The growing demand for high speed networks and electronics as well is working as the changing aspect for the automated optical inspection systems. High speed printed board circuits increase the complexity during the process. These beneficiary factors are acting as the major factors driving the growth of the market over the forecasted period

- Growing adoptions of AOI systems in electronics

The growing adoptions of automated optical inspection systems across electronics and semiconductor industries is the factor that fuels the market growth. The growing advancements in the system such as enhanced accuracy and efficiency and high speed results are the factors that are increasing the demands for the automated optical inspection systems and driving the growth of the offline automated optical inspection system market over the forecasted period.

Opportunities

- Growing Penetration and Technological Advancements

The growing penetration of offline automated optical inspection system across various sectors such as automotive, food and beverages, electronic, pharmaceuticals, medical and others are estimated to generate lucrative opportunities for the market, further expanding the offline automated optical inspection system market's growth rate in the future. Additionally, the advancements and applications offered by the system such as assembly verification, defect detection in printed board circuits, barcode and data matrix identification and others are the factors that are creating significant growth opportunities for the offline automated optical inspection system market over the forecasted period.

Restraints/Challenges

- False Call Rates (FCR)

The false call rates is the most critical phenomena in the image-based automated optical inspection system and can be defined as the number of good components found as defective measured in parts-per-million. Sometimes, falsely classified images can be put in the image database. This factor is expected to obstruct the market growth.

- Lack of Superior Inspection Technology

The main drawback is the lack of superior inspection technology such as x-ray inspection and others. This factor is projected to be a challenge for the offline automated optical inspection system market over the forecast period.

This offline automated optical inspection system market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the offline automated optical inspection system market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Impact and Current Market Scenario of Raw Material Shortage and Shipping Delays

Data Bridge Market Research offers a high-level analysis of the market and delivers information by keeping in account the impact and current market environment of raw material shortage and shipping delays. This translates into assessing strategic possibilities, creating effective action plans, and assisting businesses in making important decisions.

Apart from the standard report, we also offer in-depth analysis of the procurement level from forecasted shipping delays, distributor mapping by region, commodity analysis, production analysis, price mapping trends, sourcing, category performance analysis, supply chain risk management solutions, advanced benchmarking, and other services for procurement and strategic support.

Recent developments

- In 2021, Viscom developed a new Heavy Flex Handling Solution to meet the need of flexible handling of large and heavy objects.

- In 2021, Saki Corporation enhanced the 3Di Series AOI system with its new Z-axis solution to accelerate inspection of tall components, press fit components and PCBAs in jigs.

Expected Impact of Economic Slowdown on the Pricing and Availability of Products

When economic activity slows, industries begin to suffer. The forecasted effects of the economic downturn on the pricing and accessibility of the products are taken into account in the market insight reports and intelligence services provided by DBMR. With this, our clients can typically keep one step ahead of their competitors, project their sales and revenue, and estimate their profit and loss expenditures.

Global Offline Automated Optical Inspection System Market Scope

The offline automated optical inspection system market is segmented on the basis of application, system, type and industry. The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Application

- Fabrication Phase

- Assembly Phase

System

- Elements of Automated Optical Inspection

- Camera System

- Lighting System

- Computer System

- Software

- Defect Detection Process

- Others

- Type of printed circuit boards (PCB) for defect detection

Type

- 2D Automated Optical Inspection System

- 3D Automated Optical Inspection System

Industry

- Consumer Electronics

- Telecommunication

- Automotive

- Medical Devices

- Aerospace and Defense

- Industrial Electronics

- Energy and Power

Offline Automated Optical Inspection System Market Regional Analysis/Insights

The offline automated optical inspection system market is analyzed and market size insights and trends are provided by application, system, type and industry as referenced above.

The countries covered in the offline automated optical inspection system market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America

North America dominates the offline automated optical inspection system market because of the increasing number of technological advancements along with prevalence of various compulsory inspection standards within the region.

Asia-Pacific is expected to witness significant growth during the forecast period of 2022 to 2029 due to the rising prevalence of various regional electronic device manufacturing companies.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points like down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Competitive Landscape and Offline Automated Optical Inspection System Market Share Analysis

The offline automated optical inspection system market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to offline automated optical inspection system market.

Some of the major players operating in the offline automated optical inspection system market are

- KOH YOUNG TECHNOLOGY inc. (South Korea)

- Test Research, Inc. (Taiwan)

- OMRON Corporation (Japan)

- Viscom AG (Germany)

- SAKI CORPORATION. (Japan)

- Nordson Corporation (U.S.)

- DAIICHI JITSUGYO CO., LTD. (U.S.)

- KLA Corporation. (U.S.)

- CyberOptics (U.S.)

- GÖPEL electronic GmbH. (Germany)

- MIRTEC CO., LTD. (U.S.)

- SMTnet (U.S.)

- Camtek (Israel)

- Vi TECHNOLOGY (U.S.)

- DCB Automation (U.K.)

- Pemtron Europe GmbH (Germany)

- Stratus Vision GmbH (Germany)

- MEK Marantz Electronics Ltd (U.S.)

- Chroma ATE Inc. (China)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Offline Automated Optical Inspection System Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Offline Automated Optical Inspection System Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Offline Automated Optical Inspection System Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.