Global Methacrylate Monomers Market

Market Size in USD Billion

CAGR :

%

USD

12.35 Billion

USD

18.13 Billion

2024

2032

USD

12.35 Billion

USD

18.13 Billion

2024

2032

| 2025 –2032 | |

| USD 12.35 Billion | |

| USD 18.13 Billion | |

|

|

|

|

Methacrylate Monomers Market Size

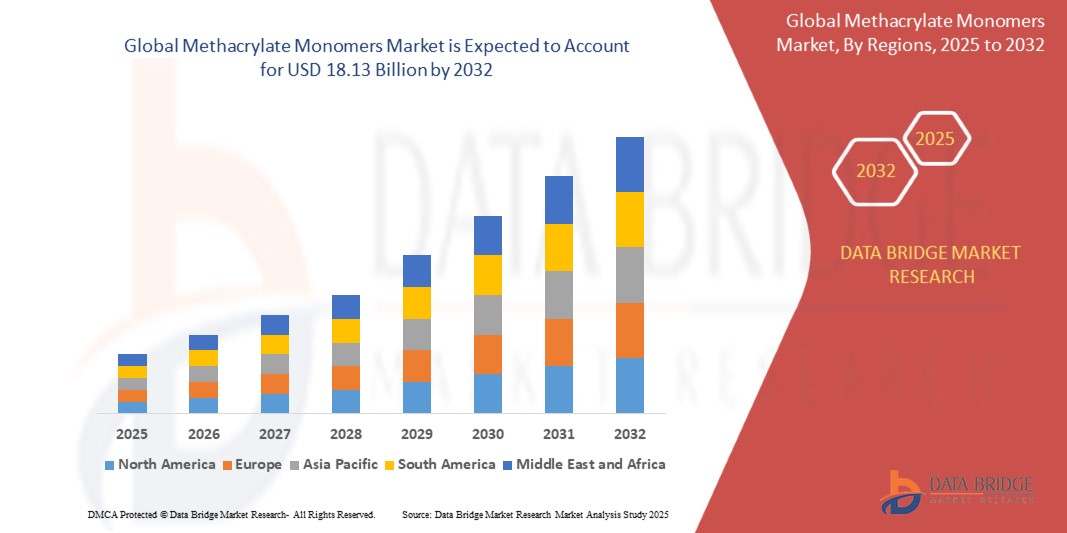

- The global methacrylate monomers market size was valued at USD 12.35 billion in 2024 and is expected to reach USD 18.13 billion by 2032, at a CAGR of 4.9% during the forecast period

- Market growth is fueled by rising demand for methacrylate monomers in adhesives, coatings, sealants, and acrylic applications, driven largely by the automotive, construction, and electronics industries.

- The increasing consumer preference for sustainable and environmentally friendly materials is also propelling the adoption of methacrylate monomers in the production of biodegradable polymers. Rapid urbanization and infrastructure development in emerging economies further accelerate market growth.

Methacrylate Monomers Market Analysis

- Methacrylate monomers are characterized by their reactive double bonds and are key precursors in manufacturing acrylic resins, coatings, adhesives, and molding compounds with properties such as UV resistance, durability, and strong adhesion.

- The automotive sector is a major end-user, incorporating methacrylate-based materials in glazing, coatings, and lightweight components to enhance fuel efficiency and durability.

- The construction industry extensively uses methacrylate monomers in concrete admixtures, liquid waterproofing, industrial flooring, and road construction projects, benefiting from their performance and longevity.

- Asia-Pacific dominates the market share, attributed to rapid industrialization, growth in automotive and electronics manufacturing, and increasing infrastructure development in countries like China, India, and Japan.

Report Scope and Methacrylate Monomers Market Segmentation

|

Attributes |

Methacrylate Monomers Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Methacrylate Monomers Market Trends

Shift Toward Sustainable and Performance-Enhanced Polymeric Materials

- The increasing focus on sustainability is fueling innovations in bio-based methacrylate monomers and eco-friendly production processes aimed at reducing carbon footprints.

- Rising demand for high-performance coatings and adhesives with enhanced durability, UV stability, and chemical resistance is stimulating development of specialized methacrylate derivatives.

- Growing application of methacrylate monomers in healthcare devices, such as dental restoratives and medical plastics, is expanding the market scope.

- Rapid urbanization and modernization in emerging economies encourage increased use of methacrylate monomers in construction and automotive sectors.

Methacrylate Monomers Market Dynamics

Driver

Rising Demand from Automotive, Construction, and Electronics Industries

- The automotive sector’s increasing adoption of lightweight, durable, and corrosion-resistant materials is significantly boosting methacrylate monomer consumption. Methacrylate-based polymers are valued for their ability to improve fuel efficiency and vehicle lifespan, which align with regulatory and consumer demands for eco-friendly and high-performance vehicles. Innovations in clear and impact-resistant acrylic components, coatings, and adhesives further stimulate usage.

- The construction industry is a major growth driver, with methacrylate monomers playing a crucial role in concrete admixtures, waterproof coatings, adhesives, and sealants. Growing global infrastructure investments and the need for durable, weather-resistant materials to enhance building longevity are fueling demand. Methacrylate derivatives enable fast curing times and exceptional bonding, making them indispensable in modern construction

- The electronics industry’s persistent trend towards miniaturization and enhanced device durability supports demand for methacrylate monomer-based polymers used in insulating coatings, display technologies, and circuit boards. Their excellent UV resistance and optical clarity suit the evolving design requirements.

- Increasing environmental regulations and green building certifications motivate manufacturers to select methacrylate-based materials that offer lower emissions, recyclability, and reduced volatile organic compounds (VOCs), reinforcing adoption in regulated markets.

Restraint/Challenge

Fluctuating Raw Material Prices and Environmental Regulations Compliance

- The volatility in prices of key raw materials such as methacrylic acid, acetone, and other petrochemical feedstocks leads to cost fluctuations, which can constrain profit margins and lead to price instability for downstream products. Supply chain vulnerabilities and geopolitical factors exacerbate this volatility.

- The methacrylate monomer production process involves handling hazardous chemicals, and increasingly stringent environmental and safety regulations require investment in cleaner technologies and pollution control systems, raising operational costs. Compliance with emission limits and waste management regulations across different countries adds complexity and expense for manufacturers.

- Challenges in scaling bio-based methacrylate monomer production to commercial volumes limit the speed at which more sustainable products can fully penetrate the market, impeding faster transition to greener alternatives.

- Competition from alternative polymer technologies, including newer bio-based or hybrid materials, may pressure methacrylate monomer producers to innovate rapidly to maintain market share.

Methacrylate Monomers Market Scope

The market is segmented on the basis of derivative, application, and end-use industry.

- By Derivative

On the basis of derivative, the global methacrylate monomers market is segmented into methyl methacrylate, butyl methacrylate, ethyl methacrylate, stearyl methacrylate, and others. The methyl methacrylate segment dominates the largest market revenue share in 2024, primarily due to its wide application in acrylic sheets, coatings, and adhesives. Specialized derivatives like butyl and ethyl methacrylate are gaining market traction for tailored applications requiring specific mechanical and chemical properties.

- By Application

On the basis of application, the market is segmented into acrylic sheets, molding compounds, paints & coatings, adhesives & sealants, composites, additives, and others. Acrylic sheets and paints & coatings account for the largest shares in 2024, driven by their extensive use in automotive, construction, and consumer goods industries. Adhesives and sealants are also expanding rapidly due to their critical role in bonding and sealing applications requiring durability and weather resistance.

- By End-Use Industry

On the basis of end-use industry, the market is segmented into automotive, architecture & construction, electronics, advertisement & communication, healthcare, industrial, and others. The automotive and construction industries hold the major market shares in 2024, reflecting robust activity in infrastructure development and the demand for lightweight, high-performance materials in vehicle manufacturing. Electronics and healthcare sectors are witnessing steady growth owing to increasing demand for specialized methacrylate-based polymer products offering durability and biocompatibility.

Methacrylate Monomers Market Regional Analysis

- Asia-Pacific dominates the global methacrylate monomers market with the largest revenue share of approximately 41.5% in 2024, driven by rapid industrialization, expanding automotive and construction industries, and increased infrastructure development across countries like China, India, Japan, and South Korea.

- The region benefits from a growing manufacturing base and government initiatives promoting sustainable chemical processes, which support higher methacrylate monomer consumption in coatings, adhesives, and specialty polymers.

- Demand is further propelled by rising urbanization and the expanding electronics sector, increasing the use of methacrylate-based polymers for durable and lightweight products. Affordable labor, availability of raw materials, and export-oriented production centers reinforce Asia-Pacific’s position as the largest market globally.

U.S. Methacrylate Monomers Market Insight

The U.S. leads the North American methacrylate monomers market in 2024, supported by advanced chemical manufacturing infrastructure and strong demand from automotive, construction, and electronics sectors. Regulatory focus on environmentally friendly materials and rising use of high-performance coatings and adhesives further drive market growth. Ongoing innovation in bio-based monomers and specialty polymers strengthens the market position.

Europe Methacrylate Monomers Market Insight

Europe's methacrylate monomers market is poised for steady expansion, driven by stringent environmental regulations and growing adoption of sustainable polymeric materials in construction, automotive, and healthcare industries. Countries like Germany, France, and the U.K. spearhead demand, supported by robust R&D initiatives and active implementation of green chemistry practices.

U.K. Methacrylate Monomers Market Insight

The U.K. market is expected to witness notable growth due to rising construction activities and increased use of methacrylate-based materials in medical devices and coatings. Government support for sustainable manufacturing and innovation in polymer technologies underpin the expanding demand.

Germany Methacrylate Monomers Market Insight

Germany’s market growth is propelled by its leadership in chemical engineering, sustainability mandates, and strong automotive and construction industries. The country focuses on developing recyclable and low-emission methacrylate polymers, driving steady demand.

Asia-Pacific Methacrylate Monomers Market Insight

Asia-Pacific dominates the global methacrylate monomers market with the largest revenue share in 2024, fueled by rapid industrialization, expanding automotive and construction sectors, and infrastructure development in China, India, Japan, and South Korea. Favorable government policies and a growing manufacturing base enhance regional market growth.

India Methacrylate Monomers Market Insight

India is expected to register the highest CAGR over the forecast period, supported by rapid urbanization, government initiatives like “Make in India,” and increased investments in construction and automotive industries. Growing awareness regarding sustainable chemicals accelerates market adoption.

China Methacrylate Monomers Market Insight

China dominates the Asia-Pacific methacrylate monomers market, backed by its large-scale chemical manufacturing capabilities and immense demand from automotive, construction, and electronics sectors. Strong domestic consumption, export orientation, and government incentives for green production foster market leadership.

Methacrylate Monomers Market Share

The Methacrylate Monomers industry is primarily led by well-established companies, including:

- LyondellBasell Industries (U.S.)

- BASF (Germany)

- ExxonMobil (U.S.)

- Dow Inc. (U.S.)

- DuPont de Nemours, Inc. (U.S.)

- Evonik Industries AG (Germany)

- Arkema S.A. (France)

- Akzo Nobel N.V. (Netherlands)

- Clariant AG (Switzerland)

- Eastman Chemical Company (U.S.)

- Mitsui Chemicals, Inc. (Japan)

- SABIC (Saudi Arabia)

- Shin-Etsu Chemical Co., Ltd. (Japan)

- Kaneka Corporation (Japan)

- Lanxess (Germany)

- Sumitomo Chemical Co., Ltd. (Japan)

- LG Chem Ltd. (South Korea)

- Mitsubishi Chemical Holdings Corporation (Japan)

- INEOS (U.K.)

- Formosa Plastics Corporation (Taiwan)

Latest Developments in Global Methacrylate Monomers Market

- In January 2025 Arkema launched a new bio-based methyl methacrylate product aimed at reducing environmental impact across automotive and construction applications.

- In September 2024 BASF SE expanded its methacrylate monomer production capacity in Asia to meet growing regional demand.

- In June 2024: Dow introduced advanced adhesive formulations based on methacrylate monomers offering enhanced bonding strength and durability for automotive uses.

- In April 2023 Evonik Industries AG developed novel coating resins using methacrylate monomers for improved UV resistance and anti-corrosion performance.

- In November 2022 Mitsubishi Chemical Holdings entered a joint venture to enhance bio-based monomer production capabilities to align with sustainability goals.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Methacrylate Monomers Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Methacrylate Monomers Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Methacrylate Monomers Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.