Global Metal Forming Market

Market Size in USD Billion

CAGR :

%

USD

247.65 Billion

USD

441.68 Billion

2023

2031

USD

247.65 Billion

USD

441.68 Billion

2023

2031

| 2024 –2031 | |

| USD 247.65 Billion | |

| USD 441.68 Billion | |

|

|

|

|

Global Metal Forming Market Overview

Metal forming is a substantive process in the industrial production that crafts and produces high-value components from various metal alloys. Continuous research in production techniques is crucial for understanding how metals are shaped, minimizing defects, and predicting the final properties of the products. Understanding the key metal-forming methods, such as forging, stamping, and extrusion, are essential for both manufacturers and buyers. Mastery of these techniques helps to enhance production efficiency and ensures that final components meet specific requirements. Innovations in metal forming processes contribute to the growth of the metal forming market. According to AMPCO METAL, the metal forming industry represents 15-20% of the GDP of industrialized nations, highlighting its significant economic impact.

Data Bridge Market research market report provides details of recent developments, trade regulations, market share, market trends on the basis of its segmentations and regional analysis, impact of market players, analysis of opportunities in terms of emerging revenue pockets, market regulations, strategic market growth analysis, market size, category wise market growths, application niches and dominance, product approvals, product launches, geographic expansions, and technological innovations in the market. To gain more info on the market, contact Data Bridge Market Research’s team of expert analysts. Our team will help you make informed market decisions to achieve business growth.

Global Metal Forming Market Size

|

Global Metal Forming Market Report Metrics |

|

|

Forecast Period |

2024-2031 |

|

Base Year |

2023 |

|

Historic Year |

2022 (Customizable 2016-2021) |

|

Measuring Unit |

USD Million |

|

Data Pointers |

Market value, growth rate, market segments, geographical coverage, market players, and market scenario, in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis. |

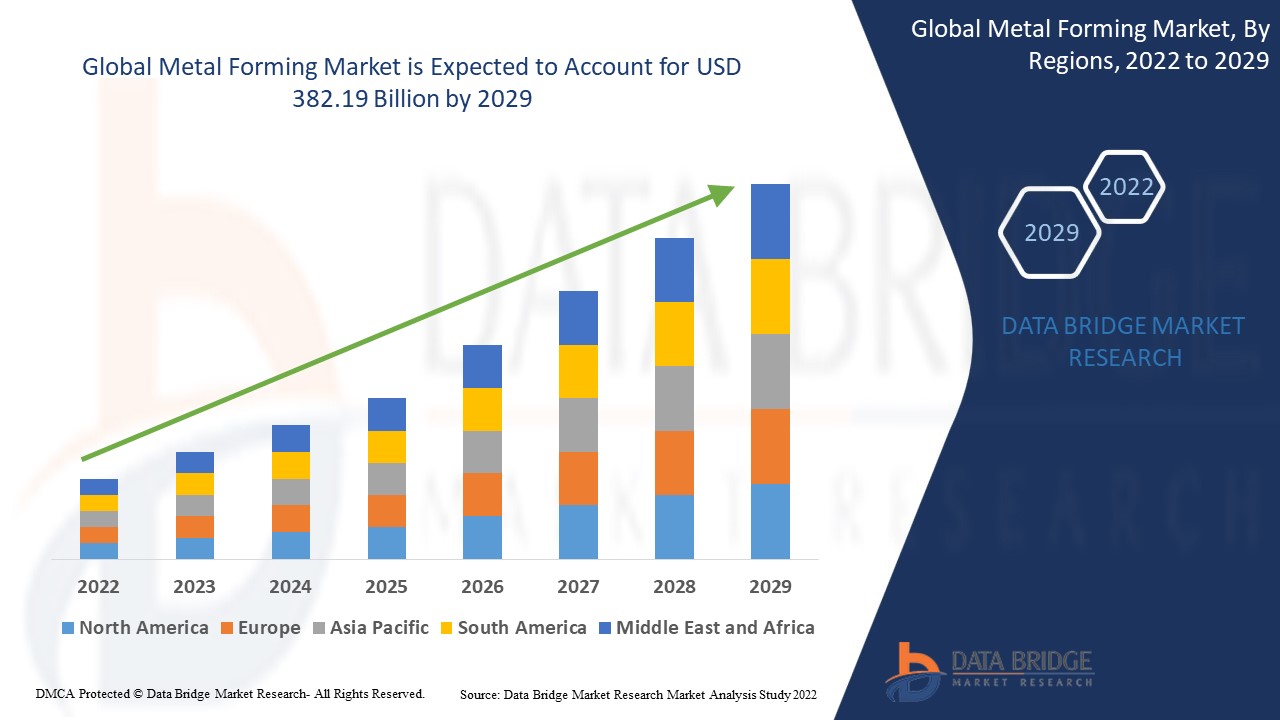

There is a wide array of metal forming techniques, such as bending, stretching, deep drawing, roll forming, extrusion, punching, stamping, ironing, and hydroforming that helps manufactures to provide desired results. As the formation of metal is expanding in various industries such as automotive, aerospace, and consumer electronic, there is a rising demand of metal forming market. Databridge Market Research took a dive into comprehensively analyzing the market and unveiled that the Global Metal Forming Market is increasing at a CAGR of 7.50%. The market size was valued at USD 247.65 billion in 2023 and is expected to grow up to 441.68 billion by 2031. The widening of automotive and construction industries stimulating the demand for pipe and tube bending equipments such as CNC manufacturing machines which offer maximal effectiveness, and enhanced process transparency, that directly benefits the market.

Global Metal Forming Market Dynamics

Global Metal Forming Market Growth Drivers

Innovative Forming Techniques Propels Market Growth

As industries increasingly prioritize innovative designs and functional capabilities, the demand for complex geometric shapes in metal forming is driving market growth. Advanced forming techniques are essential to accommodate these intricate shapes, augmenting product performance and fostering creativity in sectors such as automotive, aerospace, and consumer electronics. This capability improves material efficiency and reduces weight. The integration of advanced manufacturing technologies such as computer-aided design (CAD) and precision tooling facilitates the creation of these complex shapes, meeting the market's demand for high-quality, and customized solutions.

Diverse Properties of Metals

The diverse properties of metals are crucial in accelerating the metal forming market, especially within the automotive sector. As manufacturers increasingly prioritize lightweight, high-strength materials, the demand for advanced metal forming techniques has surged. This process is essential as the industry evolves towards electric and hybrid vehicles, necessitating unique structural properties. The incorporation of materials such as aluminum and magnesium enhance fuel efficiency and which benefits manufactures to meets the high demand of recreational vehicle in the automotive industry.

Rising Disposable Incomes leads to Automotive Customization

The demand for automotive customization among the consumers is flourishing due to the rising disposable income, which in turn, significantly propels the metal forming market. As consumers increasingly seek personalized vehicle features, manufacturers are investing in advanced metal forming technologies to fulfill these bespoke demands. This shift towards individualized automotive solutions stimulates advancement and growth within the metal forming sector. The need for precision engineering and tailored design to cater to a more affluent customer base highlights the major role of metal forming in adapting to evolving market preferences. Therefore, the intersection of consumer wealth and customization desires is reshaping the industry landscape.

Metal Forming Market Growth Opportunities

The metal forming market is expected to have substantial growth due to several emerging opportunities. Innovations in aeronautics by organizations such as NASA and ISRO urge for lightweight, high-strength metals, creating opportunities for advanced forming techniques such as stamping and hydroforming. For instance, in April 2022, NASA launched Alloy GRX-810, a high-temperature-resistant oxide dispersion strengthened alloy. Its use of advanced 3D printing for uniform oxide dispersion enhances strength and flexibility, offering aerospace and automotive sectors a path to lighter, more efficient parts. This innovation expands the demand of cutting-edge forming techniques and sustainable manufacturing practices to improve performance and reduce costs. Another opportunity is surge of hybrid and electric vehicles (EVs) necessitates smart manufacturing technologies such as computer aided machines that make metal forming processes more efficient and productive. Furthermore, high EV production is expected to boost growth of automotive industry

Metal Forming Market Size Growth Challenges

The metal forming industry faces skilled labor shortage, which poses a major challenge to its growth and productivity. The American Welding Society estimates a shortage of 400,000 welders by 2024, while the Machinery and Plant Engineering sector in Germany reported that almost 80% of companies experienced serious or noticeable shortages of skilled workers as of June 2022. This shortage is attributed to several factors, including an aging workforce, a lack of interest among younger generations, and competition from other industries for skilled workers. However, the shortage of skilled labor remains a major concern as it effects the industry's innovative capacity and growth prospects.

Metal Forming Market Size Growth Restraints

The complexity of processes within the metal forming market is significantly influenced by stringent environmental regulations, which serve as a restraint on industry growth. These regulations mandate compliance with standards related to emissions, waste management, and resource utilization, compelling manufacturers to invest in cleaner technologies and practices. While adherence to these regulations is essential for minimizing ecological impact, it often incurs substantial costs and requires considerable time for implementation, which can disrupt production efficiency and increase operational expenses. Ultimately, while environmental regulations are crucial for promoting sustainability, they introduce complexities that can hinder the growth and efficiency of the metal forming market.

Global Metal Forming Market Scope and Trends

|

Global Metal Forming Market Segmentation Overview

|

|

|

Technique |

Roll Forming, Stretch Forming, Stamping, Deep Drawing, Hydroforming, and Others |

|

Application Type |

BIW, Chassis, Closures, and Others |

|

Electric and Hybrid Vehicle Type |

Fuel Cell Electric Vehicle (FCEV), Plug-in Hybrid Electric Vehicle (PHEV) and Battery Electric Vehicle (BEV) |

|

ICE Vehicle Type |

Passenger Car, LCV, Truck, and Bus |

|

Forming Type |

Cold Forming, and Hot Forming, and Warm Forming |

|

Material Type |

Steel, Aluminum, Magnesium, and Others |

Key Insight

- Hydroforming is a modern metal forming technique that utilizes high-pressure hydraulic fluid, exerting a very high forces to shape metal into complex geometries. This technique offers significant advantages over traditional cold forming methods by reducing the number of operations needed, resulting in lighter, stiffer components with less material waste. The technology is evolving, with innovations categorized by their readiness level, and future trends indicate a focus on further advancements and research in hydroforming applications across various industries.

- The increasing demand for electric vehicles, reflects a significant shift in consumer preferences towards more sustainable transportation options. It requires advanced metal components for their structures and battery systems. The growth in PHEV sales indicates a rising demand for lightweight and high-strength materials, which are essential for improving vehicle efficiency and performance.

- Cold forming is the largest and most widely used metal forming technique for ICE vehicles. It involves forming components at room temperature, which is cost-effective compared to hot forming. Cold forming is the preferred choice for OEMs globally due to its low overall costs

- Aluminum alloy 5052 is the most used alloy for sheet metal fabrication due to its excellent ductility and resistance to cracking during forming processes, making it ideal for applications requiring high workability such as marine environments and automotive components. While aluminum alloy 6061 is preferred for CNC machining due to its strength, 5052's unique properties ensure its dominance in sheet metal applications, significantly influencing the overall aluminum segment of the metal forming market

- The increase in U.S. passenger car sales to 11.9 million units in 2021 positively impacts the metal forming market, as higher car production demands more metal components. This surge in automotive manufacturing drives the growth of metal forming processes used to produce parts such as chassis, body panels, and engine components.

Metal Forming Market Regional Analysis – Market Trends

|

Metal Forming Market Regional Overview |

|

|

Regions |

Country |

|

Europe |

Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe |

|

APAC |

China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific |

|

North America |

U.S., Canada and Mexico |

|

MEA |

Saudi Arabia, U.A.E., South Africa, Egypt, Israel, Rest of Middle East and Africa |

|

South America |

Brazil, Argentina and Rest of South America |

Key Insights

- North America is leading a significant transformation towards eco-friendly products due to stringent environmental regulations, and changing consumer preferences that favor sustainable manufacturing practices.

- Stringent regulations in North America are compelling manufacturers to adopt practices that minimize the use of Volatile Organic Compounds (VOCs), which are harmful to both health and the environment.

- The U.S. Environmental Protection Agency (EPA) enforces stringent standards under 40 CFR 59 to regulate volatile organic compound (VOC) emissions from industrial activities, including metal forming. These regulations impact the metal forming market by requiring manufacturers to adopt cleaner technologies and processes to comply with emissions limits, thereby influencing operational costs and driving innovation towards more environmentally friendly practices.

- North America is at the forefront of innovation in sustainable practices, setting global trends in response to environmental imperatives and regulatory frameworks.

- The Asia-Pacific is expected to experience substantial growth in the automotive market due to major vehicle manufacturing companies and the increasing production of luxury, compact, and mid-size vehicles.

- Countries such as Japan, South Korea, China, and India are crucial in this growth due to their robust industrial infrastructure and skilled labor force.

- The high-record of light vehicle production in the Asia-Pacific region, reaching 51.8 million units in 2023, significantly influences the metal forming market. This surge is largely attributed to robust manufacturing in China and Japan, which directly increases demand for metal components used in vehicle production.

Leading Players in the Metal Forming Market

- Bradbury Group (U.K.)

- Formtek Moulding Solutions (South Africa)

- Mestek Machinery (U.S.)

- Avic Manufacturing Technology Institute (China)

- VNT Automotive GmbH (Austria)

- Westway Machinery (Canada)

- Benteler International AG (Germany)

- AES Automotive Company Pvt. Ltd. (India)

- Toyota Boshoku Corporation (Japan)

- Samco Machinery (India)

- Aisin Seiki Co. Ltd (Japan)

- Heck Industries (U.S.)

- Wuhan Huagong, Schuler India Private Ltd. (India)

- Magna International Inc. (Canada)

- Drexler Companies Inc. (U.S.)

- Hirotec Corporation (Japan)

- CIE Automotive (Spain)

Recent Developments

- In February 2024, Allied Nippon launched EV+, a specialized line of brake pads specifically designed for Electric Vehicles (EVs). With over one million EVs in the U.K. alone, EV+ addresses the unique needs of electric vehicles with a new friction compound and BRAKEBOOST Instant Friction layer, ensuring improved stability and quiet operation. This launch underscores Allied Nippon's commitment to meeting the growing demand for aftermarket products tailored to electric vehicles.

- In October 2023, Brembo announced a new aftermarket pads strategy at AAPEX, unveiling their Copper Free XTRA line. This includes Low Met and Ceramic NAO formulations, designed to enhance vehicle safety and environmental sustainability. The new pads complement Brembo's existing XTRA lineup, offering high-performance friction materials for aftermarket brake pads tailored to enthusiasts and high-performance vehicles.

- In December 2022, Torque Capital Group acquired MFC Netform, a move intended to bolster MFC Netform's market offerings. The acquisition aims to infuse new technologies and capabilities into the company, enhancing its competitiveness and growth potential. This strategic investment underscores Torque Capital Group's commitment to innovation and industry leadership.

- In April 2020, Veoneer and ZF Friedrichshafen AG entered into an agreement to transfer Veoneer's US brake control business to ZF. This strategic move aimed to expand ZF Friedrichshafen AG's market presence globally, leveraging Veoneer's expertise in brake control systems to enhance their product offerings and geographical reach in the automotive industry.

Data Bridge Market Research’s report on the biosimilar market takes you through valuable insights that can contribute to making several important business decisions. Based on our reports and research expertise you can create realistic growth strategies for your business.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.