Global Metal Foam Market

Market Size in USD Billion

CAGR :

%

USD

95.03 Billion

USD

132.07 Billion

2022

2030

USD

95.03 Billion

USD

132.07 Billion

2022

2030

| 2023 –2030 | |

| USD 95.03 Billion | |

| USD 132.07 Billion | |

|

|

|

|

Metal Foam Market Analysis and Size

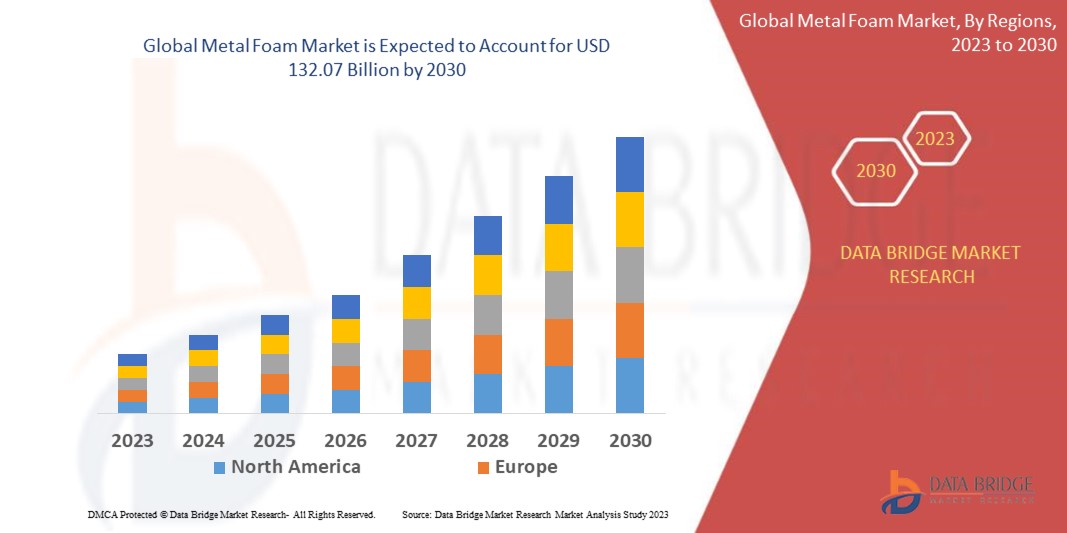

The global metal foam market is expected to maintain steady growth due to the exceptional properties these materials offer, including effective thermal management, shock absorption, and electrical conductivity. Aluminum metal foams, in particular, are gaining traction in the manufacturing of lightweight vehicles due to their advantages, such as reduced weight, enhanced strength, and prolonged durability. Consequently, the market is poised for sustained growth throughout the projected period of 2023 to 2030.

Data Bridge Market Research analyses that the global metal foam market which was USD 95.03 billion in 2022, is expected to reach USD 132.07 billion by 2030, and is expected to undergo a CAGR of 4.20% during the forecast period of 2023 to 2030. “Closed Cell Metal Foam” dominates the type segment of the global metal foam market due to its widespread applications and structural versatility. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand.

Metal Foam Market Scope and Segmentation

|

Report Metric |

Details |

|

Forecast Period |

2023 to 2030 |

|

Base Year |

2022 |

|

Historic Years |

2021 (Customizable to 2015-2020) |

|

Quantitative Units |

Revenue in USD Billion, Pricing in USD, Volume in Units |

|

Segments Covered |

Type (Closed Cell Metal Foam, Open Cell Metal Foam, Stochastic Metal Foam), Material (Aluminum, Copper, Zinc, Titanium, Fecral, NiCr, Others), Production Technology (Blowing Agents, Gas Injection, Solid-Gas Eutectic Solidification, Powder Compact, Ingots Containing Blowing Agent, Space Holder, Others), Metal Form (Melt, Powder), Application (Energy Absorption, Energy Management, Thermal Management, Exhaust System, Low-Pressure Exhaust Gas Recirculation For Gasoline Engines (LP EGR), Compact Exhaust Heat Recovery System (EHRS), Others), End-User (Automotive, Aerospace, Marine, Energy, Consumer Goods, Others) |

|

Countries Covered |

U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific , Saudi Arabia, U.A.E., South Africa, Egypt, Israel, Rest of Middle East and Africa, Brazil, Argentina and Rest of South America |

|

Market Players Covered |

Cymat Technologies Ltd. (Canada), ERG Aerospace Corporation (U.S.), Alantum Corporation (South Korea), Admatis Ltd. (Hungary), Shanxi Putai Aluminum Foam Manufacturing Co., Ltd. (China), SMC Metal (Thailand) Co., Ltd. (Thailand), Reade Advanced Materials (U.S.), Aluinvent Zrt (Hungary), Alveotec (France), American Elements (U.S.), ERG Materials and Aerospace Corp. (U.S.), Ultramet (U.S.), Nanoshell Company (Russia), Ressource Metal Groupe (France), AlFoam Technologies Ltd. (Canada) |

|

Market Opportunities |

|

Market Definition

Metal foams are structured materials consisting of solid metal containing numerous gas-filled voids. These voids can either be sealed, forming closed-cell foam, or interlinked, creating open-cell foam. Open-cell foam is often referred to as porous metal, while closed-cell foam is termed metal foam. Metal foam finds applications across diverse industries such as automotive, construction, and infrastructure.

Global Metal Foam Market Dynamics

Drivers

- Growing Light-Weighting Metal Forms Trends

The global metal foam market is driven by the pervasive light-weighting trend, especially in industries such as automotive and aerospace. Metal foams are a compelling choice because they offer reduced weight while maintaining structural integrity. This property makes them highly desirable for applications where weight reduction is crucial, as it contributes to enhance fuel efficiency, reduced emissions, and improved overall performance. As stringent regulations regarding emissions and fuel economy continue to evolve, metal foams play a pivotal role in helping manufacturers meet these requirements and consumer preferences for more environmentally friendly products.

- Escalating Demand for Energy-Efficient Solutions

The escalating demand for energy-efficient solutions across various industries is fuelling the adoption of metal foams, particularly in thermal insulation and heat exchange applications. Metal foams exhibit remarkable thermal conductivity and heat dissipation properties, making them ideal for improving energy efficiency in appliances, heating, ventilation, and air conditioning (HVAC) systems. Their ability to efficiently transfer and manage heat translates to lower energy consumption, which aligns with sustainability goals and cost-saving initiatives. As the emphasis on energy conservation grows, the market for metal foams in energy-efficient technologies is poised for significant expansion.

Opportunities

- Growth in the Automotive Industry

The automotive sector offers a substantial growth opportunity for the global metal foam market. Metal foams are increasingly recognized for their potential to revolutionize vehicle design and safety. They can absorb kinetic energy during collisions, enhancing occupant protection. In addition, their lightweight nature contributes to lower vehicle weight, which, in turn, improves fuel economy and reduces greenhouse gas emissions. With the automotive industry's evolving focus on safety, fuel efficiency, and emissions reduction, metal foams are well-positioned to play a pivotal role in the development of next-generation vehicles.

- Green Building Technologies

Metal foams hold significant promise in the construction industry, aligning with the increasing adoption of green building technologies and sustainable construction practices. These foams are employed for thermal insulation and as structural components in energy-efficient buildings. The incorporation of metal foams contributes to improved insulation properties, reducing energy consumption for heating and cooling. Moreover, their structural capabilities enhance the resilience and sustainability of building designs. As green building certifications and sustainable construction practices gain prominence worldwide, metal foams are poised to thrive as a preferred choice for creating energy-efficient and environmentally friendly structures.

Restraints/Challenges

- Limited Material Availability and Accessibility

The availability and accessibility of specific metals used in metal foam production, such as titanium and nickel, present a notable restraint. These metals, though prized for their exceptional properties, face limitations in terms of availability and high costs. This restricts the widespread adoption of metal foams, particularly in applications where these specific metals are in high demand. Addressing material constraints through alternative alloys or exploring recycling and sustainability measures is essential to ensure the broader utilization of metal foams across diverse industries.

- High Production Costs

A noteworthy challenge in the global metal foam market pertains to the relatively high production costs associated with these specialized materials. The complex manufacturing processes, including foaming and shaping, can be resource-intensive and require advanced technologies. In addition, the choice of metal alloy significantly impacts production costs, as certain alloys are more expensive and scarce. Consequently, finding cost-effective manufacturing methods and achieving economies of scale are essential hurdles to overcome. Addressing this challenge is crucial to making metal foams more accessible and competitive in a broader range of applications.

This global metal foam market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the global metal foam market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Impact and Current Market Scenario of Raw Material Shortage and Shipping Delays

Data Bridge Market Research offers a high-level analysis of the market and delivers information by keeping in account the impact and current market environment of raw material shortage and shipping delays. This translates into assessing strategic possibilities, creating effective action plans, and assisting businesses in making important decisions. Apart from the standard report, we also offer in-depth analysis of the procurement level from forecasted shipping delays, distributor mapping by region, commodity analysis, production analysis, price mapping trends, sourcing, category performance analysis, supply chain risk management solutions, advanced benchmarking, and other services for procurement and strategic support.

Expected Impact of Economic Slowdown on the Pricing and Availability of Products

When economic activity slows, industries begin to suffer. The forecasted effects of the economic downturn on the pricing and accessibility of the products are taken into account in the market insight reports and intelligence services provided by DBMR. With this, our clients can typically keep one step ahead of their competitors, project their sales and revenue, and estimate their profit and loss expenditures.

Recent Developments

- In August 8, 2023, Nickel foam batteries utilize catalyst carriers like carbon materials and precious metals to enhance electrochemical reactions, improving energy density. Electromagnetic shielding materials, including metals and conductive polymers, protect batteries from external electromagnetic interference. The choice of materials depends on performance goals and cost considerations

- On September 7, 2023, ERG Materials and Aerospace is showcasing its Duocel foam, a lightweight, versatile material, at Solar Power International 2023. Duocel foam offers high performance in compact designs, making it suitable for applications like heat exchangers, flame arrestors, and battery electrodes. ERG's team of engineers collaborates with customers to create custom foam-based products, reducing design time. With production facilities in the US, ERG caters to high and low-volume customers. Duocel foam comes in various materials, including aluminum, copper, steel, carbon, and ceramics

Global Metal Foam Market Scope

The global metal foam market is segmented on the basis of type, material, production technology, metal form, application and end-user. The growth amongst these segments will help you analyse meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Type

- Closed Cell Metal Foam

- Open Cell Metal Foam

- Stochastic Metal Foam

Material

- Aluminum

- Copper

- Zinc

- Titanium

- Fecral

- NiCr

- Others

Production Technology

- Blowing Agents

- Gas Injection

- Solid-Gas Eutectic Solidification

- Powder Compact

- Ingots Containing Blowing Agent

- Space Holder

- Others

Metal Form

- Melt

- Powder

Application

- Energy Absorption

- Energy Management

- Thermal Management

- Exhaust System

- Low-Pressure Exhaust Gas Recirculation For Gasoline Engines (LP EGR)

- Compact Exhaust Heat Recovery System (EHRS)

- Others

End-User

- Automotive

- Aerospace

- Marine

- Energy

- Consumer Goods

- Others

Global Metal Foam Market Regional Analysis/Insights

The global metal foam market is analysed and market size insights and trends are provided by country, type, material, production technology, metal form, application and end-user referenced above.

The countries covered in the global metal foam market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific , Saudi Arabia, U.A.E., South Africa, Egypt, Israel, Rest of Middle East and Africa, Brazil, Argentina and Rest of South America

North America dominates the global metal foam market due to robust demand in automotive, aerospace, and construction industries.

Asia-Pacific is the fastest-growing region in the global metal foam market in the forecasted period of 2023 to 2030, due to expanding industries and demand for lightweight materials.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points like down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Competitive Landscape and Global Metal Foam Market Share Analysis

The global metal foam market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to global metal foam market.

Some of the major players operating in the global metal foam market are:

- Cymat Technologies Ltd. (Canada)

- ERG Aerospace Corporation (U.S.)

- Alantum Corporation (South Korea)

- Admatis Ltd. (Hungary)

- Shanxi Putai Aluminum Foam Manufacturing Co., Ltd. (China)

- SMC Metal (Thailand) Co., Ltd. (Thailand)

- Reade Advanced Materials (U.S.)

- Aluinvent Zrt (Hungary)

- Alveotec (France)

- American Elements (U.S.)

- ERG Materials and Aerospace Corp. (U.S.)

- Ultramet (U.S.)

- Nanoshell Company (Russia)

- Ressource Metal Groupe (France)

- AlFoam Technologies Ltd. (Canada)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Metal Foam Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Metal Foam Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Metal Foam Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.