Global Machine Tools Market

Market Size in USD Billion

CAGR :

%

USD

80.35 Billion

USD

106.62 Billion

2024

2032

USD

80.35 Billion

USD

106.62 Billion

2024

2032

| 2025 –2032 | |

| USD 80.35 Billion | |

| USD 106.62 Billion | |

|

|

|

Machine Tools Market Size

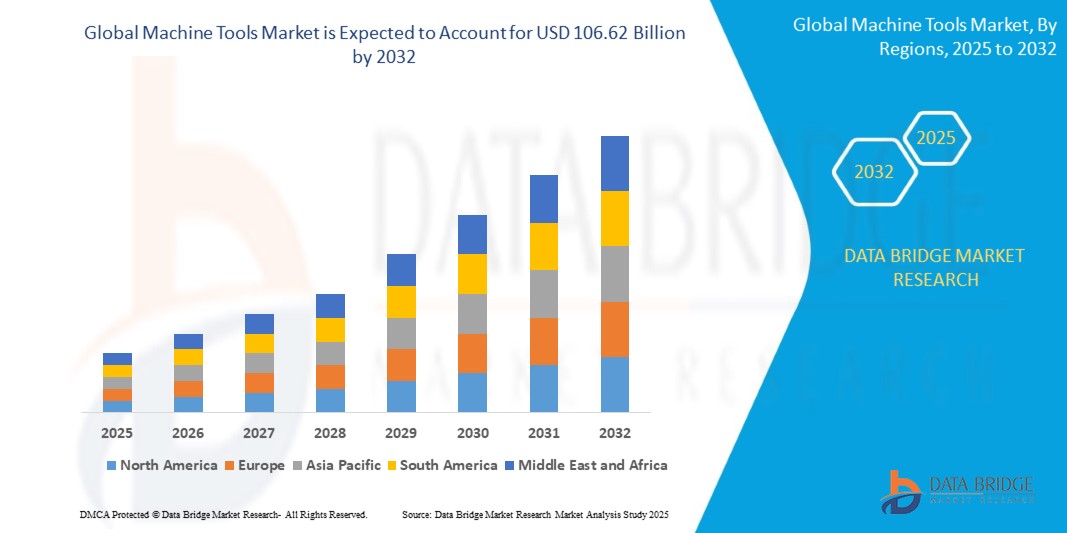

- The global machine tools market was valued at USD 80.35 billion in 2024 and is expected to reach USD 106.62 billion by 2032

- During the forecast period of 2025 to 2032 the market is likely to grow at a CAGR of 3.60%, primarily driven by industrialization in emerging economies

- This growth is driven by factors such as pro-business policies, urbanization and manufacturing growth

Machine Tools Market Analysis

- Machine tools are mechanical devices used to shape or machine metal, wood, or other rigid materials through processes such as cutting, grinding, drilling, and milling. These tools include equipment such as lathes, milling machines, and CNC systems, and are essential for precision manufacturing across industries such as automotive, aerospace, electronics, and construction.

- The market is experiencing consistent growth due to industrial expansion, increasing automation, and the growing demand for high-precision components. Manufacturers are adopting advanced machine tools to improve productivity, maintain quality standards, and remain competitive in modern production environments.

- The machine tools market is advancing with a strong focus on technological innovation, digital connectivity, and energy efficiency. As smart manufacturing becomes more widespread, there is rising demand for CNC-enabled tools integrated with sensors, IoT capabilities, and data-driven systems for predictive maintenance and operational efficiency

- For instance, companies such as DMG Mori and Mazak are offering smart, connected machine tools designed to integrate with Industry 4.0 systems, improving performance and reducing downtime

- The machine tools market is expected to maintain steady growth, supported by infrastructure investments, industrialization in emerging economies, and the rise of sectors such as electric vehicles and aerospace. With ongoing developments in automation, software integration, and sustainable manufacturing, the market is well-positioned for long-term expansion

Report Scope and Machine Tools Market Segmentation

|

Attributes |

Machine Tools Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. |

Machine Tools Market Trends

“Increasing Integration of Industry 4.0 Technologies”

- One prominent trend in the global machine tools market is the increasing integration of Industry 4.0 technologies

- This trend is driven by the rising demand for automation, data-driven decision-making, and the need for improved operational efficiency across manufacturing sectors. Companies are increasingly adopting smart machine tools equipped with IoT sensors, cloud connectivity, and advanced analytics to enable real-time monitoring and predictive maintenance

- For instance, manufacturers such as Mazak and DMG Mori are introducing intelligent CNC machines that support seamless data exchange, automation, and remote diagnostics, helping users optimize performance and reduce downtime

- The growing shift toward smart factories and digital manufacturing is expected to further accelerate the adoption of connected machine tools, as industries seek scalable solutions that enhance precision, efficiency, and flexibility

- As industrial operations become more digitally driven, manufacturers are focusing on the development of smart, user-friendly, and adaptive machine tools. The integration of Industry 4.0 technologies will continue to shape product innovation, improve production workflows, and drive competitiveness in the global machine tools market over the coming years

Machine Tools Market Dynamics

Driver

“Integration of Computer-Aided Manufacturing (CAM)”

- The growing adoption of Computer-Aided Manufacturing (CAM) software is a key driver of growth in the machine tools market. As manufacturers seek greater precision, automation, and customization in their operations, CAM systems are becoming essential for streamlining complex machining processes

- This influence is particularly strong in industries such as automotive, aerospace, and electronics, where high-performance parts demand exacting standards. CAM software allows for seamless programming of CNC machines, reducing manual errors and enhancing production speed

- With companies prioritizing faster product development cycles and efficient resource utilization, the use of CAM is accelerating across small and large manufacturing operations

- Features such as toolpath optimization, simulation capabilities, and integration with CAD systems are transforming how manufacturers plan and execute machining tasks, improving quality while lowering operational costs

- Vendors and software developers are increasingly collaborating with machine tool manufacturers to ensure compatibility and performance optimization, creating a more unified digital manufacturing environment

For instance,

- Autodesk and Siemens have integrated their CAM solutions with leading CNC platforms, enabling real-time feedback and smarter machining strategies

- HyperMill by Open Mind is being widely adopted by precision parts manufacturers for its high-performance multi-axis machining capabilities

- With continuous improvements in software capabilities, the push for digitalization, and increasing demand for automated, high-precision manufacturing, CAM integration is expected to play a central role in shaping the future of the machine tools market

Opportunity

“Increasing Demand for Customized and Small-Batch Production”

- Customized and small-batch production presents a significant opportunity for growth in the machine tools market. As manufacturers across various industries prioritize flexibility and responsiveness, the demand for adaptable machine tools that can support low-volume, high-mix production continues to increase

- Machine tools designed for rapid changeovers, modular setups, and precision machining are gaining traction among users seeking efficiency without sacrificing quality. In addition, customizable machining capabilities that cater to specific part geometries and production requirements are enabling manufacturers to meet diverse client needs more effectively

- The ability of machine tool providers to offer compact, versatile, and digitally integrated systems is driving broader adoption, especially among small and mid-sized enterprises aiming to produce prototypes or limited-run components

For instance,

- Haas Automation offers space-efficient CNC machines that deliver high precision for short-run and custom jobs, catering to manufacturers in industries such as medical devices and specialty electronics

- DMG Mori has developed modular machining centers that support flexible production workflows, making them ideal for businesses that focus on customized parts or niche market demands

- As market needs continue to shift toward personalization and on-demand production, ongoing investment in advanced CNC technology, user-friendly programming software, and hybrid machine configurations will be key. Collaborations with software developers and component suppliers will further enhance flexibility and help position customized manufacturing as a major opportunity in the evolving machine tools market

Restraint/Challenge

“High Cost Associated with the Initial Investment”

- The high cost associated with initial investment presents a significant challenge for the machine tools market. Acquiring advanced machinery, particularly CNC and digitally integrated systems, requires substantial capital, which can be a barrier for many small and medium-sized enterprises

- The machine tools segment, heavily tied to technological innovation and production efficiency, often demands ongoing expenditures for installation, software integration, operator training, and maintenance. These added costs increase the overall financial burden on businesses aiming to modernize or scale their manufacturing capabilities

- For many manufacturers, particularly in cost-sensitive or emerging markets, the high upfront cost can delay investment decisions or limit access to the latest machine tool technologies, hindering competitiveness and productivity

For instance,

- Small-scale manufacturers in regions such as Southeast Asia and Latin America often face financial constraints when attempting to adopt multi-axis CNC systems or automated tool changers, impacting their ability to participate in high-precision manufacturing segments

- As the demand for advanced manufacturing grows, the market continues to face challenges in affordability and accessibility. The need for cost-effective financing options, leasing models, and government subsidies will be critical in helping manufacturers overcome high entry barriers and support wider adoption of modern machine tools

Machine Tools Market Scope

The market is segmented on the basis of product type, automotive, industry segment, and sales channel.

|

Segmentation |

Sub-Segmentation |

|

By Product Type |

|

|

By Automotive |

|

|

By Industry Segment |

|

|

By Sales Channel

|

|

Machine Tools Market Regional Analysis

“Asia-Pacific is the Dominant Region in the Machine Tools Market”

- Asia-Pacific dominates the machine tools market, driven by the government-led manufacturing initiatives, rising foreign direct investments, and rapid industrial development across countries such as China, India, Japan, and South Korea. The region benefits from robust infrastructure projects, an expanding automotive sector, and a well-established base of small to large manufacturing enterprises

- The China holds a significant share due to its advanced manufacturing ecosystem, large-scale machinery exports, and the implementation of programs such as "Made in China 2025" which promote the adoption of smart and automated production technologies

- India is also emerging as a strong player, driven by initiatives such as "Make in India," increased spending on infrastructure and defense, and growing support for domestic industrialization. These factors are encouraging significant investment in machine tool upgrades and installations across sectors

- With a growing pool of skilled labor, rapid urbanization, and continuous modernization of factory operations, Asia-Pacific is expected to maintain its leading position in the machine tools market throughout the forecast period 2025–2032

“North America is Projected to Register the Highest Growth Rate”

- The North America region is expected to witness the highest growth rate in the machine tools market, driven by increasing demand from high-tech industries such as aerospace and defense, automotive manufacturing, and oil and energy

- The region is seeing a strong resurgence in domestic manufacturing, with companies investing heavily in reshoring production facilities and upgrading their machinery to meet global standards of precision, efficiency, and sustainability

- The presence of major industry players, alongside supportive government policies for reshoring manufacturing and enhancing industrial productivity, is boosting the demand for advanced machine tools

- As industries in North America continue to shift toward smart factories, the need for intelligent, high-performance, and connected machine tools is accelerating. This trend, combined with rising capital investments in modernizing production infrastructure, is expected to position North America as the fastest-growing region in the machine tools market during the forecast period

Machine Tools Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- Doosan Corporation (South Korea)

- Amada (India) Pvt. Ltd (India)

- Makino Inc. (Japan)

- JTEKT Corporation (Japan)

- Georg Fischer Ltd (Switzerland)

- Komatsu NTC (Japan)

- Okuma Corporation (Japan)

- HYUNDAI WIA CORP. (South Korea)

- CHIRON Group SE (Germany)

- Haas Automation, Inc. (U.S.)

- GROB-WERKE GmbH & Co. KG (Germany)

- Spinner GmbH (Germany)

- YAMAZAKI Mazak Corporation (Japan)

- DMG MORI Co., Ltd. (Japan)

- Electronic HiTech Engineering Pvt. Ltd (India)

Latest Developments in Global Machine Tools Market

- In October 2024, Nidec Machine Tool Corporation launched the ZI25A, a high-speed, high-precision internal gear grinding machine. Designed for planetary gear mechanisms in automotive drive units, reducers, and robotic joints, the ZI25A meets rising demand for larger, more durable gears with improved efficiency and NVH performance

- In September 2022, Mitsubishi Electric India launched the M800V and M80V series of computerized numerical controllers with built-in wireless LAN, marking a first in the industry. These advanced CNC systems are designed to support remote access and control, meeting the growing need for smart and flexible manufacturing. The introduction of these solutions is expected to enhance Mitsubishi Electric's presence in the machine tools market by driving the adoption of automation and connected manufacturing in India

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Machine Tools Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Machine Tools Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Machine Tools Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.