Global Machine Safety Market

Market Size in USD Billion

CAGR :

%

USD

5.50 Billion

USD

8.70 Billion

2024

2032

USD

5.50 Billion

USD

8.70 Billion

2024

2032

| 2025 –2032 | |

| USD 5.50 Billion | |

| USD 8.70 Billion | |

|

|

|

|

Machine Safety Market Size

Machine Safety Market Size

-

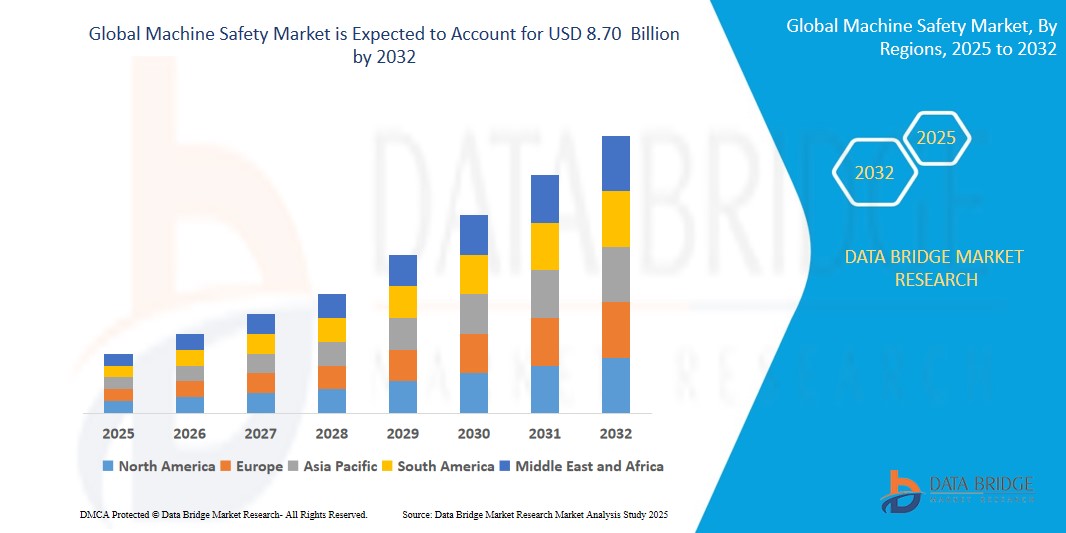

The Global Machine Safety Market size was valued at USD 5.5 billion in 2024 and is expected to reach USD 8.70 billion by 2032, at a CAGR of 6.8% during the forecast period.

-

This growth is driven by the rising number of workplace accidents and occupational hazards across industries emphasizes the critical need for enhanced safety measures.

Machine Safety Market Analysis

- The rising number of workplace accidents and occupational hazards across industries surge in incidents compels organizations to prioritize and invest in advanced machine safety solutions to mitigate risks, prevent injuries and fatalities, and comply with stringent regulations. For example, industries with heavy machinery like manufacturing, construction, and mining are particularly focused on implementing safety measures due to the high potential for severe accidents.

- The market is propelled by Governments and regulatory bodies worldwide are increasingly implementing and enforcing stricter safety standards in industrial settings. These regulations mandate the adoption of machine safety solutions to protect workers and equipment, driving the demand for safety products like safety mats, emergency stops, and interlock switches. For instance, the EU's Machinery Directive 2006/42/EC sets comprehensive safety requirements for machinery within the European Economic Area.

- Europe holds a significant market share due to its Growing Adoption of Industrial Automation and Industry.

- Asia-Pacific is expected to register the fastest growth, fuelled by due to rising growing awareness among businesses regarding the importance of protecting their workforce and assets from potential hazards. Workplace accidents can lead to significant financial losses due to compensation claims, medical expenses, production downtime, and legal liabilities. Consequently, companies are increasingly investing in machine safety to create safer work environments, reduce downtime, improve operational efficiency, and protect their reputation.

- The Presence-Sensing Safety Sensors segment is projected to account for a significant market share of approximately 30.1% in 2025, driven by the widespread adoption of Machine Safety systems in operations and.

Report Scope and Machine Safety Market Segmentation

|

Attributes |

Machine Safety Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Machine Safety Market Trends

“Advancements in AI, IoT, and Smart Grid Integration”

- The incorporation of Artificial Intelligence (AI) and the Internet of Things (IoT) into machine safety systems is enhancing real-time monitoring and predictive maintenance. This integration improves operational efficiency and reduces downtime by enabling proactive fault detection and system optimization

- Machine safety solutions are increasingly being integrated into smart grid infrastructures, facilitating bidirectional communication and enhancing overall energy efficiency. This integration supports better grid management and contributes to the reliability of energy systems

- August 2021: OMRON Corporation introduced the VT-S10 Series, utilizing artificial intelligence and image technology to automate high-precision processes for PCB sub-assemblies, enhancing safety compliance.

- The adoption of Edge AI allows for real-time data processing at the source, improving response times and reducing latency in safety systems. Coupled with the rollout of 5G networks, these technologies are enabling more responsive and reliable machine safety solutions.

Machine Safety Market Dynamics

Driver

“Rising Adoption of Automation”

- Industries are increasingly embracing automation to enhance productivity and safety. The need to protect workers and equipment in automated environments is driving the demand for advanced machine safety solutions.

- Governments and regulatory bodies are enforcing strict safety standards, compelling industries to implement comprehensive machine safety measures to ensure compliance and avoid penalties.

- For instance, March 2024: Secured a contract to provide comprehensive machine safety systems for a new automotive manufacturing plant in North America, including advanced safety sensors and emergency stop controls.

- Machine Safety are increasingly being integrated into Automotive Industry, Manufacturing Sector allowing users to monitor and manage energy usage more effectively. This integration enhances the functionality of Machine Safety within modern energy management systems.

Opportunity

“Expansion in Emerging Markets”

- Rapid industrialization in regions like Asia-Pacific presents significant opportunities for the machine safety market. The increasing focus on workplace safety and the adoption of international safety standards are driving market growth in these areas.

- The development of predictive maintenance technologies is enabling industries to anticipate equipment failures and schedule timely interventions, thereby reducing downtime and maintenance costs. This advancement is creating new avenues for machine safety solutions.

- For instance, June 2022: Clarion Safety Systems acquired Machine Safety Specialists to broaden its risk compliance and assessment offerings, providing clients with additional consulting and machine safety training services.

- The adoption of Edge AI allows for real-time data processing at the source, improving response times and reducing latency in safety systems. Coupled with the rollout of 5G networks, these technologies are enabling more responsive and reliable machine safety solutions.

Restraint/Challenge

“High Implementation Costs”

- The initial investment required for advanced machine safety systems can be substantial, posing a barrier for small and medium-sized enterprises (SMEs) with limited budgets.

- As machine safety systems become more connected through IoT and cloud technologies, they are increasingly vulnerable to cyber threats. Ensuring the cybersecurity of these systems is a growing concern that requires continuous attention and investment.

- For instance, October 2024: Awarded a contract to upgrade the machine safety infrastructure of a major oil and gas company's offshore drilling platforms, focusing on deploying advanced safety interlock systems and real-time monitoring solutions.

- The shortage of skilled professionals in machine safety further complicates market expansion.

Machine Safety Market Scope

The market is segmented based on component, Implementation, Application, End User.

|

Segmentation |

Sub-Segmentation |

|

By Component |

|

|

By Implementation |

|

|

By Application |

|

|

By End User |

|

In 2025, the Oil and Gas segment is projected to dominate the end-user segment

The Oil and Gas segment is expected to hold a market share of approximately 28.1% in 2025, driven by Rising Adoption of Automation.

The Assembly application segment is expected to account for the largest share during the forecast period in the application market

In 2025, the Assembly application segment is projected to account for a market share of 35.1%, driven by compelling industries to implement comprehensive machine safety measures to ensure compliance and avoid penalties.

“Europe Holds the Largest Share in the Machine Safety Market”

-

Europe dominates the market due to Industries are increasingly embracing automation to enhance productivity and safety. The need to protect workers and equipment in automated environments is driving the demand for advanced machine safety solutions.

- The Germany holds a significant share, driven by Rising Adoption of Automation.

- The globe benefits from significant Stringent Safety Regulations.

“Asia-Pacific is Projected to Register the Highest CAGR in the Machine Safety Market”

-

Asia-Pacific’s growth is driven by rising Stringent Safety Regulations in countries like China, India, and Japan.

- India is projected to exhibit the highest CAGR due to its increasing investments in machine safety.

- The combination of Machine Safety with Governments and regulatory bodies are enforcing strict safety standards, compelling industries to implement comprehensive machine safety measures to ensure compliance and avoid penalties improving safety independence.

Machine Safety Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- Rockwell Automation, Inc.,

- Schneider Electric

- Honeywell International Inc.

- Siemens

- KEYENCE CORPORATION

- Mitsubishi Electric Corporation

- OMRON Corporation

- IDEC Corporation

- Euchner-USA, Inc.

- PHOENIX CONTACT

- SICK AG

- Pilz GmbH & Co. KG

- ABB

- Pepperl+Fuchs

- K.A. Schmersal GmbH & Co. KG

- Datalogic S.p.A.

- Stronghold Safety Engineering

- Rockford Systems

- LLCTroax Group and Rite-Hite

Latest Developments in Global Machine Safety Market

-

March 2024: ABB Secured a contract to provide comprehensive machine safety systems for a new automotive manufacturing plant in North America, including advanced safety sensors and emergency stop controls.

- July 2024: Siemens AG Entered into an agreement with a leading food and beverage company to implement machine safety solutions across multiple processing facilities in Europe, aiming to integrate safety controllers and programmable safety systems.

- October 2024: Rockwell Automation Awarded a contract to upgrade the machine safety infrastructure of a major oil and gas company's offshore drilling platforms, focusing on deploying advanced safety interlock systems and real-time monitoring solutions.

- January 2025: Schneider Electric Announced a partnership with a prominent pharmaceutical manufacturer to design and implement machine safety systems in new production lines, integrating safety modules and emergency stop devices.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Machine Safety Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Machine Safety Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Machine Safety Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.