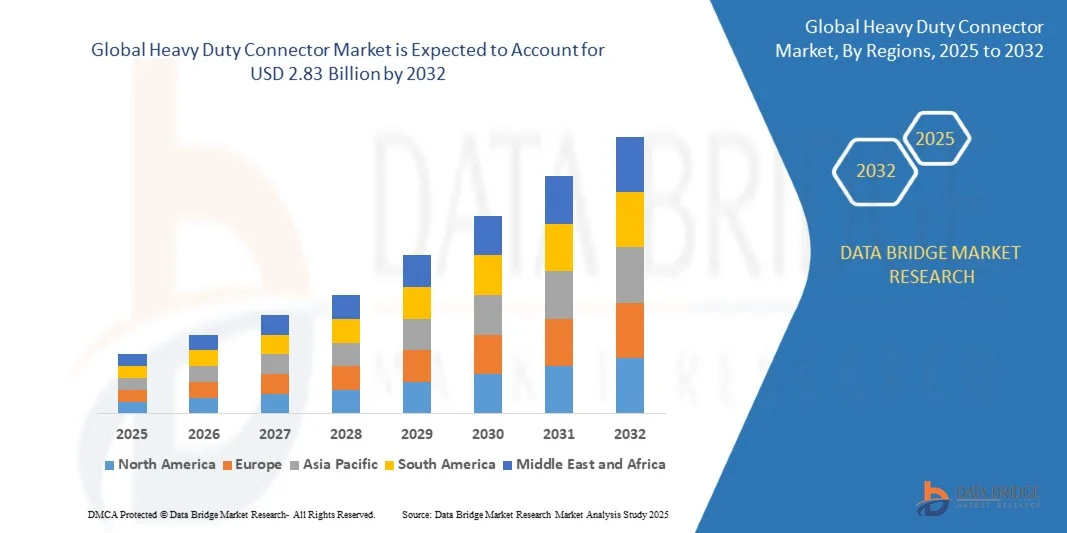

Global Heavy Duty Connector Market

Market Size in USD Billion

CAGR :

%

USD

1.87 Billion

USD

2.83 Billion

2024

2032

USD

1.87 Billion

USD

2.83 Billion

2024

2032

| 2025 –2032 | |

| USD 1.87 Billion | |

| USD 2.83 Billion | |

|

|

|

|

Heavy Duty Connector Market Size

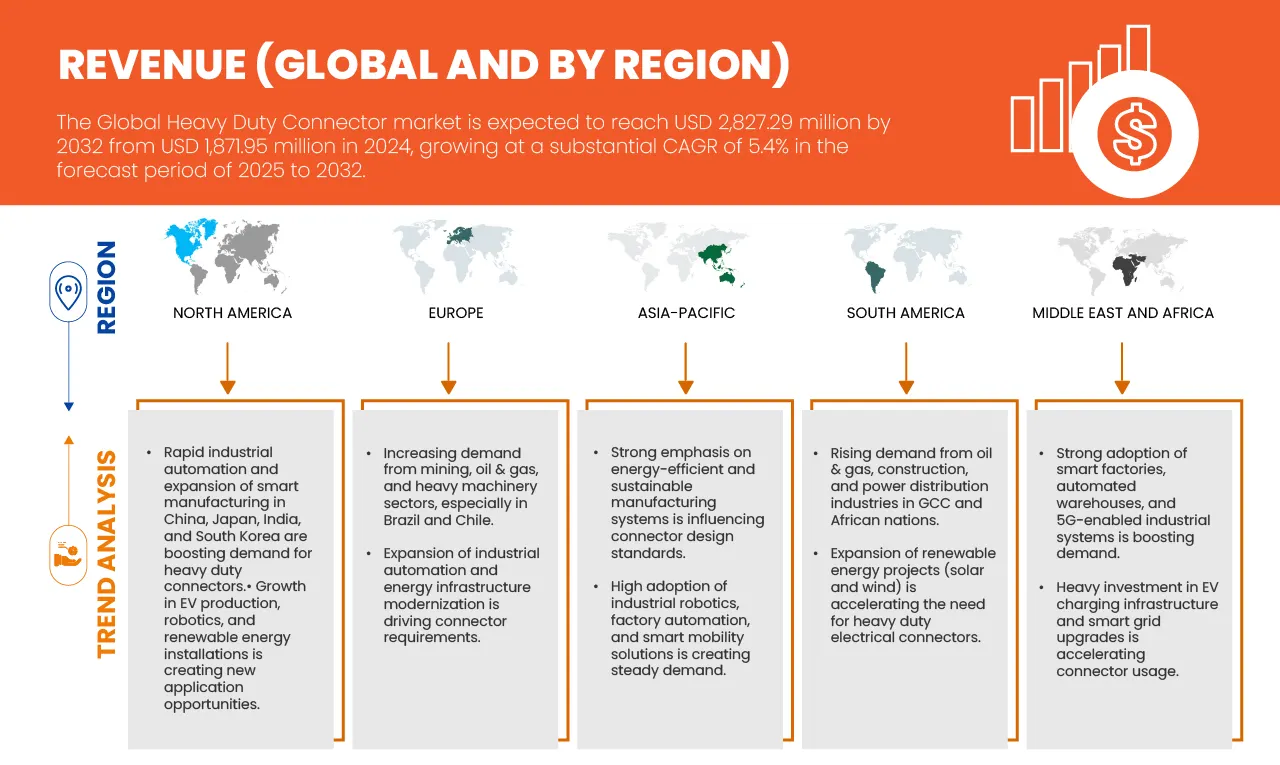

- The Heavy Duty Connector Market size was valued at USD 1.87 Billion in 2024 and is expected to reach USD 2.83 Billion by 2032, at a CAGR of 5.4% during the forecast period

- Rising industrial automation across sectors is accelerating the demand for heavy duty connectors is a major factor driving demand across the region

- Increased investment in smart grid & power distribution networks is further strengthening market reach

Heavy Duty Connector Market Analysis

- The heavy-duty connector market is experiencing strong growth as industries increasingly require durable, high-capacity connectors capable of withstanding vibration, moisture, extreme temperatures, and demanding operating conditions across automation, machinery, transportation, and energy sectors.

- Market expansion is further supported by rapid advancements in Industry 4.0, rising adoption of robotics, growth in renewable energy installations, expanding EV charging infrastructure, and increased investments in upgrading manufacturing facilities to enhance productivity and operational safety.

- Asia-Pacific continues to dominate the global market, driven by its large-scale manufacturing ecosystem, ongoing industrialization, significant infrastructure development, and accelerating adoption of automation across China, India, Japan, and Southeast Asian economies.

- In 2025, bases dominate the Heavy Duty Connector Market with a market share of 23.57% due to their essential role in providing stable mechanical support, secure mounting, and reliable alignment for inserts and housings in demanding industrial environments. Their durability and ability to withstand vibration, moisture, and heavy loads make them indispensable.

- The Asia-Pacific heavy duty connector market is poised to grow at the fastest CAGR of approximately 5.7% from 2025 to 2032, driven by rapid industrialization, expansion of electronics and automotive manufacturing, and increasing adoption of automation across emerging economies. Large-scale infrastructure development, growth in renewable energy projects, and strong investment in EV production further accelerate demand, making the region the most dynamic and high-growth market globally.

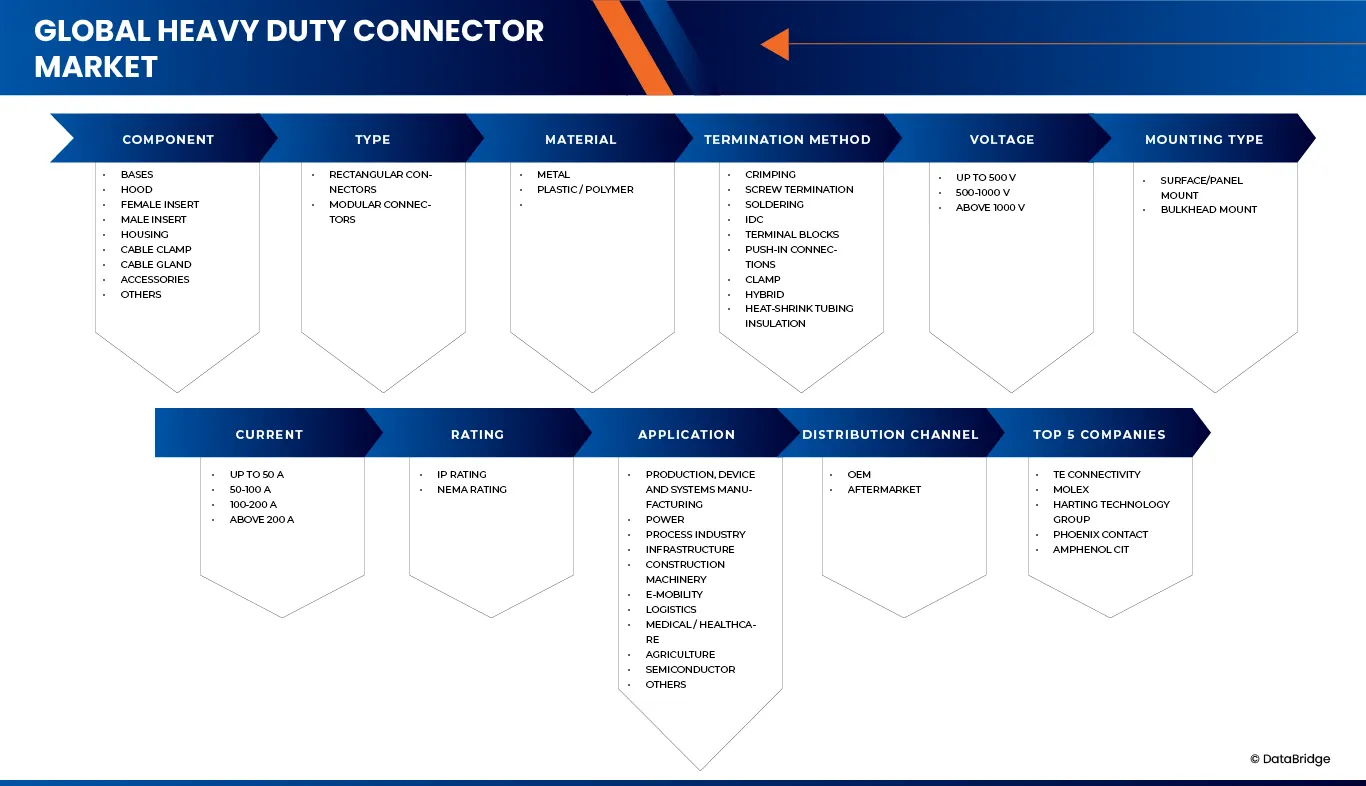

Report Scope and Heavy Duty Connector Market Segmentation

|

Attributes |

Heavy Duty Connector Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Heavy Duty Connector Market Trends

“Smart & IoT-Enabled Heavy-Duty Connectors”

- Smart and IoT-enabled heavy-duty connectors are rapidly becoming a core requirement across industrial automation because they offer real-time visibility into equipment performance, helping organizations operate with greater precision and reliability.

- These connectors incorporate advanced sensors that track variables such as heat, vibration, moisture, and electrical load, allowing systems to detect abnormalities early and prevent equipment failures before they escalate into costly downtime.

- Their ability to support predictive maintenance transforms how factories and infrastructure networks manage assets, shifting from traditional time-based service schedules to condition-based maintenance that reduces unnecessary inspections and optimizes resource allocation.

- Integration capabilities with PLCs, SCADA platforms, cloud dashboards, and digital twins make these connectors essential components in Industry 4.0 ecosystems, enabling seamless data flow and enhancing automation, energy efficiency, and process control.

- As these connectors become smarter, manufacturers are moving beyond selling physical hardware and increasingly offering value-added digital services such as real-time monitoring, analytics tools, and performance-optimization insights—creating new revenue models and strengthening long-term customer relationships while boosting operational reliability across sectors.

Heavy Duty Connector Market Dynamics

Driver

Rising Industrial Automation Across Sectors

- The rapid advancement of industrial automation across manufacturing, logistics, energy, transportation, and process industries has emerged as a fundamental driver for the global heavy-duty connector market. As industries increasingly adopt robotics, smart machinery, and IIoT-enabled systems to enhance productivity and reduce operational risks, the need for robust, reliable, and modular connectivity solutions has intensified. Heavy duty connectors—known for their high durability, environmental resistance, and modular architecture—are indispensable for powering automated equipment, enabling seamless signal and data transfer, and ensuring safe operation in harsh industrial conditions.

- The rising penetration of smart factories and Industry 4.0 technologies is further accelerating the deployment of advanced automation solutions. This includes collaborative robots (cobots), AGVs/AMRs, automated assembly lines, and high-frequency production cells—all of which require connectors with high IP ratings, vibration resistance, and hybrid power-data configurations. Increasing demand for predictive maintenance and real-time monitoring also drives the use of heavy-duty connectors capable of supporting high-speed communication interfaces and sensor networks.

- Additionally, the adoption of AGVs and AMRs in intralogistics, automated warehousing systems, and energy-grid automation is expanding the role of heavy-duty connectors in facilitating high-power charging interfaces, safe quick-disconnect mechanisms, and secure data transmission. These automation trends are especially prominent in Asia-Pacific, where China, Japan, and South Korea account for nearly 70% of global robot installations, reinforcing the region’s position as a critical market for advanced connector solutions.

- As industrial automation continues to evolve, heavy-duty connectors are becoming increasingly essential for enabling flexible manufacturing cells, rapid machine retooling, and plug-and-play modular production architectures. Their ability to ensure electrical integrity, protect against environmental stressors, and support hybrid (power + signal + data) interfaces positions them as vital components in the automation ecosystem. Thus, the global acceleration of industrial automation—driven by robotics adoption, smart factory development, and digitalized production processes—is directly boosting demand for heavy-duty connectors. This positions heavy-duty connector technology as a core enabler of next-generation manufacturing, ensuring safe, efficient, and scalable automation across diverse industrial sectors.

Restraint/Challenge

High Initial Cost of Installation and Components

- The global heavy-duty connector market faces a significant restraint due to the high initial cost of installation, system integration, and component procurement, especially in industrial, renewable energy, rail, and process automation sectors. Heavy-duty connectors whether used in high-current power distribution, harsh-environment automation, offshore wind installations, or railway rolling stock require specialized housings, precision engineered contacts, advanced sealing systems (IP65–IP69K), corrosion-resistant alloys, EMC shielding, and high-temperature insulation materials, all of which contribute to elevated upfront costs.

- Beyond component pricing, integrating heavy-duty connector systems into existing industrial infrastructure often requires custom cabling assemblies, panel modifications, enclosure redesigns, certification processes, and skilled labor. These installation activities significantly increase Capital Expenditure (CAPEX) for end users, especially in sectors with legacy systems that require rewiring or mechanical retrofits.

- High-power connectors for wind turbines, grid infrastructure, railway applications, and heavy machinery further add to cost barriers due to stringent performance standards, including IEC 61984, EN 45545-2 for railway fire safety, UL/CSA requirements for North America, and DNV/ABS certifications for offshore and marine installations.

- Moreover, long-distance renewable energy deployments, offshore wind farms, and substation upgrades require connector systems that are corrosion-proof, arc-resistant, and compatible with high-voltage or high-current transmission, which elevates both material and installation costs. As a result, small and medium-scale manufacturers, utility operators, and industrial plants often delay modernization projects or adopt phased installation strategies to reduce short-term expenditure.

- Overall, the high initial cost of heavy-duty connectors remains a critical barrier to market expansion, particularly in sectors undergoing electrification, automation, and infrastructure modernization. The combined effect of advanced material requirements, stringent global certification standards, and complex installation procedures significantly inflates CAPEX for end users. Real-world industry evidence from offshore wind installations and utility-scale grid upgrades to industrial automation and military-grade systems consistently shows that specialized housings, high-current contacts, corrosion-resistant alloys, and ruggedized IP66–IP69K enclosures carry substantial procurement and integration costs. As documented by leading manufacturers and technical bodies, projects that involve harsh-environment deployment or legacy system retrofits require skilled labor, panel redesigns, and certified high-performance components, further amplifying expenditure. Consequently, small and medium enterprises, utilities, and industrial operators often postpone modernization initiatives or adopt gradual implementation approaches to manage financial pressures. These cost challenges collectively form one of the most persistent restraints limiting the broader adoption of heavy-duty connectors across global industries.

Heavy Duty Connector Market Scope

The market is segmented on the basis of component, type, material, termination method, voltage, mounting type, current, rating, application, distribution channel.

- By Component

On the basis of component, the Heavy Duty Connector Market is segmented into bases, hood, female insert, male insert, housing, cable clamp, cable gland, accessories, others. In 2025, bases dominate the Heavy Duty Connector Market with a market share of 23.57% due to their essential role in providing stable mechanical support, secure mounting, and reliable alignment for inserts and housings in demanding industrial environments. Their durability and ability to withstand vibration, moisture, and heavy loads make them indispensable.

However, the female insert segment is projected to register the highest CAGR of 6.2% during the forecast period of 2025 to 2032, as industries demand higher-density, safer, and more efficient signal and power interfaces.

- By Type

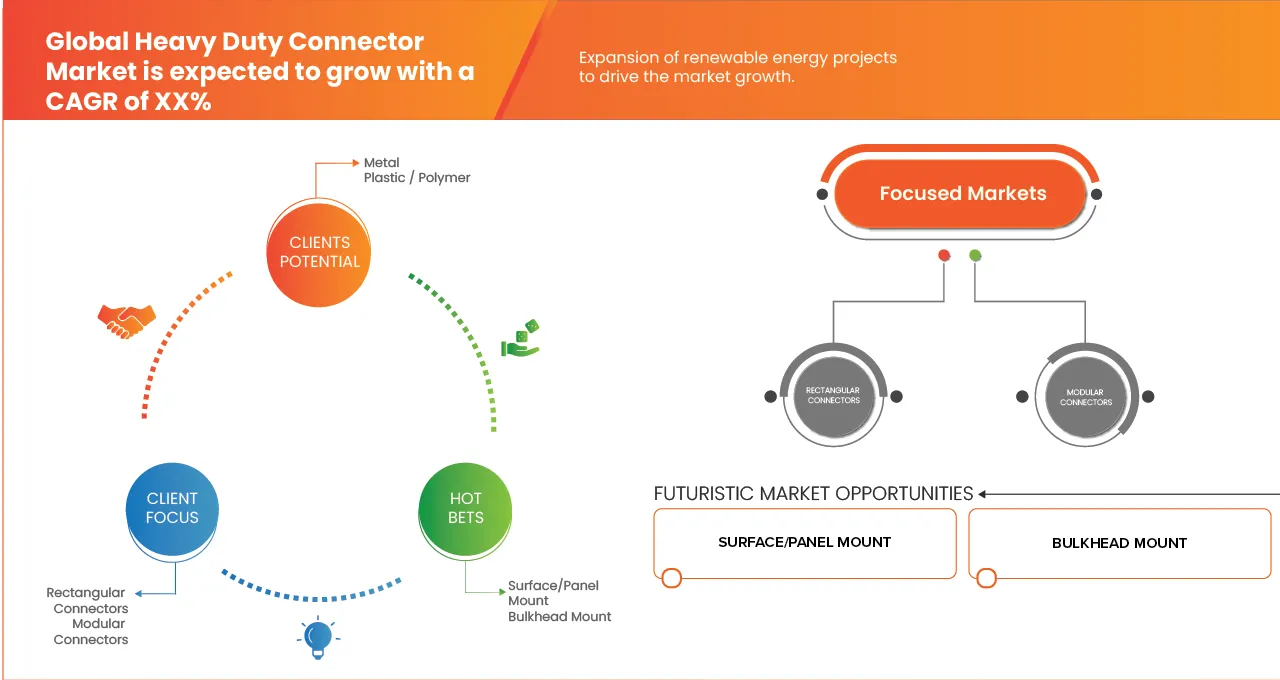

On the basis of type, the Heavy Duty Connector Market is segmented into rectangular connector and modular connector. In 2025, rectangular connector dominates the global market with a market share of 63.69% owing to its robust construction, high contact density, and easy integration into industrial automation systems. Their standardized designs support fast installation and compatibility across equipment.

However, the modular connector segment is projected to register the highest CAGR of 5.8% during the forecast period of 2025 to 2032, owing to the rising demand for customizable, space-saving solutions that allow mixing power, signal, and data modules within a single connector body.

- By Material

On the basis of material, the Heavy Duty Connector Market is segmented into metal and plastic. In 2025, metal dominates the global market with a market share of 66.41% owing to their superior durability, shielding effectiveness, and resistance to harsh environmental conditions, making them ideal for heavy machinery, power systems, and outdoor applications.

However, the plastic segment is projected to register the highest CAGR of 5.9% during the forecast period of 2025 to 2032, as industries increasingly adopt lightweight, corrosion-resistant, and cost-effective materials suitable for less demanding environments and applications requiring easier handling and reduced overall system weight.

- By Termination Method

On the basis of termination method, the Heavy Duty Connector Market is segmented into crimping, screw termination, soldering, IDC, terminal blocks, push-in connections, clamp, hybrid, heat-shrink tubing insulation, wire-wrapping. In 2025, crimping dominates the global market with a market share of 37.98% owing to its strong, vibration-resistant electrical connections, high reliability, and suitability for mass production. It ensures consistent quality and reduced assembly errors.

However, the push-in connections segment is projected to register the highest CAGR of 6.4% during the forecast period of 2025 to 2032, owing to the tool-free installation, reduced labor time, and rising popularity in automation environments where quick, secure, and maintenance-friendly wiring is essential for efficient system setup.

- By Voltage

On the basis of voltage, the Heavy Duty Connector Market is segmented into up to 500 V, 500-1000 V, above 1000 V. In 2025, up to 500 V dominates the global market with a market share of 60.01% owing to its most industrial control systems, automation equipment, and machinery operate within this voltage range, driving widespread connector use.

However, the above 1000 V segment is projected to register the highest CAGR of 6.1% during the forecast period of 2025 to 2032, owing to the growth in renewable energy, electric mobility infrastructure, and high-power industrial equipment increases demand for connectors capable of safely handling higher voltages and ensuring long-term operational reliability.

- By Mounting Type

On the basis of mounting type, the Heavy Duty Connector Market is segmented into surface/panel mount, bulkhead mount. In 2025, surface/panel mount dominates the global market with a market share of 69.04% owing to their ease of installation, compatibility with a wide range of enclosures, and suitability for space-constrained industrial equipment. Their sturdy mounting ensures secure connections in environments with vibration or mechanical stress.

Moreover, this segment is projected to register the highest CAGR during the forecast period of 2025 to 2032, driven by increasing adoption in automation, machinery manufacturing, and modular equipment requiring flexible, front-panel connector integration.

- By Current

On the basis of current, the Heavy Duty Connector Market is segmented into up to 50 A, 50-100 A, 100-200 A, above 200 A. In 2025, up to 50 A dominates the global market with a market share of 48.35% owing to most industrial devices, automation systems, and control equipment require low to moderate current ratings, making these connectors widely applicable and cost-effective

However, the above 200 A segment is projected to register the highest CAGR of 6.0% during the forecast period of 2025 to 2032, as sectors like electric mobility, power distribution, and heavy machinery demand connectors capable of handling high-power loads with enhanced thermal stability and safety.

- By Rating

On the basis of rating, the Heavy Duty Connector Market is segmented into IP rating and NEMA rating. In 2025, IP rating dominates the global market with a market share of 69.06% due to their strong protection against dust, water, and harsh environmental conditions critical in industries such as manufacturing, construction, and transportation. Their popularity is rising as companies prioritize equipment reliability and safety

Moreover, this segment is further projected to register the highest CAGR during the forecast period of 2025 to 2032, driven by increasing outdoor installations, higher safety standards, and expansion of applications requiring ruggedized, sealed connector systems.

- By Application

On the basis of application, the Heavy Duty Connector Market is segmented into production, device and systems manufacturing, power, process industry, infrastructure, construction machinery, e-mobility, logistics, medical / healthcare, agriculture, semiconductor, others. In 2025, production, device and systems manufacturing dominates the global market with a market share of 32.77% due to the sectors rely heavily on automation, robotics, and machinery that require durable connectors for power and signal transmission.

However, the E-Mobility segment is projected to register the highest CAGR of 6.5% during the forecast period of 2025 to 2032, fueled by rapid expansion of EV charging infrastructure, battery systems, and electric drivetrains that demand high-performance connectors with superior safety, current-handling capability, and environmental resistance.

- By Distribution Channel

On the basis of distribution channel, the Heavy Duty Connector Market is segmented into OEM, aftermarket. In 2025, OEM dominates the global market with a market share of 69.13% because manufacturers prefer integrating reliable, certified connectors directly into machinery and equipment during production, ensuring compatibility and performance.

However, the aftermarket segment is projected to register the highest CAGR of 5.8% during the forecast period of 2025 to 2032, as increasing industrial automation and equipment lifespan drive demand for replacement parts, upgrades, and retrofits, particularly in sectors prioritizing maintenance efficiency and minimizing downtime.

Heavy Duty Connector Market Regional Analysis

- Asia-Pacific dominated the heavy duty connector market with the large revenue share of 53.29%, driven by rapid industrialization and large-scale adoption of automation across manufacturing hubs in China, Japan, South Korea, and Southeast Asia.

- Strong growth in sectors such as electronics, automotive, construction machinery, and renewable energy has accelerated the demand for robust, reliable connectors to support expanding production capacities.

- Heavy investments in infrastructure development, smart factories, and electric mobility initiatives further boosted regional demand, positioning Asia-Pacific as the fastest-growing and most influential market.

U.S. Heavy Duty Connector Market Insight

The U.S. heavy duty connector market accounted for a significant share within North America in 2024, due to its advanced industrial base, strong adoption of automation technologies, and large presence of manufacturing, aerospace, and energy sectors requiring high-performance connectivity solutions. Growing investments in smart infrastructure, EV expansion, and modernization of industrial equipment further strengthened demand, positioning the U.S. as a key contributor to regional market growth.

Europe Heavy Duty Connector Market Insight

Europe heavy duty connector market is expected to grow steadily over the forecast period, driven by the region’s emphasis on industrial automation, renewable energy expansion, and stringent safety and performance standards. Increasing adoption of Industry 4.0 technologies and rising demand for rugged connectors in transportation, robotics, and power applications support market expansion. Replacement of aging infrastructure and strong presence of connector manufacturers also contribute to consistent, long-term growth.

U.K. Heavy Duty Connector Market Insight

The U.K. heavy duty connector market is expected to register steady growth over the forecast period, supported by rising investment in advanced manufacturing, renewable energy projects, and EV infrastructure development. Demand is further strengthened by the country’s growing automation initiatives, increased adoption of robotics in logistics, and modernization of industrial equipment. Government-led digitalization programs and the expansion of data centers also create opportunities for reliable, high-performance connectors across multiple industries.

Germany Heavy Duty Connector Market Insight

Germany heavy duty connector market is anticipated to expand at a notable CAGR during the forecast period, supported by its strong engineering and manufacturing ecosystem, particularly in automotive, machinery, and industrial automation. High adoption of smart factory technologies and a robust focus on precision, reliability, and safety drive continuous demand. Additionally, the country’s leadership in renewable energy and electric mobility accelerates the need for advanced connector solutions across critical industrial applications.

Asia-Pacific Heavy Duty Connector Market Insight

Asia-Pacific heavy duty connector market is poised to grow at the fastest CAGR of approximately 5.7% from 2025 to 2032, driven by rapid industrialization, expansion of electronics and automotive manufacturing, and increasing adoption of automation across emerging economies. Large-scale infrastructure development, growth in renewable energy projects, and strong investment in EV production further accelerate demand, making the region the most dynamic and high-growth market globally.

China Heavy Duty Connector Market Insight

China holds the largest share of the Asia-Pacific heavy duty connector market in 2024, attributable to its massive manufacturing base, strong automation adoption, and extensive production of electronics, machinery, and electric vehicles. Large infrastructure projects and expansion of renewable energy installations further boost demand for durable, high-capacity connectors. Favorable government policies and strong domestic production capabilities solidify China’s dominant position within the regional market.

Japan Heavy Duty Connector Market Insight

Japan heavy duty connector market is growing steadily, propelled by the country’s advanced robotics industry, high precision manufacturing, and strong focus on automation. Increasing investment in smart factories, automotive innovation, and next-generation electronics fuels demand for reliable, high-performance connectors. Additionally, Japan’s emphasis on quality, safety, and long equipment lifecycles supports consistent market growth across industrial, transportation, and energy applications.

The Major Market Leaders Operating in the Market are:

- TE Connectivity (Ireland)

- Molex (U.S.)

- HARTING Technology Group (Germany)

- Phoenix Contact (Germany)

- Amphenol Corporation (U.S.)

- LAPP Group (Germany)

- ODU GmbH & Co. KG (Germany)

- Stäubli International AG (Switzerland)

- Wieland Electric GmbH (Germany)

- ITT Inc. (U.S.)

- Smiths Interconnect (U.K.)

- Weidmüller (Germany)

- Belden Inc. (U.S.)

- Hirose Electric Co., Ltd (Japan)

- Guangzhou Weipu Mechanical & Electrical Co., Ltd. (China)

- Zhejiang Haoke Electric Co., Ltd. (China)

- Xiamen WAIN Electrical Co., Ltd. (China)

- Schaltbau (Germany)

- Indo Electricals (India)

- Bulgin Limited (U.K.)

- F. Walther Electric Corporation (Germany)

- I.L.M.E. S.p.A. (Italy)

- Ningbo Oukerui Connector Co., Ltd. (China)

- Ningbo Degson Electrical Co., Ltd. (China)

- Milnec Interconnect Systems (U.S.)

- Yueqing Boese Electronic Plastic Co., Ltd. (China)

Latest Developments in Global Heavy Duty Connector

- In October 2025, Phoenix Contact introduced its new Click-in Modular Frames for heavy-duty connectors, featuring a tool-free assembly design that allows modules to be quickly and securely installed. The innovation enhances installation efficiency, flexibility, and reliability in industrial connection systems.

- In August 2025, WEIPU showcased its latest industrial connector innovations at the Guangzhou GETshow International Exhibition presenting live demonstrations such as IP68 waterproof and anti vibration tests, and unveiling the 2025 Energy Storage Connector Reliability Technical Manual, reinforcing its commitment to high-reliability, application-driven connector solutions

- In March 2025, HARTING Technology Group introduced its new Han-Modular Domino modules, featuring a vibration-proof USB-C interface and supporting data transfer rates up to 20 Gbit/s, designed for compact industrial installations with improved space efficiency.

- In January 2025, TE Connectivity introduced its new MULTIGIG HD connector system, which has been approved by the VITA Standards Organization (VSO) as the next-generation standard for the VPX plug-in module interface. The latest design doubles the pin count of its predecessor and supports data transfer speeds up to 112 Gb/s, meeting rugged environment standards such as VITA 47.3 and VITA 72 for vibration and durability. This innovation strengthens TE Connectivity’s leadership in high-performance embedded interconnects, enabling advanced capabilities for defense, aerospace, and mission-critical computing applications.

- In September 2024, ITT Inc. completed its acquisition of kSARIA Parent, Inc., a leading producer of connectivity solutions for the aerospace and defence markets, for approximately USD 460 million thereby enhancing ITT’s high‑performance interconnect portfolio

- In May 2024, ODU GmbH & Co. KG broke ground on a new state-of-the-art logistics centre at its Mühldorf am Inn headquarters. The five-storey facility will feature an automated small-parts warehouse with more than 37,000 container storage slots and handle up to 300 storage/retrieval operations per hour.

- In June 2022, ITT Inc. announced a strategic minority investment in CRP Technology and CRP USA — acquiring approximately 46% of CRP Technology and 33% of CRP USA — to gain access to advanced additive manufacturing capabilities and expand its material‑science portfolio for aerospace, defence, premium automotive and motorsports applications.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Table of Content

1 INTRODUCTION

1.1 OBJECTIVES OF THE STUDY

1.2 MARKET DEFINITION

1.3 OVERVIEW OF GLOBAL HEAVY DUTY CONNECTOR MARKET

1.4 LIMITATIONS

1.5 MARKETS COVERED

2 MARKET SEGMENTATION

2.1 MARKETS COVERED

2.2 GEOGRAPHICAL SCOPE

2.3 YEARS CONSIDERED FOR THE STUDY

2.4 CURRENCY AND PRICING

2.5 DBMR TRIPOD DATA VALIDATION MODEL

2.6 MULTIVARIATE MODELLING

2.7 PRIMARY INTERVIEWS WITH KEY OPINION LEADERS

2.8 DBMR MARKET POSITION GRID

2.9 MARKET DISTRIBUTION CHANNEL GRID

2.1 SECONDARY SOURCES

2.11 ASSUMPTIONS

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

4.1 PORTER’S FIVE FORCES

4.2 BRAND COMPARATIVE ANALYSIS

4.3 COMPANY EVALUATION QUADRANT

4.4 CONSUMER BEHAVIOR

4.4.1 BUYING PATTERN

4.4.2 USES ANALYSIS

4.5 FUNDING DETAILS

4.5.1 SMITHS INTERCONNECT

4.5.2 TE CONNECTIVITY

4.5.3 HUBBELL → ACQUISITION OF DMC POWER

4.5.4 AMPHENOL CORPORATION – ACQUISITION OF TREXON

4.6 INDUSTRY ANALYSIS AND FUTURISTIC SCENARIO

4.6.1 INTRODUCTION

4.6.2 INDUSTRY ANALYSIS

4.6.3 INDUSTRY ANALYSIS

4.6.4 CONCLUSION

4.7 INHOUSE IMPLEMENTATION/OUTSOURCED (THIRD PARTY) IMPLEMENTATION

4.7.1 CUSTOMER BASE

4.7.2 SERVICE POSITIONING STRATEGIES

4.7.3 CUSTOMER FEEDBACK AND RATING DYNAMICS (B2B FOCUS)

4.7.4 APPLICATION REACH

4.7.5 SERVICE PLATFORM MATRIX

4.8 NEW BUSINESS & EMERGING BUSINESS — REVENUE OPPORTUNITIES

4.8.1 ELECTRIFICATION & E-MOBILITY ECOSYSTEM

4.8.2 RENEWABLE ENERGY & DISTRIBUTED POWER SYSTEMS

4.8.3 INDUSTRIAL AUTOMATION & INDUSTRY 4.0

4.8.4 SMART INFRASTRUCTURE & GRID MODERNIZATION

4.8.5 DEFENSE, AEROSPACE & HARSH-ENVIRONMENT APPLICATIONS

4.8.6 ROBOTICS, AGVS & AUTOMATED WAREHOUSING

4.8.7 HIGH-TEMPERATURE & HIGH-CONTAMINATION INDUSTRIAL SEGMENTS

4.8.8 EMERGING MARKETS & LOCALIZED MANUFACTURING

4.8.9 CONCLUSION

4.9 PENETRATION AND GROWTH PROSPECT MAPPING

4.9.1 MAPPING FRAMEWORK OVERVIEW

4.9.2 STRATEGIC IMPLICATIONS

4.1 TECHNOLOGY ANALYSIS

4.10.1 KEY TECHNOLOGIES

4.10.2 COMPLEMENTARY TECHNOLOGIES

4.10.3 ADJACENT TECHNOLOGIES

4.11 USE CASE ANALYSIS

5 TARIFFS & IMPACT ON THE GLOBAL HEAVY DUTY CONNECTOR MARKET

5.1 OVERVIEW

5.2 TARIFF STRUCTURES

5.3 GLOBAL VS. REGIONAL TARIFF STRUCTURES

5.4 UNITED STATES: ICT TARIFF POLICIES

5.5 EUROPEAN UNION: CROSS-BORDER TARIFF REGULATIONS AND REIMBURSEMENT POLICIES

5.6 ASIA-PACIFIC: GOVERNMENT-IMPOSED TARIFFS ON SERVICES PROVIDED

5.7 EMERGING MARKETS: CHALLENGES IN TARIFF IMPLEMENTATION

5.8 INCREASED COSTS

5.9 SUPPLY CHAIN DISRUPTIONS

5.1 UNCERTAINTY AND INVESTMENT

5.11 IMPACT ON INNOVATION

5.12 COMPETITION AND MARKET DYNAMICS

5.13 EFFECT ON SMALL AND MEDIUM ENTERPRISES (SMES)

5.14 DEPLOYMENT OF TELECOMMUNICATION INFRASTRUCTURE

5.15 STRATEGIC RESPONSES AND INDUSTRY OUTLOOK

5.16 DIVERSIFICATION OF SUPPLY CHAINS

5.17 LEVERAGING ADVANCED LOGISTICS

5.18 ADVOCACY FOR POLICY ADJUSTMENTS

6 REGULATION COVERAGE

6.1 INTRODUCTION

6.1.1 INTERNATIONAL ELECTROTECHNICAL COMMISSION (IEC) STANDARDS

6.1.2 UL AND CSA STANDARDS FOR NORTH AMERICA

6.1.3 EUROPEAN UNION DIRECTIVES

6.1.4 RAILWAY AND TRANSPORTATION-SPECIFIC STANDARDS

6.1.5 ELECTRIC VEHICLE & HIGH-VOLTAGE CHARGING STANDARDS

6.1.6 INDUSTRY-SPECIFIC REGULATIONS

6.1.7 IMPACT OF REGULATORY STANDARDS ON MARKET DYNAMICS

6.2 CONCLUSION

7 MARKET OVERVIEW

7.1 DRIVERS

7.1.1 RISING INDUSTRIAL AUTOMATION ACROSS SECTORS IS ACCELERATING THE DEMAND FOR HEAVY DUTY CONNECTORS

7.1.2 EXPANSION OF RENEWABLE ENERGY PROJECTS

7.1.3 RAPID ELECTRIFICATION OF OFF-HIGHWAY AND HEAVY MOBILE MACHINERY

7.1.4 GROWING DEMAND FOR HIGH-RELIABILITY CONNECTIVITY IN HARSH ENVIRONMENTS

7.2 RESTRAINTS

7.2.1 HIGH INITIAL COST OF INSTALLATION AND COMPONENTS

7.2.2 AVAILABILITY OF LOW-COST COUNTERFEIT PRODUCTS

7.3 OPPORTUNITIES

7.3.1 GROWING DEMAND IN EMERGING ECONOMIES

7.3.2 MINIATURIZATION AND MODULARIZATION TRENDS

7.3.3 INCREASED INVESTMENT IN SMART GRID & POWER DISTRIBUTION NETWORKS

7.4 CHALLENGES

7.4.1 CUSTOMIZATION REQUIREMENTS ACROSS APPLICATIONS

7.4.2 COMPLEX SUPPLY CHAIN AND LOGISTICS IN HARSH ENVIRONMENT DEPLOYMENT

8 GLOBAL HEAVY DUTY CONNECTOR MARKET, BY COMPONENTS

8.1 OVERVIEW

8.2 BASES

8.2.1 BULKHEAD

8.2.2 BOX MOUNT

8.3 HOOD

8.3.1 REAR EXIT

8.3.2 SIDE EXIT

8.3.3 EXTENDED SIDE EXIT

8.3.4 LATCHING

8.3.4.1 SINGLE LATCH BASE

8.3.4.2 SINGLE LATCH HOOD

8.3.4.3 DUAL LATCH HOOD

8.3.4.4 DUAL LATCH BASE

8.4 FEMALE INSERT

8.5 MALE INSERT

8.6 HOUSING

8.7 CABLE CLAMP

8.8 CABLE GLAND

8.9 ACCESSORIES

8.9.1 LOCKING LEVERS

8.9.2 PROTECTIVE COVERS

8.9.3 CODING ELEMENTS

8.9.4 ADAPTER FRAMES

8.1 OTHERS

9 GLOBAL HEAVY DUTY CONNECTOR MARKET, BY TYPE

9.1 OVERVIEW

9.2 RECTANGULAR CONNECTORS

9.2.1 SINGLE LATCH

9.2.2 DUAL LATCH

9.2.3 LEVER-LOCKING

9.2.4 SCREW-LOCKING

9.2.5 OTHERS

9.3 MODULAR CONNECTORS

9.3.1 SIGNAL MODULES

9.3.2 POWER MODULES

9.3.3 HYBRID MODULES ( SIGNAL + POWER)

10 GLOBAL HEAVY DUTY CONNECTOR MARKET, BY MATERIAL

10.1 OVERVIEW

10.2 METAL

10.2.1 COPPER

10.2.2 STAINLESS STEEL

10.2.3 ALUMINUM

10.2.4 ZINC

10.2.5 OTHERS

10.3 PLASTIC / POLYMER

10.3.1 POLYAMIDE

10.3.2 THERMOPLASTIC ELASTOMERS (TPE)

10.3.3 POLYCARBONATE

10.3.4 OTHERS

11 GLOBAL HEAVY DUTY CONNECTOR MARKET, BY TERMINATION METHOD

11.1 OVERVIEW

11.2 CRIMPING

11.3 SCREW TERMINATION

11.4 SOLDERING

11.5 IDC

11.6 TERMINAL BLOCKS

11.7 PUSH-IN CONNECTIONS

11.8 CLAMP

11.9 HYBRID

11.1 HEAT-SHRINK TUBING INSULATION

11.11 WIRE-WRAPPING

12 GLOBAL HEAVY DUTY CONNECTOR MARKET, BY VOLTAGE

12.1 OVERVIEW

12.2 UP TO 500 V

12.3 500-1000 V

12.4 ABOVE 1000 V

13 GLOBAL HEAVY DUTY CONNECTOR MARKET, BY MOUNTING TYPE

13.1 OVERVIEW

13.2 SURFACE/PANEL MOUNT

13.3 BULKHEAD MOUNT

14 GLOBAL HEAVY DUTY CONNECTOR MARKET, BY CURRENT

14.1 OVERVIEW

14.2 UP TO 50 A

14.3 50-100 A

14.4 100-200 A

14.5 ABOVE 200 A

15 GLOBAL HEAVY DUTY CONNECTOR MARKET, BY RATING

15.1 OVERVIEW

15.2 IP RATING

15.2.1 IP67

15.2.2 IP68

15.2.3 IP66

15.2.4 IP65

15.2.5 IP69K

15.2.6 ATEX-RATED

15.3 NEMA RATING

15.3.1 NEMA 4 / 4X

15.3.2 NEMA 12 / 12K

15.3.3 NEMA 6 / 6P

15.3.4 NEMA 3 / 3R

15.3.5 NEMA 13

15.3.6 NEMA 1

16 GLOBAL HEAVY DUTY CONNECTOR MARKET, BY APPLICATION

16.1 OVERVIEW

16.2 PRODUCTION, DEVICE AND SYSTEMS MANUFACTURING

16.2.1 BY CATEGORY

16.2.1.1 AUTOMOTIVE INDUSTRY

16.2.1.2 CONTROL CABINET BUILDING

16.2.1.3 DEVICE MANUFACTURERS

16.2.1.4 AUTOMATED GUIDED VEHICLES (AGV)

16.2.1.5 DIGITAL FACTORY

16.2.1.6 ELECTRICAL INSTALLATIONS

16.2.1.7 MACHINE BUILDING

16.2.1.8 OTHERS

16.2.2 BY TYPE

16.2.2.1 RECTANGULAR CONNECTORS

16.2.2.2 MODULAR CONNECTORS

16.3 POWER

16.3.1 BY CATEGORY

16.3.1.1 BATTERY STORAGE SYSTEMS

16.3.1.2 CONVENTIONAL POWER GENERATION

16.3.1.3 POWER TRANSMISSION & DISTRIBUTION

16.3.1.4 DC GRIDS IN INDUSTRY

16.3.1.5 SOLAR POWER

16.3.1.6 WIND POWER

16.3.1.7 POWER RELIABILITY

16.3.1.8 OTHERS

16.3.2 BY TYPE

16.3.2.1 RECTANGULAR CONNECTORS

16.3.2.2 MODULAR CONNECTORS

16.4 PROCESS INDUSTRY

16.4.1 BY CATEGORY

16.4.1.1 MARINE AND OFFSHORE

16.4.1.2 MINING

16.4.1.3 PROCESS AUTOMATION

16.4.1.4 POWER-TO-X

16.4.1.5 OTHERS

16.4.2 BY TYPE

16.4.2.1 RECTANGULAR CONNECTORS

16.4.2.2 MODULAR CONNECTORS

16.5 INFRASTRUCTURE

16.5.1 BY CATEGORY

16.5.1.1 BUILDING AUTOMATION

16.5.1.2 DATA CENTERS

16.5.1.3 DATA CONNECTORS FOR SMART NETWORKS

16.5.1.4 RAILWAY INDUSTRY

16.5.1.5 VIDEO SURVEILLANCE

16.5.1.6 TRANSPORTATION INFRASTRUCTURE

16.5.1.7 SMART CITY

16.5.1.8 WATER AND WASTEWATER TREATMENT

16.5.1.9 FUNCTIONAL SAFETY

16.5.1.10 OTHERS

16.5.2 BY TYPE

16.5.2.1 RECTANGULAR CONNECTORS

16.5.2.2 MODULAR CONNECTORS

16.6 CONSTRUCTION MACHINERY

16.6.1 BY CATEGORY

16.6.1.1 EXCAVATOR

16.6.1.2 CRANE

16.6.1.3 LOADER

16.6.1.4 BULLDOZER

16.6.1.5 DUMP TRUCK

16.6.1.6 CONCRETE MIXER

16.6.1.7 OTHERS

16.6.2 BY TYPE

16.6.2.1 RECTANGULAR CONNECTORS

16.6.2.2 MODULAR CONNECTORS

16.7 E-MOBILITY

16.7.1 BY CATEGORY

16.7.1.1 ELECTRIC VEHICLES

16.7.1.1.1 BATTERY PACKS

16.7.1.1.1.1 TESTING

16.7.1.1.1.2 POWER DELIVERY

16.7.1.1.1.3 ENERGY STORAGE MODULES

16.7.1.1.2 BATTERY MANAGEMENT SYSTEM

16.7.1.1.2.1 MONITORING & CONTROL

16.7.1.1.2.2 TESTING

16.7.1.1.2.3 THERMAL MANAGEMENT

16.7.1.1.3 ON BOARD CHARGER

16.7.1.1.3.1 AC TO DC CONVERSION

16.7.1.1.3.2 TESTING

16.7.1.1.4 MOTOR CONTROL UNIT (MCU)

16.7.1.1.4.1 TESTING

16.7.1.1.4.2 OTHERS

16.7.1.1.5 VEHICLE CONTROL UNIT (VCU)

16.7.1.1.5.1 CENTRAL CONTROL OF EV SUBSYSTEMS

16.7.1.1.5.2 TESTING

16.7.1.1.6 ELECTRONIC CONTROL UNIT (ECU)

16.7.1.1.6.1 SUBSYSTEM CONTROL

16.7.1.1.6.2 TESTING

16.7.1.1.7 E-MOTOR

16.7.1.1.7.1 TESTING

16.7.1.1.7.2 OTHERS

16.7.1.1.8 INTERNAL COMBUSTION ENGINE

16.7.1.1.8.1 TESTING

16.7.1.1.8.2 POWER GENERATION

16.7.1.1.9 CHARGING STATIONS, GUNS, AND WALL BOXES

16.7.1.1.9.1 TESTING

16.7.1.1.9.2 VEHICLE GRID INTEGRATION

16.7.1.1.10 INFOTAINMENT, NAVIGATOR AND SOUND SYSTEMS

16.7.1.1.10.1 TESTING

16.7.1.1.10.2 USER INTERFACE AND ENTERTAINMENT

16.7.1.1.11 LIGHTING SYSTEMS

16.7.1.1.11.1 TESTING

16.7.1.1.11.2 EXTERIOR & INTERIOR ILLUMINATION

16.7.1.1.12 SEATS

16.7.1.1.12.1 TESTING

16.7.1.1.12.2 POWER AND MOVEMENT

16.7.1.1.12.3 HEATING

16.7.1.1.13 AIRBAGS

16.7.1.1.13.1 OCCUPANT SAFETY SYSTEMS

16.7.1.1.13.2 TESTING

16.7.1.1.14 HVAC SYSTEMS

16.7.1.1.14.1 CABIN TEMPERATURE CONTROL

16.7.1.1.14.2 TESTING

16.7.1.1.15 PARKING ASSISTANCE SYSTEM

16.7.1.1.15.1 DRIVER ASSISTANCE & SAFETY

16.7.1.1.15.2 OTHERS

16.7.1.1.16 OTHERS

16.7.1.2 CHARGING INFRASTRUCTURE

16.7.2 BY TYPE

16.7.2.1 RECTANGULAR CONNECTORS

16.7.2.2 MODULAR CONNECTORS

16.8 LOGISTICS

16.8.1 BY CATEGORY

16.8.1.1 FORKLIFT

16.8.1.2 CONVEYOR SYSTEM

16.8.1.3 AUTOMATED GUIDED VEHICLE

16.8.1.4 WAREHOUSE ROBOTICS

16.8.1.5 MATERIAL HANDLING

16.8.1.6 PALLETIZING SYSTEM

16.8.1.7 DRONES

16.8.1.8 OTHERS

16.8.2 BY TYPE

16.8.2.1 RECTANGULAR CONNECTORS

16.8.2.2 MODULAR CONNECTORS

16.9 MEDICAL / HEALTHCARE

16.9.1 BY CATEGORY

16.9.1.1 DIAGNOSTIC & IMAGING EQUIPMENT

16.9.1.2 THERAPEUTIC EQUIPMENT

16.9.1.3 LABORATORY EQUIPMENT, R&D

16.9.1.4 AESTHETIC AND COSMETIC DEVICES

16.9.1.5 PHARMACEUTICAL PRODUCTION

16.9.1.6 SURGERY DEVICES

16.9.1.7 OTHERS

16.9.2 BY TYPE

16.9.2.1 RECTANGULAR CONNECTORS

16.9.2.2 MODULAR CONNECTORS

16.1 AGRICULTURE

16.10.1 BY CATEGORY

16.10.1.1 FARM MACHINERY AND EQUIPMENT

16.10.1.2 PRECISION AGRICULTURE SYSTEMS

16.10.1.3 IRRIGATION SYSTEMS

16.10.1.4 GREENHOUSE AUTOMATION

16.10.1.5 LIVESTOCK MONITORING AND AUTOMATION

16.10.1.6 AGRI-DRONES AND ROBOTICS

16.10.1.7 POST-HARVEST EQUIPMENT

16.10.1.8 OTHERS

16.10.2 BY TYPE

16.10.2.1 RECTANGULAR CONNECTORS

16.10.2.2 MODULAR CONNECTORS

16.11 SEMICONDUCTOR

16.11.1 BY CATEGORY

16.11.1.1 WAFER HANDLING

16.11.1.2 CLEANROOM

16.11.1.3 TEST EQUIPMENT

16.11.1.4 ASSEMBLY LINE

16.11.1.5 CHIP PACKAGING

16.11.1.6 INSPECTION SYSTEM

16.11.1.7 OTHERS

16.11.2 BY TYPE

16.11.2.1 RECTANGULAR CONNECTORS

16.11.2.2 MODULAR CONNECTORS

16.12 OTHERS

17 GLOBAL HEAVY DUTY CONNECTOR MARKET, BY DISTRIBUTION CHANNEL

17.1 OVERVIEW

17.2 OEM

17.3 AFTERMARKET

17.3.1 DISTRIBUTORS

17.3.2 SERVICE CENTERS

17.3.3 MAINTENANCE PROVIDERS

17.3.4 ONLINE PLATFORMS

17.3.5 RETAILERS

18 GLOBAL HEAVY DUTY CONNECTOR MARKET, BY REGION

18.1 OVERVIEW

18.2 ASIA-PACIFIC

18.2.1 CHINA

18.2.2 JAPAN

18.2.3 INDIA

18.2.4 SOUTH KOREA

18.2.5 THAILAND

18.2.6 TAIWAN

18.2.7 VIETNAM

18.2.8 INDONESIA

18.2.9 MALAYSIA

18.2.10 SINGAPORE

18.2.11 AUSTRALIA

18.2.12 PHILIPPINES

18.2.13 NEW ZEALAND

18.2.14 HONG KONG

18.2.15 REST OF ASIA-PACIFIC

18.3 EUROPE

18.3.1 GERMANY

18.3.2 U.K.

18.3.3 FRANCE

18.3.4 ITALY

18.3.5 SPAIN

18.3.6 NETHERLANDS

18.3.7 SWITZERLAND

18.3.8 POLAND

18.3.9 TURKEY

18.3.10 RUSSIA

18.3.11 BELGIUM

18.3.12 SWEDEN

18.3.13 FINLAND

18.3.14 DENMARK

18.3.15 NORWAY

18.3.16 PORTUGAL

18.3.17 REST OF EUROPE

18.4 NORTH AMERICA

18.4.1 U.S.

18.4.2 CANADA

18.4.3 MEXICO

18.5 SOUTH AMERICA

18.5.1 BRAZIL

18.5.2 ARGENTINA

18.5.3 COLOMBIA

18.5.4 CHILE

18.5.5 PERU

18.5.6 ECUADOR

18.5.7 VENEZUELA

18.5.8 URUGUAY

18.5.9 BOLIVIA

18.5.10 PARAGUAY

18.5.11 REST OF SOUTH AMERICA

18.6 MIDDLE EAST AND AFRICA

18.6.1 SAUDI ARABIA

18.6.2 SOUTH AFRICA

18.6.3 EGYPT

18.6.4 UNITED ARAB EMIRATES

18.6.5 ISRAEL

18.6.6 QATAR

18.6.7 BAHRAIN

18.6.8 OMAN

18.6.9 KUWAIT

18.6.10 REST OF MIDDLE EAST AND AFRICA

19 GLOBAL HEAVY DUTY CONNECTOR MARKET: COMPANY LANDSCAPE

19.1 COMPANY SHARE ANALYSIS: GLOBAL

19.2 COMPANY SHARE ANALYSIS: ASIA-PACIFIC

19.3 COMPANY SHARE ANALYSIS: NORTH AMERICA

19.4 COMPANY SHARE ANALYSIS: EUROPE

20 SWOT ANALYSIS

21 COMPANY PROFILES

21.1 TE CONNECTIVITY

21.1.1 COMPANY SNAPSHOT

21.1.2 REVENUE ANALYSIS

21.1.3 COMPANY SHARE ANALYSIS

21.1.4 PRODUCT PORTFOLIO

21.1.5 RECENT DEVELOPMENTS

21.2 MOLEX

21.2.1 COMPANY SNAPSHOT

21.2.2 COMPANY SHARE ANALYSIS

21.2.3 PRODUCT PORTFOLIO

21.2.4 RECENT DEVELOPMENTS

21.3 HARTING TECHNOLOGY GROUP

21.3.1 COMPANY SNAPSHOT

21.3.2 COMPANY SHARE ANALYSIS

21.3.3 PRODUCT PORTFOLIO

21.3.4 RECENT DEVELOPMENTS

21.4 PHOENIX CONTACT

21.4.1 COMPANY SNAPSHOT

21.4.2 COMPANY SHARE ANALYSIS

21.4.3 PRODUCT PORTFOLIO

21.4.4 RECENT DEVELOPMENTS

21.5 AMPHENOL CORPORATION

21.5.1 COMPANY SNAPSHOT

21.5.2 REVENUE ANALYSIS

21.5.3 COMPANY SHARE ANALYSIS

21.5.4 PRODUCT PORTFOLIO

21.5.5 RECENT DEVELOPMENTS

21.6 BELDEN INC.

21.6.1 COMPANY SNAPSHOT

21.6.2 REVENUE ANALYSIS

21.6.3 PRODUCT PORTFOLIO

21.6.4 RECENT DEVELOPMENTS

21.7 BULGIN LIMITED

21.7.1 COMPANY SNAPSHOT

21.7.2 PRODUCT PORTFOLIO

21.7.3 RECENT DEVELOPMENTS

21.8 NINGBO DEGSON ELECTRICAL CO., LTD.

21.8.1 COMPANY SNAPSHOT

21.8.2 PRODUCT PORTFOLIO

21.8.3 RECENT DEVELOPMENTS

21.9 GUANGZHOU WEIPU MECHANICAL AND ELECTRICAL CO., LTD.

21.9.1 COMPANY SNAPSHOT

21.9.2 PRODUCT PORTFOLIO

21.9.3 RECENT DEVELOPMENTS

21.1 HIROSE ELECTRIC CO., LTD.

21.10.1 COMPANY SNAPSHOT

21.10.2 REVENUE ANALYSIS

21.10.3 PRODUCT PORTFOLIO

21.10.4 RECENT DEVELOPMENTS

21.11 I.L.M.E. S.P.A.

21.11.1 COMPANY SNAPSHOT

21.11.2 PRODUCT PORTFOLIO

21.11.3 RECENT DEVELOPMENTS

21.12 INDO ELECTRICALS

21.12.1 COMPANY SNAPSHOT

21.12.2 PRODUCT PORTFOLIO

21.12.3 RECENT DEVELOPMENTS

21.13 ITT INC.

21.13.1 COMPANY SNAPSHOT

21.13.2 REVENUE ANALYSIS

21.13.3 PRODUCT PORTFOLIO

21.13.4 RECENT DEVELOPMENTS

21.14 MILNEC INTERCONNECT SYSTEMS

21.14.1 COMPANY SNAPSHOT

21.14.2 PRODUCT PORTFOLIO

21.14.3 RECENT DEVELOPMENTS

21.15 NINGBO OUKERUI CONNECTOR CO., LTD.

21.15.1 COMPANY SNAPSHOT

21.15.2 PRODUCT PORTFOLIO

21.15.3 RECENT DEVELOPMENTS

21.16 ODU GMBH & CO.KG

21.16.1 COMPANY SNAPSHOT

21.16.2 PRODUCT PORTFOLIO

21.16.3 RECENT DEVELOPMENTS

21.17 SCHALTBAU

21.17.1 COMPANY SNAPSHOT

21.17.2 PRODUCT PORTFOLIO

21.17.3 RECENT DEVELOPMENTS

21.18 SMITHS INTERCONNECT (SUBSIDIARY OF SMITHS GROUP PLC)

21.18.1 COMPANY SNAPSHOT

21.18.2 REVENUE ANALYSIS

21.18.3 PRODUCT PORTFOLIO

21.18.4 ECENT DEVELOPMENTS

21.19 STÄUBLI INTERNATIONAL AG

21.19.1 COMPANY SNAPSHOT

21.19.2 PRODUCT PORTFOLIO

21.19.3 RECENT DEVELOPMENTS

21.2 F. WALTHER ELECTRIC CORPORATION (SUBSIDIARY OF WALTHER-WERKE)

21.20.1 COMPANY SNAPSHOT

21.20.2 PRODUCT PORTFOLIO

21.20.3 RECENT DEVELOPMENTS

21.21 WEIDMÜLLER

21.21.1 COMPANY SNAPSHOT

21.21.2 REVENUE ANALYSIS

21.21.3 PRODUCT PORTFOLIO

21.21.4 RECENT DEVELOPMENTS

21.22 LAPP GROUP

21.22.1 COMPANY SNAPSHOT

21.22.2 PRODUCT PORTFOLIO

21.22.3 RECENT DEVELOPMENTS

21.23 XIAMEN WAIN ELECTRICAL CO., LTD.

21.23.1 COMPANY SNAPSHOT

21.23.2 PRODUCT PORTFOLIO

21.23.3 RECENT DEVELOPMENTS

21.24 YUEQING BOESE ELECTRONIC PLASTIC CO LTD

21.24.1 COMPANY SNAPSHOT

21.24.2 PRODUCT PORTFOLIO

21.24.3 RECENT DEVELOPMENTS

21.25 ZHEJIANG HAOKE ELECTRIC CO., LTD.

21.25.1 COMPANY SNAPSHOT

21.25.2 PRODUCT PORTFOLIO

21.25.3 RECENT DEVELOPMENTS

21.26 WIELAND ELECTRIC GMBH

21.26.1 COMPANY SNAPSHOT

21.26.2 PRODUCT PORTFOLIO

21.26.3 RECENT DEVELOPMENTS

22 QUESTIONNAIRE

23 RELATED REPORTS

List of Table

TABLE 1 COMPARATIVE ANALYSIS OF LEADING HEAVY DUTY CONNECTORS BRANDS

TABLE 2 TECHNOLOGY MATRIX

TABLE 3 USE CASE ANALYSIS: HEAVY DUTY CONNECTOR APPLICATIONS

TABLE 4 KEY REGULATORY STANDARDS

TABLE 5 HEAVY DUTY CONNECTOR MARKET, BY COMPONENT, 2018-2032 (USD THOUSAND)

TABLE 6 GLOBAL BASES IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 7 GLOBAL HOOD IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 8 GLOBAL HOOD IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 9 GLOBAL LATCHING IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 10 GLOBAL FEMALE INSERT IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 11 GLOBAL MALE INSERT IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 12 GLOBAL HOUSING IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 13 GLOBAL CABLE CLAMP IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 14 GLOBAL CABLE GLAND IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 15 GLOBAL ACCESSORIES IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 16 GLOBAL ACCESSORIES IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 17 GLOBAL OTHERS IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 18 GLOBAL HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 19 GLOBAL RECTANGULAR CONNECTORS IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 20 GLOBAL RECTANGULAR CONNECTORS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 21 GLOBAL MODULAR CONNECTORS IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 22 GLOBAL MODULAR CONNECTORS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 23 GLOBAL HEAVY DUTY CONNECTOR MARKET, BY MATERIAL, 2018-2032 (USD THOUSAND)

TABLE 24 GLOBAL METAL IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 25 GLOBAL METAL IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 26 GLOBAL PLASTIC / POLYMER IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 27 GLOBAL PLASTIC / POLYMER IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 28 GLOBAL HEAVY DUTY CONNECTOR MARKET, BY TERMINATION METHOD, 2018-2032 (USD THOUSAND)

TABLE 29 GLOBAL CRIMPING IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 30 GLOBAL SCREW TERMINATION IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 31 GLOBAL SOLDERING IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 32 GLOBAL IDC IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 33 GLOBAL TERMINAL BLOCKS IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 34 GLOBAL PUSH-IN CONNECTIONS IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 35 GLOBAL CLAMP IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 36 GLOBAL HYBRID IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 37 GLOBAL HEAT-SHRINK TUBING INSULATION IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 38 GLOBAL WIRE-WRAPPING IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 39 GLOBAL HEAVY DUTY CONNECTOR MARKET, BY VOLTAGE, 2018-2032 (USD THOUSAND)

TABLE 40 GLOBAL UP TO 500 V IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 41 GLOBAL 500-1000 V IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 42 GLOBAL ABOVE 1000 V IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 43 GLOBAL HEAVY DUTY CONNECTOR MARKET, BY MOUNTING TYPE, 2018-2032 (USD THOUSAND)

TABLE 44 GLOBAL SURFACE/PANEL MOUNT IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 45 GLOBAL BULKHEAD MOUNT IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 46 GLOBAL HEAVY DUTY CONNECTOR MARKET, BY CURRENT, 2018-2032 (USD THOUSAND)

TABLE 47 GLOBAL UP TO 50 A IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 48 GLOBAL 50-100 A IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 49 GLOBAL 100-200 A IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 50 GLOBAL ABOVE 200 A IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 51 GLOBAL HEAVY DUTY CONNECTOR MARKET, BY RATING, 2018-2032 (USD THOUSAND)

TABLE 52 GLOBAL IP RATING IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 53 GLOBAL IP RATING IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 54 GLOBAL NEMA RATING IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 55 GLOBAL NEMA RATING IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 56 GLOBAL HEAVY DUTY CONNECTOR MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 57 GLOBAL PRODUCTION, DEVICE AND SYSTEMS MANUFACTURING IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 58 GLOBAL PRODUCTION, DEVICE AND SYSTEMS MANUFACTURING IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 59 GLOBAL PRODUCTION, DEVICE AND SYSTEMS MANUFACTURING IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 60 GLOBAL POWER IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 61 GLOBAL POWER IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 62 GLOBAL POWER IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 63 GLOBAL PROCESS INDUSTRY IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 64 GLOBAL PROCESS INDUSTRY IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 65 GLOBAL PROCESS INDUSTRY IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 66 GLOBAL INFRASTRUCTURE IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 67 GLOBAL INFRASTRUCTURE IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 68 GLOBAL INFRASTRUCTURE IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 69 GLOBAL CONSTRUCTION MACHINERY IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 70 GLOBAL CONSTRUCTION MACHINERY IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 71 GLOBAL CONSTRUCTION MACHINERY IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 72 GLOBAL E-MOBILITY IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 73 GLOBAL E-MOBILITY IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 74 GLOBAL ELECTRIC VEHICLES IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 75 GLOBAL BATTERY PACKS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 76 GLOBAL BATTERY MANAGEMENT SYSTEM IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 77 GLOBAL ON BOARD CHARGER IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 78 GLOBAL MOTOR CONTROL UNIT (MCU) IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 79 GLOBAL VEHICLE CONTROL UNIT (VCU) IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 80 GLOBAL ELECTRONIC CONTROL UNIT (ECU) IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 81 GLOBAL E-MOTOR IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 82 GLOBAL INTERNAL COMBUSTION ENGINE IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 83 GLOBAL CHARGING STATIONS, GUNS, AND WALL BOXES IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 84 GLOBAL INFOTAINMENT, NAVIGATOR AND SOUND SYSTEMS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 85 GLOBAL LIGHTING SYSTEMS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 86 GLOBAL SEATS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 87 GLOBAL AIRBAGS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 88 GLOBAL HVAC SYSTEMS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 89 GLOBAL PARKING ASSISTANCE SYSTEM IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 90 GLOBAL E-MOBILITY IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 91 GLOBAL LOGISTICS IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 92 GLOBAL LOGISTICS IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 93 GLOBAL LOGISTICS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 94 GLOBAL MEDICAL / HEALTHCARE IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 95 GLOBAL MEDICAL / HEALTHCARE IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 96 GLOBAL MEDICAL / HEALTHCARE IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 97 GLOBAL AGRICULTURE IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 98 GLOBAL AGRICULTURE IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 99 GLOBAL AGRICULTURE IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 100 GLOBAL SEMICONDUCTOR IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 101 GLOBAL SEMICONDUCTOR IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 102 GLOBAL SEMICONDUCTOR IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 103 GLOBAL OTHERS IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 104 GLOBAL HEAVY DUTY CONNECTOR MARKET, BY DISTRIBUTION CHANNEL, 2018-2032 (USD THOUSAND)

TABLE 105 GLOBAL OEM IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 106 GLOBAL AFTERMARKET IN HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 107 GLOBAL AFTERMARKET IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 108 GLOBAL HEAVY DUTY CONNECTOR MARKET, BY REGION, 2018-2032, (USD THOUSAND)

TABLE 109 ASIA-PACIFIC HEAVY DUTY CONNECTOR MARKET, BY COUNTRY, 2018-2032 (USD THOUSAND)

TABLE 110 ASIA-PACIFIC HEAVY DUTY CONNECTOR MARKET, BY COMPONENT, 2018-2032 (USD THOUSAND)

TABLE 111 ASIA-PACIFIC BASES IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 112 ASIA-PACIFIC HOOD IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 113 ASIA-PACIFIC LATCHING IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 114 ASIA-PACIFIC ACCESSORIES IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 115 ASIA-PACIFIC HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 116 ASIA-PACIFIC RECTANGULAR CONNECTORS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 117 ASIA-PACIFIC MODULAR CONNECTORS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 118 ASIA-PACIFIC HEAVY DUTY CONNECTOR MARKET, BY MATERIAL, 2018-2032 (USD THOUSAND)

TABLE 119 ASIA-PACIFIC METAL IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 120 ASIA-PACIFIC PLASTIC / POLYMER IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 121 ASIA-PACIFIC HEAVY DUTY CONNECTOR MARKET, BY TERMINATION METHOD, 2018-2032 (USD THOUSAND)

TABLE 122 ASIA-PACIFIC HEAVY DUTY CONNECTOR MARKET, BY VOLTAGE, 2018-2032 (USD THOUSAND)

TABLE 123 ASIA-PACIFIC HEAVY DUTY CONNECTOR MARKET, BY MOUNTING TYPE, 2018-2032 (USD THOUSAND)

TABLE 124 ASIA-PACIFIC HEAVY DUTY CONNECTOR MARKET, BY CURRENT, 2018-2032 (USD THOUSAND)

TABLE 125 ASIA-PACIFIC HEAVY DUTY CONNECTOR MARKET, BY RATING, 2018-2032 (USD THOUSAND)

TABLE 126 ASIA-PACIFIC IP RATING IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 127 ASIA-PACIFIC NEMA RATING IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 128 ASIA-PACIFIC HEAVY DUTY CONNECTOR MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 129 ASIA-PACIFIC PRODUCTION, DEVICE AND SYSTEMS MANUFACTURING IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 130 ASIA-PACIFIC PRODUCTION, DEVICE AND SYSTEMS MANUFACTURING IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 131 ASIA-PACIFIC POWER IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 132 ASIA-PACIFIC POWER IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 133 ASIA-PACIFIC PROCESS INDUSTRY IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 134 ASIA-PACIFIC PROCESS INDUSTRY IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 135 ASIA-PACIFIC INFRASTRUCTURE IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 136 ASIA-PACIFIC INFRASTRUCTURE IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 137 ASIA-PACIFIC CONSTRUCTION MACHINERY IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 138 ASIA-PACIFIC CONSTRUCTION MACHINERY IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 139 ASIA-PACIFIC E-MOBILITY IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 140 ASIA-PACIFIC ELECTRIC VEHICLES IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 141 ASIA-PACIFIC BATTERY PACKS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 142 ASIA-PACIFIC BATTERY MANAGEMENT SYSTEM IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 143 ASIA-PACIFIC ON BOARD CHARGER IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 144 ASIA-PACIFIC MOTOR CONTROL UNIT (MCU) IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 145 ASIA-PACIFIC VEHICLE CONTROL UNIT (VCU) IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 146 ASIA-PACIFIC ELECTRONIC CONTROL UNIT (ECU) IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 147 ASIA-PACIFIC E-MOTOR IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 148 ASIA-PACIFIC INTERNAL COMBUSTION ENGINE IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 149 ASIA-PACIFIC CHARGING STATIONS, GUNS, AND WALL BOXES IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 150 ASIA-PACIFIC INFOTAINMENT, NAVIGATOR AND SOUND SYSTEMS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 151 ASIA-PACIFIC LIGHTING SYSTEMS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 152 ASIA-PACIFIC SEATS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 153 ASIA-PACIFIC AIRBAGS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 154 ASIA-PACIFIC HVAC SYSTEMS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 155 ASIA-PACIFIC PARKING ASSISTANCE SYSTEM IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 156 ASIA-PACIFIC E-MOBILITY IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 157 ASIA-PACIFIC LOGISTICS IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 158 ASIA-PACIFIC LOGISTICS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 159 ASIA-PACIFIC MEDICAL / HEALTHCARE IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 160 ASIA-PACIFIC MEDICAL / HEALTHCARE IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 161 ASIA-PACIFIC AGRICULTURE IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 162 ASIA-PACIFIC AGRICULTURE IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 163 ASIA-PACIFIC SEMICONDUCTOR IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 164 ASIA-PACIFIC SEMICONDUCTOR IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 165 ASIA-PACIFIC HEAVY DUTY CONNECTOR MARKET, BY DISTRIBUTION CHANNEL, 2018-2032 (USD THOUSAND)

TABLE 166 ASIA-PACIFIC AFTERMARKET IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 167 CHINA HEAVY DUTY CONNECTOR MARKET, BY COMPONENT, 2018-2032 (USD THOUSAND)

TABLE 168 CHINA BASES IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 169 CHINA HOOD IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 170 CHINA LATCHING IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 171 CHINA ACCESSORIES IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 172 CHINA HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 173 CHINA RECTANGULAR CONNECTORS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 174 CHINA MODULAR CONNECTORS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 175 CHINA HEAVY DUTY CONNECTOR MARKET, BY MATERIAL, 2018-2032 (USD THOUSAND)

TABLE 176 CHINA METAL IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 177 CHINA PLASTIC / POLYMER IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 178 CHINA HEAVY DUTY CONNECTOR MARKET, BY TERMINATION METHOD, 2018-2032 (USD THOUSAND)

TABLE 179 CHINA HEAVY DUTY CONNECTOR MARKET, BY VOLTAGE, 2018-2032 (USD THOUSAND)

TABLE 180 CHINA HEAVY DUTY CONNECTOR MARKET, BY MOUNTING TYPE, 2018-2032 (USD THOUSAND)

TABLE 181 CHINA HEAVY DUTY CONNECTOR MARKET, BY CURRENT, 2018-2032 (USD THOUSAND)

TABLE 182 CHINA HEAVY DUTY CONNECTOR MARKET, BY RATING, 2018-2032 (USD THOUSAND)

TABLE 183 CHINA IP RATING IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 184 CHINA NEMA RATING IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 185 CHINA HEAVY DUTY CONNECTOR MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 186 CHINA PRODUCTION, DEVICE AND SYSTEMS MANUFACTURING IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 187 CHINA PRODUCTION, DEVICE AND SYSTEMS MANUFACTURING IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 188 CHINA POWER IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 189 CHINA POWER IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 190 CHINA PROCESS INDUSTRY IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 191 CHINA PROCESS INDUSTRY IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 192 CHINA INFRASTRUCTURE IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 193 CHINA INFRASTRUCTURE IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 194 CHINA CONSTRUCTION MACHINERY IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 195 CHINA CONSTRUCTION MACHINERY IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 196 CHINA E-MOBILITY IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 197 CHINA ELECTRIC VEHICLES IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 198 CHINA BATTERY PACKS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 199 CHINA BATTERY MANAGEMENT SYSTEM IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 200 CHINA ON BOARD CHARGER IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 201 CHINA MOTOR CONTROL UNIT (MCU) IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 202 CHINA VEHICLE CONTROL UNIT (VCU) IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 203 CHINA ELECTRONIC CONTROL UNIT (ECU) IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 204 CHINA E-MOTOR IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 205 CHINA INTERNAL COMBUSTION ENGINE IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 206 CHINA CHARGING STATIONS, GUNS, AND WALL BOXES IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 207 CHINA INFOTAINMENT, NAVIGATOR AND SOUND SYSTEMS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 208 CHINA LIGHTING SYSTEMS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 209 CHINA SEATS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 210 CHINA AIRBAGS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 211 CHINA HVAC SYSTEMS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 212 CHINA PARKING ASSISTANCE SYSTEM IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 213 CHINA E-MOBILITY IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 214 CHINA LOGISTICS IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 215 CHINA LOGISTICS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 216 CHINA MEDICAL / HEALTHCARE IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 217 CHINA MEDICAL / HEALTHCARE IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 218 CHINA AGRICULTURE IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 219 CHINA AGRICULTURE IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 220 CHINA SEMICONDUCTOR IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 221 CHINA SEMICONDUCTOR IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 222 CHINA HEAVY DUTY CONNECTOR MARKET, BY DISTRIBUTION CHANNEL, 2018-2032 (USD THOUSAND)

TABLE 223 CHINA AFTERMARKET IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 224 JAPAN HEAVY DUTY CONNECTOR MARKET, BY COMPONENT, 2018-2032 (USD THOUSAND)

TABLE 225 JAPAN BASES IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 226 JAPAN HOOD IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 227 JAPAN LATCHING IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 228 JAPAN ACCESSORIES IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 229 JAPAN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 230 JAPAN RECTANGULAR CONNECTORS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 231 JAPAN MODULAR CONNECTORS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 232 JAPAN HEAVY DUTY CONNECTOR MARKET, BY MATERIAL, 2018-2032 (USD THOUSAND)

TABLE 233 JAPAN METAL IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 234 JAPAN PLASTIC / POLYMER IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 235 JAPAN HEAVY DUTY CONNECTOR MARKET, BY TERMINATION METHOD, 2018-2032 (USD THOUSAND)

TABLE 236 JAPAN HEAVY DUTY CONNECTOR MARKET, BY VOLTAGE, 2018-2032 (USD THOUSAND)

TABLE 237 JAPAN HEAVY DUTY CONNECTOR MARKET, BY MOUNTING TYPE, 2018-2032 (USD THOUSAND)

TABLE 238 JAPAN HEAVY DUTY CONNECTOR MARKET, BY CURRENT, 2018-2032 (USD THOUSAND)

TABLE 239 JAPAN HEAVY DUTY CONNECTOR MARKET, BY RATING, 2018-2032 (USD THOUSAND)

TABLE 240 JAPAN IP RATING IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 241 JAPAN NEMA RATING IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 242 JAPAN HEAVY DUTY CONNECTOR MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 243 JAPAN PRODUCTION, DEVICE AND SYSTEMS MANUFACTURING IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 244 JAPAN PRODUCTION, DEVICE AND SYSTEMS MANUFACTURING IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 245 JAPAN POWER IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 246 JAPAN POWER IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 247 JAPAN PROCESS INDUSTRY IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 248 JAPAN PROCESS INDUSTRY IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 249 JAPAN INFRASTRUCTURE IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 250 JAPAN INFRASTRUCTURE IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 251 JAPAN CONSTRUCTION MACHINERY IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 252 JAPAN CONSTRUCTION MACHINERY IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 253 JAPAN E-MOBILITY IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 254 JAPAN ELECTRIC VEHICLES IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 255 JAPAN BATTERY PACKS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 256 JAPAN BATTERY MANAGEMENT SYSTEM IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 257 JAPAN ON BOARD CHARGER IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 258 JAPAN MOTOR CONTROL UNIT (MCU) IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 259 JAPAN VEHICLE CONTROL UNIT (VCU) IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 260 JAPAN ELECTRONIC CONTROL UNIT (ECU) IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 261 JAPAN E-MOTOR IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 262 JAPAN INTERNAL COMBUSTION ENGINE IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 263 JAPAN CHARGING STATIONS, GUNS, AND WALL BOXES IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 264 JAPAN INFOTAINMENT, NAVIGATOR AND SOUND SYSTEMS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 265 JAPAN LIGHTING SYSTEMS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 266 JAPAN SEATS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 267 JAPAN AIRBAGS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 268 JAPAN HVAC SYSTEMS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 269 JAPAN PARKING ASSISTANCE SYSTEM IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 270 JAPAN E-MOBILITY IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 271 JAPAN LOGISTICS IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 272 JAPAN LOGISTICS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 273 JAPAN MEDICAL / HEALTHCARE IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 274 JAPAN MEDICAL / HEALTHCARE IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 275 JAPAN AGRICULTURE IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 276 JAPAN AGRICULTURE IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 277 JAPAN SEMICONDUCTOR IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 278 JAPAN SEMICONDUCTOR IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 279 JAPAN HEAVY DUTY CONNECTOR MARKET, BY DISTRIBUTION CHANNEL, 2018-2032 (USD THOUSAND)

TABLE 280 JAPAN AFTERMARKET IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 281 INDIA HEAVY DUTY CONNECTOR MARKET, BY COMPONENT, 2018-2032 (USD THOUSAND)

TABLE 282 INDIA BASES IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 283 INDIA HOOD IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 284 INDIA LATCHING IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 285 INDIA ACCESSORIES IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 286 INDIA HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 287 INDIA RECTANGULAR CONNECTORS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 288 INDIA MODULAR CONNECTORS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 289 INDIA HEAVY DUTY CONNECTOR MARKET, BY MATERIAL, 2018-2032 (USD THOUSAND)

TABLE 290 INDIA METAL IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 291 INDIA PLASTIC / POLYMER IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 292 INDIA HEAVY DUTY CONNECTOR MARKET, BY TERMINATION METHOD, 2018-2032 (USD THOUSAND)

TABLE 293 INDIA HEAVY DUTY CONNECTOR MARKET, BY VOLTAGE, 2018-2032 (USD THOUSAND)

TABLE 294 INDIA HEAVY DUTY CONNECTOR MARKET, BY MOUNTING TYPE, 2018-2032 (USD THOUSAND)

TABLE 295 INDIA HEAVY DUTY CONNECTOR MARKET, BY CURRENT, 2018-2032 (USD THOUSAND)

TABLE 296 INDIA HEAVY DUTY CONNECTOR MARKET, BY RATING, 2018-2032 (USD THOUSAND)

TABLE 297 INDIA IP RATING IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 298 INDIA NEMA RATING IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 299 INDIA HEAVY DUTY CONNECTOR MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 300 INDIA PRODUCTION, DEVICE AND SYSTEMS MANUFACTURING IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 301 INDIA PRODUCTION, DEVICE AND SYSTEMS MANUFACTURING IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 302 INDIA POWER IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 303 INDIA POWER IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 304 INDIA PROCESS INDUSTRY IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 305 INDIA PROCESS INDUSTRY IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 306 INDIA INFRASTRUCTURE IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 307 INDIA INFRASTRUCTURE IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 308 INDIA CONSTRUCTION MACHINERY IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 309 INDIA CONSTRUCTION MACHINERY IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 310 INDIA E-MOBILITY IN HEAVY DUTY CONNECTOR MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 311 INDIA ELECTRIC VEHICLES IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 312 INDIA BATTERY PACKS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 313 INDIA BATTERY MANAGEMENT SYSTEM IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 314 INDIA ON BOARD CHARGER IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 315 INDIA MOTOR CONTROL UNIT (MCU) IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 316 INDIA VEHICLE CONTROL UNIT (VCU) IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 317 INDIA ELECTRONIC CONTROL UNIT (ECU) IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 318 INDIA E-MOTOR IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 319 INDIA INTERNAL COMBUSTION ENGINE IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 320 INDIA CHARGING STATIONS, GUNS, AND WALL BOXES IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 321 INDIA INFOTAINMENT, NAVIGATOR AND SOUND SYSTEMS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 322 INDIA LIGHTING SYSTEMS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 323 INDIA SEATS IN HEAVY DUTY CONNECTOR MARKET, BY TYPE, 2018-2032 (USD THOUSAND)