Global Heat Shrink Tubing Market

Market Size in USD Billion

CAGR :

%

USD

2.17 Billion

USD

3.49 Billion

2024

2032

USD

2.17 Billion

USD

3.49 Billion

2024

2032

| 2025 –2032 | |

| USD 2.17 Billion | |

| USD 3.49 Billion | |

|

|

|

|

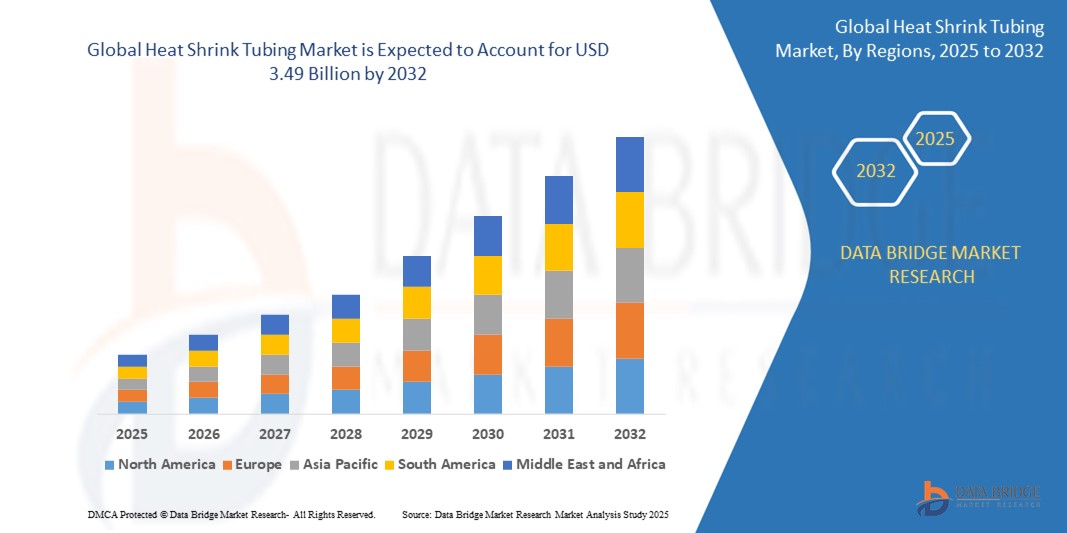

What is the Global Heat Shrink Tubing Market Size and Growth Rate?

- The global heat shrink tubing market size was valued at USD 2.17 billion in 2024 and is expected to reach USD 3.49 billion by 2032, at a CAGR of 6.10% during the forecast period

- The global heat shrink tubing market is experiencing significant growth due to its extensive applications across industries such as electronics, automotive, aerospace, and telecommunications

- This tubing is valued for its ability to provide insulation, environmental protection, and strain relief for wires, connectors, and other components, helping to safeguard them from moisture, chemicals, and abrasion

What are the Major Takeaways of Heat Shrink Tubing Market?

- The electric power transmission and distribution (T&D) system serves as a crucial link between generating stations and consumers, and its efficiency is becoming increasingly important due to growing electricity demands and the stresses posed by aging infrastructure, which elevate the risk of widespread blackouts. In today’s society, reliable and cost-effective electricity delivery is essential

- The U.S. T&D landscape includes various economic drivers, organizational frameworks, technologies, and regulatory oversight from federal, municipal, state, and customer-owned cooperatives

- Asia-Pacific dominated the global heat shrink tubing market, accounting for the largest revenue share of 46.2% in 2024, driven by rapid industrialization, robust growth in telecommunications, automotive, and electronics sectors, and increased infrastructure development across emerging economies

- North America heat shrink tubing market is projected to grow at the fastest CAGR of 16.1% from 2025 to 2032, driven by rising investments in energy infrastructure, electric vehicles, and telecommunications

- The Single Wall segment dominated the heat shrink tubing market with the largest revenue share of 57.2% in 2024, attributed to its broad application across electrical insulation, protection, and bundling of wires and cables in multiple industries

Report Scope and Heat Shrink Tubing Market Segmentation

|

Attributes |

Heat Shrink Tubing Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

What is the Key Trend in the Heat Shrink Tubing Market?

“Rising Shift towards Eco-Friendly, Halogen-Free Heat Shrink Tubing”

- The global heat shrink tubing market is experiencing growth due to the increasing demand for robust insulation solutions across industries such as automotive, electronics, and telecommunications

- A key trend driving this market is the shift toward eco-friendly, halogen-free heat shrink tubing, driven by heightened environmental regulations and corporate sustainability goals

- For instance, electric vehicle (EV) manufacturers are increasingly adopting halogen-free tubing to ensure flame resistance while reducing toxic emissions in case of fire, enhancing both safety and sustainability

- Heat shrink tubing offers protective, space-saving insulation that enhances wire durability and performance, especially in high-stress, high-temperature environments. With the rise of EVs and advanced electronics, this tubing solution is being extensively used to shield against moisture, abrasion, and chemical exposure, crucial in settings such as automotive battery systems

- As industries focus on minimizing environmental impact, demand for eco-friendly heat shrink tubing is projected to further expand in the coming years

What are the Key Drivers of Heat Shrink Tubing Market?

- The growing demand for self-service banking, branch automation, and enhanced customer convenience is a significant driver of the Heat Shrink Tubing market worldwide. Financial institutions are investing heavily in kiosks to reduce operational costs, increase efficiency, and extend banking services beyond traditional locations

- For instance, in September 2024, Ashley Furniture Industries announced an USD 80 million investment to expand operations, reflecting broader industry trends where organizations are modernizing infrastructure and deploying kiosks to serve evolving consumer needs

- The rising emphasis on financial inclusion, particularly in emerging markets, is accelerating the adoption of heat shrink tubing that offer critical services such as account opening, cash deposits/withdrawals, and loan applications in both urban and rural areas

- The rapid expansion of digital banking, coupled with the need for contactless, 24/7 service delivery, further propels kiosk deployments. AI-powered functionalities and real-time customer assistance enable banks to offer efficient, secure, and user-friendly services, improving accessibility and satisfaction

- In addition, technological advancements such as biometric authentication, touchscreen interfaces, and video teller machines are making kiosks a central component of modern banking, especially for enhancing service delivery in high-footfall locations

Which Factor is challenging the Growth of the Heat Shrink Tubing Market?

- Price fluctuations in raw materials significantly impact the procurement of cable, wire, and connectivity products, influencing budget projections in finance, supply chain management, and product development

- With the surge in industrial production and robust sustainable energy initiatives, China has become the largest consumer of copper globally. Countries such as Europe, the U.S., and China are aggressively pursuing renewable energy strategies to promote greener economies, and copper's exceptional thermal and electrical conductivity is essential for achieving these goals.

- However, leading copper-producing nations, including Chile, Peru, China, and the United States, are struggling to meet the soaring demand associated with these green initiatives, driving copper prices to unprecedented levels

- In addition, speculation suggests that as the U.S. dollar weakens against other global currencies, users of those currencies may find their purchasing power for copper and other commodities increasing. This situation presents a significant market challenge for businesses reliant on these materials, as rising costs can affect profitability and project feasibility

How is the Heat Shrink Tubing Market Segmented?

The market is segmented on the basis of type, product type, voltage, shrink ratio, material, and end-user.

- By Type

On the basis of type, the heat shrink tubing market is segmented into Single Wall and Dual Wall. The Single Wall segment dominated the Heat Shrink Tubing market with the largest revenue share of 57.2% in 2024, attributed to its broad application across electrical insulation, protection, and bundling of wires and cables in multiple industries. Its cost-effectiveness, flexibility, and ease of installation make it a preferred choice for both industrial and consumer applications.

The Dual Wall segment is expected to witness the fastest CAGR from 2025 to 2032, driven by increasing demand for advanced tubing solutions that provide both insulation and adhesive-lined sealing for enhanced environmental protection in automotive, aerospace, and marine industries.

- By Product Type

On the basis of product type, the market is segmented into Spools, Pre-Cut Length, and Others. The Spools segment held the largest revenue share of 49.8% in 2024, supported by high demand in large-scale manufacturing and assembly lines, where bulk tubing is required for continuous operations. The spool format offers convenience, cost savings, and operational efficiency for various industries.

The Pre-Cut Length segment is anticipated to register the fastest growth rate during the forecast period, driven by rising adoption in maintenance, repair, and consumer applications, where ready-to-use, pre-sized tubing enhances convenience and reduces waste.

- By Voltage

On the basis of voltage, the heat shrink tubing market is segmented into Low, Medium, and High voltage. The Low Voltage segment accounted for the largest market share of 61.4% in 2024, driven by its widespread use in consumer electronics, automotive wiring, and low-voltage cable assemblies. These products are essential for insulation, abrasion protection, and wire bundling in everyday applications.

The High Voltage segment is expected to grow at the fastest CAGR, propelled by rising demand in utility, industrial, and energy sectors where tubing must withstand extreme conditions and provide superior electrical insulation for high-power transmission lines and equipment.

- By Shrink Ratio

On the basis of shrink ratio, the market is segmented into 2:1, 3:1, 4:1, 6:1, and Others. The 2:1 segment dominated the market with the largest revenue share of 44.5% in 2024, owing to its cost-efficiency and suitability for a broad range of general-purpose applications such as wire insulation, strain relief, and cable bundling across industries.

The 4:1 segment is projected to experience the fastest growth during the forecast period, driven by increasing demand for applications requiring larger diameter reductions and superior sealing performance, especially in harsh environments such as marine, automotive, and heavy industrial sectors.

- By Material

On the basis of material, the market is segmented into Polyolefin, Perfluoroalkoxy Alkanes (PFA), Polytetrafluoroethylene (PTFE), Ethylene Tetra Fluoro Ethylene (ETFE), Fluorinated Ethylene Propylene (FEP), Polyetheretherketone (PEEK), and Others. The Polyolefin segment dominated the market with the largest revenue share of 66.7% in 2024, due to its excellent balance of flexibility, durability, flame resistance, and electrical insulation properties, making it the preferred material for a wide range of industrial and consumer applications.

The PEEK segment is expected to grow at the fastest CAGR, driven by its exceptional mechanical strength, chemical resistance, and thermal stability, making it ideal for high-performance applications in aerospace, defense, and critical electronics sectors.

- By End-user

On the basis of end-user, the market is segmented into Utilities, IT and Telecommunication, Automotive, Electronics, Aerospace, Healthcare, Oil and Gas, Marine, Food and Beverages, Construction, Chemical, and Others. The Automotive segment held the largest revenue share of 23.9% in 2024, fueled by the growing need for reliable electrical insulation, wire protection, and sealing solutions to enhance vehicle safety and durability amid rising vehicle electrification trends.

The Aerospace segment is anticipated to register the fastest growth rate during the forecast period, driven by stringent safety standards and the increasing demand for lightweight, high-performance insulation solutions capable of withstanding extreme temperatures and harsh operating environments.

Which Region Holds the Largest Share of the Heat Shrink Tubing Market?

- Asia-Pacific dominated the global heat shrink tubing market, accounting for the largest revenue share of 46.2% in 2024, driven by rapid industrialization, robust growth in telecommunications, automotive, and electronics sectors, and increased infrastructure development across emerging economies

- Countries such as China, India, Japan, and South Korea are leading the demand for heat shrink tubing due to growing investments in power distribution, 5G networks, and electric vehicle (EV) manufacturing, where insulation, protection, and cable management are critical

- The region's thriving manufacturing ecosystem, coupled with the increasing focus on safety, durability, and energy-efficient solutions, continues to solidify Asia-Pacific's position as the global leader in the heat shrink tubing market

China Heat Shrink Tubing Market Insight

The China heat shrink tubing market accounted for the largest revenue share in Asia-Pacific in 2024, supported by the country’s dominant position in electronics, automotive, and renewable energy industries. The rapid expansion of EV production, smart grid projects, and industrial automation is fueling demand for reliable insulation and protection solutions. Moreover, government policies promoting infrastructure development and technological advancements are further accelerating market growth.

India Heat Shrink Tubing Market Insight

The India heat shrink tubing market is projected to grow significantly, driven by increased investments in energy distribution, telecommunications infrastructure, and railway electrification. With rising demand for affordable, high-performance insulation materials in utilities and automotive industries, manufacturers are expanding their product offerings to cater to the diverse needs of the Indian market. Government initiatives such as "Make in India" and expanding renewable energy capacity further support the adoption of heat shrink tubing across key sectors.

Japan Heat Shrink Tubing Market Insight

The Japan heat shrink tubing market is witnessing steady growth, fueled by the country's mature automotive, electronics, and aerospace industries, where reliability and high-performance materials are paramount. The demand for advanced insulation and protective tubing in precision applications, alongside Japan’s strong emphasis on product quality and technological innovation, is boosting market expansion. The growing adoption of EVs and renewable energy systems further supports the demand for heat shrink solutions in the country.

Which Region is the Fastest Growing in the Heat Shrink Tubing Market?

North America heat shrink tubing market is projected to grow at the fastest CAGR of 16.1% from 2025 to 2032, driven by rising investments in energy infrastructure, electric vehicles, and telecommunications. The increasing focus on modernizing aging grid networks, coupled with growing demand for reliable, high-performance cable insulation in harsh environments, is fueling market growth across the region.

U.S. Heat Shrink Tubing Market Insight

The U.S. heat shrink tubing market dominated the revenue share within North America in 2024, supported by strong demand from defense, aerospace, automotive, and data center industries. The rapid deployment of 5G infrastructure, rising EV production, and the need for robust electrical insulation in extreme environments are driving product adoption. In addition, stringent safety regulations and the focus on improving operational efficiency across industrial applications further contribute to market expansion.

Canada Heat Shrink Tubing Market Insight

The Canada heat shrink tubing market is poised for notable growth, driven by increasing investments in renewable energy projects, telecommunications expansion, and infrastructure upgrades. The demand for high-performance insulation solutions in the oil & gas, utilities, and automotive sectors is encouraging greater use of heat shrink tubing. In addition, Canada’s growing emphasis on sustainability and energy efficiency is driving the adoption of durable, environmentally friendly insulation materials.

Which are the Top Companies in Heat Shrink Tubing Market?

The heat shrink tubing industry is primarily led by well-established companies, including:

- ABB (Switzerland)

- Sumitomo Electric Industries, Ltd. (Japan)

- TE Connectivity (Switzerland)

- Thermosleeve USA (U.S.)

- Techflex, Inc. (U.S.)

- Dasheng Group (China)

- Shenzhen Woer Heat - Shrinkable Material Co., Ltd. (China)

- Huizhou Guanghai Electronic Insulation Materials Co., Ltd. (China)

- Panduit (U.S.)

- HellermannTyton (Germany)

- Alpha Wire (U.S.)

- 3M (U.S.)

- SHAWCOR (Canada)

- Zeus Industrial Products, Inc. (U.S.)

- Molex (U.S.)

- PEXCO (U.S.)

- Prysmian Group (Italy)

- GREMCO GmbH (Germany)

- Qualtek Electronics Corp. (U.S.)

- Hilltop (U.K.)

- Dunbar Products, LLC. (U.S.)

- Changyuan Electronics (Dongguan) Co., Ltd. (China)

What are the Recent Developments in Global Heat Shrink Tubing Market?

- In October 2024, Junkosha, a materials specialist and leader in peelable heat shrink tubing (PHST) technology, introduced six new sizes of its 1.8:1 shrink ratio Translucent PHST solution. This addition provides an expanded range of sizes, both small and large, and reflects Junkosha's dedication to delivering innovative, customer-focused solutions in the medical device industry

- In July 2024, Cortec launched the VpCI-126 Shrink Film, a product combining advanced film technology with effective corrosion protection. Designed to prevent rust, tarnish, stains, white rust, and oxidation on various metals, this shrink film offers up to five years of protection and simplifies product sealing processes

- In February 2024, Medical Extrusion Technologies (MET) launched over thirty sizes of FEP heat shrink tubing for the medical device sector on the Chamfr.com platform. MET’s FEP Heat Shrink is designed to provide controlled elongational growth after recovery, with 2%-5% elongation versus the standard 10%, catering specifically to R&D needs in medical device development

- In April 2023, TE Connectivity introduced its new EV Single Wall (EVSW) tubing, designed specifically for high-voltage applications to provide electrical insulation and protection for conductive components and cables. This product, a single-wall tube, focuses on safeguarding high-voltage components in electric vehicles. By offering this innovative solution, the company aims to diversify its product portfolio and address the unique challenges associated with EV applications

- In April 2021, 3M introduced new silicone adhesives to improve medical devices for individuals with fragile skin, reinforcing its commitment to innovative, patient-centered healthcare solutions

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.