Market Analysis and Insights of Gas Delivery System for Wafer Fab Equipment Market

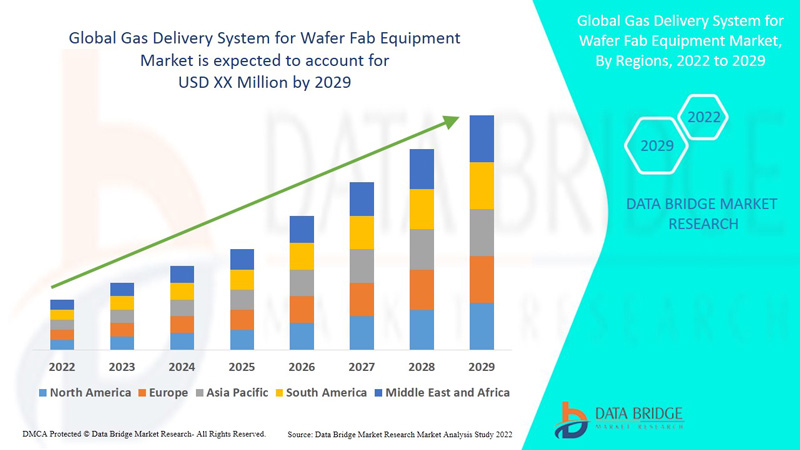

Growing demand form the semiconductors and materials industry especially in the emerging economies, rising up gradation of existing infrastructure with advanced systems and increasing infrastructural development activities are the major factors attributable to the growth of gas delivery system for wafer fab equipment market. Data Bridge Market Research analyses that the gas delivery system for wafer fab equipment market will exhibit a CAGR of 8.80% for the forecast period of 2022-2029.

Gas delivery stems are the safe and effective mode of transportation and storage of toxic and hazardous materials. Wafer fab process is used in the production of photonic and electrical circuits such as radio frequency amplifiers (RFA), and optical computer components. Therefore, the wafer fab equipment helps in building components with required electrical structures.

Rising globalization and growing usage of high purity gases will emerge as the major market growth driving factors. Growing need to adopt international measurement standards, surging technological advancements in telecom and semiconductor sector, increasing buildings and construction activities especially in the developing economies, and widespread industrialization will further aggravate the market value. Growing expenditure to undertake research and development proficiencies, surging inspection, measurement and quality control activities in different manufacturing industries, growing demand from consumer electronics industry and growing demand for optimum resource utilization will further carve the way for the growth of the market.

However, high costs associated with the research and development proficiencies will act as a growth restraint for the market. Complexities associated with the gas delivery systems will further dampen the growth rate of the market. Large scale technological limitations in the underdeveloped economies will further challenge the market growth rate.

This gas delivery system for wafer fab equipment market report provides details of new recent developments, trade regulations, import export analysis, production analysis, value chain optimization, market share, impact of domestic and localised market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographical expansions, technological innovations in the market. To gain more info on gas delivery system for wafer fab equipment market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Global Gas Delivery System for Wafer Fab Equipment Market Scope and Market Size

The gas delivery system for wafer fab equipment market is segmented on the basis of bulk gas type, type, component and specialty gases type. The growth amongst the different segments helps you in attaining the knowledge related to the different growth factors expected to be prevalent throughout the market and formulate different strategies to help identify core application areas and the difference in your target market.

- On the basis of bulk gas type, the gas delivery system for wafer fab equipment market has been segmented into atmospheric gases, hydrogen, helium and acetylene.

- Based on type, the gas delivery system for wafer fab equipment market has been segmented into semi-automatic switchover systems, fully automatic programmable switchover systems and single station systems.

- On the basis of component, the gas delivery system for wafer fab equipment market has been segmented into gas cylinders, manifolds, gas cabinets, switchovers, protocol stations and changeovers.

- The specialty gases type segment is segmented into ammonia (NH3), hydrogen chloride (HCL), tungsten hexafluoride (WF6), nitrogen trifluoride (NF3), nitrous oxide (N2O), disilane (SI2H6), germane (GEH4) and high Purity carbon dioxide (CO2).

Gas Delivery System for Wafer Fab Equipment Market Country Level Analysis

The gas delivery system for wafer fab equipment market is analysed and market size, volume information is provided by country, bulk gas type, type, component and specialty gases type as referenced above.

The countries covered in the gas delivery system for wafer fab equipment market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, Israel, Egypt, South Africa, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

North America region dominates the gas delivery system for wafer fab equipment market and will continue to flourish its trend of dominance during the forecast period owing to the strong presence of major manufacturers in this region. Asia-Pacific region is projected to undergo substantial gains and score the highest CAGR for this period. This is because of the growth and expansion of semiconductors industry in this region.

The country section of the gas delivery system for wafer fab equipment market report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as consumption volumes, production sites and volumes, import export analysis, price trend analysis, cost of raw materials, down-stream and upstream value chain analysis are some of the major pointers used to forecast the market scenario for individual countries. Also, presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Competitive Landscape and Gas Delivery System for Wafer Fab Equipment Market Share Analysis

The gas delivery system for wafer fab equipment market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies’ focus related to gas delivery system for wafer fab equipment market.

Some of the major players operating in the gas delivery system for wafer fab equipment market are Linde plc, Messer SE & Co. KGaA, GCE Group, CVD Equipment Corporation, Applied Energy Systems, Inc., Indiana Oxygen, Critical Process Systems Group, INTEGA GmbH, Powerblanket, IEEE, Kelington Group Berhad, Critical Systems, Inc., Ichor Systems, MATHESON TRI-GAS, INC., Praxair Technology, Inc., Air Products Inc., Iwatani Corporation, BASF SE, Air Liquide and Colfax Corporation among others.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Table of Content

1 INTRODUCTION

1.1 OBJECTIVES OF THE STUDY

1.2 MARKET DEFINITION

1.3 OVERVIEW OF GLOBAL GAS DELIVERY SYSTEM FOR WAFER FAB EQUIPMENT MARKET

1.4 CURRENCY AND PRICING

1.5 LIMITATION

1.6 MARKETS COVERED

2 MARKET SEGMENTATION

2.1 KEY TAKEAWAYS

2.2 ARRIVING AT THE GLOBAL GAS DELIVERY SYSTEM FOR WAFER FAB EQUIPMENTMARKET SIZE

2.2.1 VENDOR POSITIONING GRID

2.2.2 TECHNOLOGY LIFE LINE CURVE

2.2.3 MARKET GUIDE

2.2.4 COMPANY POSITIONING GRID

2.2.5 MULTIVARIATE MODELLING

2.2.6 STANDARDS OF MEASUREMENT

2.2.7 TOP TO BOTTOM ANALYSIS

2.2.8 VENDOR SHARE ANALYSIS

2.2.9 DATA POINTS FROM KEY PRIMARY INTERVIEWS

2.2.10 DATA POINTS FROM KEY SECONDARY DATABASES

2.3 GLOBAL GAS DELIVERY SYSTEM FOR WAFER FAB EQUIPMENT MARKET: RESEARCH SNAPSHOT

2.4 ASSUMPTIONS

3 MARKET OVERVIEW

3.1 DRIVERS

3.2 RESTRAINTS

3.3 OPPORTUNITIES

3.4 CHALLENGES

4 EXECUTIVE SUMMARY

5 PREMIUM INSIGHTS

5.1 TECHNOLOGY ANALYSIS

5.2 PORTERS FIVE FORCES ANALYSIS

5.3 CASE STUDIES

5.4 IMPACT OF ECONOMIC SLOWDOWN

6 GLOBAL GAS DELIVERY SYSTEM FOR WAFER FAB EQUIPMENT MARKET,BY TYPE

6.1 OVERVIEW

6.2 SEMI AUTOMATIC SWITCHOVER SYSTEMS

6.3 FULLY AUTOMATIC PROGRAMMABLE SWITCHOVER SYSTEMS

6.4 SINGLE STATION SYSTEMS

7 GLOBAL GAS DELIVERY SYSTEM FOR WAFER FAB EQUIPMENT MARKET,BY SUB-SYSTEM

7.1 OVERVIEW

7.2 GAS SOURCES

7.2.1 CYLINDERS

7.2.2 BULK STORAGE TANKS

7.2.3 ON-SITE GAS GENERATION SYSTEMS

7.3 GAS DISTRIBUTION SYSTEMS

7.3.1 PIPES

7.3.2 VALVES

7.3.3 REGULATORS

7.4 LIQUID CHEMICAL DISTRIBUTION SYSTEM

7.5 CMP (CHEMICAL MECHANICAL POLISHING) SLURRY DELIVERY SYSTEM

7.6 PURIFICATION SYSTEM

7.6.1 FILTERS

7.6.2 SCRUBBERS

7.6.3 PURIFIERS

7.7 PRESSURE CONTROL SYSTEM

7.7.1 PRESSURE REGULATORS

7.7.2 FLOW CONTROLLERS

7.8 MONITORING AND SAFETY SYSTEM

7.8.1 GAS LEAK DETECTION SENSORS

7.8.2 PRESSURE RELIEF VALVES

7.8.3 EMERGENCY SHUT-OFF SYSTEMS

7.8.4 ALARMS

7.9 MASS FLOW MEASUREMENT SYSTEM

7.1 CONTROL AND AUTOMATION SYSTEM

7.10.1 CONTROL SOFTWARE

7.10.2 PROCESS CONTROL ALGORITHMS

7.10.3 COMMUNICATION INTERFACES

7.10.4 SENSOR INTEGRATION

7.10.5 RECIPE MANAGEMENT

7.10.6 DATA LOGGING AND ANALYSIS

7.10.7 AUTOMATION AND SEQUENCING

7.10.8 INTEGRATION WITH EQUIPMENT CONTROL

8 GLOBAL GAS DELIVERY SYSTEM FOR WAFER FAB EQUIPMENT MARKET, BY BULK GAS TYPE

8.1 OVERVIEW

8.2 ATMOSPHERIC GASES

8.2.1 NITROGEN

8.2.2 ARGON

8.2.3 CARBON DIOXIDE

8.3 OXYGEN

8.4 HYDROGEN

8.5 ACETYLENE

8.6 HELIUM

8.7 OTHERS

9 GLOBAL GAS DELIVERY SYSTEM FOR WAFER FAB EQUIPMENT MARKET, BY SPECIALITY GASES TYPE

9.1 OVERVIEW

9.2 AMMONIA (NH3)

9.3 HYDROGEN CHLORIDE (HCL)

9.4 TUNGSTEN HEXAFLUORIDE (WF6)

9.5 NITROGEN TRIFLUORIDE (NF3)

9.6 NITROUS OXIDE (N2O)

9.7 DISILANE (SI2H6)

9.8 GERMANE (GEH4)

9.9 HIGH PURITY CARBON DIOXIDE (CO2)

10 GLOBAL GAS DELIVERY SYSTEM FOR WAFER FAB EQUIPMENT MARKET, BY LEVEL OF PURITY

10.1 OVERVIEW

10.2 MULTI-PURPOSE

10.3 HIGH-PURITY

10.4 ULTRA-HIGH PURITY

11 GLOBAL GAS DELIVERY SYSTEM FOR WAFER FAB EQUIPMENT MARKET, BY END USER

11.1 OVERVIEW

11.2 SEMICONDUCTOR

11.2.1 BY TYPE

11.2.1.1. SEMI AUTOMATIC SWITCHOVER SYSTEMS

11.2.1.2. FULLY AUTOMATIC PROGRAMMABLE SWITCHOVER SYSTEMS

11.2.1.3. SINGLE STATION SYSTEMS

11.3 PHARMACEUTICAL

11.3.1 BY TYPE

11.3.1.1. SEMI AUTOMATIC SWITCHOVER SYSTEMS

11.3.1.2. FULLY AUTOMATIC PROGRAMMABLE SWITCHOVER SYSTEMS

11.3.1.3. SINGLE STATION SYSTEMS

11.4 AEROSPACE

11.4.1 BY TYPE

11.4.1.1. SEMI AUTOMATIC SWITCHOVER SYSTEMS

11.4.1.2. FULLY AUTOMATIC PROGRAMMABLE SWITCHOVER SYSTEMS

11.4.1.3. SINGLE STATION SYSTEMS

11.5 FOOD AND BEVERAGES

11.5.1 BY TYPE

11.5.1.1. SEMI AUTOMATIC SWITCHOVER SYSTEMS

11.5.1.2. FULLY AUTOMATIC PROGRAMMABLE SWITCHOVER SYSTEMS

11.5.1.3. SINGLE STATION SYSTEMS

11.6 OTHERS

12 GLOBAL GAS DELIVERY SYSTEM FOR WAFER FAB EQUIPMENT MARKET, BY REGION

GLOBAL GAS DELIVERY SYSTEM FOR WAFER FAB EQUIPMENT MARKET, (ALL SEGMENTATION PROVIDED ABOVE IS REPRESENTED IN THIS CHAPTER BY COUNTRY)

12.1 NORTH AMERICA

12.1.1 U.S.

12.1.2 CANADA

12.1.3 MEXICO

12.2 EUROPE

12.2.1 GERMANY

12.2.2 FRANCE

12.2.3 U.K.

12.2.4 ITALY

12.2.5 SPAIN

12.2.6 RUSSIA

12.2.7 TURKEY

12.2.8 BELGIUM

12.2.9 NETHERLANDS

12.2.10 SWITZERLAND

12.2.11 DENMARK

12.2.12 POLAND

12.2.13 SWEDEN

12.2.14 NORWAY

12.2.15 FINLAND

12.2.16 REST OF EUROPE

12.3 ASIA PACIFIC

12.3.1 JAPAN

12.3.2 CHINA

12.3.3 SOUTH KOREA

12.3.4 INDIA

12.3.5 AUSTRALIA

12.3.6 SINGAPORE

12.3.7 THAILAND

12.3.8 MALAYSIA

12.3.9 INDONESIA

12.3.10 TAIWAN

12.3.11 PHILIPPINES

12.3.12 VIETNAM

12.3.13 NEW ZEALAND

12.3.14 REST OF ASIA PACIFIC

12.4 SOUTH AMERICA

12.4.1 BRAZIL

12.4.2 ARGENTINA

12.4.3 REST OF SOUTH AMERICA

12.5 MIDDLE EAST AND AFRICA

12.5.1 SOUTH AFRICA

12.5.2 U.A.E.

12.5.3 EGYPT

12.5.4 ISRAEL

12.5.5 SAUDI ARABIA

12.5.6 KUWAIT

12.5.7 OMAN

12.5.8 QATAR

12.5.9 BAHRAIN

12.5.10 REST OF MIDDLE EAST AND AFRICA

12.6 KEY PRIMARY INSIGHTS: BY MAJOR COUNTRIES

13 GLOBAL GAS DELIVERY SYSTEM FOR WAFER FAB EQUIPMENT MARKET,COMPANY LANDSCAPE

13.1 COMPANY SHARE ANALYSIS: GLOBAL

13.2 COMPANY SHARE ANALYSIS: NORTH AMERICA

13.3 COMPANY SHARE ANALYSIS: EUROPE

13.4 COMPANY SHARE ANALYSIS: ASIA-PACIFIC

13.5 MERGERS & ACQUISITIONS

13.6 NEW PRODUCT DEVELOPMENT & APPROVALS

13.7 EXPANSIONS

13.8 REGULATORY CHANGES

13.9 PARTNERSHIP AND OTHER STRATEGIC DEVELOPMENTS

14 GLOBAL GAS DELIVERY SYSTEM FOR WAFER FAB EQUIPMENT MARKET, SWOT AND DBMR ANALYSIS

15 GLOBAL GAS DELIVERY SYSTEM FOR WAFER FAB EQUIPMENT MARKET, COMPANY PROFILE

15.1 MERCK KGAA

15.1.1 COMPANY SNAPSHOT

15.1.2 REVENUE ANALYSIS

15.1.3 GEOGRAPHIC PRESENCE

15.1.4 PRODUCT PORTFOLIO

15.1.5 RECENT DEVELOPMENTS

15.2 ICHOR SYSTEMS

15.2.1 COMPANY SNAPSHOT

15.2.2 REVENUE ANALYSIS

15.2.3 GEOGRAPHIC PRESENCE

15.2.4 PRODUCT PORTFOLIO

15.2.5 RECENT DEVELOPMENTS

15.3 VEECO INSTRUMENTS INC.

15.3.1 COMPANY SNAPSHOT

15.3.2 GEOGRAPHIC PRESENCE

15.3.3 PRODUCT PORTFOLIO

15.3.4 RECENT DEVELOPMENTS

15.4 COLLABRATECH

15.4.1 COMPANY SNAPSHOT

15.4.2 GEOGRAPHIC PRESENCE

15.4.3 PRODUCT PORTFOLIO

15.4.4 RECENT DEVELOPMENTS

15.5 ENTEGRIS

15.5.1 COMPANY SNAPSHOT

15.5.2 GEOGRAPHIC PRESENCE

15.5.3 PRODUCT PORTFOLIO

15.5.4 RECENT DEVELOPMENTS

15.6 BRONKHORST

15.6.1 COMPANY SNAPSHOT

15.6.2 GEOGRAPHIC PRESENCE

15.6.3 PRODUCT PORTFOLIO

15.6.4 RECENT DEVELOPMENTS

15.7 TELEDYNE TECHNOLOGIES INCORPORATED

15.7.1 COMPANY SNAPSHOT

15.7.2 GEOGRAPHIC PRESENCE

15.7.3 PRODUCT PORTFOLIO

15.7.4 RECENT DEVELOPMENTS

15.8 LINDE

15.8.1 COMPANY SNAPSHOT

15.8.2 GEOGRAPHIC PRESENCE

15.8.3 PRODUCT PORTFOLIO

15.8.4 RECENT DEVELOPMENTS

15.9 SVCS PROCESS INNOVATION S.R.O

15.9.1 COMPANY SNAPSHOT

15.9.2 GEOGRAPHIC PRESENCE

15.9.3 PRODUCT PORTFOLIO

15.9.4 RECENT DEVELOPMENTS

15.1 SDC

15.10.1 COMPANY SNAPSHOT

15.10.2 REVENUE ANALYSIS

15.10.3 GEOGRAPHIC PRESENCE

15.10.4 PRODUCT PORTFOLIO

15.10.5 RECENT DEVELOPMENTS

15.11 GCE GROUP

15.11.1 COMPANY SNAPSHOT

15.11.2 GEOGRAPHIC PRESENCE

15.11.3 PRODUCT PORTFOLIO

15.11.4 RECENT DEVELOPMENTS

15.12 SILPAC

15.12.1 COMPANY SNAPSHOT

15.12.2 GEOGRAPHIC PRESENCE

15.12.3 PRODUCT PORTFOLIO

15.12.4 RECENT DEVELOPMENTS

15.13 BLOCKCYPHER, INC

15.13.1 COMPANY SNAPSHOT

15.13.2 GEOGRAPHIC PRESENCE

15.13.3 PRODUCT PORTFOLIO

15.13.4 RECENT DEVELOPMENTS

15.14 SYMBIONT

15.14.1 COMPANY SNAPSHOT

15.14.2 GEOGRAPHIC PRESENCE

15.14.3 PRODUCT PORTFOLIO

15.14.4 RECENT DEVELOPMENTS

15.15 BIGCHAINDB GMBH

15.15.1 COMPANY SNAPSHOT

15.15.2 GEOGRAPHIC PRESENCE

15.15.3 PRODUCT PORTFOLIO

15.15.4 RECENT DEVELOPMENTS

15.16 PRAXAIR TECHNOLOGY, INC.

15.16.1 COMPANY SNAPSHOT

15.16.2 REVENUE ANALYSIS

15.16.3 GEOGRAPHIC PRESENCE

15.16.4 PRODUCT PORTFOLIO

15.16.5 RECENT DEVELOPMENTS

15.17 DIVERSIFIED FLUID SOLUTIONS

15.17.1 COMPANY SNAPSHOT

15.17.2 REVENUE ANALYSIS

15.17.3 GEOGRAPHIC PRESENCE

15.17.4 PRODUCT PORTFOLIO

15.17.5 RECENT DEVELOPMENTS

15.18 MATHESON TRI-GAS, IN

15.18.1 COMPANY SNAPSHOT

15.18.2 GEOGRAPHIC PRESENCE

15.18.3 PRODUCT PORTFOLIO

15.18.4 RECENT DEVELOPMENTS

15.19 APPLIED ENERGY SYSTEMS, INC.

15.19.1 COMPANY SNAPSHOT

15.19.2 GEOGRAPHIC PRESENCE

15.19.3 PRODUCT PORTFOLIO

15.19.4 RECENT DEVELOPMENTS

15.2 POWERBLANKET

15.20.1 COMPANY SNAPSHOT

15.20.2 GEOGRAPHIC PRESENCE

15.20.3 PRODUCT PORTFOLIO

15.20.4 RECENT DEVELOPMENTS

15.21 AXENICS

15.21.1 COMPANY SNAPSHOT

15.21.2 GEOGRAPHIC PRESENCE

15.21.3 PRODUCT PORTFOLIO

15.21.4 RECENT DEVELOPMENTS

15.22 CAMBRIDGE FLUID SYSTEMS

15.22.1 COMPANY SNAPSHOT

15.22.2 GEOGRAPHIC PRESENCE

15.22.3 PRODUCT PORTFOLIO

15.22.4 RECENT DEVELOPMENTS

15.23 AIR LIQUIDE ELECTRONICS SYSTEMS

15.23.1 COMPANY SNAPSHOT

15.23.2 GEOGRAPHIC PRESENCE

15.23.3 PRODUCT PORTFOLIO

15.23.4 RECENT DEVELOPMENTS

15.24 AIR PRODUCTS AND CHEMICALS, INC.

15.24.1 COMPANY SNAPSHOT

15.24.2 GEOGRAPHIC PRESENCE

15.24.3 PRODUCT PORTFOLIO

15.24.4 RECENT DEVELOPMENTS

15.25 TAIYO NIPPON SANSO CORPORATION

15.25.1 COMPANY SNAPSHOT

15.25.2 GEOGRAPHIC PRESENCE

15.25.3 PRODUCT PORTFOLIO

15.25.4 RECENT DEVELOPMENTS

15.26 CRITICAL SYSTEMS, INC.

15.26.1 COMPANY SNAPSHOT

15.26.2 GEOGRAPHIC PRESENCE

15.26.3 PRODUCT PORTFOLIO

15.26.4 RECENT DEVELOPMENTS

16 CONCLUSION

17 QUESTIONNAIRE

18 RELATED REPORTS

19 ABOUT DATA BRIDGE MARKET RESEARCH

Global Gas Delivery System For Wafer Fab Equipment Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Gas Delivery System For Wafer Fab Equipment Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Gas Delivery System For Wafer Fab Equipment Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.