Global Flexible Intermediate Bulk Container Market

Market Size in USD Billion

CAGR :

%

USD

5.30 Billion

USD

9.03 Billion

2024

2032

USD

5.30 Billion

USD

9.03 Billion

2024

2032

| 2025 –2032 | |

| USD 5.30 Billion | |

| USD 9.03 Billion | |

|

|

|

|

Flexible Intermediate Bulk Container Market Size

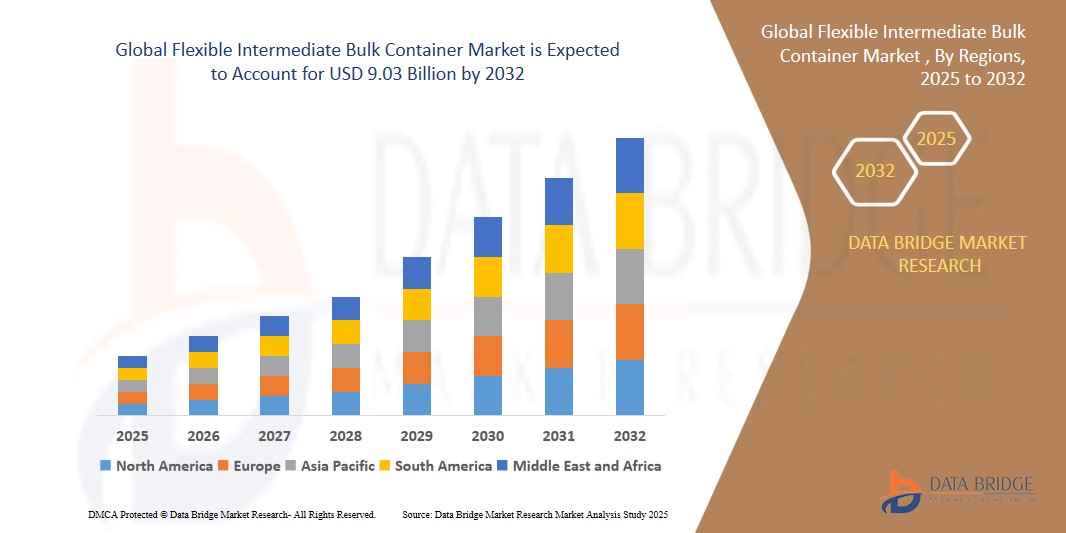

- The Global Flexible Intermediate Bulk Container Market size was valued at USD 5.30 billion in 2024 and is expected to reach USD 9.03 billion by 2032, at a CAGR of 6.1% during the forecast period

- The market growth is largely fueled by the surge in global industrial activities, particularly in chemicals, agriculture, and pharmaceuticals, has escalated the demand for efficient bulk packaging solutions. FIBCs offer cost-effective and safe transportation, aligning with the needs of these expanding sectors.

- Furthermore, growing environmental concerns and stringent regulations have propelled the adoption of recyclable and biodegradable FIBCs. Manufacturers are innovating to meet sustainability goals, thereby significantly boosting the industry's growth

Flexible Intermediate Bulk Container Market Analysis

- Flexible intermediate bulk containers refer to type of bulk transporting packaging method that are made up of flexible and foldable fabric materials woven together. These containers are highly utilized in transportation, storage and protection of dry products and contents.

- These containers are known to be light weight, recyclable and environment friendly. These products have the capability of being transported with the assistance of pallets fitted below them that makes them easier to lift and handle

- North America dominates the Flexible Intermediate Bulk Container Market with the largest revenue share of 38.01% in 2025, characterized by robust demand in the chemical, food, and pharmaceutical sectors.

- Asia-Pacific is expected to be the fastest growing region in the Flexible Intermediate Bulk Container Market during the forecast period due to expanding manufacturing sectors and rising exports, particularly in chemicals and food processing industries

- Chemicals segment is expected to dominate the Flexible Intermediate Bulk Container Market with a market share of 43.2% in 2025, driven by the need for high-strength, leak-proof FIBCs for safe transportation of hazardous materials

Report Scope and Flexible Intermediate Bulk Container Market Segmentation

|

Attributes |

Flexible Intermediate Bulk Container Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Flexible Intermediate Bulk Container Market Trends

“Enhanced Efficiency Through AI-Enabled Logistics”

- A major trend shaping the Global FIBC Market is the integration of artificial intelligence (AI) and voice-assisted systems into supply chain and inventory management processes. These technologies streamline operations, reduce human error, and increase the traceability of goods transported in FIBCs, improving overall efficiency.

- For instance, AI-powered warehouse systems now allow real-time tracking and status updates of goods stored in FIBCs through integration with voice-controlled platforms like Amazon Alexa and Google Assistant, enabling inventory managers to access data using simple voice commands.

- AI adoption enables predictive analytics for load optimization and demand forecasting, which helps businesses minimize empty FIBC returns and enhance load planning. Smart FIBCs embedded with sensors offer real-time condition monitoring, adding a layer of intelligence to bulk material handling.

- Voice control further supports hands-free operation of warehouse management systems, where commands to retrieve, store, or reposition FIBCs can be issued vocally. This enhances operational safety and speed in environments requiring quick, responsive handling of bulk materials.

- The move toward AI-integrated, voice-enabled FIBC logistics is aligning with broader smart manufacturing and Industry 4.0 trends, allowing companies to create interconnected, automated workflows that reduce downtime and increase output efficiency.

- As manufacturers increasingly prioritize automation and seamless connectivity in warehousing and bulk logistics, FIBC systems that offer such smart features are experiencing rising demand across chemical, food, pharmaceutical, and agricultural sectors.

Flexible Intermediate Bulk Container Market Dynamics

Driver

“Rising Demand for Cost-Efficient, Bulk Handling Solutions Across Industries”

- The surge in global trade and the need for efficient bulk packaging solutions are significant drivers for the FIBC market. FIBCs offer a cost-effective and space-saving alternative for transporting powdered, granulated, and flowable products across numerous industries.

- For instance, in February 2024, Greif, Inc. introduced high-strength, UV-resistant FIBCs tailored for the agrochemical industry, showcasing ongoing innovation to meet evolving sector-specific needs.

- With their lightweight design and high load-bearing capacity, FIBCs enable reduced packaging material use, lower transportation costs, and quicker handling—critical for industrial users seeking operational savings.

- Additionally, the growing popularity of flexible packaging over rigid containers in food and pharmaceutical supply chains is bolstering the adoption of FIBCs due to their sanitary benefits and reusability.

- Customization options, including conductive materials for hazardous material handling or breathable fabrics for agricultural produce, further fuel demand by catering to specialized logistics requirements.

- The growing e-commerce and third-party logistics sectors also rely on FIBCs for fulfillment center operations, further reinforcing their indispensable role in modern supply chains and warehouse operations.

Restraint/Challenge

“Volatility in Raw Material Prices and Limited Recycling Infrastructure”

- The dependency on polypropylene (PP) and polyethylene (PE) resins exposes the FIBC market to price volatility due to fluctuating crude oil prices, which increases production costs and affects profit margins.

- For instance, during 2023, global resin prices witnessed a spike due to supply chain disruptions and rising energy costs, directly impacting FIBC manufacturing and pricing stability.

- Environmental concerns regarding plastic-based packaging and insufficient recycling infrastructure in emerging markets present challenges to sustainability goals, making users hesitant to adopt FIBCs without circular-use assurances.

- Although several companies offer recyclable or biodegradable FIBC options, the lack of a global standard and limited post-use collection networks hinder large-scale implementation and disposal efficiency.

- High-strength FIBCs with multi-use capabilities often come at a premium, deterring cost-sensitive buyers from adopting these solutions despite their longer life cycle and environmental advantages.

- Addressing these challenges requires investment in advanced material science, development of closed-loop recycling systems, and policies promoting circular economy practices to secure long-term market resilience and sustainability

Flexible Intermediate Bulk Container Market Scope

The market is segmented on the basis of grade and end-user.

- By Grade

On the basis of grade, the flexible intermediate bulk container market is segmented into Type A, Type B, Type C, Type D, and food grade. The type c segment dominates the largest market revenue share of 39.8% in 2025, owing to its superior electrostatic discharge control, making it ideal for handling flammable and explosive materials in the chemical and pharmaceutical industries. Type C FIBCs offer added safety compliance, making them the preferred choice in sensitive manufacturing environments. The increased regulatory scrutiny surrounding static control during bulk material transport continues to drive demand for this grade.

The Food Grade segment is projected to witness the fastest CAGR of 19.5% from 2025 to 2032, fueled by growing global food exports and stringent food safety standards. These FIBCs are manufactured under certified hygienic conditions and are widely adopted by the food processing industry for the bulk handling of grains, powders, and additives. Rising health awareness and the global push for contamination-free packaging significantly contribute to the rapid growth of Food Grade containers.

- By End-User

On the basis of end-user, the flexible intermediate bulk container market is segmented into pharmaceuticals, food, chemicals, construction, textiles, oil and glass, and others. The chemicals segment held the largest market revenue share in 2025, supported by the extensive use of FIBCs for safe and efficient transportation of dry chemical powders, granules, and other hazardous materials. Chemical manufacturers rely heavily on FIBCs due to their high strength-to-weight ratio, reusability, and compatibility with automated handling systems. The global chemical industry's focus on cost-effective and scalable packaging further bolsters this segment.

The food segment is expected to witness the fastest CAGR from 2025 to 2032, driven by the expanding global food trade and increasing demand for safe, hygienic, and cost-efficient packaging solutions. FIBCs are widely used for transporting grains, pulses, flour, and other bulk food products. Their reusability, space efficiency, and compliance with international food-grade standards make them the preferred choice for food exporters and processors.

Flexible Intermediate Bulk Container Market Regional Analysis

- North America dominates the flexible intermediate bulk container market with the largest revenue share of 24.11% in 2024, driven by a robust demand in the chemical, food, and pharmaceutical sectors.

- The use of Type C and D FIBCs is prevalent due to stringent safety regulations concerning hazardous materials.

- Additionally, a well-established logistics and transportation infrastructure continues to support market expansion. High consumer safety standards and the increasing need for efficient bulk packaging solutions further solidify the region’s dominance in the global market.

U.S. Flexible Intermediate Bulk Container Market Insight

The U.S. Flexible Intermediate Bulk Container Market captured the largest revenue share of 83% within North America in 2025, fueled by its advanced manufacturing capabilities and strict industrial packaging regulations. Rising demand for eco-friendly and recyclable FIBCs among chemical manufacturers and agribusinesses is fueling adoption. Furthermore, the expansion of e-commerce and warehousing has increased the use of FIBCs for material handling. The country’s strong export-oriented industries and safety compliance standards also enhance the market outlook.

Europe Flexible Intermediate Bulk Container Market Insight

The European Flexible Intermediate Bulk Container Market is projected to expand at a substantial CAGR throughout the forecast period, primarily driven by high standards in food safety and chemical handling. Regulatory bodies such as REACH and EFSA have necessitated the use of certified FIBCs in various applications. The demand for durable and anti-static FIBCs is particularly strong in Germany, France, and the UK. As sustainability gains momentum across industries, the region is shifting toward reusable and recyclable bulk packaging alternatives for environmental compliance.

U.K. Flexible Intermediate Bulk Container Market Insight

The U.K. Flexible Intermediate Bulk Container Market is anticipated to grow at a noteworthy CAGR during the forecast period, driven by increasing demand in the food processing and construction sectors. The country’s rising emphasis on sustainable logistics and material storage has spurred FIBC adoption. Governmental regulations supporting biodegradable packaging and the growth of chemical exports are additional contributors. The incorporation of FIBCs in warehouse automation and material optimization systems is further expected to sustain market growth.

Germany Flexible Intermediate Bulk Container Market Insight

The German Flexible Intermediate Bulk Container Market is expected to expand at a considerable CAGR during the forecast period, backed by its well-established manufacturing and export sectors. The country places strong emphasis on precision packaging and quality compliance, especially in chemicals, pharmaceuticals, and food-grade materials. Demand for Type C and D FIBCs is growing due to safety mandates in handling hazardous substances. Germany’s focus on sustainability is also encouraging the shift toward reusable and recyclable FIBC materials. The integration of automated filling and unloading systems in logistics enhances operational efficiency and supports widespread adoption across industries.

Asia-Pacific Flexible Intermediate Bulk Container Market Insight

The Asia-Pacific Flexible Intermediate Bulk Container Market is poised to grow at the fastest CAGR of over 38% in 2025, driven by industrial expansion in China, India, and Southeast Asia, coupled with the surge in agricultural and construction activities, drives significant demand. The region benefits from cost-effective manufacturing, a large consumer base, and increasing cross-border trade. Additionally, government-led infrastructure projects and export incentives support FIBC usage across key end-user industries.

Japan Flexible Intermediate Bulk Container Market Insight

The Japan Flexible Intermediate Bulk Container Market is gaining momentum driven by rising applications in chemicals, electronics, and food industries, where contamination-free handling is critical. As a technology leader, Japan is integrating FIBCs with IoT-enabled supply chains for better tracking and management. The growing aging population also promotes the need for lightweight, ergonomically manageable packaging in agriculture and small-scale operations. Sustainability trends are leading to increased use of biodegradable and reusable FIBC variants in line with national environmental policies.

China Flexible Intermediate Bulk Container Market Insight

The China Flexible Intermediate Bulk Container Market accounted for the largest market revenue share in Asia Pacific in 2025, led by its large-scale manufacturing and export-oriented economy. With the growth of agriculture, construction, and chemical sectors, the demand for safe, high-capacity packaging is rising. China’s role as a global supplier of FIBCs, combined with technological advancements and competitive pricing, strengthens its market presence. Investments in automated packaging lines and bulk logistics also drive adoption across commercial and industrial applications.

Flexible Intermediate Bulk Container Market Share

The Flexible Intermediate Bulk Container industry is primarily led by well-established companies, including:

- Berry Global Inc. (U.S.)

- Yixing Changfeng Container Bag Co., Ltd. (China)

- BAG Corp. (U.S.)

- minibulk (U.S.)

- Shenzhen Riversky Packing Materials Co., Ltd. (China)

- Greif (U.S.)

- AmeriGlobe L.L.C (U.S.)

- Conitex Sonoco (U.S.)

- LC Packaging (Netherlands)

- Plastipak Holdings, Inc. (U.S.)

- Yantai Haiwan Plastic Products Co., Ltd. (China)

- RDA Bulk Packaging Ltd. (U.K.)

- FlexiTuff Ventures International Ltd. (India)

- Flexpack FIBC (India)

- Mondi (U.K.)

- ALPINE FIBC PVT. LTD. (India)

- Century FIBC (India)

- Ganpati Plastfab Limited (India)

- Rishi FIBC Solutions PVT. Ltd. (India)

Latest Developments in Global Flexible Intermediate Bulk Container Market

- In May 2023, FlexSack launched an environmentally friendly polypropylene FIBC featuring 30% recycled polypropylene (rPP). Designed as a direct substitute for conventional PP bulk bags, this innovation maintains performance and price while promoting recyclability. Although the initial market response was cautious, the launch supports broader sustainability efforts, including lowering carbon emissions and reducing manufacturing waste.

- In December 2022, New Water Capital (NWC) expanded its holdings by acquiring Bulk Lift International LLC and Bagwell Supply Ltd., two major North American FIBC suppliers. This strategic acquisition has formed one of the region’s largest FIBC providers, strengthening offerings and supply chain capabilities for sectors such as food, chemicals, and pharmaceuticals.

- In September 2022, Global-Pak announced a new recycling collaboration with PureCycle Technologies, involving facilities in Ironton, Ohio, and a future site in Augusta, Georgia. The program aims to recycle used bulk bags using PureCycle’s solvent-based purification process, which converts polypropylene waste into high-purity, reusable resin.

- In September 2022, Berry Global Group, Inc. (NYSE: BERY), in partnership with Mars, Incorporated, unveiled lighter, eco-friendly PET jars containing 15% post-consumer recycled (PCR) content for popular brands like M&M’S, SKITTLES, and STARBURST. This initiative is part of a shared commitment to sustainable packaging innovation.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Flexible Intermediate Bulk Container Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Flexible Intermediate Bulk Container Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Flexible Intermediate Bulk Container Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.