Global Continuous Manufacturing Market

Market Size in USD Billion

CAGR :

%

USD

43.86 Billion

USD

74.63 Billion

2023

2031

USD

43.86 Billion

USD

74.63 Billion

2023

2031

| 2024 –2031 | |

| USD 43.86 Billion | |

| USD 74.63 Billion | |

|

|

|

|

Global Continuous Manufacturing Market - Industry Overview

The robust growth in the global pharmaceutical sector, with revenues surpassing 1 trillion USD in 2014 and the Indian pharmaceutical industry's turnover reaching USD 42.34 billion in the fiscal year 2021-22, highlights a significant expansion trajectory. This expansion, driven by diverse segments such as generic drugs, OTC medicines, bulk drugs, vaccines, and advanced areas like biosimilars and biologics, necessitates advanced manufacturing solutions. Continuous manufacturing processes, known for their enhanced efficiency, cost-effectiveness, and flexibility, are increasingly vital to meet the rising demand for rapid and high-quality production. As pharmaceutical companies seek to streamline operations and respond swiftly to market needs, the adoption of continuous manufacturing is expected to accelerate. This shift will spur substantial growth in the global continuous manufacturing market.

This market report provides details of new recent developments, market share, market trends on the basis of segmentations and regional analysis, impact of market leaders, analysis of the opportunities in terms of emerging revenue pockets, market regulations, strategic market growth analysis, market size, category wise market growths, application niches and dominance, product approvals, product launches, geographic expansions, and technological innovations in the market. To gain more info on the market, contact Data Bridge Market Research’s team of expert analysts. Our team will help you make an informed market decision to achieve market growth.

Global Continuous Manufacturing Market Size and Market Analysis

|

Continuous Manufacturing Market Report Metric Details |

|

|

Forecast Period |

2024-2031 |

|

Base Year |

2023 |

|

Historic Year |

2022 (Customizable 2016-2021) |

|

Measuring Unit |

USD Billion |

|

Data Pointers |

Market value, growth rate, segmentation, geographical coverage, major player’s depth expert analysis, patient epidemiology, pipeline analysis, pricing analysis, and regulatory framework. |

As industries seek to improve operational performance and drive down production expenses, the adoption of continuous manufacturing is increasingly recognized as a key strategy. The resulting cost benefits and efficiency gains place continuous manufacturing as an axle in the Global manufacturing industry. Databridge Market Research took a dive into comprehensively analyzing the market and unveiled that the Global Continuous Manufacturing Product Market is increasing at a CAGR of 6.87%. The market size was valued at USD 43.86 billion in 2023 and is expected to grow up to USD 74.63 billion by 2031.

Continuous Manufacturing Market Dynamics

Continuous Manufacturing Market Growth Drivers

Efficiency Demand in Manufacturing

The demand for efficiency in the manufacturing sector is intensifying as companies seek to reduce costs, streamline operations, and boost productivity. Technological advancements and a need for quicker response times to market changes fuel this drive for operational excellence. As manufacturers adopt more efficient processes, this trend acts as a key global growth driver for the continuous manufacturing market, promoting innovation and scalability across industries.

Globalization and Market Expansion

Businesses increasingly operate on a global scale, driving the need for scalable and efficient production systems. Globalization has expanded market reach, necessitating production methods that can swiftly adapt to diverse and growing consumer demands across various regions. Continuous manufacturing offers the agility and consistency required to meet the complexities of a global market. By providing high-volume, rapid production capabilities, continuous manufacturing systems address the challenges posed by global supply chains and diverse market requirements, hence contributing to continuous global manufacturing market growth.

Continuous Manufacturing Market Growth Opportunities

Harnessing Customization for Global Growth

The increasing demand for customized products and the ability to rapidly adjust production processes present significant opportunities for continuous manufacturing systems. For instance, companies like Novartis are adopting continuous manufacturing techniques to efficiently produce a range of pharmaceutical products, including personalized medicines. With more pharmaceutical companies embracing these techniques, it drives global continuous manufacturing market growth by expanding the application of continuous processes beyond traditional sectors and into new, high-demand areas such as personalized medicine.

Stricter regulatory Compliances

Stricter regulatory requirements in industries such as pharmaceuticals and chemicals are driving the demand for continuous manufacturing systems that ensure consistent quality and safety. For instance, the U.S. Food and Drug Administration (FDA) has emphasized the importance of quality by design (QbD) and process control, which are integral to continuous manufacturing. Moreover, in the chemical industry, regulations such as the European Union's REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) require rigorous safety and quality measures. Continuous manufacturing processes enable producers to meet these regulatory demands by providing better control over production parameters and reducing the risk of contamination.

Continuous Manufacturing Market Growth Challenges

Lack of Skilled Labor, a Key Challenge for Continuous Manufacturing Market Growth

The global continuous manufacturing market faces a significant challenge due to the shortage of skilled labor. Continuous manufacturing systems are highly complex, requiring a workforce that possesses specialized knowledge in areas such as automation, process control, and real-time data analysis. The advanced technologies involved in these systems, including AI-driven monitoring and precision engineering, demand operators and technicians with a deep understanding of both the technical and operational aspects of the process.

Supply Chain Disruptions

Continuous manufacturing systems depend heavily on a steady and reliable supply of raw materials to maintain uninterrupted production processes. Disruptions in the supply chain, whether due to global events like pandemics, geopolitical conflicts, or local issues such as transportation strikes or natural disasters, can severely impact production efficiency and output. For Instance, during the COVID-19 pandemic, many industries experienced significant supply chain disruptions that led to shortages of critical raw materials, halting continuous manufacturing processes and leading to delays in product delivery.

Continuous Manufacturing Market Size Growth Restraints

Regulatory Hurdles acting as a Barrier to Continuous Manufacturing Market Growth

Continuous manufacturing offers significant advantages in quality control and efficiency. The complexity arises from the fact that different regulatory bodies, such as the FDA (Food and Drug Administration), EMA (European Medicines Agency), and other global agencies, may have varying requirements and standards for approving continuous manufacturing practices. Navigating these diverse regulations often requires extensive documentation, validation, and demonstration of process consistency, which can delay implementation and increase costs for manufacturers looking to adopt continuous production methods. Consequently, hindering the Global continuous manufacturing market growth.

Continuous Manufacturing Market Scope and Trends

|

Continuous Manufacturing Market Segmentation Overview |

|

|

Segments Type |

Sub-Segments |

|

Product |

Integrated system, Semi-continuous system, Continuous Granulators, Continuous Coaters, Continuous Blenders, Continuous Dryers, Continuous Compressors, Control or Software |

|

Application |

API system, End Product Manufacturing, Solid Dosage, Liquid Dosage |

|

End User |

Research and Development Departments, Contract Research Organizations (CRO), Pharmaceutical Companies, Full-scale Manufacturing Companies, Contract Manufacturing Organizations (CMO) |

- Germany-based THM Recycling Solutions is introducing its PG Power Granulator series, a modern and highly powerful line of granulators designed to meet the latest technological standards, replacing the ZM machine series, which has proven its efficiency worldwide in shredding metals, cable scrap, and plastic scrap.

- AMF Bakery Systems mixers offer automation, sanitation, and continuous processing, ensuring consistent quality and efficiency in large-scale production. Their advanced design also reduces downtime and enhances overall productivity.

- Geelen Counterflow introduces a new Continuous Dryer MkIII, which is suitable for energy-efficient drying of extruded products across a capacity range from 1 to 10 tonnes per hour.

- Cimbria has just won an order, the order includes a newly developed ECO-Logic continuous flow dryer, which is the latest generation of grain dryers with factors such as automatic operation control and process control as an essential part of the drying process.

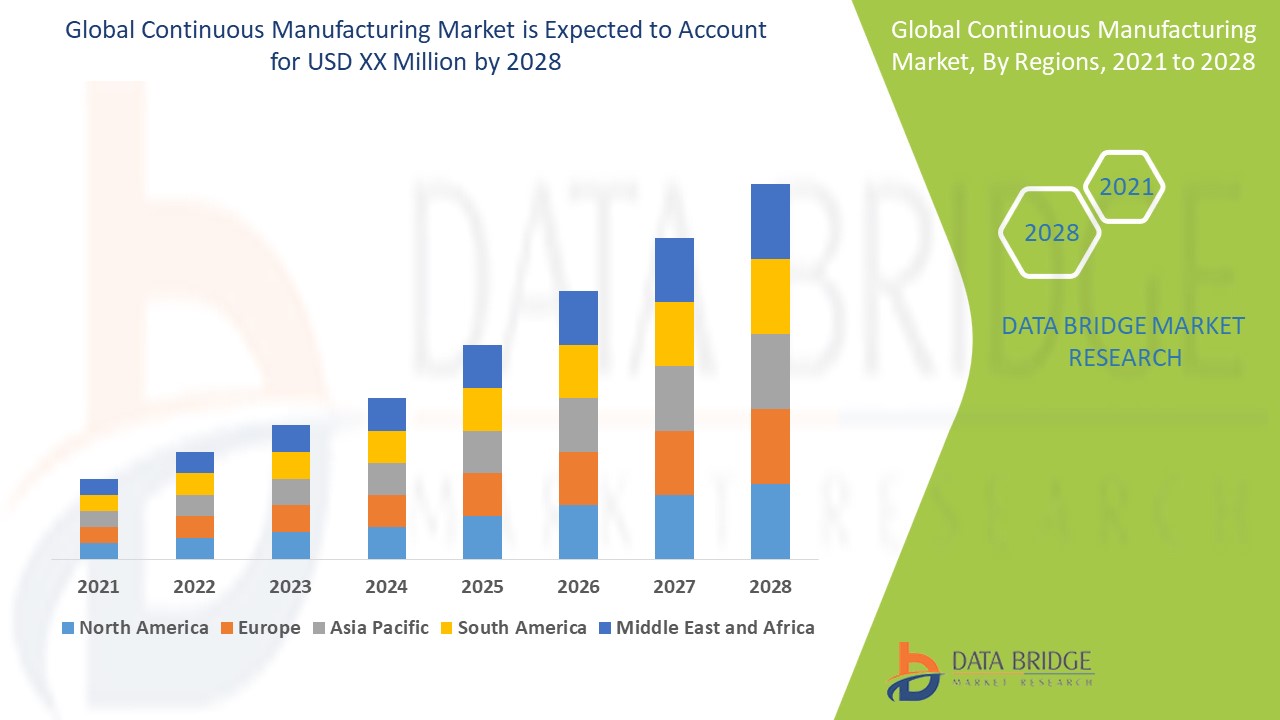

Continuous Manufacturing Market Regional Analysis – Market Trends

|

Continuous Manufacturing Market Regional Overview |

|

|

Regions |

Countries |

|

Europe |

Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe |

|

APAC |

China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific |

|

North America |

U.S., Canada, and Mexico |

|

MEA |

Saudi Arabia, U.A.E., South Africa, Egypt, Israel, Rest of Middle East, and Africa |

|

South America |

Brazil, Argentina, and Rest of South America |

Key Insights

- The North American continuous manufacturing market is experiencing substantial growth, driven by increasing demand for efficiency, innovation, supportive regulatory frameworks across various industries. Leading companies such as Pfizer, Merck, and Dow Chemical are at the forefront of adopting continuous manufacturing systems.

- The European continuous manufacturing market is rapidly Key factors fueling this growth includes expanding advancements in automation and process control technologies, supportive regulatory frameworks from agencies like the European Medicines Agency (EMA), and a strong focus on sustainability and resource efficiency.

- Shanghai Pharmaceuticals and Syntegon have entered into an agreement to establish a laboratory for continuous manufacturing technology in China. This collaboration aims to advance the application of this innovative technology, expedite the development cycles of new drugs, lower drug development costs, enhance the availability of new medications in China, and ultimately deliver greater value to patients.

- WuXi STA, a subsidiary of WuXi AppTec, has announced that its inaugural continuous manufacturing (CM) line for oral solid drugs is now operational at its drug product facility in Wuxi, China.

Continuous Manufacturing Market Leading Players

- GEA Group Aktiengesellschaft

- Thermo Fisher Scientific Inc.

- Hosokawa Micron Group

- Glatt GmbH

- Coperion GmbH

- L.B. BOHLE

- KORSCH AG

- Munson Machinery Co., Inc.

- Robert Bosch GmbH

- Gebrüder Lödige Maschinenbau GmbH

- Baker Perkins

- Scott Equipment Company, LLC

- Sturtevant, Inc.

- Novartis AG

- Siemens Medical Solutions USA, Inc.

- Genzyme Corporation

- Bayer AG

- Janssen Global Services, LLC

- Lilly

- Syntegon Technology GmbH

- 3P Biopharmaceuticals

- Abbott

- AbbVie Inc.

- ABN Cleanroom Technology

- AC Immune

Continuous Manufacturing Market Recent Developments

- In November 2023, Bayer has invested €130 million in the construction of a new production facility dedicated to innovative parenteral products, incorporating advanced continuous manufacturing technologies.

- In August 2024, Hovione and GEA have announced the launch of the ConsiGma CDC Flex and installation of a new lab-scale R&D continuous tableting rig at Hovione's facilities in Portugal.

- In April 2024, the European Medicines Agency (EMA) published new ICH guideline Q13 supporting the use of continuous manufacturing technologies. These guidelines are expected to streamline the approval process and encourage wider adoption of continuous manufacturing in Europe.

- Process Analytical Technology (PAT) is a recent technological advancement in continuous manufacturing, providing real-time monitoring and control. By employing cutting-edge sensors and analytical tools, PAT enables precise management of product quality and process efficiency, allowing for immediate adjustments and minimizing variability

DBMR’s market report on the global Continuous Manufacturing market takes you through valuable insights that can contribute to making several important business decisions. Based on our reports and research expertise you can create realistic growth strategies for your business.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.