Global Cold Chain Monitoring Market

Market Size in USD Billion

CAGR :

%

USD

7.40 Billion

USD

19.17 Billion

2024

2032

USD

7.40 Billion

USD

19.17 Billion

2024

2032

| 2025 –2032 | |

| USD 7.40 Billion | |

| USD 19.17 Billion | |

|

|

|

|

Cold Chain Monitoring Market Size

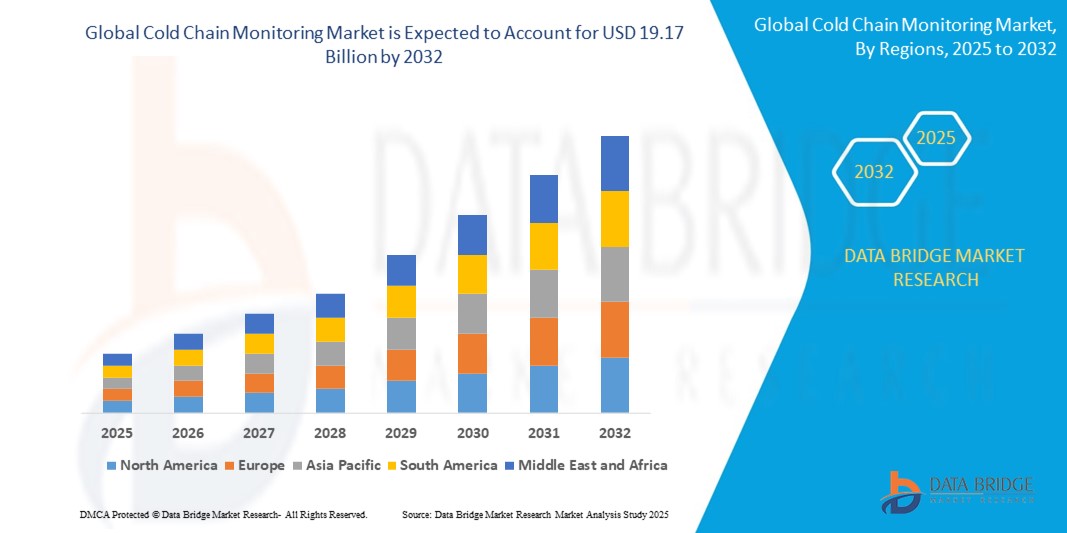

- The global cold chain monitoring market was valued at USD 7.4 billion in 2024 and is expected to reach USD 19.17 billion by 2032

- During the forecast period of 2025 to 2032 the market is likely to grow at a CAGR of 12.64 % primarily driven by the increasing demand for temperature-sensitive products, such as pharmaceuticals, biologics, and perishable foods, in emerging markets

- This growth is driven by factors such as the growing focus on quality control and regulatory compliance in industries such as healthcare and food, technological advancements in IoT and sensor technologies, and the expanding global trade of temperature-sensitive goods

Cold Chain Monitoring Market Analysis

- The cold chain monitoring market is witnessing rapid growth due to the increasing demand for temperature-sensitive goods, especially in pharmaceuticals and perishable food sectors, where maintaining specific temperatures is critical to product quality and safety

- For instance, the distribution of COVID-19 vaccines required precise temperature control, driving a surge in cold chain technologies

- Technologies such as real-time tracking sensors and RFID devices are becoming standard in cold chain management, allowing businesses to continuously monitor shipments and reduce the risk of spoilage, such as in the transport of fresh produce such as berries and meats, where temperature consistency is essential for shelf life

- The integration of Internet of Things (IoT) solutions is improving visibility across the supply chain, allowing for instant alerts on temperature fluctuations, which can help companies react quickly to avoid product loss

- For instance, Pfizer’s use of IoT-enabled temperature sensors during the distribution of their COVID-19 vaccine to ensure it stayed within the required -70°C range

- With industries facing stricter regulations, such as the European Union’s Falsified Medicines Directive, cold chain monitoring has become essential to comply with legal requirements while ensuring the safety and integrity of temperature-sensitive products

- For instance, companies such as UPS have implemented cold chain solutions to meet such regulatory standards for pharmaceuticals

- Real-time monitoring is transforming logistics operations by reducing waste and improving operational efficiency, as seen with companies such as DHL and FedEx, which have implemented temperature-controlled packaging solutions to enhance their cold chain capabilities for sensitive goods such as organ transplants or high-value medications

Report Scope and Cold Chain Monitoring Market Segmentation

|

Attributes |

Cold Chain Monitoring Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. |

Cold Chain Monitoring Market Trends

“Increasing Use of Internet of Things Technology”

- The increasing use of Internet of Things (IoT) technology in cold chain monitoring enables real-time tracking of temperature, humidity, and location, improving the efficiency of temperature-sensitive product management, such as in the transport of pharmaceuticals such as vaccines

- IoT sensors are being integrated into logistics and storage systems, providing continuous data to detect temperature fluctuations instantly, allowing quick interventions

- For instance, during the distribution of COVID-19 vaccines, IoT technology helped maintain strict temperature requirements, ensuring vaccine efficacy

- The data gathered from IoT devices is often transmitted to cloud-based platforms, where it can be analyzed in real time, allowing businesses to track shipments globally. Companies such as DHL use this to monitor the conditions of shipments across various countries

- IoT-based cold chain monitoring solutions can trigger immediate alerts when conditions go out of range, reducing product spoilage and waste. This is critical in industries such as the food industry, where products such as seafood or meat need constant temperature control

- As industries focus more on automation and operational efficiency, IoT technology allows businesses to streamline processes

- For instance, FedEx uses IoT solutions to monitor temperature-sensitive shipments, reducing the need for manual checks and improving overall logistics efficiency

Cold Chain Monitoring Market Dynamics

Driver

“Increasing Demand for Temperature-Sensitive Goods”

- The primary driver for the growth of the cold chain monitoring market is the increasing demand for temperature-sensitive products, particularly in the pharmaceutical and food industries

- For instance, the distribution of COVID-19 vaccines required highly controlled cold chain management to ensure the vaccines remained effective during transpor

- In the pharmaceutical industry, drugs such as vaccines and insulin must be stored and transported within precise temperature ranges

- For, instance is the global distribution of COVID-19 vaccines, where temperature deviations during transit could render the product ineffective, driving the adoption of real-time monitoring systems to ensure compliance with temperature regulations

- The food industry, particularly for perishable products such as seafood, dairy, and fresh produce, relies heavily on cold chain monitoring to extend shelf life and prevent spoilage. Retailers such as Walmart and Whole Foods have implemented advanced cold chain monitoring to ensure the freshness of their food products from farm to table

- Consumers’ increasing preference for fresh, organic, and minimally processed foods has raised the demand for better cold chain solutions. Companies such as HelloFresh and Blue Apron, which deliver fresh meal kits, use cold chain monitoring systems to guarantee the quality of their ingredients during shipping

- The growing emphasis on product safety and regulatory compliance in temperature-sensitive industries is making cold chain monitoring crucial to business success

- For instance, pharmaceutical companies such as Pfizer and Moderna have invested heavily in cold chain technologies to ensure that their temperature-sensitive products meet stringent health and safety standards across global markets

Opportunity

“Adoption of Advanced Technologies”

- A significant opportunity in the cold chain monitoring market is the adoption of advanced technologies such as artificial intelligence, machine learning, and blockchain, which are revolutionizing how temperature-sensitive goods are managed

- Artificial intelligence and machine learning enable predictive analytics that help businesses forecast potential risks in the supply chain

- For instance, AI-driven systems can analyze data from IoT sensors to predict when a shipment might experience a temperature breach, allowing companies to take preemptive action and reduce spoilage, such as in pharmaceutical shipments that require strict temperature control

- Blockchain technology is enhancing transparency and traceability in cold chain operations. By creating a secure, tamper-proof ledger of every product's journey, blockchain ensures that stakeholders, such as manufacturers, distributors, and retailers, have access to accurate data regarding product conditions. This is especially important in industries such as pharmaceuticals, where regulatory compliance is essential

- The use of AI, machine learning, and blockchain allows businesses to reduce waste, optimize logistics routes, and improve supply chain efficiency, benefiting industries such as food and pharmaceuticals where temperature consistency is crucial for product quality

- These advanced technologies not only enhance operational efficiency but also provide companies with new business opportunities by offering smarter, more secure, and data-driven solutions, helping them stand out in a competitive market and attract more customers

Restraint/Challenge

“High Implementation Costs”

- One of the key challenges facing the cold chain monitoring market is the high initial cost of implementing advanced technologies such as real-time temperature sensors, data loggers, and IoT devices, which require substantial investment in both hardware and software infrastructure

- For small and medium-sized enterprises (SMEs), these upfront costs can be a significant barrier, preventing them from adopting or maintaining modern cold chain monitoring systems. This issue is particularly prominent in developing regions, where budget constraints make it harder for businesses to transition from traditional methods to more advanced solutions

- As these systems require significant investments in installation, training, and ongoing maintenance, many SMEs may continue to rely on less efficient methods of managing temperature-sensitive goods, increasing the risks of spoilage or quality issues

- For instance, in the food industry, using outdated temperature tracking methods could lead to product wastage

- The evolving nature of cold chain technology also adds to the challenge, as systems require regular updates and upgrades to remain compatible with new standards and improve performance

- For instance, sensors and software updates are necessary to keep up with regulatory changes or technological advancements, further increasing operational costs

- While the high implementation cost presents a challenge, the technology is expected to become more affordable over time. Larger companies are leading the way in adopting scalable solutions, which could drive down costs for smaller businesses and make advanced cold chain monitoring technologies more accessible in the future

Cold Chain Monitoring Market Scope

The market is segmented on the basis of components, logistics, and application

|

Segmentation |

Sub-Segmentation |

|

By Component |

|

|

By Logistics |

|

|

By Application |

|

Cold Chain Monitoring Market Regional Analysis

“North America is the Dominant Region in the Cold Chain Monitoring Market”

- North America dominates the cold chain monitoring market, primarily driven by its strong pharmaceutical, food, and healthcare industries

- The U.S. leads the market due to its well-established infrastructure and stringent regulatory requirements for temperature-sensitive products, particularly in the pharmaceutical sector

- The need to monitor vaccines and biologics during transit is a major factor driving the demand for cold chain monitoring solutions in North America

- The growing demand for fresh and perishable goods in the food industry has further contributed to the widespread adoption of advanced cold chain technologies across the region

- Companies such as ORBCOMM and Geotab Inc. based in North America are key players, offering innovative cold chain solutions that fuel the region’s market growth

“Asia-Pacific is Projected to Register the Highest Growth Rate”

- Asia-Pacific is the fastest-growing region for cold chain monitoring due to rapid industrialization, a burgeoning middle class, and increasing demand for perishable goods are fuelling the growth of this market

- Countries such as China and India are witnessing significant investments in infrastructure and logistics, enhancing the capability for cold chain management

- The increasing focus on food safety and the rising consumption of temperature-sensitive goods, such as fresh produce, dairy products, and pharmaceuticals, are further driving the market's growth in this region

- The adoption of modern cold chain technologies is accelerating, with more businesses seeking solutions to meet consumer demand for fresh, safe products

Cold Chain Monitoring Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- Berlinger & Co. AG (Switzerland)

- Mesa Labs, Inc. (U.S.)

- Carrier (U.S.)

- ORBCOMM (U.S.)

- ELPRO-BUCHS AG (Switzerland)

- Monnit Corporation (U.S.)

Latest Developments in Global Cold Chain Monitoring Market

- In August 2024, Sensitech completed its acquisition of Berlinger, a leader in temperature monitoring solutions. This strategic development aims to expand Sensitech's portfolio by incorporating Berlinger's advanced monitoring technologies, enhancing its cold chain visibility capabilities. The acquisition will provide customers with a more comprehensive range of products, improving real-time tracking and monitoring of temperature-sensitive goods. The move is expected to strengthen Sensitech’s position in the cold chain market by offering integrated solutions, further enhancing operational efficiency, and ensuring better regulatory compliance for industries such as pharmaceuticals and food

- In June 2024, Sensitech announced the acquisition of Berlinger, a global leader in temperature monitoring solutions. This acquisition aims to enhance Sensitech’s cold chain monitoring capabilities by integrating Berlinger's advanced technologies. The acquisition will allow Sensitech to offer more comprehensive and innovative solutions for tracking temperature-sensitive products in transit, especially in industries such as food and pharmaceuticals. By combining Berlinger's expertise with its own, Sensitech will strengthen its market position and provide customers with improved real-time visibility and regulatory compliance, driving greater efficiency and reducing risks in cold chain operations

- In February 2024, Sensitech launched the TempTale Geo-X, a next-generation temperature monitoring device that integrates GPS tracking with real-time temperature monitoring. This device aims to enhance the management of temperature-sensitive shipments, offering improved visibility and ensuring regulatory compliance. The TempTale Geo-X will benefit industries such as pharmaceuticals and food by reducing spoilage risks, improving operational efficiency, and ensuring product integrity during transit. This innovation is set to make a significant impact on the cold chain market by increasing reliability and reducing losses

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Cold Chain Monitoring Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Cold Chain Monitoring Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Cold Chain Monitoring Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.