Global Carbon Felt And Graphite Felt Market

Market Size in USD Million

CAGR :

%

USD

551.25 Million

USD

1,151.89 Million

2024

2032

USD

551.25 Million

USD

1,151.89 Million

2024

2032

| 2025 –2032 | |

| USD 551.25 Million | |

| USD 1,151.89 Million | |

|

|

|

|

Carbon Felt and Graphite Felt Market Size

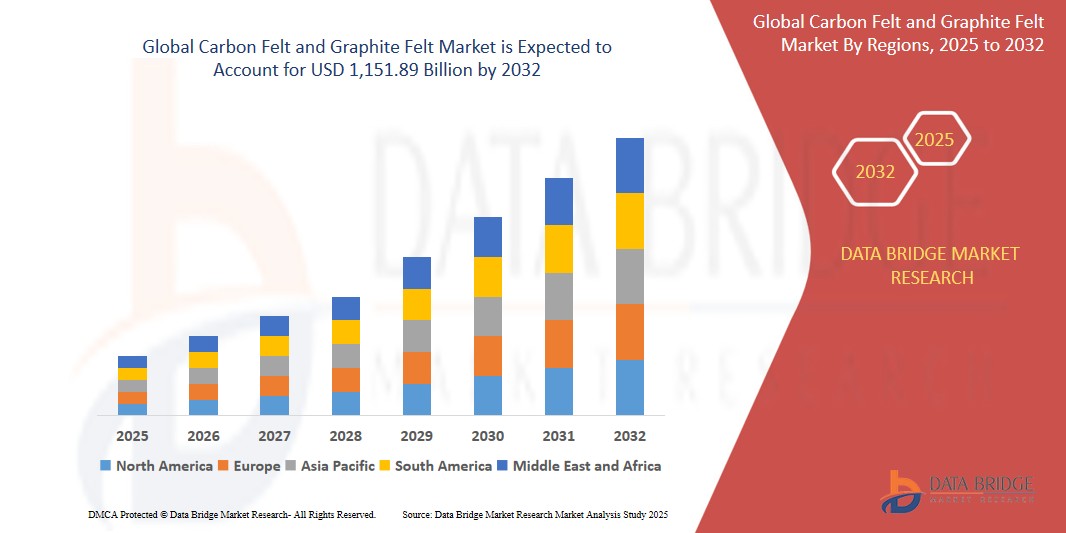

- The Global Carbon Felt and Graphite Felt Market size was valued at USD 551.25 Million in 2024 and is expected to reach USD 1,151.89 Million by 2032, at a CAGR of 9.7% during the forecast period

- This growth is driven by factors such as rising demand in energy storage, high-temperature insulation, aerospace applications, and increasing investments in renewable energy

Carbon Felt and Graphite Felt Market Analysis

- Carbon felt and graphite felt are essential components used in high-temperature insulation, energy storage systems, and furnace applications, offering superior thermal stability, chemical resistance, and electrical conductivity

- The demand for carbon felt and graphite felt is significantly driven by the growing adoption of renewable energy solutions, such as flow batteries and solar power systems, along with the expansion of metallurgical and aerospace industries

- North America is expected to dominate the Carbon Felt and Graphite Felt market due to advanced energy storage projects, robust industrial infrastructure, and strong presence of key manufacturers

- Asia-Pacific is expected to be the fastest growing region in the Carbon Felt and Graphite Felt market during the forecast period, fuelled by rapid industrialization, expanding electronics sector, and government initiatives promoting clean energy

- The carbon felt segment is expected to dominate the market with a 56.72% share in 2025, owing to its cost-effectiveness, excellent thermal insulation properties, and extensive usage in high-temperature industrial furnaces and energy storage systems such as redox flow batteries.

Report Scope and Carbon Felt and Graphite Felt Market Segmentation

|

Attributes |

Carbon Felt and Graphite Felt Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Carbon Felt and Graphite Felt Market Trends

“Sustainability Drive and Technological Advancements in Carbon and Graphite Felt Applications”

- One prominent trend in the Carbon Felt and Graphite Felt market is the growing focus on sustainable energy storage and insulation solutions driven by global decarbonization efforts and clean energy policies

- Manufacturers are innovating with advanced production techniques to improve the purity, conductivity, and durability of felts for use in redox flow batteries, fuel cells, and high-temperature insulation systems

- For instance, the development of PAN-based felts with enhanced porosity and surface area is gaining momentum due to their superior electrochemical performance in energy storage systems.

- The growing application of graphite felts in hydrogen energy and electric vehicle (EV) battery technology is also fueling demand for high-performance materials, opening new avenues for market expansion

Carbon Felt and Graphite Felt Market Dynamics

Driver

“Rising Demand for Clean Energy and High-Temperature Industrial Applications”

- The growing global shift toward renewable energy sources and electrification is significantly contributing to the increased use of Carbon Felt and Graphite Felt in various energy storage and high-temperature applications

- Industrial expansion, decarbonization targets, and increasing government investments in solar power, fuel cells, and redox flow batteries are boosting the demand for reliable thermal and electrical insulating materials

- Carbon and graphite felts are essential in these applications due to their excellent conductivity, chemical resistance, and ability to perform in extreme temperatures without degradation

For instance,

- According to the International Renewable Energy Agency (IRENA, 2023), global investment in energy storage systems exceeded USD 60 billion, fueling demand for advanced electrode materials such as carbon and graphite felts.

- As a result, the rising emphasis on clean technology in both industrial and energy sectors is expected to propel the demand for high-performance carbon and graphite felts to support efficiency and sustainability goals

Opportunity

“Expansion of Energy Storage Systems and Flow Battery Technology”

- The accelerating global adoption of renewable energy has created a significant opportunity for carbon and graphite felts used in flow batteries and advanced energy storage systems

- Flow batteries, particularly vanadium redox batteries, rely heavily on high-performance felts as electrodes due to their superior conductivity, chemical resistance, and long operational lifespan

- As countries aim to stabilize renewable energy output and enhance grid reliability, demand for scalable, efficient storage solutions is growing rapidly

For instance,

- In 2024, SGL Carbon partnered with leading battery manufacturers to supply customized carbon felts for grid-scale redox flow battery installations across Europe and Asia.

- This growth in energy storage infrastructure provides a lucrative opportunity for felt manufacturers to cater to the expanding clean energy value chain and contribute to global electrification goals.

Restraint/Challenge

“Fluctuating Raw Material Prices and Regulatory Compliance”

- The Carbon Felt and Graphite Felt market is vulnerable to volatility in raw material costs—such as polyacrylonitrile (PAN), petroleum pitch, and specialty binders—which can squeeze production margins and pricing strategies

- Additionally, tightening environmental and safety regulations—covering emissions controls, waste treatment, and chemical handling—vary significantly across regions, creating compliance hurdles for manufacturers

- These factors add complexity for producers seeking to scale operations globally while keeping costs predictable and meeting disparate regulatory frameworks

For instance,

- Under the EU’s REACH regulation updates in 2023, restrictions on certain pitch-processing additives forced several felt manufacturers to reformulate processes and invest in new emission‑control equipment.

- Such cost pressures and compliance burdens may delay product launches, curb R&D investments, and disproportionately impact small to mid‑sized suppliers

Carbon Felt and Graphite Felt Market Scope

The market is segmented on the basis of type, product type, raw material, and application.

|

Segmentation |

Sub-Segmentation |

|

By Type |

|

|

By Product Type |

|

|

By Raw Material |

|

|

By Application |

|

In 2025, the Carbon Felt is projected to dominate the market with a largest share in type segment

The Carbon Felt segment is expected to dominate the Carbon Felt and Graphite Felt market with the largest share of 56.72% in 2025 due to outstanding thermal stability, excellent mechanical strength, and cost‑effectiveness in high‑temperature insulation for industrial furnaces and as electrodes in redox flow batteries. Carbon felts’ porous structure enhances electrolyte flow and heat retention, making them indispensable in energy storage and metallurgical processes.

The Furnace is expected to account for the largest share during the forecast period in application market

In 2025, the Furnace segment is expected to dominate the market with the largest market share of 51.31% due to critical role in high‑temperature industrial processes—such as metallurgy, glass production, and ceramics—where carbon and graphite felts provide unmatched thermal insulation, chemical resistance, and energy‑saving performance.

Carbon Felt and Graphite Felt Market Regional Analysis

“North America Holds the Largest Share in the Carbon Felt and Graphite Felt Market”

- North America dominates the carbon felt and graphite felt market with a share of 35.87%, driven by the region’s advanced energy storage initiatives, robust metallurgical sector, and extensive use of high‑temperature insulation in industrial furnaces

- The U.S. accounts for the largest share due to surging deployment of redox flow batteries, proton exchange membrane (PEM) fuel cells, and stringent energy‐efficiency regulations in manufacturing

- Federal and state incentives for clean‑energy projects—coupled with substantial R&D investment in next‑generation electrode materials—are accelerating adoption of carbon and graphite felts

- The presence of leading felt producers and a dense network of research institutions ensures rapid commercialization of high‑performance felt grades, reinforcing North America’s market leadership

“Asia-Pacific is Projected to Register the Highest CAGR in the Carbon Felt and Graphite Felt Market”

- The Asia‑Pacific region is expected to experience the fastest growth (CAGR ~10.5%) in the carbon felt and graphite felt market, fuelled by rapid industrialization, soaring demand for electric vehicles, and large‑scale renewable energy rollouts

- China and India are expanding metallurgical and chemical processing capacities, driving strong requirements for thermal insulation and filtration felts

- Japan and South Korea lead in fuel cell and semiconductor applications, where ultra‑high‑purity graphite felts are critical for performance and reliability

- Massive investments in grid modernization, hydrogen infrastructure, and green hydrogen electrolyzers are further propelling demand for specialty carbon and graphite felts throughout the region

Carbon Felt and Graphite Felt Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- SGL Carbon (Germany)

- Toray Industries Inc. (Japan)

- Beijing Great Wall Co., Ltd. (China)

- Kureha Corporation (Japan)

- Nippon Carbon Co., Ltd. (Japan)

- CM Carbon (China)

- CFCCARBON Co., Ltd. (China)

- CeraMaterials (U.S.)

- Sinotek Materials Co., Ltd. (China)

- Texpack S.r.l. (Italy)

- Buffalo Felt Products Corporation (U.S.)

- Chemshine Carbon Co., Ltd. (China)

- Fuel Cell Store (U.S.)

- Carbon Composites, Inc. (U.S.)

- Cetech Co., Ltd. (Taiwan)

- Amsted Graphite Materials (U.S.)

- Anssen Metallurgy Group Co., Ltd. (China)

- Liaoning Jingu Carbon Material Co., Ltd. (China)

- Olmec Advanced Materials (United Kingdom)

- Mersen Graphite (France)

Latest Developments in Global Carbon Felt and Graphite Felt Market

- In February 2025, SGL Carbon SE announced a strategic restructuring of its loss‑making Carbon Fibers business unit to focus on its profitable core segments and improve overall financial performance

- In August 2024, Toray Industries presented its latest continuous composite and carbon felt solutions at the CAMX 10th Anniversary Conference in San Diego, highlighting advances for aerospace and energy storage applications

- In July 2024, Mersen enhanced its graphite processing portfolio by acquiring two U.S. companies—GMI and Bar‑Lo Carbon Products—expanding capacity for specialty extruded graphite and insulating felts

- In September 2021, SGL Carbon expanded and upgraded the production of soft felts. The company has invested some million euros into the additional carbonization facility located at its Meitingen site near Augsburg in Germany. This facility is now in regular operation

- In August 2019, Toray Industries, Inc. announced a new line of fabric products and carbonized felt targeted at various energy storage applications. Zoltek's new fabric materials and carbonized felt has been evaluated and qualified as product of the choice for the battery electrode for redox flow and other new battery storage technologies

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Carbon Felt And Graphite Felt Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Carbon Felt And Graphite Felt Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Carbon Felt And Graphite Felt Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.