Global Bioprocessing Systems Market

Market Size in USD Million

CAGR :

%

USD

287.82 Million

USD

838.48 Million

2025

2033

USD

287.82 Million

USD

838.48 Million

2025

2033

| 2026 –2033 | |

| USD 287.82 Million | |

| USD 838.48 Million | |

|

|

|

|

Bioprocessing Systems Market Size

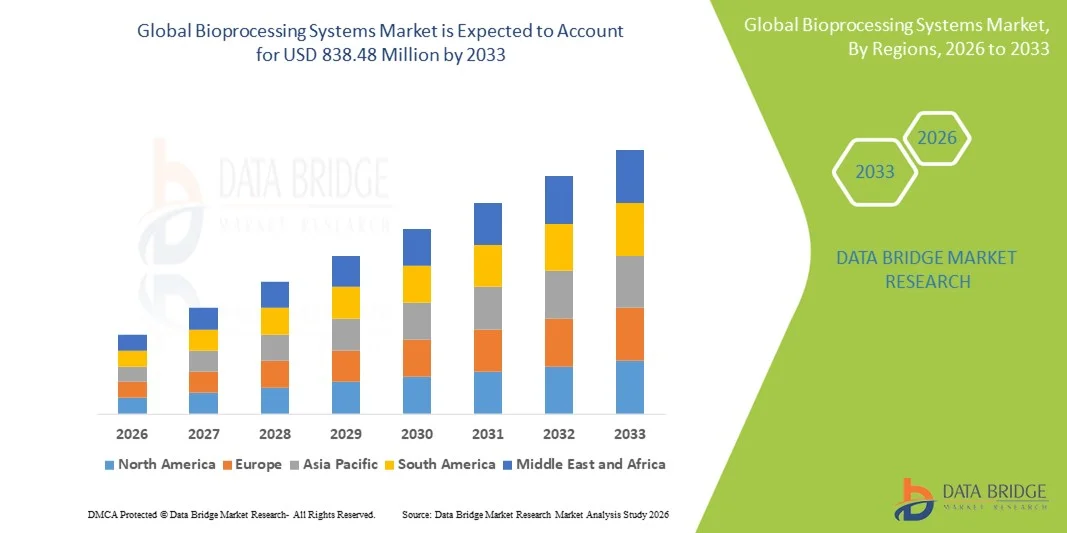

- The global bioprocessing systems market size was valued at USD 287.82 million in 2025 and is expected to reach USD 838.48 million by 2033, at a CAGR of 14.30% during the forecast period

- The market growth is largely fueled by the increasing demand for biopharmaceuticals, vaccines, and cell & gene therapies, coupled with advancements in bioprocessing technologies that enhance production efficiency and scalability

- Furthermore, rising investments in biopharmaceutical R&D, stringent regulatory requirements for high-quality biologics, and the growing adoption of single-use systems are driving the shift towards automated and integrated bioprocessing solutions. These converging factors are accelerating the adoption of bioprocessing systems, thereby significantly boosting the industry's growth

Bioprocessing Systems Market Analysis

- Bioprocessing systems, encompassing equipment and technologies for cell culture, fermentation, purification, and downstream processing, are becoming essential components of modern biopharmaceutical manufacturing, enabling efficient, scalable, and high-quality production of biologics, vaccines, and cell & gene therapies

- The rising demand for biopharmaceuticals, coupled with technological advancements in single-use systems, automation, and integrated bioprocessing solutions, is driving the growth of bioprocessing systems globally. Increasing focus on process optimization, reproducibility, and regulatory compliance further accelerates adoption

- North America dominated the bioprocessing systems market with the largest revenue share of 37.2% in 2025, attributed to the presence of leading biopharmaceutical companies, strong R&D infrastructure, and early adoption of advanced bioprocessing technologies. The U.S. witnessed significant expansion in both large-scale and flexible manufacturing facilities, fueled by innovations in single-use bioreactors, continuous processing, and digital bioprocess monitoring

- Asia-Pacific is expected to be the fastest-growing region in the bioprocessing systems market during the forecast period, driven by increasing investments in biologics manufacturing, government initiatives supporting biotech infrastructure, and rising demand for cost-effective, scalable bioprocessing solutions

- Single-use systems segment dominated the bioprocessing systems market with a market share of 44.3% in 2025, driven by their flexibility, reduced contamination risk, lower capital expenditure, and faster turnaround times compared to traditional stainless-steel systems

Report Scope and Bioprocessing Systems Market Segmentation

|

Attributes |

Bioprocessing Systems Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, patient epidemiology, pipeline analysis, pricing analysis, and regulatory framework |

Bioprocessing Systems Market Trends

Rise of Single-Use and Continuous Bioprocessing Technologies

- A significant and accelerating trend in the global bioprocessing systems market is the increasing adoption of single-use technologies (SUT) and continuous bioprocessing, which streamline manufacturing, reduce contamination risk, and lower capital expenditure

- For instance, GE Healthcare’s Xcellerex™ single-use bioreactors offer integrated solutions for upstream processing, while Sartorius’ ambr® 250 modular systems enable automated, small-scale bioprocess optimization that can be scaled to commercial production

- Continuous bioprocessing integration enables real-time monitoring of critical process parameters, improving product quality and yield while reducing production timelines. Systems such as Cytiva’s KUBio® modular facilities allow manufacturers to implement flexible, end-to-end continuous workflows

- The combination of SUT and continuous bioprocessing facilitates streamlined, flexible, and scalable biologics production, allowing companies to respond quickly to changing demand for vaccines, cell therapies, and other biologics

- This trend towards more automated, efficient, and scalable bioprocessing systems is reshaping manufacturing strategies in the biopharma sector. Consequently, companies such as Thermo Fisher Scientific and Pall Corporation are expanding their portfolios with integrated single-use and continuous bioprocessing solutions

- The demand for flexible, scalable, and efficient bioprocessing systems is growing rapidly across both large-scale commercial and contract manufacturing organizations, driven by the need for faster development timelines and cost-effective biologics production

- Increasing adoption of digital bioprocessing tools, including AI-driven process optimization and predictive analytics, is enhancing operational efficiency and enabling real-time decision-making in production workflows

- Rising focus on sustainability is driving interest in single-use and energy-efficient bioprocessing systems, which reduce water, cleaning chemicals, and energy usage compared to traditional stainless-steel setups

Bioprocessing Systems Market Dynamics

Driver

Rising Biopharmaceutical Demand and Technological Advancements

- The growing demand for biopharmaceuticals, vaccines, and cell & gene therapies, coupled with technological advancements in single-use and continuous bioprocessing systems, is a significant driver for market growth

- For instance, in March 2025, Sartorius launched an upgraded ambr® 250 automated system with enhanced process analytics for faster cell line development. Such innovations are expected to drive broader adoption of bioprocessing systems globally

- As pharmaceutical and biotech companies aim to improve production efficiency, reduce contamination risks, and comply with stringent quality regulations, integrated bioprocessing solutions become essential for modern manufacturing

- Furthermore, the rising investments in contract manufacturing organizations (CMOs) and adoption of modular facilities enhance flexibility, scalability, and rapid deployment, accelerating the uptake of advanced bioprocessing systems

- The increasing focus on process automation, digital monitoring, and real-time data analytics is propelling the adoption of bioprocessing systems in both upstream and downstream manufacturing.

Restraint/Challenge

High Capital Costs and Regulatory Compliance Complexities

- The high initial investment required for advanced bioprocessing systems, particularly single-use and continuous processing equipment, can hinder adoption among smaller manufacturers and emerging biotech firms

- For instance, setting up a modular facility with integrated bioreactors and downstream purification systems can require substantial capital expenditure and skilled personnel for operation

- In addition, stringent regulatory requirements for biologics manufacturing, including cGMP compliance and validation of single-use systems, pose a challenge for companies aiming for rapid implementation

- Addressing these challenges through cost-effective, scalable solutions, simplified validation protocols, and workforce training is crucial for wider market penetration. Companies such as Thermo Fisher and Cytiva emphasize compliance-ready systems and support services to mitigate regulatory hurdles

- While technological advancements offer efficiency and scalability, balancing cost, compliance, and operational complexity remains a critical factor influencing adoption in the bioprocessing systems market

- Limited availability of skilled workforce trained in advanced bioprocessing techniques can slow the deployment of sophisticated systems, particularly in emerging markets

- Dependence on disposable consumables in single-use systems may create supply chain challenges and increase operational costs if manufacturers face shortages or logistical delays

Bioprocessing Systems Market Scope

The market is segmented on the basis of type, applications, and end users.

- By Type

On the basis of type, the bioprocessing systems market is segmented into upstream, downstream, single-use, and integrated systems. The single-use systems segment dominated the market with the largest revenue share of 44.3% in 2025. This dominance is driven by their flexibility, reduced contamination risk, and lower capital and operational expenditure compared to traditional stainless-steel systems. Single-use systems are widely adopted in biopharmaceutical manufacturing for vaccines, cell therapies, and recombinant proteins due to their ease of deployment and faster turnaround times. The ability to scale production up or down quickly without extensive cleaning validation also contributes to their widespread use. Moreover, single-use systems support modular and continuous bioprocessing approaches, which are increasingly preferred by contract manufacturing organizations (CMOs) and large pharma players.

The integrated systems segment is anticipated to witness the fastest growth from 2026 to 2033, driven by increasing demand for end-to-end bioprocessing solutions that combine upstream, downstream, and monitoring components in a single platform. Integrated systems allow manufacturers to achieve higher efficiency, reduce manual intervention, and maintain consistent product quality. The growing adoption of Industry 4.0 technologies and digital bioprocess monitoring further enhances the appeal of integrated solutions. Pharmaceutical companies focusing on rapid biologics development and modular facility setups are key adopters, accelerating market growth.

- By Application

On the basis of application, the market is segmented into vaccine development, cell therapy and plant cell cultivation, filters, tissue engineering, biosensors, bioreactors and mixers, plasma fractionation, chromatography, and bio-therapeutic molecule production. The vaccine development segment dominated the market in 2025 due to the high global demand for vaccines, accelerated vaccine R&D programs, and the urgent need for rapid, scalable manufacturing solutions. Bioprocessing systems are critical in ensuring high yields, quality, and reproducibility during vaccine production. Government initiatives, pandemic preparedness programs, and increasing investments in vaccine manufacturing infrastructure are also supporting growth.

The cell therapy and plant cell cultivation segment is expected to witness the fastest growth during the forecast period. This surge is driven by the rising adoption of cell and gene therapies, personalized medicine, and plant-based biologics. Bioprocessing systems tailored for cell therapy enable controlled environments, automated monitoring, and precise scaling, which are critical for reproducible cell expansion and differentiation. Increasing collaborations between biotech companies and research institutions, coupled with regulatory support for advanced therapies, is further propelling market growth in this subsegment.

- By End User

On the basis of end user, the market is segmented into biopharmaceuticals industry, pharmaceuticals industry, nutraceuticals industry, chemicals industry, research laboratories, and others. The biopharmaceuticals industry dominated the market in 2025 due to the widespread manufacturing of biologics, vaccines, and advanced therapies, which require high-quality, scalable, and compliant bioprocessing systems. Companies in this sector prioritize single-use and integrated systems for faster development, reduced contamination, and regulatory compliance, making them key contributors to revenue.

The research laboratories segment is expected to witness the fastest growth from 2026 to 2033, driven by increasing academic and industrial research in biologics, cell therapy, and bioprocess optimization. Research labs are adopting compact, automated, and single-use bioprocessing systems to accelerate R&D cycles, improve reproducibility, and conduct high-throughput experiments. Rising funding for biotechnology research, government grants, and the expansion of life sciences hubs worldwide are further boosting adoption in research and academic settings.

Bioprocessing Systems Market Regional Analysis

- North America dominated the bioprocessing systems market with the largest revenue share of 37.2% in 2025, attributed to the presence of leading biopharmaceutical companies, strong R&D infrastructure, and early adoption of advanced bioprocessing technologies

- Manufacturers and contract development and manufacturing organizations (CDMOs) in the region are increasingly adopting single-use and integrated bioprocessing systems to enhance production efficiency, scalability, and compliance with stringent quality standards

- This widespread adoption is further supported by significant investments in biologics, vaccines, and cell & gene therapy manufacturing, coupled with a strong regulatory framework and availability of skilled workforce, establishing North America as a preferred hub for high-quality bioprocessing operations in both commercial and research settings

U.S. Bioprocessing Systems Market Insight

The U.S. bioprocessing systems market captured the largest revenue share of 42% in 2025 within North America, driven by the rapid expansion of biopharmaceutical manufacturing and increasing demand for vaccines, biologics, and cell & gene therapies. Companies are increasingly adopting single-use and integrated bioprocessing solutions to enhance efficiency, scalability, and regulatory compliance. The strong presence of contract development and manufacturing organizations (CDMOs), along with advanced R&D infrastructure, further propels market growth. Moreover, ongoing innovations in continuous processing, automation, and digital bioprocess monitoring are significantly contributing to the U.S. market expansion.

Europe Bioprocessing Systems Market Insight

The Europe bioprocessing systems market is projected to expand at a substantial CAGR throughout the forecast period, driven by increasing investments in biologics manufacturing and stringent regulatory requirements for quality and safety. Rising adoption of single-use technologies, modular facilities, and continuous processing solutions is enhancing production efficiency. Countries such as Germany, France, and Switzerland are witnessing significant growth across pharmaceutical and biopharmaceutical sectors, with bioprocessing systems being incorporated into both large-scale manufacturing plants and R&D facilities. European initiatives supporting biotech innovation and sustainable manufacturing further accelerate adoption.

U.K. Bioprocessing Systems Market Insight

The U.K. bioprocessing systems market is anticipated to grow at a noteworthy CAGR during the forecast period, fueled by the country’s focus on advanced biologics production, personalized medicine, and cell & gene therapies. Rising demand for flexible, scalable manufacturing solutions encourages the adoption of single-use and integrated bioprocessing systems. In addition, government support for biotech research, a strong academic-industrial collaboration ecosystem, and increasing contract manufacturing services are expected to continue stimulating market growth in both commercial and research applications.

Germany Bioprocessing Systems Market Insight

The Germany bioprocessing systems market is expected to expand at a considerable CAGR during the forecast period, driven by growing awareness of biopharmaceutical quality standards and adoption of cutting-edge technologies. Germany’s robust infrastructure, emphasis on innovation, and focus on sustainable, energy-efficient manufacturing promote the integration of automated and modular bioprocessing systems. Adoption is particularly strong in vaccine manufacturing, recombinant proteins, and cell therapy production, with companies prioritizing compliance, efficiency, and environmental sustainability.

Asia-Pacific Bioprocessing Systems Market Insight

The Asia-Pacific bioprocessing systems market is poised to grow at the fastest CAGR of 25% during the forecast period of 2026 to 2033, driven by increasing investments in biologics manufacturing, government-backed biotech initiatives, and rising demand for vaccines and cell & gene therapies. Countries such as China, India, and Japan are rapidly expanding their biopharma infrastructure, adopting single-use and integrated bioprocessing solutions to enhance production capacity and efficiency. The growing availability of skilled workforce and cost-competitive manufacturing facilities further supports market expansion.

Japan Bioprocessing Systems Market Insight

The Japan bioprocessing systems market is gaining momentum due to the country’s strong focus on advanced biologics, regenerative medicine, and cell therapy development. The market growth is driven by rapid adoption of single-use systems, automation, and digital monitoring for process optimization. Integration of bioprocessing systems in research laboratories and commercial manufacturing facilities is increasing efficiency and reproducibility. In addition, Japan’s aging population and emphasis on healthcare innovation are such asly to spur demand for scalable, high-quality bioprocessing solutions across pharmaceutical and biotech sectors.

India Bioprocessing Systems Market Insight

The India bioprocessing systems market accounted for the largest market revenue share in Asia Pacific in 2025, attributed to the country’s expanding biopharmaceutical manufacturing base, increasing contract manufacturing services, and rising domestic demand for vaccines and biologics. Adoption of cost-effective single-use and modular bioprocessing systems is accelerating, supported by government initiatives promoting biotechnology and research infrastructure. Strong local manufacturing capabilities and rapid technological adoption are key factors propelling the market in India, making it a preferred hub for both domestic production and export-oriented bioprocessing solutions.

Bioprocessing Systems Market Share

The Bioprocessing Systems industry is primarily led by well-established companies, including:

- Thermo Fisher Scientific Inc. (U.S.)

- Sartorius AG (Germany)

- Danaher (U.S.)

- Pall Corporation (U.S.)

- Merck KGaA (Germany)

- Eppendorf AG (Germany)

- Corning Incorporated (U.S.)

- Avantor, Inc. (U.S.)

- Saint‑Gobain Life Sciences (France)

- Entegris, Inc. (U.S.)

- Meissner Filtration Products (U.S.)

- PBS Biotech, Inc. (U.S.)

- Lonza (Switzerland)

- Getinge AB (Sweden)

- Bio‑Rad Laboratories, Inc. (U.S.)

- Solaris Biotechnology Srl (Italy)

- Parker Hannifin Corporation (U.S.)

- Infors HT (Switzerland)

- Repligen Corporation (U.S.)

What are the Recent Developments in Global Bioprocessing Systems Market?

- In April 2025, Sartorius Stedim Biotech expanded its manufacturing and R&D capacities in Aubagne, France nearly doubling cleanroom space and automating production lines for single‑use bags, with a new high-bay warehouse and additional lab, demo, and training space

- In April 2025, Sartorius teamed up with Tulip Interfaces to launch Biobrain® Operate a no‑code, cloud-based digital manufacturing execution system (MES) tailored for single-use bioprocessing aimed at reducing variability, boosting compliance, and enabling paperless batch records

- In August 2023, as reported by industry media, Repligen and Sartorius introduced an integrated bioreactor system that combines Repligen’s XCell ATF perfusion‑intensification technology with Sartorius’s Biostat STR bioreactor offering enhanced upstream intensification and simplified perfusion operations for biopharma manufacturers

- In June 2023, Cytiva and Culture Biosciences announced a collaboration to combine Cytiva’s Bioreactor Scaler tool with Culture’s 250 mL single‑use bioreactor, enabling predictive, cloud-based, and virtually monitored upstream bioprocessing and de-risking scale-up from lab to commercial scale

- In March 2022, Cellexus International launched a disposable single‑use airlift bioreactor system designed for gentle mixing optimized for delicate cell cultures supporting cost‑effective and scalable cell culture development

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.