Global Ball Grid Array Bga Packaging Market

Market Size in USD Billion

CAGR :

%

USD

1.66 Billion

USD

2.62 Billion

2024

2032

USD

1.66 Billion

USD

2.62 Billion

2024

2032

| 2025 –2032 | |

| USD 1.66 Billion | |

| USD 2.62 Billion | |

|

|

|

Ball Grid Array (BGA) Packaging Market Analysis

The Global Ball Grid Array (BGA) Packaging Market is growing steadily as the demand for miniaturized and high-performance electronic devices increases. The market is driven by the expanding consumer electronics sector, where BGAs are preferred for their superior performance in compact designs. The automotive industry’s adoption of BGAs for advanced driver-assistance systems (ADAS) and electric vehicles (EVs) is also contributing to market growth. The telecommunications industry, especially with the roll-out of 5G networks, has further increased the need for reliable and high-density packaging solutions.

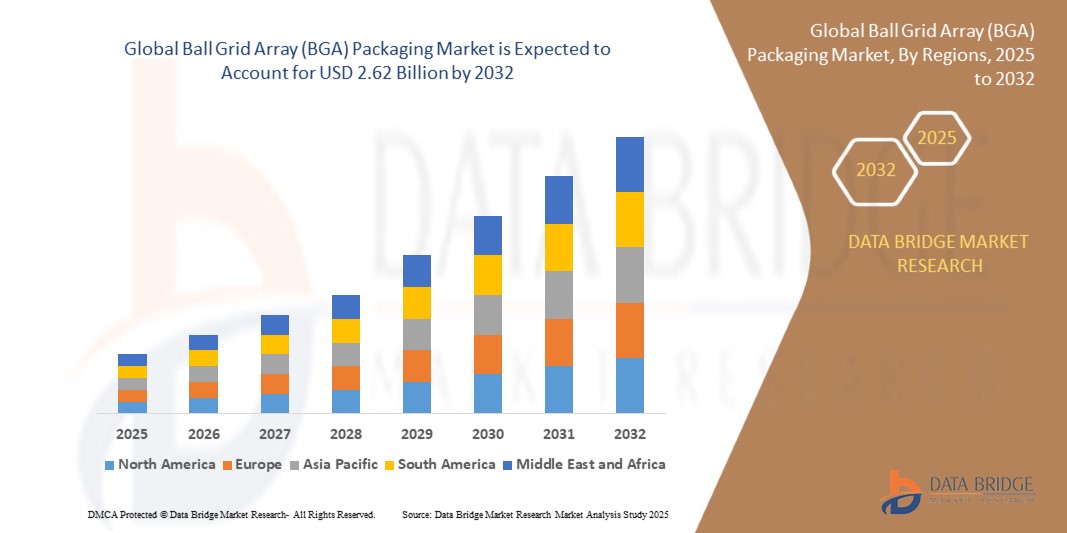

Ball Grid Array (BGA) Packaging Market Size

Global Ball Grid Array (BGA) Packaging market size was valued at USD 1.66 billion in 2024 and is projected to reach USD 2.62 billion by 2032, with a CAGR of 5.80% during the forecast period of 2025 to 2032. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework.

Ball Grid Array (BGA) Packaging Trends

“Growing adoption of miniaturized and high-performance electronic devices”

The Ball Grid Array (BGA) packaging market is witnessing key trends such as the growing adoption of miniaturized and high-performance electronic devices, particularly in consumer electronics and telecommunications. Demand for advanced interconnection technologies such as flip chip BGA is rising due to their superior electrical performance and thermal management. Increasing applications in automotive electronics, such as advanced driver assistance systems (ADAS), are further driving innovation in BGA packaging.

Report Scope and Ball Grid Array (BGA) Packaging Market Segmentation

|

Attributes |

Ball Grid Array (BGA) Packaging Key Market Insights |

|

Segmentation |

|

|

Countries Covered |

U.S., Canada, Mexico, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, Saudi Arabia, U.A.E., South Africa, Egypt, Israel, Rest of Middle East and Africa, Brazil, Argentina, Rest of South America |

|

Key Market Players |

Amkor Technology (U.S.), TriQuint Semiconductor Inc. (U.S.), Jiangsu Changjiang Electronics Technology Co. (China), STATS ChipPAC Ltd. (Singapore), ASE Group (Taiwan), PARPRO Cooperation Inc. (U.S.), Advanced Interconnections Inc. (U.S.), Quick Pak Inc. (U.S.), Corintech Ltd. (United Kingdom), Cypress Semiconductor Corp. (U.S.), Infineon Technologies AG (Germany), NXP Semiconductors NV (Netherlands) |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Ball Grid Array (BGA) Packaging Definition

Ball Grid Array (BGA) is a type of surface-mount packaging used for integrated circuits (ICs) that consists of an array of solder balls arranged in a grid pattern on the underside of the chip. These solder balls serve as the connection points between the chip and the printed circuit board (PCB), enabling high-density interconnects. BGA technology offers improved electrical performance, reduced signal interference, and better thermal management compared to traditional packaging methods. It is commonly used in consumer electronics, automotive, telecommunications, and computing devices for its ability to handle complex and miniaturized electronic components.

Ball Grid Array (BGA) Packaging Market Dynamics

Drivers

- Rising Demand for Miniaturized Electronics

The increasing demand for smaller, lighter, and more powerful electronic devices drives the adoption of Ball Grid Array (BGA) packaging. Smartphones, tablets, wearables, and other portable devices require compact and efficient packaging solutions to accommodate their advanced functionalities. BGA packaging provides high input/output density, reduced signal interference, and excellent thermal management, making it a preferred choice for miniaturized devices. The global consumer electronics market, valued at approximately USD 1 trillion, showcases significant demand for such technologies. Manufacturers are leveraging BGA's capability to support high-performance processors and memory chips, ensuring optimal device functionality while meeting space constraints.

- Expansion of 5G Networks and IoT Devices

The global rollout of 5G networks and the proliferation of IoT devices drive demand for advanced semiconductor packaging technologies such as BGA. These applications require high-speed, high-frequency chips with efficient power management and reliable connectivity, capabilities that BGA packaging effectively delivers. With over 5 billion IoT-connected devices expected globally by 2030, BGA technology plays a critical role in supporting seamless data transmission and connectivity. Additionally, 5G-enabled smartphones and infrastructure equipment increasingly integrate BGA-packaged components to ensure high-speed processing and reduced latency. For Instance the expansion of 5G networks is revolutionizing IoT, enabling faster connections, reduced latency, and enhanced device interactions. With over 15 billion IoT devices today and projections to surpass 75 billion by 2030, 5G is driving the seamless integration of smart technologies, powering innovation across industries and enhancing automated, data-driven decision-making systems.

Opportunities

- Growth in Artificial Intelligence and Machine Learning Applications

The rising adoption of artificial intelligence (AI) and machine learning (ML) in various sectors offers significant opportunities for BGA packaging. AI accelerators and ML processors, such as NVIDIA’s Tensor Cores or Google’s TPU chips, require efficient and high-density packaging solutions such as BGA to handle intensive computations with reduced power consumption and heat generation. This demand extends to sectors such as healthcare, where AI-driven imaging and diagnostics systems rely on BGA-packaged chips for fast and accurate data processing. The market can further capitalize on this trend with the growing use of AI in autonomous vehicles, robotics, and predictive analytics. BGA packaging’s ability to integrate complex circuits in a compact format positions it as a preferred choice, presenting a lucrative growth avenue for semiconductor manufacturers. For instance advancements in artificial intelligence (AI) and machine learning (ML) are driving innovation across industries, enabling smarter automation, enhanced predictive analytics, and data-driven decision-making. These technologies have transformed applications in healthcare, finance, and transportation, while fueling research in robotics and natural language processing, marking a new era of efficiency and problem-solving.

- Rising Demand for High-Performance Automotive Electronics

The growing adoption of electric and autonomous vehicles presents substantial opportunities for BGA packaging in automotive electronics. EVs and self-driving cars require advanced chips for functions such as battery management systems, advanced driver-assistance systems (ADAS), and infotainment modules. These chips demand compact and robust packaging solutions, making BGA an ideal choice due to its high thermal and electrical performance. Companies such as Tesla, BMW, and Volkswagen increasingly rely on BGA-packaged chips for their vehicles, driving growth in this segment. Additionally, the development of connected car technologies, which integrate vehicle systems with IoT, further amplifies the need for BGA packaging. As the automotive sector transitions towards electrification and automation, the market for BGA packaging in automotive applications is poised for rapid growth.

Restraints/Challenges

- Reliability Issues Due to Solder Joint Failures

Solder joint failures in BGA packaging represent a significant reliability issue, particularly in applications subjected to mechanical stress, vibration, and extreme temperature fluctuations. Automotive and aerospace electronics, for instance, often operate in harsh environments where solder fatigue can lead to device malfunction or failure. In consumer electronics, thermal cycling during regular use can cause cracks in solder joints, compromising long-term performance. Addressing these failures requires rigorous testing, advanced solder materials, and improved manufacturing techniques, which raise production costs and complexity. Real-world instances, such as product recalls in automotive or smartphone industries due to component failures, underscore the challenges posed by solder joint reliability. These issues impact customer trust and add pressure on manufacturers to ensure high-quality assembly processes.

- High Manufacturing Costs and Technological Complexity

BGA packaging involves intricate manufacturing processes, including precise placement of solder balls and advanced inspection methods to ensure defect-free assemblies. These complexities increase production costs, especially for manufacturers in regions with high labor expenses. Furthermore, as devices demand more compact and high-performance packaging, the need for sophisticated equipment and highly skilled engineers grows. Small and medium-sized enterprises (SMEs) often find it challenging to adopt such technologies due to cost constraints. For instance, companies in developing regions face difficulties competing with established players in countries such as Taiwan or South Korea. Moreover, defects during the assembly process, such as misalignment or bridging, can lead to high rejection rates, further increasing costs. These financial and technical barriers limit the accessibility of BGA packaging for smaller firms, slowing overall market growth.

This market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Impact and Current Market Scenario of Raw Material Shortage and Shipping Delays

Data Bridge Market Research offers a high-level analysis of the market and delivers information by keeping in account the impact and current market environment of raw material shortage and shipping delays. This translates into assessing strategic possibilities, creating effective action plans, and assisting businesses in making important decisions.

Apart from the standard report, we also offer in-depth analysis of the procurement level from forecasted shipping delays, distributor mapping by region, commodity analysis, production analysis, price mapping trends, sourcing, category performance analysis, supply chain risk management solutions, advanced benchmarking, and other services for procurement and strategic support.

Expected Impact of Economic Slowdown on the Pricing and Availability of Products

When economic activity slows, industries begin to suffer. The forecasted effects of the economic downturn on the pricing and accessibility of the products are taken into account in the market insight reports and intelligence services provided by DBMR. With this, our clients can typically keep one step ahead of their competitors, project their sales and revenue, and estimate their profit and loss expenditures.

Ball Grid Array (BGA) Packaging Market Scope

The market is segmented on the basis of package type, application, and end-user. The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Package Type

- Plastic Ball Grid Array (PBGA)

- Ceramic Ball Grid Array (CBGA)

- Tape Ball Grid Array (TBGA)

- Metal Ball Grid Array (MBGA)

Application

- Consumer Electronics

- Automotive

- Industrial Electronics

- Telecommunications

- Aerospace and Defense

End-User

- OEMs

- EMS

Ball Grid Array (BGA) Packaging Regional Analysis

The market is analyzed and market size insights and trends are provided by country, package type, application, and end-user as referenced above.

The countries covered in the market are U.S., Canada, Mexico, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, rest of Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, rest of Asia-Pacific, Saudi Arabia, U.A.E., South Africa, Egypt, Israel, rest of Middle East and Africa, Brazil, Argentina, and rest of South America.

North America is expected to dominate the Ball Grid Array (BGA) Packaging Market due to the region's established semiconductor and electronics manufacturing base, coupled with significant investments in R&D.

Asia Pacific is the fastest-growing region in the global Ball Grid Array (BGA) packaging market due to its dominant position in the semiconductor manufacturing and electronics industries. Countries such as China, South Korea, Taiwan, and Japan are home to leading semiconductor companies and foundries, driving demand for advanced packaging solutions such as BGA. The rapid growth of consumer electronics, such as smartphones, tablets, and wearables, in the region is a key factor fueling the adoption of BGA packaging, which offers high-performance and compact solutions for electronic components.

The growing demand for miniaturized, high-performance electronic components across sectors such as telecommunications, defense, and consumer electronics is propelling the market in North America. Continuous advancements in autonomous vehicles and electric vehicles are increasing the need for reliable and efficient packaging solutions such as BGA.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Ball Grid Array (BGA) Packaging Share

The market competitive landscape provides details by competitors. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

Ball Grid Array (BGA) Packaging Leaders Operating in the Market Are:

- Amkor Technology(U.S.)

- TriQuint Semiconductor Inc.(U.S.)

- Jiangsu Changjiang Electronics Technology Co.(China)

- STATS ChipPAC Ltd.(Singapore)

- ASE Group (Taiwan)

- PARPRO Cooperation Inc.(U.S.)

- Advanced Interconnections Inc.(U.S.)

- Quick Pak Inc.(U.S.)

- Corintech Ltd.: United Kingdom

- Cypress Semiconductor Corp.(U.S.)

- Infineon Technologies AG (Germany)

- NXP Semiconductors NV (Netherlands)

Latest Developments in Ball Grid Array (BGA) Packaging Market

- In March 2024, Micron Technology is established an Assembly and Test Facility in Gujrat, India, which will be focusing on forming wafers in ball grid array (BGA) integrated circuit packages, memory modules, and solid-state drives.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Ball Grid Array Bga Packaging Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Ball Grid Array Bga Packaging Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Ball Grid Array Bga Packaging Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.